The gas burner for roofing works is designed to melt the bituminous coating and waterproof the roof during repair work. Also, the tool is used for drying concrete and brick, heating metal and plastic when bending. A working gas cylinder is required to operate the device. Features of work, the choice of tools and recommendations for creating a structure with your own hands - all this information is contained in the article.

Content [Hide]

- 1 Gas burner for roofing: what is it

- 2 Propane burners: professional and budget models

- 3 Gas burner for roofing on a cylinder or spray

- 4 Roof gas burner: stacking material

- 5 Gas burner: price and characteristics of some popular models

- 6 How to use a gas burner: safety rules

- 7 How to make a gas burner with your own hands: stages of making a device

Roofing gas burner: what it is

Very often, during the installation and repair of roofing works, it is necessary to warm up or dry the material, for example, when laying a waterproofing layer, to create a soft roof or melt bitumen mastic. A roofing gas burner will help to carry out these tasks. Using this device, you can carry out several types of operations, namely:

- drying surfaces and materials;

- cutting or soldering metal parts;

- burning and removing the old paint layer;

- sealing small cracks;

- melting bitumen-based mastic;

- heating sheets of material before laying;

- strengthening of seams and joints;

- other work that requires the use of high temperature.

A roofing torch is usually a torch with a hose and a fuel tank. This design is very convenient, reliable and mobile. The volume of the gas cylinder can be different, the hose with the torch has a standard look. The flame is controlled by the controls installed on the device.

It is interesting! Roofing gas burner is a specialized unit of gas-air type, which is used for installation and dismantling of soft roofing, as well as for drying various building structures.

Propane burners: professional and budget models

Experienced foremen usually buy expensive professional models that are reliable and safe to use. But for a self-taught master for home use, simple and small designs are quite suitable. Let us consider further how the choice of this or that equipment will affect the quality of work.

A simple burner is not intended for industrial work, where it must be used almost every day. In this case, you need a reliable model that can withstand trouble-free operation and guarantee absolute safety. At the same time, a cheap and simple design in the hands of a skilled and careful craftsman can serve for several decades. Especially if you have to use it only once a season.

Regardless of which product is chosen: an expensive and professional burner with a cylinder or a cheap household structure - before each use, it is necessary to check the tightness of the product, especially the connection points, fuel supply hose and mouthpiece for clogging. If you miss even a minor defect, then you can provoke serious problems.

Helpful advice! Even for home use, you shouldn't buy the cheapest burner. Most likely, this model will have a weak gearbox, which means that the tool's performance will be on a par with the power of the blowtorch. Working with such a device will be very slow.

Gas burner for a roof on a cylinder or spray

At first glance, it may seem that tightening a gas cylinder to the roof is the most dangerous idea, especially since the sale is full of hand burners. In fact, it is the canister burners that often cause burns, fires and injuries. This is due to the sale of fake and cheap Chinese products. The safety of burners with a large cylinder lies in the fact that the container itself is located far from the flame during operation.

When buying, do not pay attention to too cheap models. The main problem of such structures is that the technical passport indicates the working pressure of 0.05-0.08 MPa, which during operation turns out to be several times higher. The gearbox installed on the device is absolutely not designed for heavy loads, so a closed valve may simply not withstand such a voltage.

Gas burner for cylinder: device characteristics

The design of the gas burner includes a handle, a gas supply tube and a metal cup fixed at its end. A hose is connected to the handle through which the working gas flows from the gas cylinder. The handle can be made of plastic or wood.

The gas burner bowl is designed in such a way that the flame is protected from the wind during operation. Glasses of different models have a different design, but the principle of operation is the same. It is also possible to adjust the flame length. Modern models are equipped with a special gearbox, on which the pressure and fuel consumption can be controlled using a valve.

Pressing the lever on the handle opens the valve and gas enters the glass through the tube and hose. The combustible mixture of working gas and air is ignited with a lighter or with ordinary matches. The combustion temperature of a gas burner is very high and can reach between 500 and 1500 ° C.

Absolutely all models of gas roofing burners are equipped with an atmospheric air supply system. There is also a device for adjusting the operating modes: operating mode and standby mode. Only high quality and very durable materials are used for the manufacture of devices, since the burner heats up to the highest temperatures.Usually, the weight of the structure is small and varies from 1 to 1.5 kg, so the tool is easy to hold in your hands.

Modern roof burners differ from each other in the principle of adding oxygen to the fuel. Older samples require connection to an oxygen cylinder, which is not very convenient. Modern designs take air from the atmosphere. Typically propane is used as burner gas, but there are samples that run on pure methane.

It is important! The length of the handle for holding the gas burner should measure about one meter, but not more. At the same time, it is necessary that it be equipped with a special holder made of heat-resistant plastic or high quality wood, so that the hands of the master are protected from burns.

Gas burners on a spray can: tool description

The burner in the form of a nozzle on a gas cylinder with a collet connection is used only with the strictest observance of fire safety rules, as well as in places where heavy construction equipment is not working and the risk of damaging the burner with a spray is minimal.

The simplest models have a combustion temperature of about 700-1000 ° C. Oxygen enters the burner from the air, so it is always in short supply. The higher cost tools have a flame temperature of 1200 ° C and have a specific shape for the air inlets that increase the amount of oxygen in the burner.

Ejector-type manual gas burners have an even higher flame temperature. In these designs, air is supplied to the fire due to rarefaction. Thanks to this, the flame reaches a temperature of 1500-1600 ° C. It is also possible with a crane to relatively smoothly adjust the length of the flame. This model is not designed for delicate work, but is great for heating large areas.

All types of gas burners are equipped with flexible or swivel tube, piezo ignition and high sensitivity flame control valve. Currently, there is a large selection of tools according to their power and fuel consumption.

Gas burner for brazing: model features

Soldering ejector lamps have a special design and purpose. Most often, these tools are used by craftsmen for processing non-ferrous metals. The high temperature and adjustable flame of the burner makes it ideal for brazing and quenching metals or any other heat treatment that requires high temperature accuracy and a well-defined flame cone.

The sizes of canister burners and nozzles can vary significantly, which allows them to be used in various fields. Quite miniature models are used for soldering jewelry and thin metal. Although the instrument is not equipped with an oxygen supply device, it does an excellent job of filigree work.

Medium type fixtures have a cone thickness of 0.3 to 0.9 cm and are ideal for brazing copper and aluminum pipes. Large size burners due to their high power should be used in artistic forging or metal stamping.

For ejector burners, the concept of an unstable flame is not entirely correct. Since, although flashes are possible from time to time, this has little effect on the temperature in the flame core of the instrument.

Roof gas burner: stacking material

Very often roofing material is used in roofing works, and it is impossible to create high-quality waterproofing from this material without a gas burner. You will also need a tool to cover the roof with fused types of modern materials.

The whole process of working with the burner can be divided into several stages:

- First, the preparation of the base for laying the coating is organized, for this it is necessary to clean it of debris. If necessary, you can level the surface with a screed.

- The entire surface is covered with roll material so that adjacent sheets form an overlap 8.5-9 cm wide.

- After leveling the material and completing the markings, the rolls are folded back and, using a burner, are fixed at the base of the roof. For this, the lower part of the roll and the base of the roof are heated with a flame, after which the roll of material is slowly unfolded and pressed against the base.

- To prevent the appearance of folds and air bubbles, it is necessary to walk with a hand roller on the attached canvas.

- At the final stage, you should also use a burner, with which the seams of the material are heated. After that, they also need to be compacted with a hand roller.

Before operating a roof burner, there are several important points to be aware of:

- you cannot use the device at a temperature of 15 degrees below zero;

- if roofing work is performed at low temperature conditions, it is allowed to use a liquid fuel burner;

- the use of a gas burner with high technical characteristics for the roof allows you to lay about 500-600 m of roofing material per day;

- since the process takes place in the open air, the burner must operate smoothly and have reliable protection against wind blowing.

Related article:

Petroleum bitumens for construction, roofing (GOST)

Bituminous material provides waterproofing of complex structures, where other materials cannot be used.

Gas burner: price and characteristics of some popular models

Roofing gas burners are the safest tools. They are easy to use, lightweight, capable of creating a flame of sufficiently high power. Modern manufacturers offer models that work without oxygen:

- GG-2 - propane burner for the roof. This is the best option for craftsmen who carry out repair work with their own hands. Differs in an acceptable cost;

- GG-2U is a device similar to the previous version, but this model is characterized by a shortened version of the gas supply hose for a gas burner. Such a device is ideal for performing work in hard-to-reach areas of the roof, as well as for gluing joints;

Before purchasing a burner, it is important to read the characteristics of the model and check the quality certificates

- GG-2S is a model that belongs to professional tools, it runs on propane. The main advantage of the device is that it can be used even in strong winds. The device is equipped with two valves and consists of two cases, which makes it easier to control the operating modes of the device;

- ГГС1-1,7 is a universal design, which, despite its small size and weight, is characterized by a high degree of performance. The device can only be used on level horizontal areas;

- GGK-1 - this burner is heavier than previous designs, equipped with a very strong glass. This model is suitable for firing old paint, wood surfaces, as well as for waterproofing works. Fuel is supplied using a special lever.

- ГГС1-1,0 is used for small works of small volumes. Ideally used on roofs with a large slope;

- GGS1-0.5 is used for minor repair work. The model is characterized by low fuel consumption;

- GGS4-1.0 consists of four sockets, thanks to which the entire roll is simultaneously heated at once.The use of this option allows you to increase labor productivity and save fuel;

- GV-3 is a propane torch designed for welding and even manual metal brazing. The diameter of the glass is 5 cm;

- GV-111R is used for melting bituminous materials, firing a layer of paint.

- GV-550 and GV-900 are very easy-to-use designs that differ from each other only in the maximum flame length. The first model is more suitable for performing tasks at the joints of the roof, and the second device allows you to work standing upright, since the length of the torch reaches 90 cm;

- GV 500 is used to perform weld overlay work during the laying of roofing materials. This model melts bitumen with ease. The flame temperature of the GV 500 gas burner is 300 ° C;

- GV-850 is a burner with a special valve, thanks to which the amount of technical gas supply from the cylinder can be controlled with high precision. Also, a lever is installed here, with which the master adjusts the length of the torch. This gas burner does not run on pure propane, but on a mixture that contains technical oxygen. The price of a gas burner for the GV-850 roof is 1700-2200 rubles.

As you can see, the choice of gas burners is very wide, and where to buy a burner: in a store or on a website - depends on the desires of buyers. The main thing is to read the characteristics of the model and check the quality certificates for the product.

Helpful advice! Models of the GV class are suitable for heating non-ferrous and ferrous metals, melting bituminous materials in a roll when performing waterproofing and roofing works, as well as in cases where only propane is required.

How to use a gas burner: safety regulations

The operation of gas burners requires the strictest adherence to safety rules:

- Work with burners is carried out in overalls and shoes with non-slip soles. You will also need a belt and walking bridges.

- Before using the tool, it is necessary to carry out an external inspection and make sure that the burner, cylinders and connecting hoses are in full serviceability.

- During use of the device, only one gas cylinder can be at the place of work.

- Do not stand in front of the nozzle while igniting the gas in the burner. The direction of the metal cup must be such that the fire cannot touch anyone in the vicinity, the gas cylinder and the connection hoses.

- In the case of using the materials to be welded, it is imperative to ensure that they do not overheat and do not catch fire. It is necessary to control that only the lower part is warmed up; the material must not be allowed to soften completely.

- The burner can be ignited only with matches or a lighter.

- While working with the device, the foreman is forbidden to leave the boundaries of the working space, as well as go down or go up the scaffolding.

The extinguishing of the tool takes place in two stages: first, the gas supply is cut off, and then the locking lever is released. Even with a short break in work, the device should be extinguished. If a significant break is ahead, then the gas supply must be shut off at the cylinder itself.

Before using the gas-air burner, it is necessary to conduct an external examination and make sure that it is in full serviceability.

Helpful advice! If the mouthpieces or connecting hoses are clogged, the appliance must not be used as kickbacks and pops occur. In the event of kickbacks or overheating of the equipment, stop work immediately and shut off the fuel supply to the cylinder. You can cool the tool by immersing it in a container of water.

How to make a gas burner with your own hands: stages of making a fixture

Almost no machining is required to assemble the tool. The gas burner is assembled from ready-made elements. To do this, you need to prepare:

- propane reducer for a gas cylinder;

- plug, which is used to transport gas tanks;

- blowtorch jet - nozzle diameter 0.8 mm;

- part of the pipe having the following dimensions: length - 1 meter, diameter - 1 cm, steel thickness - 2 mm;

- a wooden handle (suitable from an old non-working soldering iron).

The process of making a gas burner with your own hands is not particularly difficult.

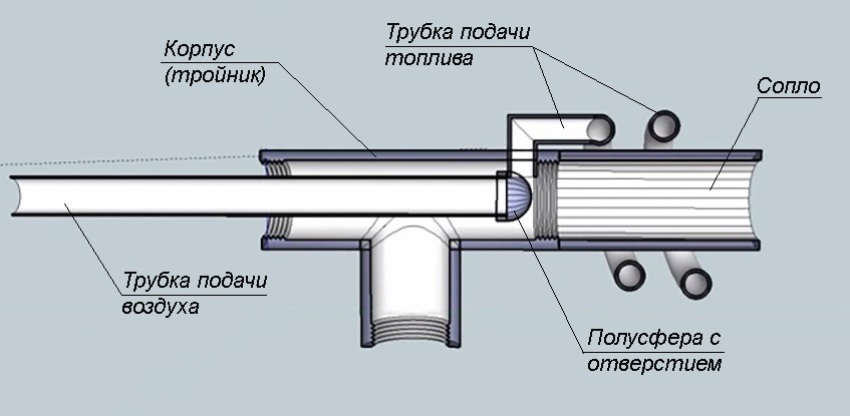

First of all, you need to insert the steel supply tube into the handle and fix it with glue. The splitter and body of the structure are made of a brass rod with a diameter of 20 mm. In the finished case, you need to drill two radial holes (5 mm each) and four holes with a diameter of 1 mm in the splitter rod.

Before as make a burner yourself, you need to study its component

It is required to press the divider into the body with a slight interference. The inner diameter of the body must be 0.6 mm larger than the diameter of the grooves. The resulting gap is designed to decelerate the gas flow, which is supplied to the holes in the pilot.

Next, you need to make a nozzle. Since the hole is very thin, you will need a 2 mm drill to drill it. It creates a blind hole at a distance of 1.5 mm from the outlet. Using a drill with a diameter of 0.4 mm, make a jumper.

The resulting hole should be completely stamped, for this you will need to hit it lightly with a hammer several times. Grind the end with sanding paper until the nozzle can be slipped onto the torch tube tip.

The end of the gas supply tube must be fitted with a fabric-rubber supply hose. It should be secured with a clamp. Then the working pressure is set and gas is supplied. Before setting fire, you need to wait until air comes out of the nozzle.

The length of the burner torch should be 5 cm. The body together with the diffuser is put on the external thread of the nozzle. It is important to make sure that the flame of the gas burner with your own hands is even and without soot.

Helpful advice! In the event that the threaded connection turned out to be free, it can be sealed using an FUM tape.

Repair and roofing work necessarily requires the use of hot air or even an open flame. To melt bitumen, melt a roll of roofing material or solder metal - a gas burner for a roof will perfectly cope with these tasks. To perform a significant amount of work, you need to buy a reliable professional model, and for home use you can create a structure yourself.