A metal lathe for a home is a device that is a miniature copy of a factory unit and is used to perform various technological operations. The compactness of such a machine allows you to place it in a small home workshop or garage. This article discusses the main types of small-sized machines, their technical characteristics, and provides advice on choosing.

Content [Hide]

- 1 Varieties of lathes for metal processing

- 2 Features of table metal lathes

- 3 Advantages of mini lathes

- 4 Mini-lathe device for metal

- 5 Tips for buying a used machine for your home

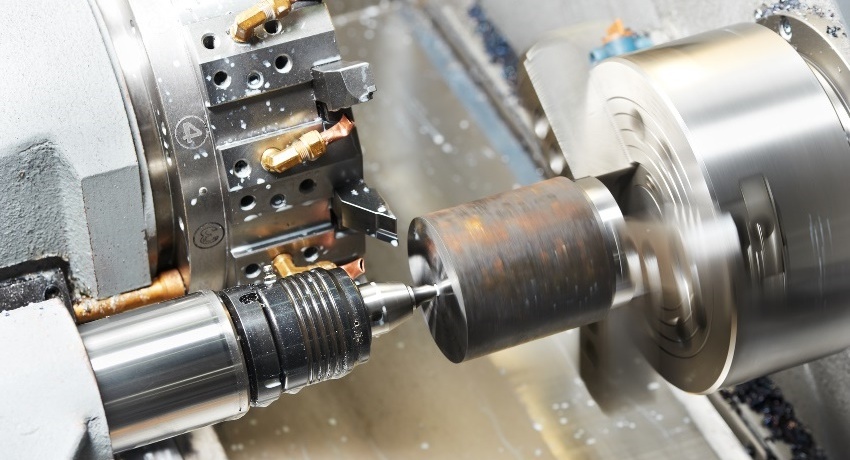

- 6 CNC home metal lathe

- 7 Which lathe for metal to buy: recommendations for choosing

- 8 Prices of table lathes for metal

- 9 Features of working on a metal lathe

Varieties of lathes for metal processing

The main factor that influences the choice of such equipment for the home is the purpose. Before buying such a small machine, you need to know exactly what it will be used for.

Depending on the purpose, all turning units are divided into three main types:

- desktop;

- semi-professional;

- professional.

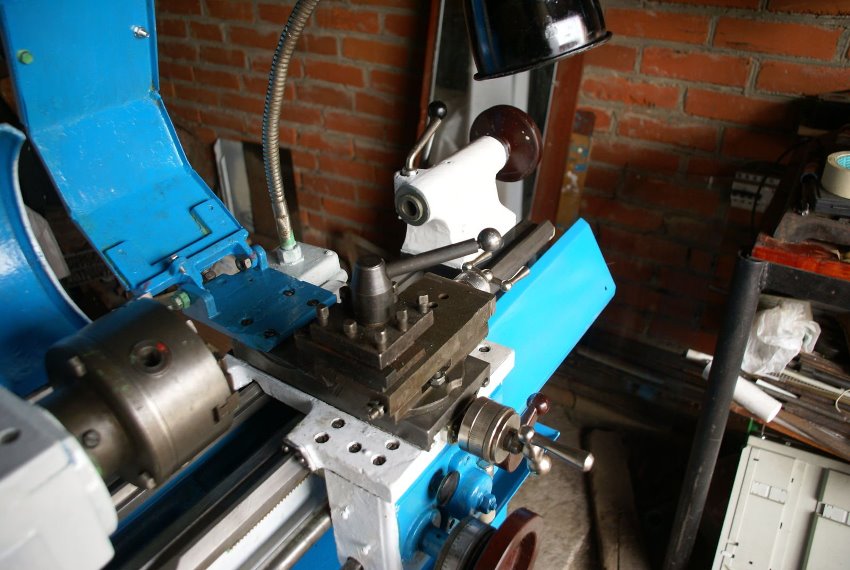

Desktop devices for private use at home are distinguished by their small dimensions and, accordingly, weight. The minimum weight of such micro-tanks is 13 kg, and the maximum does not exceed 100 kg. In turn, semi-professional floor options, which are also often used in home workshops, can weigh up to 400 kg. The power of the tabletop unit reaches 400 watts.

Semi-professional machines are also used in small industries and are distinguished by higher power (up to 1000 watts) and functionality. As a rule, such units combine, in addition to turning functions, two more: drilling and milling. This expansion of capabilities significantly increases the functionality of the machines.

Professional units are installed in large and medium-sized industries. They are often managed by software. They are distinguished by their large dimensions and weight.

Only the first type of machine is suitable for home use.Depending on the method of processing parts, they are divided into three main types:

- turning and milling;

- screw-cutting lathe;

- combined.

Metal turning and milling machines are used, as a rule, for chamfering from workpieces, as well as for organizing holes and facing. The second type of tabletop device is used for sharpening and threading parts. In turn, combined devices used at home are capable of performing all of the above functions.

Features of table metal lathes

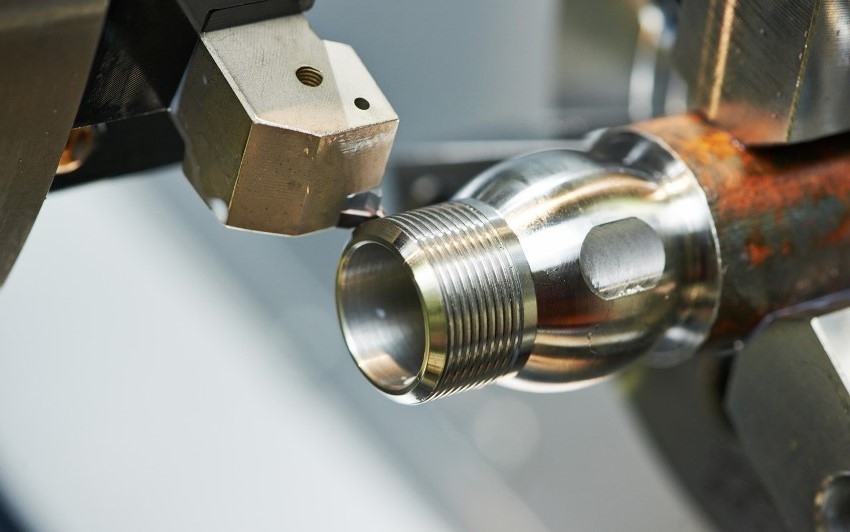

Such units are adapted for processing metal parts, which are small in size. The use of such a unit allows you to perform the following operations:

- turning parts in the form of a cylinder or cone;

- trimming the ends of parts;

- grinding;

- organization of holes by drilling;

- expansion of holes;

- threading (both external and internal).

Helpful information! The processing of various parts on a home lathe is carried out at a significantly lower speed than on professional equipment. However, this does not in any way affect the quality of the finished product, especially if the operation of the unit is controlled using a numerical control system (CNC).

Small devices of this type are capable of many functions. They have found their application not only at home, but also in small workshops, as well as in car repair shops. Since the times of the USSR, such mini-lathes have been used to teach turning schoolchildren and students of professional technical institutions.

Thus, small-sized turning units are used for different purposes. They are indispensable and useful devices that allow technical operations with small details. You can buy a metal lathe for your home in any specialized store or on the Internet.

Advantages of mini lathes

Units of this type have a number of advantages over large-sized, professional devices. For example, for the operation of such equipment, a standard household electrical network is sufficient, the voltage of which is 220 V. If desired, the mini-machine can be adapted to connect to a network that has a voltage of 380 V (three-phase).

Another important advantage of the home turning unit is that it consumes a small amount of electricity during operation. The shelf life of micro-jars of this type can reach several decades. How long it will serve you directly depends on two factors: correct use and timely maintenance.

Due to its compactness, such a microstand can be placed in any suitable room (room in an apartment, garage, etc.). Units of this type allow beginners to quickly learn how to process metal parts. And it is also worth saying that the cost of home lathes is more than affordable for most people.

And, finally, an important advantage of such devices is also the fact that they can be equipped with additional devices. This allows for milling of metal parts on them, which significantly expands their operational range.

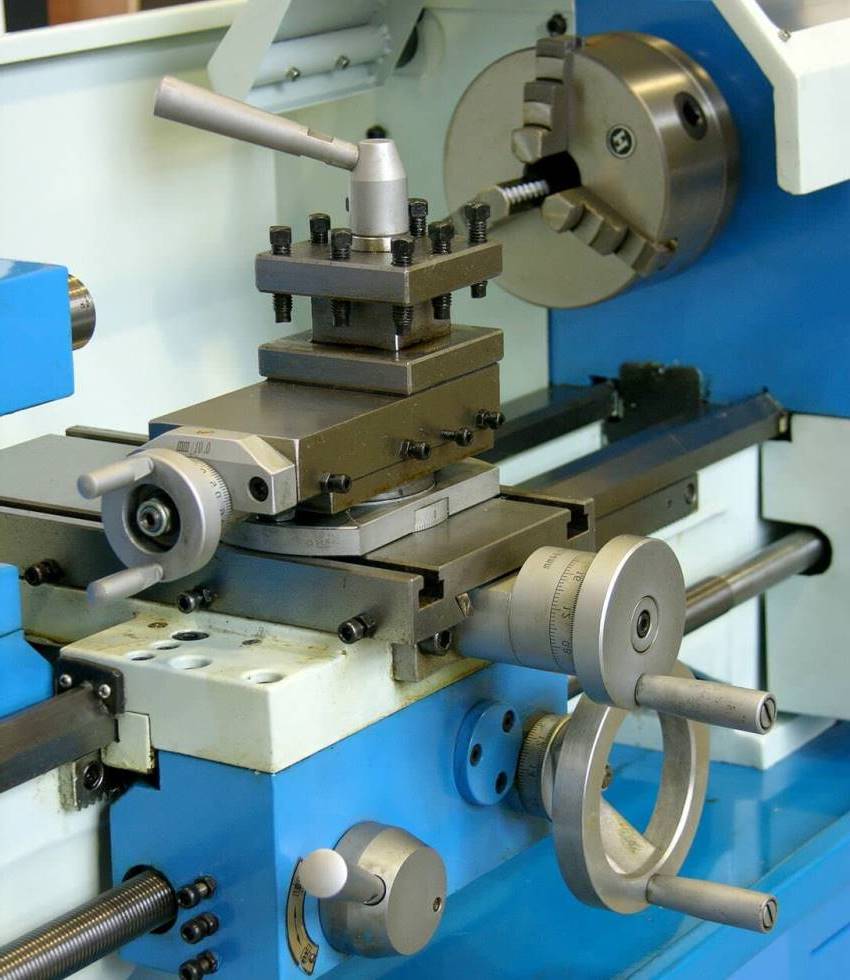

Mini-lathe device for metal

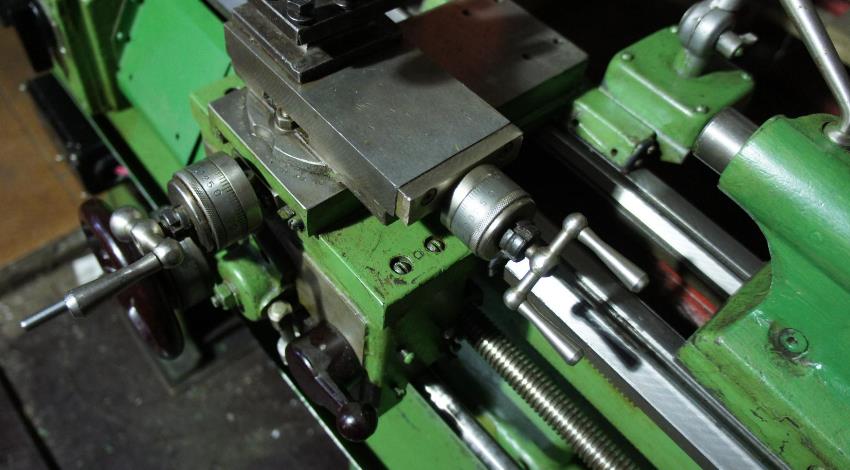

From a constructive point of view, such units are quite complex devices, as they copy industrial machines.Let's consider the main components:

- bed;

- spindle (front) unit or headstock;

- support.

The bed is the basis of any machine, which is provided with holes for fixing to a working surface (for example, a table). As a rule, this element is made of cast iron and equipped with guides for other units.

The support performs two important functions, namely: fixing the processing tool and changing its position during operation. The following can act as a processing device:

- drill;

- cutter;

- countersink.

The front assembly includes an electric motor, spindle, drive and gearbox. Thanks to these components, the shaft rotates and this effect is transferred to the second unit.

In most cases, the drive of a home lathe used to machine metal parts is driven by a V-belt. Some units have a speed control function. For this, the V-belt is rearranged from one pulley cavity to another.

Note! Sometimes, to provide a more accurate speed setting, the mini-machine is equipped with an additional electric type regulator. The indisputable advantage of the belt drive is that its presence reduces the risk of engine burnout if the workpiece is jammed.

On the smallest lathes, a caliper with limited functionality is often installed. It is a tool holder that has one position and two positions. The machining attachment in such an element can only be used for boring or external turning. It follows from this that in order to perform other work, it will be necessary to change the incisors themselves, as well as their position.

Features of the design of school lathes for metal

The design of lathes used for teaching in schools is usually classical. Differences between devices determine their purpose and functionality. There are two types of school mini-machines, depending on their design:

- desktop;

- floor.

They include a frame that is made of cast iron or steel sheet metal. The main units of the unit are installed on it, namely: the front unit (headstock), the rear unit, the cutter retainer, and the support. There are some design features of school units, which are due to the simplicity of the design. Consider them:

- school lathes are not equipped with a gearbox;

- the change of speeds is carried out by means of a belt drive;

- the spindle head has a simpler design;

- the base of the unit does not have a special recess, which is designed to work with large parts.

In such devices, the inflow of the liquid necessary to cool the equipment is carried out through an integrated system. If there is none, then the cutting fluid is applied manually.

In mini-machines for processing metal blanks, one more important element must be present - a mechanical brake. It is necessary in order to reduce the percentage of scrap during the processing of metal parts.

In amateur workshops, which are often located in garages, school mini-machines are often used. There are three main types of such small units.

Features of the TV-4 garage lathe

This unit is one of the most popular and widespread in the CIS. The active use of such a machine in schools began in the Soviet era.It was then that they began to call it "educational TV-4". However, the functionality of this unit allows it to be used for a variety of tasks.

The main advantage of TV-4 is its compactness. Because of this, such devices are still used in home workshops. For processing various metal parts in the garage, not only desktop devices are used, but also those that have their own base.

Characteristics of the TV-4 lathe (floor-standing):

- the power indicator is 1 kW;

- required voltage of the electrical network - 220 V;

- the maximum length of a part that can be processed on such a unit is 30 cm;

- the maximum section of the workpiece is 200 mm;

- the number of revolutions per minute - up to 710;

- weight - about 280 kg.

Helpful information! You can buy such a model in any online store, where there are many offers for the sale of not only whole units of this type, but also their components. True, you will have to buy a used device, since it is almost impossible to find a model that has not been in use.

The price of the TV-4 lathe varies from 25,000 to 65,000 rubles. Its cost is influenced by the condition and functional equipment of the structure.

Characteristics of screw-cutting lathe TV-6

The unit of this type was also actively used in the schools of the USSR. TV-6 is used to perform the simplest technical operations, including:

- drilling holes;

- trimming the ends;

- cutting off part of the part;

- application of metric threads;

- boring of workpieces (cylindrical and conical).

Mini-machines TV-6 are used for processing parts made of non-ferrous metals or steel. The limited possibilities are due to the fact that the processing of products from other materials leads to dustiness in the room in which the unit is located. The release of dust can harm the health of the master.

Let's consider the main characteristics of this model:

- the power indicator is 1.1 kW;

- the voltage of the electrical network required for the operation of the machine - 220 V;

- the maximum length of the part for processing is 35 cm;

- the maximum indicator of the section of the workpiece with which you can work is 200 mm;

- the number of revolutions per minute - up to 700;

- weight - about 300 kg.

Despite the fact that the maximum length of the product that can be processed on TV-6 is 35 cm, the length of the part groove is possible only at an interval of 30 cm.

The small size is a big advantage of this metal lathe. You can buy a used model of this type for 35,000-70000 rubles. TV-6 is perfect for working with metal parts in the home workshop.

TV-7 machines: main differences from TV-6

A lathe of this type is an improved version of the TV-6 device. The main differences between these two models lie in the gearbox arrangement. It should also be said that TV-7 differs from TV-6 in the design of the spindle head.

Consider the main characteristics of the TV-7 mini-machine:

- the power indicator is 1.1 kW;

- required mains voltage - 220 V;

- the maximum length of the workpiece for processing - 33 cm;

- the largest diameter of the workpiece with which this unit can work - 220 mm;

- the number of revolutions per minute - up to 1000;

- weight - 400 kg.

Helpful information! The speed box of such a mini-machine used for processing metal parts can function in two modes. It is also worth noting that the TV-7 has one more difference from earlier school units, namely, the absence of levers necessary to switch gears.

The price of a lathe for metal of this type ranges from 55,000 to 85,000 rubles. As in previous cases, purchasing a new device is extremely difficult, so the choice must be made among the models that were in use.

Tips for buying a used machine for your home

Buying a used unit can significantly save money. However, when choosing such a product, you must be very careful not to purchase equipment that has functional problems. Let's take a look at the basic rules to help you choose the right device.

When buying a mini-machine, it is advisable to inquire about the documentation that comes with it. If the seller does not have all the necessary documents for this equipment, then it is better to refuse to purchase a mini lathe for metal. It is quite difficult to buy a used device that is capable of processing workpieces with high accuracy, however, if desired, it is possible.

Before purchasing a used mini-machine, it is recommended to check its operation. Moreover, it is necessary to test the functionality of the device in all possible modes. And also it is worth paying attention to the backlash of moving parts. The clearances must match the specifications of the device.

CNC home metal lathe

The CNC lathe is capable of performing the same functions as manual models. However, it performs all technological operations much faster and, most importantly, more accurately than conventional mini-devices. Thanks to the numerical software system, the possibility of errors when machining the workpiece is virtually eliminated.

The computer program provides, if necessary, the timely replacement of a functional part, and also monitors the accuracy during the operation of the machine. Such mini-units function almost autonomously. The wizard is only required to enter the necessary parameters in accordance with which the technological operation will be performed.

CNC machines are especially effective when performing the following types of work:

- marking;

- engraving;

- shaped sharpening.

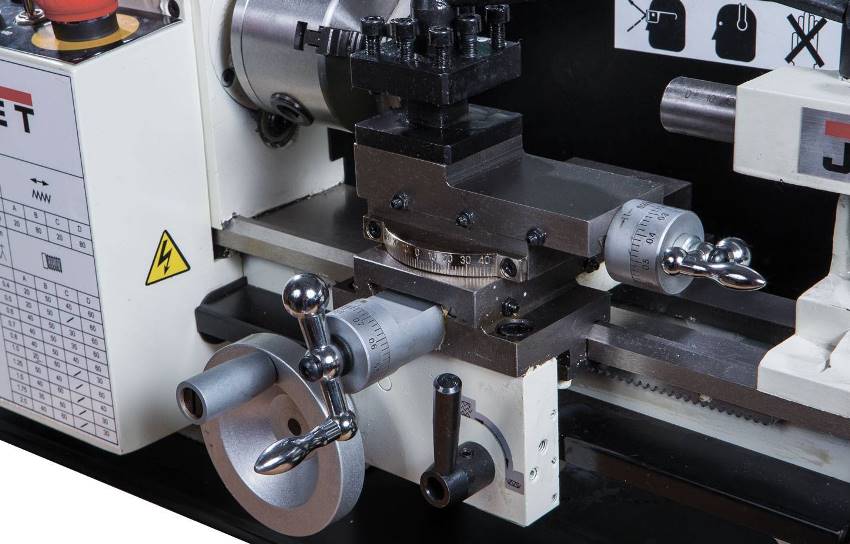

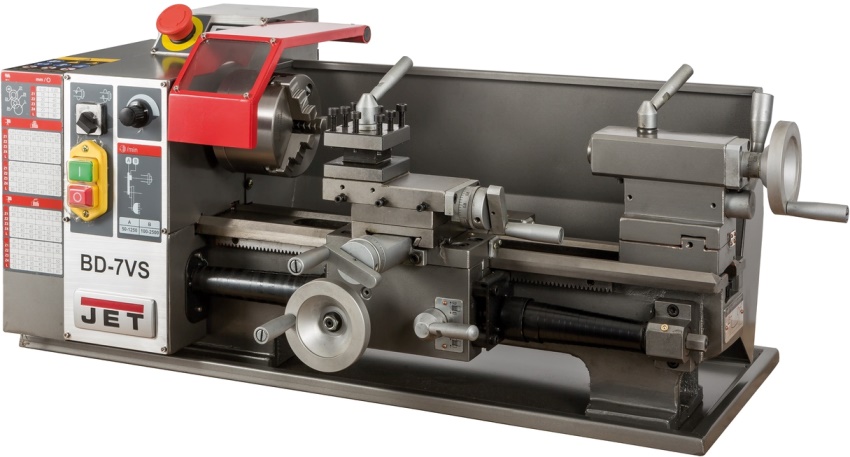

The most popular models of CNC lathes for metal today are manufactured by OPTIMUM and JET. Miniature units from these brands are of high quality and precision in performing technological operations.

Which lathe for metal to buy: recommendations for choosing

When choosing a table lathe, you need to pay attention to a number of important parameters. Mini home machines used to machine metal workpieces can have different weights. The minimum weight of such a unit is 13 kg, and the maximum is 400 kg. Accordingly, the higher the mass of the device, the larger it is.

Note! Experts recommend choosing mini-machines for home workshops that have the lowest weight (up to 50 kg). Such models are compact and versatile, and they are also very convenient to install. In addition, if necessary, it will not be difficult to change the location of such a small-sized unit.

Another important parameter to consider when choosing a desktop mini-machine is its power. For small units, this figure is no more than 2.25 kW. Separately, it should be said that there are devices that are commonly called "low-power". They include a 0.15 kW drive.

Before choosing the power with which you want to purchase a small-sized lathe, it is recommended to decide on its purpose. For small workpieces made of non-ferrous metals, less powerful desktop metal lathes are suitable. Mini-aggregates with higher power are suitable, in turn, for large parts made of durable material (for example, steel).

Even desktop devices intended for home workshops are technically complex designs. Therefore, when choosing a mini-machine, it is also recommended to pay attention to the quality of its components. Of no small importance is the material from which the structural elements of the device are made.

Experts recommend paying special attention to the following components when choosing a small-sized machine: the bed and the support. These elements must be made of durable metal. The outer surface of the material must be carefully sanded.

Today you can find many units of this type. To buy a mini metal lathe that is suitable for use in your case, it is recommended to study the technical characteristics of popular models of these devices on the Internet.

Prices of table lathes for metal

When choosing a suitable tabletop unit for your home workshop, you need to pay attention to its cost. The price of mini-machines depends on several factors, such as:

- brand;

- power;

- performance.

Also, other, smaller, characteristics of metal lathes are reflected in pricing. The price of a mini-unit, the power of which does not exceed 500 watts, is approximately 15,000-55,000 rubles. Such devices do not differ in functionality, but they are more than completely suitable for basic tasks.

Desktop units with a wider list of options (screw-cutting lathe) are slightly more expensive. For example, a mini-machine of this type with a power of up to 500 watts can be purchased at a price of 27,000-75,000 rubles.

And, finally, turning and milling machines are considered the most expensive desktop units. The price range in this case is 65-150 thousand rubles. Depending on the functional features and technical equipment, the price of desktop metal lathes is formed. You can buy the necessary device both in a specialized store and on the Internet by placing an order online.

The most popular companies for the production of such equipment, as mentioned above, are OPTIMUM and JET. They produce high-quality, wear-resistant units that have a long service life. The price for such devices is quite high, however, they all correspond to the declared quality.

For example, the cost of the Metal Master table lathe from the JET company ranges from 50 to 150 thousand rubles. Models from the OPTIMUM brand are even more expensive (from 60 to 330 thousand rubles).

Features of working on a metal lathe

The process of processing metal parts on small-sized units is not particularly complicated. However, it must always be remembered that there are certain rules for the use of such equipment, as well as safety precautions that should be followed.

Working tools are placed in a special section of the mini-machine - quill. This section of the machine is mobile and can be moved along the guide elements. Quill placement is carried out with an orientation to the dimensions of the processed metal product.The carriage, which is the main component of the caliper, is also able to move along the guides, thereby changing the position of the working part.

The elements in which the working cutters are fixed are of different types. The type of tool holder is determined, depending on the characteristics of the workpiece, as well as the general loads during operation. Single-type cutting heads are usually used when it is necessary to perform work of an average level of complexity. However, today the most popular are tool holders, which are able to simultaneously fix several cutting devices.

Consider a few basic safety rules when working with a mini-machine:

- the unit must be securely fixed to the working surface (if we are talking about a tabletop model);

- on the bed, which is the base of the mini-machine, it is strictly forbidden to put foreign objects. This rule also applies to tools used in the course of work;

- parts of the belt drive must be fenced;

- it is strictly forbidden to lean on any part of the unit;

- if the processing of the workpiece involves the formation of chips, then it is necessary to wear protective goggles.

Before starting the home turning device, you need to make sure that the buttons on the unit work properly. To do this, set the device to idle and first press the "Start" button, and then "Stop". In the event of any malfunction, the use of the mini-machine is strictly prohibited until the problem is eliminated.

Helpful information! Masters advise to monitor the cleanliness of the workplace and check the presence of oil in time.

And one more rule that must be observed when working with such a device - in no case should you leave the turned on lathe unattended. Videos, which describe in detail all the subtleties of working on such units, can be easily found on the Internet.

Despite the wide variety of models of tabletop units used for processing metal parts, they all have common principles of operation. They are also capable of performing many tasks, just like professional models. Having studied the main technical characteristics of different models, you can easily make the choice of a desktop lathe for metal. You can buy a similar unit in any specialized store or order it on the Internet.