Terminals for crimping wires provide a reliable and tight connection of cables, which is one of the conditions for safe connection of household appliances to the mains. From this article you can learn in detail about all the features of these products, including their types, sizes and marking. The text provides an overview of crimping technology with double and single lugs, as well as products for connecting power cables.

Content [Hide]

Tips for crimping wires: main characteristics

Lugs (ends) of wires are universal parts used for contact connection of cables. The use of such products has a positive effect on the functioning of the electrical circuit as a whole. There is a huge assortment of handpieces of various types on the market, so it is not difficult for consumers to choose the appropriate option for performing certain electrical work.

Stranded wire terminals allow you to create a reliable connection to various components of the electrical circuit:

- screw clamp;

- terminal block;

- household electrical appliance;

- with another cable.

The tips perform well in circuits where strong vibrations are common. They can also be used in cases where standard joining methods are not suitable. For example, if the conductors are not long enough, the soldering or welding method cannot be used. To crimp wires in such a situation, a tip or sleeve is simply installed on the bare end, after which this section is crimped.

Advantages of using handpieces:

- The bundle of veins remains intact, it does not flatten or fall apart.

- The connection area does not burn or heat up.

- The integrity of the wires is preserved.

- Metal conductors are reliably protected from moisture and air.

- All wires of the bundle take part in the transmission of current.

- The tips have a large contact area.

The connection of cables by crimping is used in production (connection of power lines) and in domestic conditions. The popularity of this method, in contrast to the use of conventional clamps, is due to its high reliability. In addition, it is much easier to connect wires with a ferrule than using soldering or welding.

Note! The size of the lugs for crimping wires, as well as sleeves, must be selected taking into account the main characteristics of the wire. These parameters include the diameter of the cable and the type of metal from which it is made.

How to decipher the marking of the lug for wires

To make it easier for consumers to navigate the offered range of handpieces, a special marking system is provided. It allows you to determine the material from which the part is made, as well as its purpose.

Decoding of letter designations:

- L - products made of brass.

- T - for the manufacture of parts used metal of tubular section.

- A - aluminum sleeve.

- M - copper product.

- U - angular tip.

The decoding of the TML 70-10-11.5 tip is as follows:

- T - for the manufacture of the connecting part, a semi-finished product in the form of a pipe was used.

- M - copper was used as the material of manufacture.

- L - the third letter displays the method of processing the material from which the part is made. In this case, the tip is made of tinned copper.

- 70 - section size (measured in mm).

- 10 - the size of the hole intended for fastening the bolt (diameter is indicated in mm).

- 11.5 is the size of the shank inserted into the wire. This refers to the inner diameter, which is measured in millimeters.

Table containing information on common labeling options:

| Letter designation | Decoding |

| TML | A universal product made of tinned copper, which has a high degree of protection against external factors |

| THERE | Lug designed for connecting aluminum wires. Has copper contacts |

| NShVI | Sleeve pin type of products with insulation, used in domestic conditions |

| TA | Part made of aluminum, which is used exclusively for connecting wires of the same material |

| SIP | Aluminum ferrule with insulated tube and terminal made of copper |

Note! Sometimes the marking of the lugs on the wire contains the letter "O". This indicates that the product has a viewing window. It is used to monitor the connection area and to ensure that the wires inside the grommet are positioned correctly.

Crimp connectors: types of lugs, sleeves and terminals

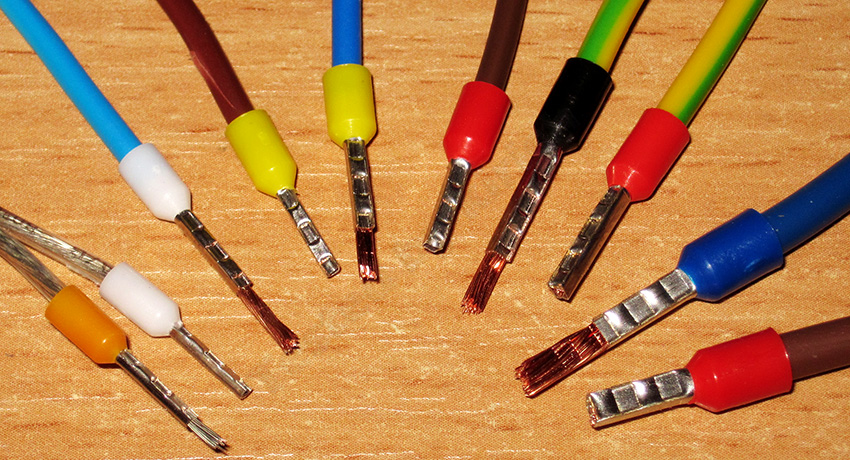

There are many options for crimping ferrules. It is imperative to take into account how the wiring will be installed. If the cables are expected to be trapped in the circuit breaker, it is better to use pin grommets for the connection. Lugs with or without insulation can be found commercially. The same version of products is used for cables that are clamped using terminal blocks.

If the wiring is to be fastened under a nut-screw, then special connectors are required. These include U, J, and O ferrules. Once installed, the same screw is used to clamp them to the pad. There is another class of connections - male-to-female tips. They are quick-release products that are very easy to use.

By the shape of the structure, the following types of ferrules for crimping wires are distinguished:

- ring;

- power;

- fork;

- tubular (sleeve);

- in the form of a socket (used for quick connection);

- pin.

In addition, ferrules are classified according to the type of material from which they are made.

Tips for wires: types of products, their purpose

The connecting element is selected taking into account the type of wires on which it will be installed. The most common and demanded are the following types of handpieces:

- copper;

- aluminum;

- aluminum-copper;

- bolted.

Copper versions of products are designed for crimping cables made of the same material. For the production of these parts, seamless tubes are used. On one side of the tip there is a clamping part. On the other side of the connector is a tubular hole where the wire will be inserted. Purpose of copper lugs:

Copper and aluminum lugs are designed for wires made of the same materials as the products themselves

- connection to the circuit of input and distribution devices;

- installation of electrical appliances;

- grounding.

Aluminum products, like copper, are designed for wires made of the same material. On one side they also have a tubular opening, but on the other side they have a contact blade.

Important! Before connecting the wires with a crimping tool for lugs, aluminum products should be treated with quartz-vaseline grease. It will protect the contact area from oxidation.

Copper busbars are sometimes used in valves. In this case, aluminum-copper connectors are used. In these elements, the landing tube is made of aluminum, and the contact blade is made of copper. Frictional diffusion is used in the manufacture of these products. Gas-dynamic copper deposition technology can also be used, during which the metal is sprayed over the tip, ensuring a stable contact.

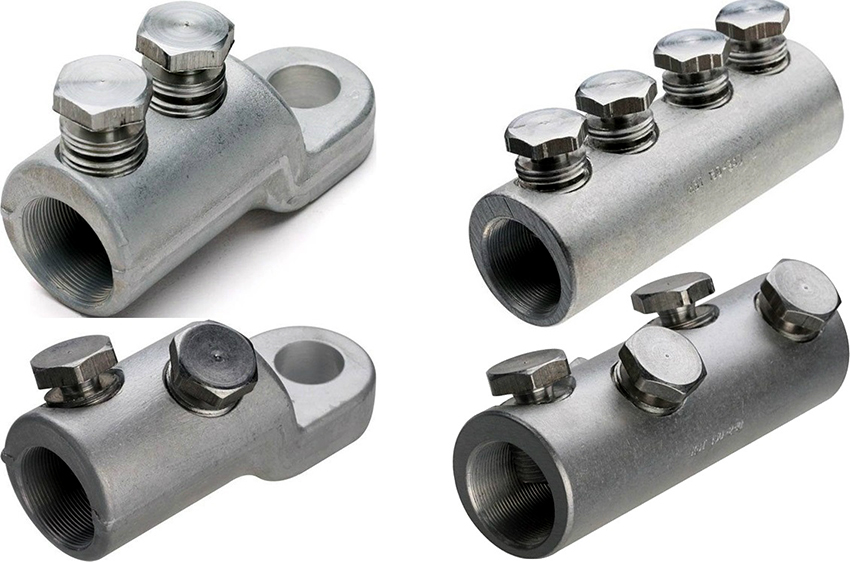

In bolt-type lugs, fixation is carried out by means of a clamping bolt. You will need a wrench to tighten it securely. This method does not require crimping as the bolt itself makes a contact connection.

Main types of crimp terminals for copper wires

In the process of making copper connectors, pipes are cut appropriately. After that, a contact blade is formed on one side by flattening. A hole is made in it for fasteners, the size of which depends on the diameter of the bolt.

Copper cable lugs are of two types:

- without a protective layer;

- with a tinned coating.

Tin plated contacts are much more practical because they are corrosion protected. Due to this, this type of product has a long service life. Tin plated connectors are resistant to the aggressive attack of various acids:

- sulfuric;

- nitrogen;

- saline.

They are not destroyed under the influence of moisture, air and other negative environmental factors. Due to the presence of a protective coating, the level of electrical conductivity of the handpieces is reduced, but this does not prevent them from maintaining optimal performance.

For copper connectors without a protective coating, the oxidation of these products is much faster. Their current conductivity is very low, which increases the resistance. As a result, the bonding zone heats up.

The scope of application of copper tips covers:

- to create a contact between devices (possible use on a group of devices);

- formation of a connection between the device and the electrical network;

- increasing the length of the cable by splicing wires.

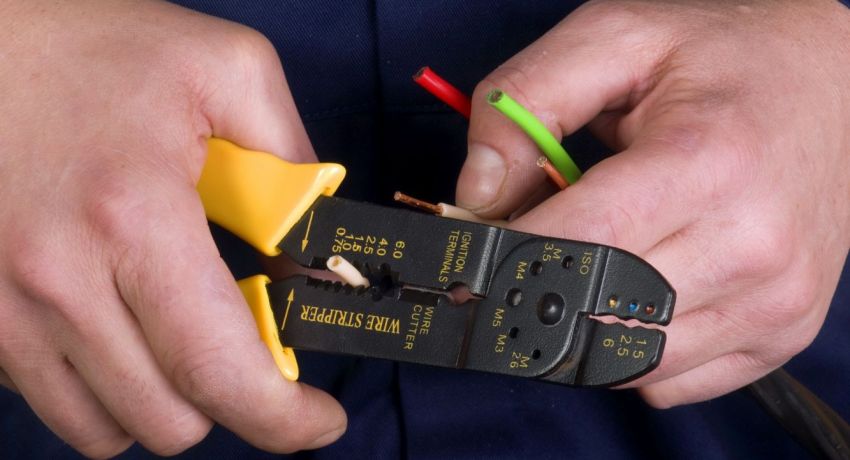

Experts advise using crimping pliers for crimping terminals to install copper connectors on wires.Despite the wide selection of products offered by manufacturers, it is far from always possible to find an element of the required size. In this case, it is worth making the tip yourself. To do this, a copper tube of the desired size is selected, and then flattened at one end. For the mounting bolt, a hole of the corresponding diameter is made in it.

Important! Hand-crafted handpieces are significantly inferior in their characteristics to factory-made products. It is very difficult to calculate what degree of load they can withstand, so it is not recommended to use homemade connectors in critical sections of the electrical circuit.

Using wire sleeves for crimping

In some cases, as connectors, they can be used instead of ferrules for wire sleeves. If splicing of cables in which the cores are made of copper is required, products marked with GML should be used for work. This marking means that the sleeve is made of copper and protected by a tinned coating. Products with the GAO marking are intended for connecting aluminum wires. They are closed-design aluminum sleeves. In addition, there are casings made of alloys. They are used in cases where it is necessary to connect aluminum and copper elements.

The connection by crimping the wires with sleeves or lugs is obtained of better quality than splicing by soldering. A multi-core cable consists of several cores, each of which is hidden in its own insulating sheath. For reliable contact, they must all be bare, which creates certain difficulties when using soldering. With crimping, such problems do not arise, because during the compression process the insulating layer on each core is destroyed. This makes the connection strong and also provides better contact.

If crimping is carried out with sleeves, it is very important to pay special attention to the choice of products, in particular their material of manufacture. As a rule, current characteristics are written on them. The main difficulties in the process of purchasing products arise when it is necessary to choose the appropriate size. Manufacturers in this regard offer a limited range. In addition, it is difficult for a person without special education to decipher the marking.

Crimping wires with sleeves is performed in the same way as when using ferrules, but more crimps are required.

The main types of crimp terminals for wires

Connecting terminals can be roughly divided into two categories: electrical and electrical. The difference between these products lies only in the amount of current load that they can withstand. This parameter must be taken into account when selecting terminals for crimping wires during the installation or repair of the circuit.

Related article:

Crimping pliers for wire lugs: types of tools and methods of application

Functional purpose. Professional and household tool. Hydraulic pliers. Crimper for crimping internet wires.

The most popular types of crimp terminals with the simplest design:

- fork;

- knife;

- pin;

- ring.

Knife terminals are the most common option. They are found primarily in household appliances such as refrigerators, irons or heating devices. Blade terminals are mounted on stranded wires with cross-sectional dimensions ranging from 0.26 to 6 mm².

There are isolated and non-isolated options on sale. The color of the insulating material depends on the rated power. It can be yellow, blue or red.Such products are used in pairs ("dad-mom").

Important! The maximum voltage that such a connection can withstand is 5 kW. Therefore, the blade terminals must not be installed in large power installations with high current ratings. Also, their installation in apartment electrical panels is not allowed.

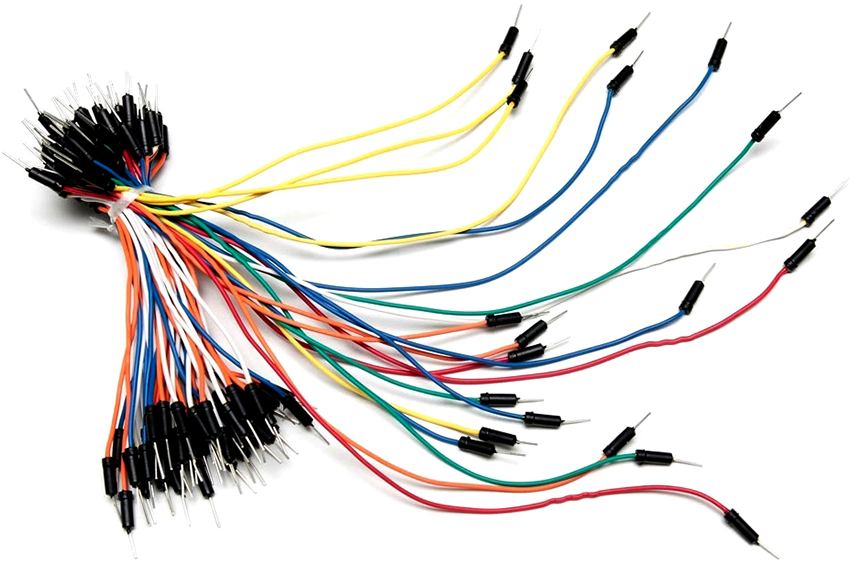

Fork terminals are used in secondary or power circuits. After their installation, screw fastening to the busbars or electrical equipment is assumed. This product variant is considered a temporary product variant. It is allowed to use plug-type terminals in areas where contacts are often reconnected. Outwardly, these terminals resemble a plug with two prongs. They are used for crimping wires with a cross-section not exceeding 6 mm². Available in two versions - with and without insulation.

Ring-shaped terminals provide very reliable contact. Like forklifts, they are subsequently attached with screws. Due to the fact that the contact part has a circular shape, the connection area is increased. In addition, the likelihood that the tip will pop out is reduced. Suitable for low-current and power networks. The cross-section of the cables can be different. Ring terminals are available in aluminum, brass, copper-aluminum and copper.

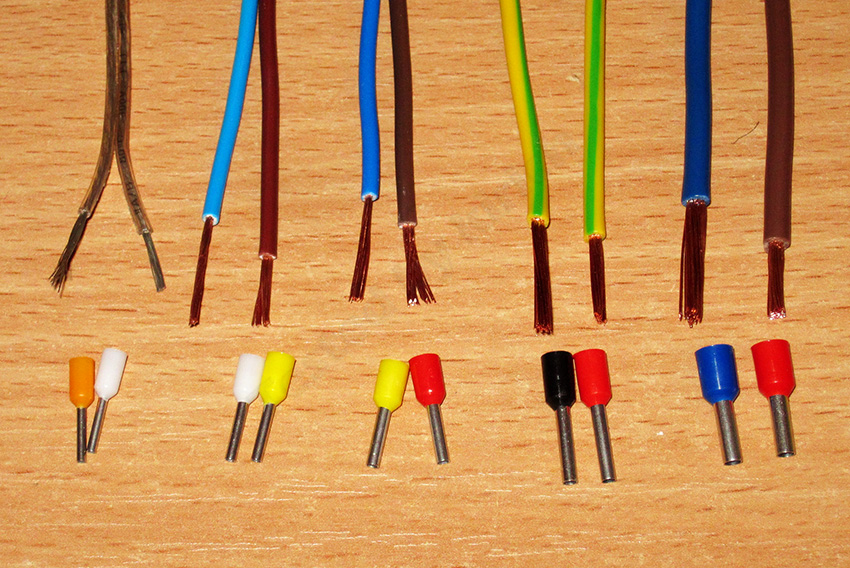

The pin terminals are of a separable design consisting of a plug and a socket. Blue products are designed for wires with a small cross-section - up to 2 mm², and yellow - from 2 to 6.64 mm².

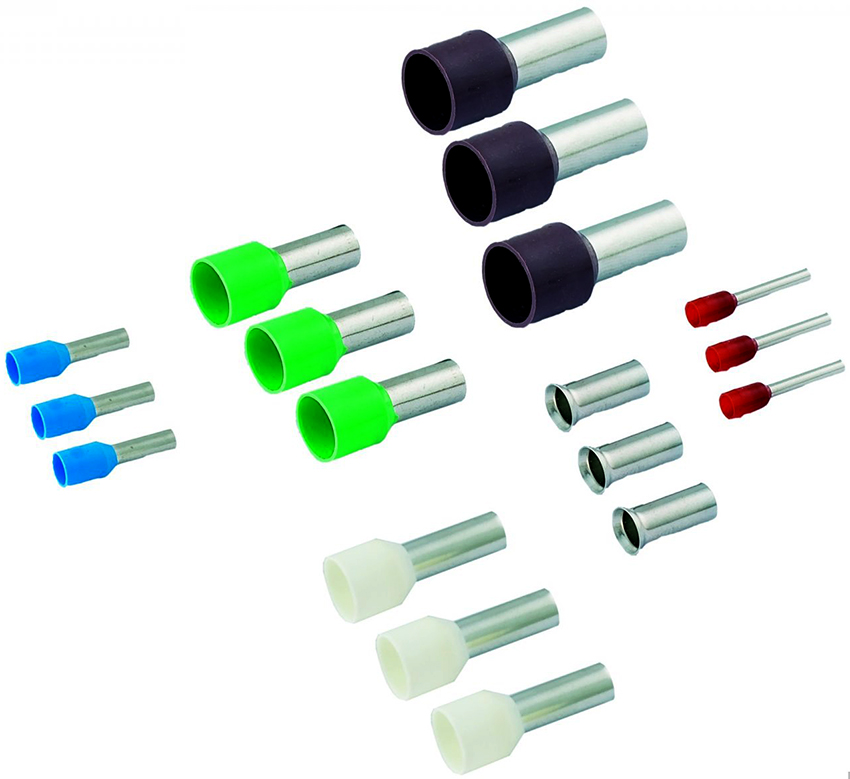

Features of using tips NShVI

Electrolytic copper is used for the manufacture of pin sleeve lugs. There is insulation on the back of the product. To prevent damage to the metal by corrosion, copper is treated with electroplating. The size of these tips ranges from 0.25mm to 150mm.

When crimping NSHVI, time is significantly saved, which makes it possible to simplify the process of connecting electrical devices. The tips are suitable for domestic use. They are designed for crimping any type of stranded wire. Manufacturers produce NShVI of two types. Some lugs are used to crimp one wire, while others are designed for two.

Products are marked as follows:

- Single - the first number of the marking means the size of the section, and the second displays the length of the contact part.

- Double - the number "2" in parentheses indicates that this lug is designed for splicing two wires, and the next number indicates the size of the cross section of each of them.

It is desirable that the size of the shank in the tip be slightly larger than the cross-section of the wire, that is, its bare cores. So, for a 1.25 mm cable, you should purchase NSHVI with a cross section of 1.5 mm.

Note! NSHVI are designed exclusively for multicore cables. It is not recommended to use crimp sleeves for single-core wires, as these products will not adhere well to them.

Basic rules for crimping wires with sleeve-type lugs

Qualitatively connect wires with the help of the tip it is possible at home, without professional skills and knowledge. To do this, you need to adhere to the basic rules:

- Select the correct type and size of ferrule for crimped wires.

- Carefully and correctly strip the veins.

- Use only a specialized tool in your work.

- Follow the crimping technology exactly.

Usually, the insulation on the wire is stripped taking into account the size of the contact part of the lug. After stripping, the end of the conductor should be aligned with the edge of the sleeve. To achieve this, add 2-3 mm to the length of the cleaned area. It is very important to choose the correct tip size.In order not to be mistaken, you need to be guided by the color coding in which the insulating cuffs are painted.

There are some subtleties with insulated connectors. It is imperative to make sure that the insulating material on the wire goes into the cuff all the way and is completely covered by it.

Preparatory work is carried out in the following order:

- The veins are cut strictly perpendicularly.

- To remove the insulating layer from the cores, the size of the shank and the allowance must be taken into account.

- If the conductors are copper, the oxide film must be removed from their surface. To do this, the bare area is degreased, after which it is lubricated with technical vaseline.

- If the shape of the veins is sectorial, you will have to round them.

- If the strands of the wire are made of aluminum, this metal must be stripped to a shine. After that, the bare area is treated with quartz-vaseline lubricant, which will prevent the appearance of an oxide film.

How to crimp cable lugs: a list of suitable tools

To install metal connectors on wires, do not use tools that are not designed for this purpose. There are special ferrules for wires. Each of them has unique capabilities, so it can be used in certain conditions. The scope of use of various types of wire crimping tools:

- Pressing tongs PK2M and PK2 are designed for crimping wires with a cross-sectional size not exceeding 10 mm².

- Pressing tongs PK1M and PK1 are manual tongs, which are much more powerful than the previous version.

- Hydraulic pliers - designed for crimping cables up to 10 mm².

- Manual press - used in industrial production on wires up to 240 mm².

- Electric hydraulic press - designed for crimping wires up to 300 mm².

Tools equipped with hinges have increased pressure. In this case, a person does not have to make much effort to install the tip. The ratchet devices are considered the most convenient to use.

Important! Before starting work, make sure that the diameter of the hole (matrix) on the tool is set correctly. Otherwise, the tip may be damaged during the crimping process.

Crimping technology for cable lugs: single, double and power

If this is the first time splicing wires with a tip, it is advisable to practice before starting work. For this, you can use an unnecessary piece of cable. Otherwise, the master runs the risk of spoiling not only the connector, but the entire wire.

Recommendations for using single pin lugs for wires:

- To prevent the wires from falling out of the socket, when placing the wire in the hole of the tool, it must be fixed.

- Crimping with pliers is carried out until the ratchet mechanism is connected, which locks the tool, preventing it from being released.

- If the connector is installed manually, the quality can be determined by pulling the tip by hand. If everything is done correctly, the part will sit tight and will not move.

- The use of a double-circuit crimping tool is allowed. In this case, the insulator and the bushing are compressed in the sockets with different diameters.

The phase connection of two wires can be made with one contact. If modular machines are being installed, special jumpers must be used for connection. As a result, two cables are connected to one contact.In this case, it is advisable to use NSHVI for crimping wires with lugs.

This procedure has its own characteristics:

- two cables are inserted into the cuff at the same time;

- for crimping, it is preferable to use pressing tongs with a matrix size of 6 mm².

Otherwise, the installation process for a double connector is the same as for a single connector.

For crimping the power cable lugs, it is recommended to use copper products with a tinned protective coating. Sometimes, after cutting the wire, its edge fluffs up and increases in size. If this happens, you need to remove the excess at the edges with a sharpener. The wire must be turned so that the grinding wheel cuts off the excess along the veins, but in no case bends them.

Regardless of the type of ferrule used, it is not allowed to combine the crimp method with soldering. It is impossible that the contact part on the wires is made of pure tin. Ferrules, as a rule, are crimped 1-2 times at a distance of 1-2 mm, sleeves - from 2 to 4 times.

Before installing the ferrule, make sure that all strands on the cut are of the same length. Otherwise, the connection will be of poor quality. Sometimes the wires are damaged or broken, so the wiring must not be twisted before mounting the tip. If this requirement is ignored, during the crimping process they will be transferred, the current transfer will be disrupted.

In general, anyone can handle crimping cables at home. The main cause of errors is a mismatch in the size of the wire and the tip. It is not recommended to use homemade fittings in the work. It is also not allowed to cut the sleeve into two parts in order to save.