The basement is one of the most important parts of the building. This is a kind of support that is constantly exposed to negative environmental influences. Finishing the basement of a private house not only gives it an aesthetic appearance, but also protects it from adverse factors. Therefore, finishing materials must be moisture resistant, frost resistant, reliable and durable.

The plinth, made of durable materials, reliably protects the house from external influences and pollution

Content [Hide]

- 1 Why do I need to finish the basement of a private house

- 2 Varieties of basement structures

- 3 The procedure for finishing the basement of the house

- 4 Arrangement of outflows for the basement base

- 5 Basement base waterproofing

- 6 How to insulate the basement outside the house with your own hands

- 7 Facing the basement of the house: which material is better to choose

Why do I need to finish the basement of a private house

Most of the building's foundations are below ground level and hidden from view. The part protruding above ground level is called the base. According to the norms, the height of the basement from the ground should be at least 20 cm. It is usually made of brick, stone or concrete slabs.

The material for covering the basement should be chosen based on the type of base and the general design of the building decoration

The construction of a stone plinth is the most practical solution, since the structure does not need additional finishing. However, it should be noted that this is the most expensive way. Brick plinth masonry is more affordable. This material is environmentally friendly, has a low thermal conductivity and good strength characteristics.

The cladding of the basement of the house is not only aesthetic. This is a reliable protection of the building from external influences. The finishing materials that will be used for the plinth cladding must have a high level of strength. Together with the plinth, its cladding will perceive the load that the wall structures of the building create and distribute it evenly over the foundation of the building. It must withstand pressure and protect the base from external factors such as precipitation, sunlight, humidity, temperature fluctuations.

The finishing material protects the foundation of the building from damage by mold, fungus and various types of insects. The plinth cladding is carried out in order to insulate the building. It is also necessary to protect the foundation from severe frosts, under the influence of which its strength decreases and the erosion process develops.

Leaving the surface of a plinth without plating will contribute to its slow destruction as a result of constant exposure to dry or liquid dirt containing aggressive chemicals and minerals.

Various options for finishing the basement of a private house, the photos clearly confirm this, turn the building into a masterpiece of design art, making its appearance complete and unique.

Varieties of basement structures

There are basic design variations that are used for projects of houses with a plinth:

- protruding beyond the surface of the walls;

- flush with the building;

- sinking, relative to the wall.

An example of a sinking type of plinth that protects the waterproofing from the weather and does not require the installation of drips

Most often, when building a private house, the photo of the basement of the house clearly confirms this, they use the first two options. A protruding basement is recommended when the house is being built with thin outer walls, a warm underground is used, or a basement is provided in the building. In these cases, this type of base will provide the building with additional thermal insulation.

If the basement part is flush with the building, when thin walls are used for its construction, dampness and condensation in the interior are inevitable. Here, the most problematic is to install thermal insulation and finish.

Important! When choosing these types of base, you should take care of the arrangement of ebb tides in advance.

The western base is less damaged by the influence of atmospheric precipitation. Here you can easily hide waterproofing, equip insulation and perform cladding with the necessary materials, which contributes to a longer service life. This type of plinth is recommended for buildings without a basement. The finishing materials for the plinth will take up the ground pressure, performing a supporting function, thereby maintaining the safety of the entire structure.

The most popular way to finish a plinth is to lay material that protrudes beyond the surface of the walls.

The procedure for finishing the basement of the house

All work on the cladding of the basement structure is carried out at the final stage of production - the exterior decoration of the building. Work is best done in warm, dry weather. The plinth plating consists of the following steps, which are performed in a specific sequence:

- A trench is being dug 20 cm deep and 50 cm wide around the entire perimeter of the building.

- Filling the space with gravel to ensure drainage. Additionally, the trench can be strengthened using a reinforcing mesh.

- The surface of the wall, 50-70 cm high for the future basement, is cleaned of dirt and processed water repellents... If necessary, all irregularities are eliminated.

- Arrangement of thermal insulation.

- Decorative plinth trim.

The choice of cladding material and the way it is laid depends on the design of the base and the method of its casting.

Before the decorative facing of the basement, you should take care of the high-quality treatment of the walls with hydrophobic and antifungal agents

Arrangement of outflows for the basement base

To protect the basement from the negative effects of precipitation, an ebb tide should be installed, which is fixed above the protruding part of the basement, and is a kind of delimiter between the base of the building and the wall structure. One part touches the wall at a certain angle, and the other hangs over the foundation, blocking it, collecting rain and melt water.

The ebb for the base is strips of 50-400 mm in size. The color, size and shape of the ebb should be selected depending on the finishing material of the foundation. The water-repellent structure can be made on your own using waterproof materials, or you can buy ready-made ebbs for the basement base at any hardware store.

Today the industry produces several types of ebb:

- plastic;

- metal;

- concrete;

- clinker.

The type of ebb is selected based on the finishing material for the facade of the building. The best combination of plastic sills is with vinyl siding, which is used for cladding a building. Thanks to a wide range of colors, you can choose the most appropriate option. The use of concrete or clinker plinths is preferable for buildings that are faced with natural stone or brick. Metal visors can be used with any kind of finishing material.

Varieties of ebb

The most budgetary option is to use plastic moldings made of polyvinyl chloride. The cost of the product is 50 rubles. for 1 r.m. Despite the high level of water resistance, ebb tides are highly sensitive to physical impact, especially in winter, when they can crack and split from the slightest impact.

Useful advice! In view of the fact that plastic ebbs have increased fragility, more durable and more expensive products should be preferred.

The strongest and most durable are ebbs made of metal: steel, copper or aluminum. Installation of products is convenient and simple, and is determined by fixing metal strips to the walls of the building using self-tapping screws and dowels. When choosing this material from a wide range of types, special attention should be paid to the aesthetic appearance of the product so that it completes the overall design of the building. The price of the product starts from 100 rubles / r.m.

Useful advice! When installing basement sills, the strips should be overlapped one after the other by at least 30 mm. To avoid damage to the protective layer of the product, which will lead to the formation of corrosion and destruction of the material, do not cut the strips.

Metal outflows are made of high-quality and frost-resistant cement of the M450 brand with the addition of river sand, granite crushed stone and plasticizers. The solution is poured into silicone molds of various geometric parameters. The result is an even and smooth product. These ebbs are attached to a special solution.

Ebb tides for the basement base, the price of which is the highest and starts at 200 rubles. per 1 running meter - these are products made of clinker tiles. This material has high strength characteristics, reliably protects the building from negative environmental influences and successfully emphasizes the design of the cladding.

For clinker coating, it is better to use ebbs of the same material, which can be purchased from one manufacturer.

Ebb installation technology

After choosing the ebb, you can start installing it. Here, one should take into account not only the material from which the ebbs are made, but also the structural features of the building. So, for a wooden house, elements that will be fastened with self-tapping screws or other fasteners are suitable. Since wood has low adhesion and is afraid of moisture, the use of adhesives is impractical.

For buildings made of brick or facing stone, you can use ebbs, which will be fixed with polymer or cement-glue mortars.

Useful advice! When using concrete or ceramic castings, their installation should be carried out simultaneously with the plinth and wall cladding.

If it is necessary to install drips on a building already finished with facing material, then it is better to use metal or vinyl elements.

Due to its high performance and low cost, plastic drips are one of the most popular ways to protect the base

Before installing the ebb, it is necessary to seal the joints of the walls with the plinth. All cracks and crevices should be treated with a water-repellent mixture, or sealed with a sealant. Next, you need to use a level to mark the wall. The highest point of the base is determined and a horizontal line is drawn along which the upper part of the low tide will be mounted. The part of the foundation that protrudes must be compared with a horizontal plane using a cement screed. The lower part of the ebb will rest on it.

Important! The ebb plane relative to the wall should have a slope of 10-15%.

Installation of metal and plastic sills

The installation of ebbs should be started from the corner using special corner pieces that can be purchased together with strips of the same width and color. Next, you need to finish all the protruding parts of the building structure: columns, pilasters, and others.

Related article:

Ebb for the base of the foundation: features of selection and installation

What materials are used for ebb tides. Which one is better to choose and in which case. Installation of ebb tides.

In the upper part of the low tide, holes are drilled with a drill at a distance of 40-50 cm from each other. Further, the element is applied to the previously marked line on the wall of the house and is attached to it with dowels with self-tapping screws. The lower part of the ebb with the help of dowels-nails is attached to the concrete base of the base with a pitch of 40-50 cm. The joint of the ebb with the wall should be sealed with putty or silicone compound.

Important! During the installation of the ebb, it should be borne in mind that it should protrude 2-3 cm beyond the edge of the base, which will provide better protection basement floor during precipitation.

After sheathing all corners and protruding elements, you should proceed with the installation of ebbs on straight sections. You need to start from one of the corners. Each next element should be overlapped with the previous one by at least 3 cm. All joints should be treated with a sealant to avoid moisture ingress.

Installation of concrete and clinker drips

Ebb and flow from clinker and concrete should be installed at the stage of cladding the facade of the building, since adjusting them to size during installation is a laborious process.

These types of ebb tides are better combined with facing materials such as bricks, porcelain stoneware, clinker tiles, natural or fake diamond... To fix them, you should use a special adhesive for ceramics and stone, which is intended for outdoor use. It is purchased in the form of a dry mixture, created on a cement or polymer base, and with the help of water is brought to the state of thick sour cream. The mortar can be made independently using cement and building sand in a ratio of 1: 3 or 1: 4.

The installation of concrete and clinker castings also starts from the corner. To avoid complex handling of concrete slabs, they should be pre-positioned in such a way as to minimize cutting. This can be achieved by using a properly sized seam between the elements. You can adjust the dimensions of clinker products by using a tile cutter or a grinder with a diamond edging wheel.

An adhesive mixture is applied to the back of each element.The low tide should be fixed strictly along the previously outlined line. After waiting some time for the mortar to set, putty or silicone sealant is applied to the joints between the casting elements. After the adhesive has completely set, the walls of the building can be clad.

Basement base waterproofing

The basement of the building is constantly in difficult conditions. It takes a significant load from the overground part of the building and comes into contact with the external environment, being exposed to moisture. To protect an important part of the house from destruction, it is necessary to provide for a number of measures, one of which is the arrangement of waterproofing the basement basement.

Waterproofing can be horizontal or vertical. Usually, a set of works is performed that includes both methods. Horizontal waterproofing is performed before the construction of walls and is aimed at protecting them from moisture. However, in order to provide a full protective complex of measures, it is also necessary to perform waterproofing between the foundation and the plinth.

The vertical waterproof protection aims to prevent the negative impact of surface and ground water on brick or concrete. Such insulation can be external and internal. The best effect is double-sided moisture protection.

Today, pile foundations are mainly used in the construction of buildings. Here, the basement plays not only a decorative role, but also protects the house from heat loss. Despite the fact that this element is not load-bearing and does not have a direct effect on the durability of the structure, the basement waterproofing is mandatory.

Materials for waterproofing the basement outside

As materials that are used for waterproofing the basement basement, coating, roll and injection compositions with a penetrating effect are widely used.

To protect the foundation from the effects of groundwater, roll waterproofing is often used, which can be fused or pasted over. The weld-on insulation consists of a base in the form of fiberglass, polyester or fiberglass and applied mastic. The glued waterproofing is laid on the surface of the foundation using bitumen mastic, which is first applied to the roll material and to the monolith, then the element is glued, pressed and smoothed.

The main advantage of roll material for waterproofing base plate is its low cost and high installation speed. However, this type of waterproofing is poorly resistant to mechanical stress and has a short service life. It cannot be used in places of passage or abutment of communications. Before installation, clean the surface from dust and dirt, and dry thoroughly.

Bituminous, polymer, bitumen-polymer mastics, binding plasters and cement coatings are used as coating waterproofing materials, which are applied to the surface of the foundation with a brush or roller. This type of insulation is used for water pressure up to 2.6 kgf / cm².

Before laying heat and waterproofing, the base material should be treated with special agents to increase adhesion

Useful advice! To ensure increased strength of waterproofing after the first layer of mastic, it is recommended to reinforce the surface with fiberglass, and apply subsequent layers over it.

The material has a low cost and can be applied to any surface configuration. However, it is not durable, requires preparatory work and the creation of additional protection against mechanical stress.

The use of injection and penetrating compounds is the latest technology for waterproofing structures.The penetrating material is applied to a damp concrete base. Reacting with water, the compound turns into crystals, which penetrate the pores of the concrete, making it waterproof. The penetration depth reaches 150-250 mm.

Injection waterproofing is carried out using a liquid solution, which is injected under pressure into cracks, pores and seams of the structure. This method can be used for waterproofing buildings made of rubble and brick. The use of this waterproofing is a very laborious process that requires cleaning the structure to concrete or brick, and the complexity of the work itself requires the involvement of an experienced craftsman. Moreover, such insulation is the most expensive.

Covering the basement with polymeric materials allows you to create a high-quality waterproofing layer, but subject to the availability of effective drainage of the site

Features of waterproofing a brick base

Ceramic bricks are most often used for the construction of a basement. The device of its waterproofing can be carried out by various methods.

Solid red brick can be used to build walls. This building material has already passed the factory processing, where a layer of waterproofing was previously applied to it. Therefore, using this brick for the construction of a building, external waterproofing does not need to be equipped. Despite the fact that the cost of this material is relatively high, these costs are compensated by the fact that after laying the brick, no other work is required.

The next method of waterproofing a brick basement is to use a bitumen grease, which is applied in several layers in a cold or hot form.

Insulation of the basement base outside penoplex you can do it yourself using high-quality adhesive

Important! When using bituminous materials, it is important to strictly observe the temperature regime. When the lubricant overheats, the coating will turn out to be of poor quality with the formation of blisters, cracks and bubbles.

The traditional method of waterproofing is the use of roofing material. For a brick base, it is recommended to cover it with this material in at least 4-5 layers.

One of the new building technologies is the use of a penetrating active two-component waterproofing composition that fills all cracks and pores of the basement, followed by crystallization. This is the most reliable waterproofing of a brick base with a minimum application thickness.

How to insulate the basement outside the house with your own hands

By insulating the basement base from the outside, protection from moisture and cold is performed not only in the internal space, but also in the enclosing structures. However, in order to achieve a good result, the insulation for the basement must be:

- durable and elastic, in order to take on mechanical stress and remain intact;

- moisture resistant;

- lightweight so as not to create additional stress on the base of the building;

- durable;

- resistant to chemical attack.

Important! When choosing an insulation material, it should be borne in mind that its application technology should not violate the integrity of the building structure.

The main features of the arrangement of external insulation for the strip foundation:

- Insulation is laid not only on the above-ground part of the building, but also on the one that is underground with a depth of about 50-80 cm. For this, a trench 80 cm deep and 1 m wide is laid along the perimeter of the house.

- To protect the insulation from the effects of groundwater, drainage pipes are laid at the bottom of the trench.

- A layer of liquid waterproofing is applied to the walls of the basement using polymer compounds or bitumen mastic.

- After complete drying of the waterproofing layer, the thermal insulation material is installed.

All of the above operations, with the exception of digging a trench, are also performed to insulate the basement of the pile-screw foundation.

Materials for insulating the basement base outside

Certain requirements are imposed on the materials used for thermal protection of the base of a building: reliable protection, durability, simple and quick installation, and an acceptable cost.

Based on the stated requirements, one of the most economical and affordable options for thermal insulation is the basement insulation with extruded polystyrene foam. It is a durable, moisture-resistant, frost-resistant and acid-resistant material that has a small thickness and weight, which makes it easy to install. Plates are produced with a thickness of 3-10 cm. If the maximum thickness is not enough, then the thermal insulation is mounted in two layers. However, it is worth noting that the material has a G1-G4 flammability, therefore, after its installation, it is required to cover the base with non-combustible materials.

Useful advice! For outdoor use, choose plates with fire retardant impregnations (G1-G2).

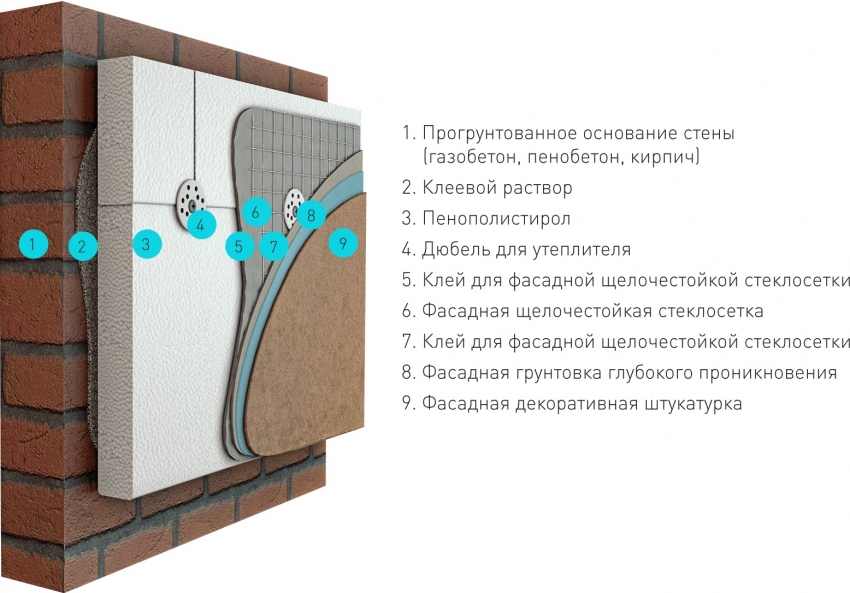

Insulation scheme of the building basement using facade plaster

Rarely, spraying of polyurethane foam is used to insulate the basement. This is due to the fact that in order to perform this option of thermal protection, it is necessary to use special equipment, certain chemical components and attract highly qualified workers. The essence of the method is that foamed polyurethane foam is sprayed onto any surface. Expanding, it penetrates into all voids and reliably adheres to the base, forming a dense coating. This material can be used not only for spraying, but also for filling individual voids and areas.

Do-it-yourself technology for insulating the basement basement outside with penoplex

At the preparatory stage, it is necessary to prepare the surface of the foundation by cleaning it from old insulation, dirt and dust. Next, you should equip a layer of waterproofing to protect the structure from rain, ground and snow water. Any type of waterproofing is suitable for penoplex, with the exception of compounds with organic components.

Work begins with insulation of the underground part of the foundation. For this purpose, PPS boards are attached using a specialized contact adhesive, which is applied around the perimeter of the product and in the center. The second level should be laid with a spacing of the joints between the plates in relation to the lower level. After installation, all gaps are filled with polyurethane foam.

To ensure reliable protection of the base, the joints between the foam should be repaired with a dry grout mixture

A layer of insulation of the basement with penoplex requires additional protection against mechanical damage. To do this, an alkali-resistant reinforcing mesh is fixed on the plates, which is subsequently plastered with a solution with hydrophobic additives. Also, as a protection, you can use wooden tongs, which are attached to the plates with dowel-nails. The wood must first be subjected to antiseptic, anti-fumigation and hydrophobic treatment.

The final stage is finishing the basement with cladding materials.

Facing the basement of the house: which material is better to choose

Do-it-yourself plinth decoration is carried out with various materials that reliably protect and decorate its surface. This process must be performed before wall cladding in order to be able to hide the ebb under the wall decoration material.

Artificial stone for finishing the basement is not inferior to natural, therefore this type of coating does not require periodic repair

The material for the plinth lining must have the following performance characteristics:

- have low thermal conductivity to avoid heat loss from the building;

- provide reliable and strong adhesion to the base;

- have a high strength and wear resistance to mechanical damage;

- have low hygroscopicity and vapor permeability to prevent moisture penetration into the foundation and wall panels.

Today, when the question is raised, how to decorate the basement of a house, the following materials are used that fully meet the above requirements:

- clinker or porcelain tiles;

- natural or artificial stone;

- brick;

- PVC panels or basement siding;

- profiled sheet;

- decorative or mosaic plaster.

Facing with natural stone carries a significant load on the foundation, so it is better to invite a specialist for work

Any finishing material can be used to clad the basement of the strip foundation. But when the question arises of how to close the basement of the house on screw piles, it is worth giving preference to brickwork, siding or profiled sheet.

Before deciding how to finish the basement of the house outside, you need to take into account some of the nuances:

- lining the base with thick material, it is necessary to install an ebb over its protruding part;

- wanting to expand the foundation, it is better to use brickwork;

- when installing siding or corrugated board, you must first install a frame, the space of which can be filled with a heat insulator for additional insulation of the foundation;

- frame-facing technology allows for work at any time of the year.

Using plaster for lining the plinth

When the question is: how to inexpensively decorate the basement of the house, the answer is obvious - to use plaster. However, this option is the least durable, moreover, it has an unaesthetic appearance. Such a cladding is easily damaged by any mechanical stress and does not provide adequate protection of the base from external factors. However, this method is very popular due to its low cost. It is also acceptable in the case of erecting a brick base on a strip foundation.

Plastering itself is not the final stage. To protect the layer from moisture and environmental influences, acrylic, alkyd, silicone paint, water-based or oil composition should be applied to it, which in turn decorates the base. A photo of home decoration clearly demonstrates the various options for using plaster.

Useful advice! It is not recommended to use enamel paints for painting the base. They are impermeable to air and environmentally unsafe.

Decorative plaster is often used, which creates the effect of a fur coat and can be colored when using a dye. The use of mosaic plaster allows you to create a multi-colored mosaic on the surface, which occurs due to the presence of small chips in the original mixture. The presence of resin as a binder gives the composition increased water resistance.

To solve the question of how to make a plinth around the house with your own hands with the effect of natural stone, the use of a special silicone stamp will help, with which impressions are made on the plastered surface.

Decorative textured plaster for facing the basement, you can paint or purchase a composition already with the required shade

Using stone for cladding the basement

In the first place in terms of environmental friendliness and sophistication is the finish of the basement with natural stone. This is the most expensive material, however, it creates the most durable, wear-resistant, resistant to external influences and durable coating that has a presentable appearance.

The stone used is granite, marble, sandstone and limestone, which is produced in the form of tiles.The material is laid on a cement mortar. The stone for the basement of the house can be with a matte, polished or rough surface. Before laying, the back of the porous material is additionally treated with a water-repellent compound to improve the waterproofing properties.

The wild stone for the basement has a significant weight, which increases the load on the foundation. Here it is necessary to additionally create a reinforced connection between the foundation and the drainage pad.

Despite the fact that lining the basement with natural stone does not require strict adherence to the distance between the individual elements, it is a very laborious and time-consuming process that requires additional costs for finishing many mortar joints.

The foundation of the building can be left without cladding only if the reinforced waterproofing is erected

An alternative to expensive natural material is the use of artificial stone for the base. This material is produced in the form of concrete slabs, the surface decorative layer of which imitates natural stone. Thanks to modern technologies, a durable, reliable, frost-resistant and moisture-resistant facing stone for a basement is obtained, which, in comparison with natural stone, has less weight and a more affordable price.

To decorate the base with artificial stone, you should choose a material of more than three matching colors, which will look more like natural stone. To obtain a uniform masonry, large elements should be interspersed with small ones, rough ones with smooth ones.

The complete set of materials for lining the basement with artificial stone necessarily includes drainage gutters that protect the material from peeling off the base after frost. The installation of products is carried out in the same way as the laying of natural stone. However, here you can do without strengthening the surface of the base.

Finishing with artificial or natural stone is possible only in the case of a reinforced base / plinth surface and the presence of gutters

Plinth clinker tiles

Clinker tiles for the basement perform two functions at once: protective, protecting the insulation and the outer wall of the foundation from atmospheric precipitation and mechanical influences, and decorative, giving the building an aesthetic and noble look.

The main advantages of the material are mechanical strength, increased moisture resistance, resistance to aggressive environments, which bring the product closer to natural stone and porcelain stoneware in terms of their performance. However, you can buy tiles for a clinker base at a lower and more affordable price.

This material can be used not only for the basement of the house. The walls and corners of the building are faced with tiles. Thanks to a wide range of shades, you can create a real masterpiece that will noticeably stand out from other buildings.

The installation of tiles for the basement can be carried out using a frame system, where you can provide for the laying of an additional layer of heat-insulating material, or stick it on the surface of the foundation using frost-resistant glue.

The price of a tile for a basement of a house depends on the country of manufacture and the brand. The most popular are Germany, Poland and Spain. The average cost is 1500 rubles / m².

The use of basement siding and corrugated board

Finishing the basement with siding is one of the cheapest options today. Due to its low weight and special fastening method, this material is easy to install. It does not require special care, it is characterized by reliability, resistance to atmospheric and mechanical influences, frost resistance, wear resistance and durability. Siding slabs reliably protect the foundation from moisture penetration.

Manufacturers also produce corner pieces.A wide range of design solutions allows you to finish the basement with panels for stone, wood, brick, mosaic tiles. Installation of panels is carried out using a wooden or metal lathing, on which the facing material is attached using self-tapping screws. This ensures air exchange between the insulation and the siding and prevents condensation from accumulating. The plates are connected to each other using a self-latching locking system.

Siding panels are equipped with the necessary shaped materials, such as corners, starting and finishing strips, which makes their installation easy and convenient.

Modern manufacturers offer a wide selection of corrugated board and siding, which allows you to choose the most suitable option for any building

Only vertical can be sheathed with siding. No material is used for horizontal sections. Therefore, if a plinth protruding above the foundation is faced, it is necessary to mount on the ledge low tide.

In private houses, plinth trim is widely used with a profiled sheet. The material has a high rate of moisture resistance, is resistant to temperature fluctuations, durable, easy to process and easily mounted on a wooden crate. However, corrugated board is not suitable as a finishing material for wooden buildings due to the fact that it is subject to corrosion under the influence of high humidity, which can lead to rotting wood.

Profiled sheets are often used for finishing the base of a pile-screw foundation, where it must be closed for reliable protection against weathering.

Features of using bricks for finishing the basement

Brick is one of the most expensive finishing materials. However, having high strength and performance characteristics, it allows you to create strong, reliable and durable protection. This material is suitable for any kind of foundation. For brickwork, use slotted, hollow, hyper-pressed or ceramic bricks. Work begins with arranging the foundation for masonry.

If the brick is used for the construction of the basement itself, it does not need additional finishing. However, here you should choose high-quality material in order to immediately solve two problems: utilitarian, protecting the walls of the house from external influences, and aesthetic, giving the building a decorative look. In deciding which brick for the basement of the foundation is better, it is necessary to give preference to red fired brick, which is resistant to the effects of an aggressive environment.

In the case of finishing the plinth of the pile screw foundation using brickwork, it is necessary to install the base in the form of a tape of reinforced concrete or a metal profile. Brick laying takes place with dressing. To connect the elements, a cement-sand mortar is used. The thickness of the seams is 10-12 mm.

The cladding of the basement of a private house is important, so you should carefully consider the choice of material for work. It acts not only as a decorative element, but also as a reliable protection of the entire building from the effects of atmospheric and mechanical factors.