Any construction requires the organization of a reliable foundation. In order to give the concrete foundation the required shape, a special structure is used - formwork. It can be of different types depending on the features of the structure. Do-it-yourself foundation formwork is performed in several stages. It can be made from different materials. Self-assembly of the structure requires studying the instructions and observing the installation rules.

Content [Hide]

- 1 Formwork: what is it? Construction assembly conditions

- 2 Variety of structures: fixed and removable formwork for foundations

- 3 What you need to know when choosing a material for formwork

- 4 Film faced plywood for formwork: material features

- 5 How to make formwork for a foundation: calculation features

- 6 How to make do-it-yourself foundation formwork (removable): preparatory stage

- 7 Do-it-yourself fence formwork: step by step instructions

Formwork: what is it? Construction assembly conditions

In order for the foundation to take shape after pouring, various materials are used from which the formwork is assembled. Most often, such structures are made of wood. There are also more modern options, which are constructed from polymer materials with high technical characteristics. The formwork performs the following functions:

- creates the shape necessary for the solidification of the concrete base;

- gives an even surface texture;

- isolates the structure from the soil (if necessary).

With the correct installation of the formwork, the foundation will turn out to be strong and reliable

In order to answer the question of what formwork is, it is necessary to familiarize yourself in more detail with the features of this design. Correct installation of the formwork requires compliance with certain conditions.

First of all, it is necessary to prepare the soil in the place where the foundation of the future building will be poured. It must be completely free of debris and foreign matter.

The foundation formwork consists of individual elements. Shields made of wood or other suitable material are used as a forming base. There should be no dirt on the inside, which will come into contact with the concrete solution. The surface should be as flat as possible. This will minimize finishing work after dismantling the molds.

When installing the formwork, special attention should be paid to the fastening of individual components to each other.The quality of the fixing elements determines how well the formwork copes with the forming function. Fastenings, improperly organized, can deform the concrete.

Formwork for a columnar foundation (as well as strip or monolithic) must be completely sealed. Only in this case is the correct shaping of the base possible. Before proceeding with the installation of the formwork, you need to familiarize yourself with its possible types.

Variety of structures: fixed and removable formwork for foundations

Currently, you can find two types of formwork. Distinguish between removable and non-removable structures. Each option has its own advantages and disadvantages that should not be ignored. Let's take a closer look at these varieties.

Removable. This type of structure is dismantled after the base of the building has solidified. In the future, all the structural elements used to assemble the form can be reused. For the organization of such formwork, wooden materials are most often used.

This option is standard and is used when pouring foundations of varying complexity. Removable formwork is also suitable for the execution of individual building elements. For walls and ceilings, this technology is used no less often.

Non-removable. Forming formwork of this type, unlike the previous version, is not disassembled. Such designs are distinguished by their manufacturability and have some advantages over standard forms.

Note! Permanent formwork performs a thermal insulation function, protecting concrete from the effects of low temperatures.

Fixed structures are made of polymeric materials of varying degrees of manufacturability. The most widespread are polystyrene foam forms. This is due to the fact that this material has an acceptable cost. Such formwork is used in the construction of monolithic buildings as the most appropriate option.

We should also mention the non-removable forms made of wood. In order to more clearly assess the differences in various designs, it is recommended to study their photos. Formwork of this type is used most often when it is necessary to make a narrow bath foundation, located at a shallow depth. After pouring concrete, such a structure is simply covered with soil.

Combined formwork: design features

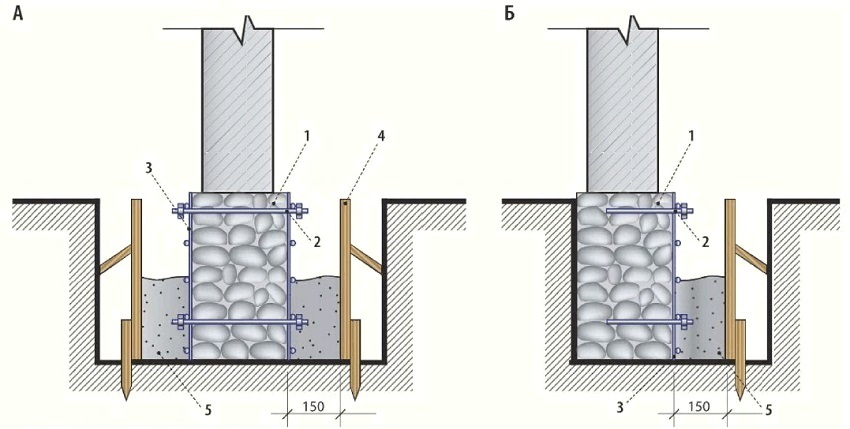

In some situations, combined structures are used to form the base of a building. The mixed version, which includes elements of removable and non-removable formwork, is recommended to be used if the building is being built on loose soil.

Such house formwork includes two layers: external and internal. On the outside, standard shapes are used that are assembled from boards. In turn, the inner side is represented by expanded polystyrene. To fix the polymer material to the ground, nails with a length of 200 mm are used. Docking of polystyrene foam with wood material is done using self-tapping screws.

The main advantage of the combined structure is that it performs both an auxiliary and a thermal insulation function. The foundation is protected from the sides and from the sole.

Scheme of two-sided (A) and one-sided (B) strengthening of the foundation: 1 - rubble foundation, 2 - anchor, 3 - reinforcing mesh, 4 - formwork, 5 - concrete mix

When installing such formwork around the house with your own hands, you must remember that thermal insulation can be organized either in the underground part, or to the entire depth of the base. In the event that the expanded polystyrene elements are located at the full depth, then you need to take care of the organization of the fasteners.To do this, dowels are inserted into them in advance, allowing the block to be fixed on the concrete surface.

Helpful information! The upper tier of the formwork is constructed using standard wooden panels, reinforced with struts and stakes.

What you need to know when choosing a material for formwork

The formative structures used to pour the foundation can be assembled from a variety of materials. The choice of the type of formwork is influenced by the following criteria: the type of foundation, its width, length, etc. The following materials are most often used to assemble the form:

- wood;

- expanded polystyrene;

- metal;

- reinforced concrete.

Wood. As mentioned above, forms for a foundation made of this material are most common. In this case, formwork panels may differ in their design. The most common use is plywood, which is fixed to spacers made of wood planks.

The advantage of a wooden structure is its availability. It is also worth noting that the cost of this form is quite low. Wooden elements are relatively easy to assemble. All that is needed for this is to know the technology of work and adhere to it. To install such a structure, complex specialized tools are not used.

The main disadvantage of concrete formwork made from wood is the need to use additional elements. This is necessary in order to strengthen the structure. Most often, such a need is due to the dimensional differences in individual parts of the form. The organization of this formwork requires a mandatory preliminary calculation of materials.

Expanded polystyrene. The second most popular material. The constituent elements of the non-removable structure are made from it. In addition to performing a formative function, it is a good insulation material, protecting the foundation of a building from low temperatures, wind and water. This design is easy to install, but its cost is not very affordable. Problems can also arise when selecting individual constituent elements.

Reinforced concrete. People wondering about what to make formwork from often choose other, less popular materials. Reinforced concrete is an example. In private construction, this method is practically not used, since the final cost of the work is too high. It is also worth noting the complexity of organizing such a formwork.

The reinforced concrete structure is assembled from individual slabs. The main advantage of such a formwork is that its installation allows you to reduce the thickness of the foundation itself.

Metal. The metal form is an excellent option when you need to build a strip foundation. It is also used for monolithic structures. The indisputable advantage of this method is that, if desired, the reinforcement reinforcing the concrete can be welded directly to the metal formwork panels. This design is highly durable and reliable.

Note! Unlike formwork boards, a metal structure does not require additional spacers.

Another advantage of metal is its versatility. Such sheets can be bent, changing their shape as needed. The disadvantage of this option is the high cost of the structure.

Do-it-yourself foundation formwork from scrap materials

For the assembly of formwork, not only specialized materials are used. For example, a small form for a foundation can be made from available tools. These can be old doors, pieces of furniture, boards, slate, etc. The main advantage of this method is its low cost.

It is worth noting that it is quite difficult to design such a shape, since it is rather difficult to find the right parts. It is very difficult to achieve the tightness of the formwork made from improvised means. That is why this method is not popular. It can be used when building a concrete fence. The form for the fence, made using this technology, requires taking into account possible problems that sometimes arise during work.

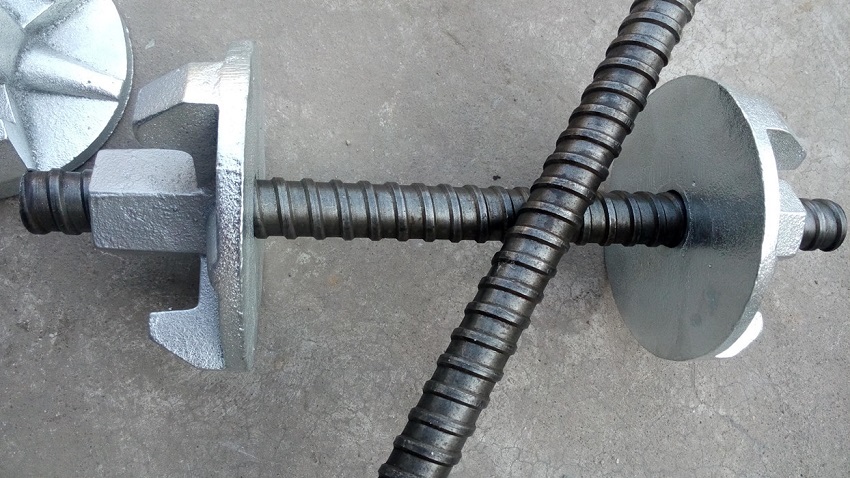

When using any material, it is recommended to use special formwork pins. They are necessary to tighten the walls of the structure. The rigidity of any formwork is much lower than this indicator of forms assembled from specialized parts. When organizing such an option, the risk of solution leakage increases.

It is recommended to take into account that in this case you cannot do without additional fasteners. To ensure good rigidity and stability of the structure, it is necessary to expose special wedges and supports. It should be remembered that this method can not be used categorically when organizing the foundation for residential buildings.

Film faced plywood for formwork: material features

Film faced plywood is a traditional material used in the assembly of forming structures. This is due to the fact that it has the most suitable technical and physical characteristics. The lamination layer is located on the surface. Its function is to protect wood from moisture.

The surface texture of laminated sheets can vary. Allocate smooth and grained plywood. When choosing laminated sheets, first of all, you need to pay attention to their thickness, which can vary from 3 to 40 mm. The price for a sheet of film faced plywood for formwork ranges from 1.5 to 4 thousand rubles. The cost depends on the type of wood from which the product is made, its thickness and dimensions.

Note! For the assembly of forming structures, it is customary to use plywood with a thickness of 15 mm and above.

How to choose a formwork for a foundation? The best option is considered to be sheets with a thickness of 18 to 21 mm. They are most often used in the design of formwork for foundations and other building elements. Such products are distinguished by the fact that they are able to withstand high loads. Moreover, their weight allows for simple transportation and installation. The dimensions of standard sheets are 1250x2500 mm.

Plywood for formwork: types of material

Today, there is a clear gradation of material such as plywood. There are several popular types of sheets that can be used as shields for a forming structure. They all differ from each other in one way - the type of glue. When assembling the formwork, the following types of plywood are used:

- FBA;

- FSF.

FBA. In this case, an albuminocasein adhesive is located between the veneer layers. This type of plywood is highly environmentally friendly. It is often chosen as an alternative to natural materials. The price of plywood for this type of formwork is quite high, but it can even be used for cladding surfaces in residential premises.

For the organization of the forming structure, it is not recommended to use the FBA, since this type of plywood is characterized by poor resistance to moisture. Therefore, this option is used only as a last resort.

FSF. This material has good resistance to moisture. This is a serious advantage that determines the performance characteristics of such plywood.The adhesive composition in this case is a resin (phenol-formaldehyde).

Related article:

Fixed formwork made of expanded polystyrene: versatility and reliability

Design advantages and disadvantages. Formwork types. Permanent formwork for foundations, walls and floors.

Many experts advise using this type of plywood when assembling the formwork with your own hands. A slightly different technology is used for the walls, but for the foundation, this option is the most acceptable. Another advantage of the FSF is that it can be used several times. It is not recommended to sheathe the interior of the room with such plywood.

How to make formwork for a foundation: calculation features

Before starting installation work, standard calculations are required. These include determining the amount of material required and finding its final cost. It is important to consider the type of raw materials that will be used to make the formwork. OSB boards, plywood, chipboard, boards - all these materials have different costs.

OSB formwork is used most often in private construction, since this material is not suitable for large projects due to its poor resistance to moisture. Calculating the number of boards is very simple. To do this, first of all, it is necessary to divide the perimeter of the planned foundation into the length of the wooden part. Next, you need to divide the height of the base by the width of the wooden board.

The last thing to do is to multiply the two values obtained earlier. The result will correspond to the number of boards you need to purchase. Experts recommend adding a small margin to the calculated data (about 10%).

Note! One cubic meter of boards holds on average 40 to 65 products.

In order to determine the cost, you need to multiply the value of the price by the amount of cubic meters of lumber required to install the foundation formwork.

Other costs should be added to this figure. For example, a certain amount of timber is required to assemble a forming structure. And also to strengthen the formwork, wooden spacers are used. The cost of purchasing additional materials can in some cases amount to 40-50% of the total price of plywood sheets and boards. The final cost estimate also includes the cost of purchasing tools and elements that will be used to fix the individual formwork components.

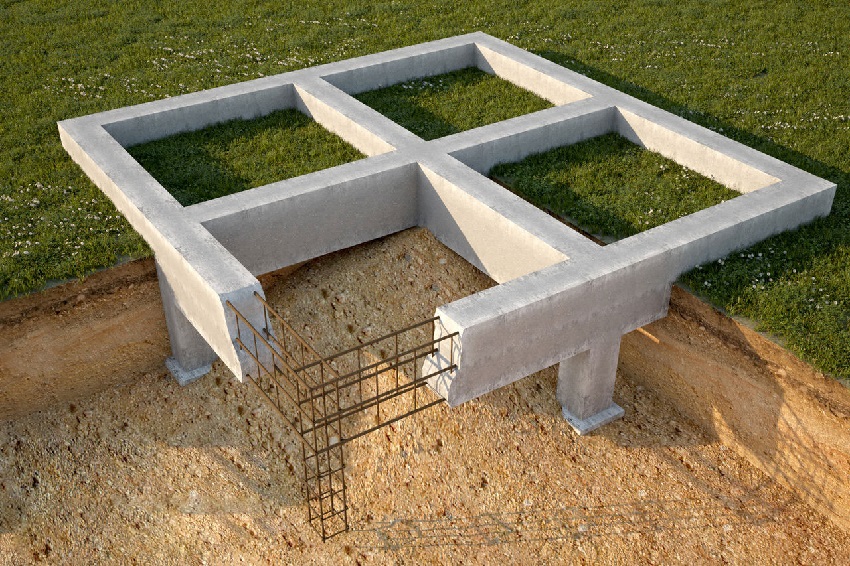

How to make do-it-yourself foundation formwork (removable): preparatory stage

Before starting the assembly of the removable forming structure, it is necessary to purchase the appropriate tools and materials, and it is also worth preparing the territory that was determined for the installation of the foundation. The most common is the strip base. For the manufacture of removable formwork, the following materials will be required:

- boards 100–150 mm wide and 25–30 mm thick;

- spacer bars 100x50 mm;

- stakes 40-50 mm thick;

- wire;

- nails;

- self-tapping screws;

- polyethylene film of sufficient density.

Before starting the construction of the formwork, you must purchase the appropriate tools and materials

The calculation of materials for organizing the formwork of a strip foundation is carried out based on the dimensions of the future foundation. It is necessary to take into account several requirements that make it possible to competently perform the forming structure. The height of the formwork assembled from plywood must exceed the level of the plinth by 50 mm. Spacers are installed at a strictly defined distance from each other (700-1000 mm).

It is important to remember that there should be as many stakes as there are side supports. The shields in the corners are fixed to each other. For this, side jumpers are used. When organizing the formwork, a dense film made of polyethylene material is used.It should cover the entire interior of the fence. Before starting work, it is recommended to watch training videos on how to make the foundation correctly.

Preparation of the place where the base will be cast includes several types of work. First of all, you need to dig a ditch in the ground. The trench must match the design depth. In this case, it is required that the width of the ditch has a margin that is 10 cm higher than that of the future strip base.

Next, you need to level and compact the earth at the bottom of the trench. Then its walls are aligned. One of the most important conditions when pouring a foundation is to organize a special cushion of gravel and sand at the bottom of the ditch. The standard width of this layer is 10-15 cm.

Note! Not all buildings require foundation organization using a formative structure. In some cases, the foundation can be poured without formwork. Such a foundation is suitable for all kinds of temporary structures. The technology of such construction takes into account digging trenches, laying polyethylene and reinforcement.

In the soil, which has a high density coefficient, a trench is made corresponding to the width of the concrete tape. Moreover, the formwork in this case should be located above the soil level.

How to make formwork for the foundation: step by step instructions

The installation of a removable structure most often takes into account its reuse. If this is not necessary, then you can purchase a non-separable polystyrene foam form. It is quite difficult to do this work on your own. To do this, you need to draw up a competent project and clearly follow the instructions for organizing the base formwork. Let's consider each stage of work in more detail.

First of all, it is necessary to make shields, which are the main forming elements. Nails are used for fastening. The height of the boards should be slightly higher than that of the base (by about 10 cm). In order to understand the features of the assembly of the forming structure, it is recommended to study the corresponding photos and videos. The do-it-yourself foundation formwork is strengthened by means of wooden stakes. As mentioned above, their step is approximately 70-100 cm. The distance from the foundation to the stakes should be approximately equal to 1 meter.

Next, you need to place the shields along the edges of the ditch and connect them to the stakes using special jumpers. Then the fence is aligned in a vertical plane, for which you will need to use the building level. After that, the structure is fixed to the mowing.

At the next stage, the inner cavity of the formwork is covered with a dense polyethylene film. The edges of the canvas are fixed with a construction stapler. Next, you need to place a reinforcing grid in the intermediate space. When installing the formwork for the strip foundation with your own hands, it may be necessary to add wooden supports under the reinforcement, the height of which is 5 cm.

Note! Before starting the filling, it is necessary to organize passageways for communications. For this, round sleeves are used.

After laying the reinforcing grill, the plywood shields should be pulled together with wire. It is worth noting that if the foundation has rounded zones, then in this case it will be necessary to bend the plywood to achieve the desired shape.

How to make the right formwork: basic requirements

During the assembly of the forming structure, it is necessary to comply with certain requirements that are put forward to the dimensions. All possible deviations from the norms should be taken into account. Otherwise, an unstable shape may result, which subsequently will negatively affect the technical characteristics of the base.So, special requirements are imposed on the manufacture of formwork.

How to make the foundation correctly? It is important to remember that the deviation of the panel structure in the vertical plane should not exceed 5 mm per 1 meter of height. Quite often, inexperienced craftsmen make a mistake related to the location of the boards in areas with a natural slope of the earth. In this case, the upper formwork board should be located strictly horizontally. Repetition of the slope is strictly not allowed.

There are also clear restrictions on the displacement of the forming structure from the initial position. The maximum allowable offset is 15 mm. When installing the boards, you need to take into account that the differences between them should not exceed 3 mm.

How to install formwork on a site with loose soil? In this case, it is necessary to make a wider ditch, on the sides of which additional struts need to be arranged.

If desired, at the stage of assembling the formwork, it is possible to insulate the future base. To do this, use any suitable, inexpensive material (for example, foam). At the same time, the trench expands in accordance with the thickness of the insulating material.

In the case of organizing a foundation without formwork in the ground, a suitable reinforcement is selected from which the lattice is constructed. It is not recommended to use this technology if the soil on the site does not have sufficient density.

When installing fixed formwork, it must be remembered that the most important criterion is its tightness. If we neglect this, then the thermal insulation qualities of a non-separable structure will greatly decrease.

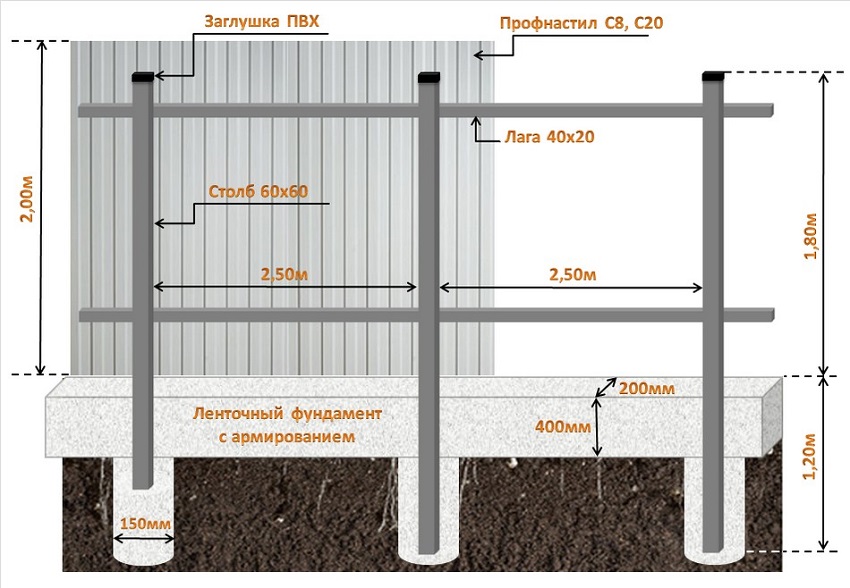

Do-it-yourself fence formwork: step by step instructions

The forming structure is used not only for pouring the foundation of residential and utility buildings. The need for formwork is also present during the installation of some protective structures. The solid foundation of the fence guarantees the protection of the site from the penetration of unauthorized persons.

Before starting the installation of the formwork, in this case, you will also need to carry out some preparation. The first step is to mark the perimeter of the future structure. Then the preparation of the soil is carried out, which involves the removal of vegetation, stones, debris and other obstacles that may interfere with the installation of formwork under the fence.

Then you can start digging a trench. In this case, it is worth considering a few rules. At the points corresponding to the installation of supporting elements (pillars), the depth should reach 80 cm. The same indicator for spans is 50 cm.

Note! After organizing the trench, it is necessary to fill it with sand and gravel in order to prepare a special pillow.

How to build the formwork for the foundation of the fence yourself? It is not so difficult to make this device at home. Even a person without relevant experience can cope with such work. To organize the forming structure under the base of the fence, one should adhere to a phased algorithm of actions.

The first step is to strengthen the waterproofing qualities of the wood from which the formwork will be made. For this purpose, waste machine oil is most often used. Next, the vertical stakes are installed. The distance between them should be at least 50 cm, but not more than 1 meter.

Then the mounting of the support posts from the timber is carried out and the shields are fixed to them. For fixing in this case, use ordinary nails or self-tapping screws. At the next stage, it is necessary to tighten the shield with wire and install the reinforcing mesh.

After the installation of the reinforcement, the upper part of the frame is fixed. For this purpose, wooden blocks are used. In the corners there are brackets that perform a fastening function.At the final stage, you will need to close up the cracks in the structure. This completes the installation of the formwork for the base of the fence.

Self-installation of formwork for the foundation of a residential or commercial building requires serious preparation. In addition to drawing up a plan, you should calculate the amount of materials required. Before assembling this structure, it is recommended to study all possible video materials on this topic.