The classic version of the form for the foundation and walls in monolithic houses is a temporary structure, which is made of wood and chipboard. Fixed formwork made of expanded polystyrene is an alternative construction method that does not involve waste. This structure increases the strength of the building and improves its energy efficiency by acting as thermal insulation. However, such material has some peculiarities that cannot be ignored.

The main advantage of the fixed formwork made of expanded polystyrene is the speed of installation and its low cost.

Content [Hide]

- 1 Advantages of fixed polystyrene formwork

- 2 Permanent foam formwork: types of structural parts

- 3 Installation of formwork for a strip foundation: installation features

- 4 Formwork for a monolithic foundation: stages of self-installation

- 5 Permanent wall formwork: casting technology

- 6 Racks for the organization of non-removable floor forms

- 7 Fixed formwork: prices on the modern market

Advantages of fixed polystyrene formwork

The manufacturers of this material point to many of its advantages over standard construction formwork options. These advantages must be known to every person who decided to use a non-removable type of construction from expanded polystyrene.

The price of a formwork made of expanded polystyrene, as a rule, is a determining factor when choosing it

The advantage of a permanent formwork made of this material is primarily that such a structure has auxiliary functions. The main one is the organization of the form for the walls and foundation of a monolithic building. Due to its physical properties, expanded polystyrene is a good insulation. This is a very important property, since this type of formwork is not dismantled after the concrete has set.

If boards are used for formwork, they must be dismantled. Wood is not a heat insulator, so polystyrene foam blocks are considered a more profitable investment. Permanent formwork from this material allows you to build a lightweight concrete structure. Moreover, such a building retains 30-35% more heat than a building with an analogue of red brick. Thus, the use of expanded polystyrene allows you to reduce the cost of other materials from which the foundation or walls are made.

An alternative to polystyrene foam forms is plastic formwork.The price for such a structure is slightly higher, but it is more reliable in strength. Fixed plastic elements can be purchased at a hardware store or ordered online.

Another advantage of such forms is that they provide protection of reinforced concrete from moisture. This is especially important in winter. As a result, thanks to the expanded polystyrene blocks, the operational life of the foundation and walls is increased by approximately 20%. Quite often, it is this fact that pushes people to use such formwork for building a house. Various (in shape and size) elements are made of expanded polystyrene.

Note! Construction of a building using polystyrene molds reduces financial costs by about a third.

The price of slab formwork made of expanded polystyrene is usually the determining factor when choosing it. However, the most useful property of such forms is that their use allows you to preserve the structure of concrete at low temperatures (but not lower than +5 ° C). In this case, concrete hardens in a normal mode, which has a positive effect on its qualities after hardening.

In turn, pouring concrete into a wooden mold gives a completely different result. In such formwork (at low temperatures), concrete hardens faster and its structure is broken.

Permanent formwork made of expanded polystyrene: design flaws

Such designs also have their drawbacks. Some of them are quite significant. For example, one of the most serious drawbacks is the fact that a building made with such a formwork cannot be rebuilt. Therefore, it is recommended to think over its design in advance. In addition, all communications located in the structure must be laid during the construction phase.

A house made of permanent formwork is carried out taking into account some rules, which are very important to follow in order to get a reliable building that is resistant to adverse environmental factors. Blocks made of expanded polystyrene require careful installation. It is very important to maintain tightness, as otherwise moisture will penetrate into the voids.

Another disadvantage of this technology for the construction of residential buildings is that polystyrene forms cannot be used at temperatures below 5 ° C. In such a situation, the concrete simply will not harden. In hot weather, concrete requires additional moisture, as otherwise it will harden incorrectly.

An important drawback of foam blocks is their fragility, so you need to work with them very carefully

It is also worth noting that fixed formwork blocks made of expanded polystyrene prevent normal ventilation of the concrete structure. The solution to the problem in this case is to install a ventilation communication. This forced system will provide the necessary ventilation, while maintaining the high efficiency of the fixed structure.

Types of permanent formwork depending on the material of manufacture

Before starting the installation, it is necessary to study the various options for fixed formwork that can be purchased today on the construction market. The main feature by which these products are classified is the material of manufacture. The choice of raw materials depends on the complexity of the future construction and its individual characteristics. Let's consider from what raw materials molds for concrete are most often made.

Expanded polystyrene. Many people are interested in the question of what is expanded polystyrene. This material is the standard raw material used in the production of permanent formwork.The second name of expanded polystyrene is gas-filled foam. It is characterized by a number of positive qualities that determine the popularity of the use of forms made from it.

Helpful information! Expanded polystyrene has rather high strength characteristics and provides reliable thermal insulation of concrete.

Formwork blocks made of polystyrene foam are very light, so construction can be carried out without the use of heavy equipment

Arbolit. This material includes 2 main components: wood chips and concrete. Individual elements of fixed timbering made of wood concrete are represented by blocks. They have empty gaps, which are reinforced during installation and filled with mortar. The advantage of this raw material is that it has high strength. The soundproofing qualities of wood concrete are also its strong point. The disadvantages of this material used for the manufacture of formwork include low thermal insulation and high cost.

Fibrolite. This raw material, like the previous one, consists of 2 components. The first of these is wood chips, which provide the fibrous structure of the individual elements of such formwork. The second component is an inorganic binder. The main advantage of such formwork is resistance to temperature fluctuations.

Chip cement. Such material is considered less popular than the above options for fixed formwork. The technology for installing wood chips has its own nuances. Of the advantages of this material, it is worth highlighting very good sound insulation and resistance to temperature fluctuations.

Economical option: fixed foam formwork

Today there is a possibility of installation of permanent formwork from foam boards. This option is quite common, as it can significantly save finances when building a house. Penoplex is a material used for insulation and has good strength characteristics. This allows it to be used as concrete molds.

Penoplex slabs have dimensions of 60x100 cm. The dimensions of these products prevail over the parameters of standard structures made of expanded polystyrene. In order to install the formwork around the penoplex house, it is necessary to perform the correct calculation of the material. It is also important to understand that such products do not have their own locking elements. Thus, before purchasing material, it is necessary to think over the system of fastening individual parts to each other.

The use of penoplex allows you to reduce financial costs to a minimum. This is especially true when compared to the costs required to build a standard structure. Slab formwork on telescopic struts, wall panels and plywood will cost significantly more.

To install the formwork around the foam house, it is necessary to perform the correct calculation of the material

Helpful information! A common option for organizing fixing parts is the use of special jumpers, which are equipped with threads along the edges. Such elements are made from reinforcement. The main thing to remember is that the installation of such jumpers is carried out between the foam plates.

Such an embodiment of the structure is less expensive, but at the same time more complicated due to the selection of the retainers. The price of fixed polystyrene foam formwork is higher, but its installation does not require unnecessary actions. If necessary, you can purchase clamps for foam boards, which are used when installing a polystyrene foam structure.

Permanent foam formwork: types of structural parts

Elements of the formwork can have a different design, which is determined by their operational purpose.Today, there are such options for these products, made of expanded polystyrene:

- panels;

There are several options for products made from expanded polystyrene: panels, blocks and frame systems

- blocks (cast and prefabricated);

- frame systems.

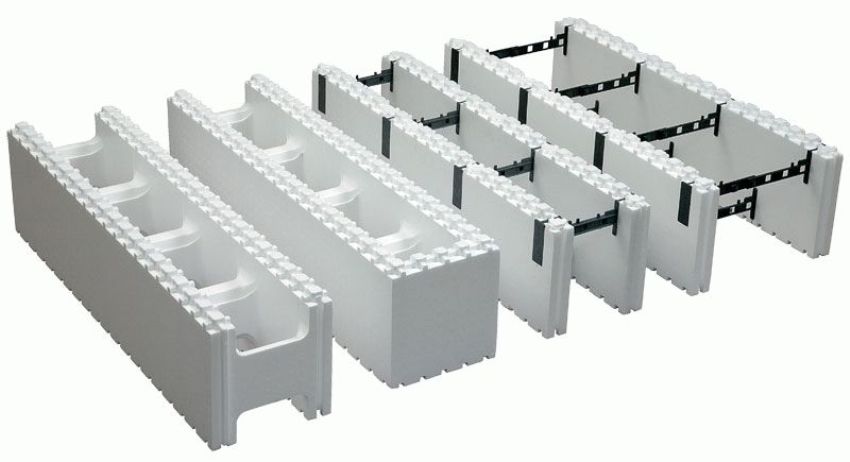

Frame systems are double-circuit structures with empty space between the walls. When installing inside such a formwork, reinforcement is laid and mortar is poured. If you make a cut of the finished wall made using this technology, then it will be possible to distinguish three layers: two outer ones, represented by formwork, and the middle one, made of reinforced concrete.

Foam blocks are divided into two large groups: cast and prefabricated. During the assembly of the formwork, these elements are aligned in such a way that they are located on top of each other. Moreover, no adhesion mixtures (for example, glue) are used for joining. The blocks are laid out in a checkerboard pattern.

Cast products are also called thermoblock. This is due to the fact that they have a rather high density (up to 40 kg / m³). Features of the structure affect the thermal insulation characteristics. A block of this type consists of 2 sheets, which are joined together by means of special jumpers. The assembly of such parts and the connection of their individual elements are carried out at the manufacturing stage. It is worth noting that such designs have one drawback: they warm up rather poorly. This is due to the location of the insulation on the inside of the wall cake.

The sizes of the blocks of the cast foam formwork can be different. However, the standard option is considered to be products with dimensions of 1000x250x250 mm. The mass of such a block is usually about 1 kg. The thickness of the insulation located on both sides (outside) is 50 mm. Accordingly, the same indicator of the concrete layer will be 150 mm.

Related article:

Calculation of reinforcement for the foundation: how to make it right

How is done for tape and plate types. A detailed example of calculating the need for reinforcing bars for a foundation.

Insulation in the forms that are used for pouring concrete can be different. The future design characteristics depend on the choice of insulator material. It is important to remember that such a layer traditionally performs two main functions. The first of them is form-building, and the second is heat-insulating. Depending on the type of blocks, the cost of expanded polystyrene also varies. How much do different types of forms cost? Pricing takes into account the design, as well as the thickness of the insulation layer.

Note! Concreting in more than 3 rows is not recommended. The ideal option would be to lay concrete in 2.5 rows, since in this case the seam will be located in the middle of the block.

Prefabricated Styrofoam Blocks for Formwork

Formwork can be represented by prefabricated elements, which differ from cast elements in their structure and have some features of application. These blocks consist of two sheets, which are assembled into a single structure before starting installation work. It is important to note that such elements can be made not only from expanded polystyrene, but also from other materials. The distance between 1 and 2 sheets remains unchanged due to special accessories, which are called spacers.

Building a house from this type of fixed formwork has several features that need to be focused on. The main difference between prefabricated forms is that their use allows the use of more than 3 layers in the walls.Moreover, the combination of materials in this case does not play a role, while buildings made with cast blocks require strict adherence to the sequence of materials. Insulation in such a situation will always be located outside.

A common solution is the wall cake, which includes two cladding layers of rigid sheet material. Insulating material (expanded polystyrene) is laid close to the outer sheet of this type. The second layer in this situation is reinforced concrete.

The project of a house from a permanent formwork is made in advance. It contains all the necessary data indicating the design features, dimensions and individual solutions in accordance with the situation.

It should be noted that such forms have one significant advantage over their cast counterparts. It consists in the fact that, if necessary, you can change the width of the internal cavity, into which the reinforcement is laid and the solution is poured. This indicator is changed by using spacers. If the need arises, longer locking elements can be purchased.

All costs are required to be indicated in the formwork estimate. The device, prices, dimensions of individual elements - all this is recommended to be noted in the preliminary wiring diagram.

The design features of prefabricated forms affect the degree of wall heating. The absence of foam allows you to increase this indicator. If necessary, collapsible structures used for the construction of buildings can be done by hand.

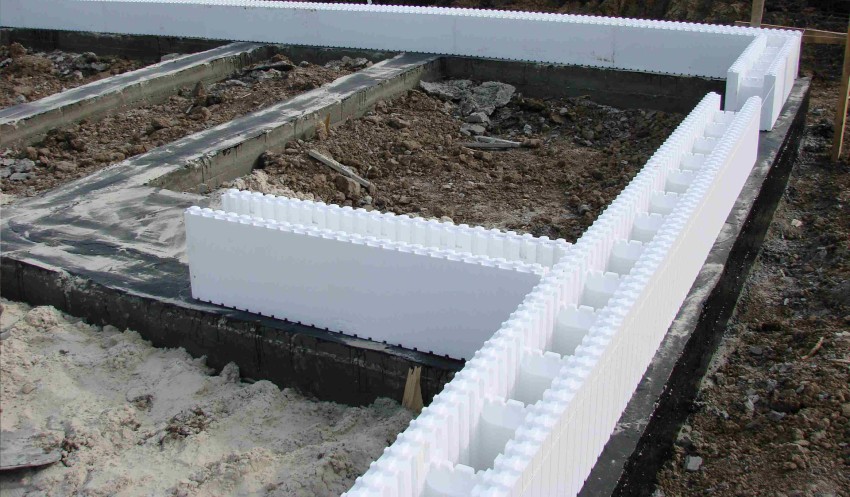

Installation of formwork for strip foundations: installation features

The most popular type of foundation used in the independent construction of houses and other structures is strip. Before starting the organization of such a foundation, it is necessary to carry out the appropriate preparatory work. These include project development and site preparation. In addition, you need to mark the place allocated for the construction of the base.

The device of the formwork for the strip foundation is not particularly complicated, but there are some nuances that you need to know and observe. For example, it is recommended to fill in layers. The process itself proceeds as follows: the cavity in the block is filled with a concrete solution, after which it remains only to wait for it to solidify.

Helpful information! The organization of the reinforcement is optional. It fits in the event that there is a need to increase the strength characteristics of the structure.

When using non-removable blocks of expanded polystyrene, the cost of organizing the foundation is reduced by a third

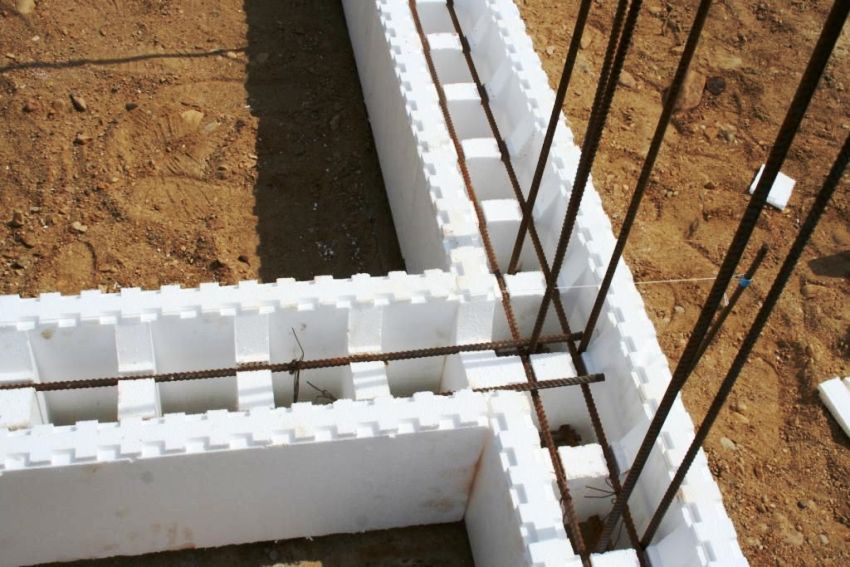

Reinforcement strapping is performed inside block elements. It is not necessary to dismantle polystyrene foam, as it will act as a heat insulator. It is important to remember that before starting to pour the grout, you will need to check the accuracy of the location of the blocks in the ditch.

If necessary, the fixed formwork for the expanded polystyrene foundation is reinforced with additional elements. It is very important to achieve the correct base geometry. This technology has many advantages. When using non-removable blocks made of expanded polystyrene, the cost of organizing the foundation is reduced by at least a third.

Formwork for a monolithic foundation: self-installation steps

After organizing the foundation of the future structure, you can proceed with the installation of the formwork. This operation is conditionally subdivided into three stages: installation of blocks, binding of reinforcement and pouring of mortar. Each stage is carried out in accordance with building codes and regulations.During work, safety precautions must be observed. Let's consider each stage in more detail.

Installation of blocks. First, the first row of the mold is mounted, which will be used for pouring concrete. It should be noted that the installation is carried out only on the waterproofed surface of the base. The formwork for the expanded polystyrene foundation should be tightly fixed by the reinforcement rods. These elements are the link between the base and the formwork itself.

Experts advise to check the accuracy of the work performed, as there may be a deviation from the original design dimensions. The presence of taps for partitions is also a very important point that you need to pay attention to. After organizing the first row, you can start laying the second. The block assembly technology assumes a chess system, in which each subsequent row is shifted relative to the previous one. As a result, the joint of the elements of the first row should fall into the middle of the block of the second strip.

Armature knitting. Installing a metal structure is one of the most important steps in organizing any type of building pie. The reinforcement is used to strengthen foundations, walls, and monolithic floors. The formwork for the foundation, consisting of blocks that fit in rows, must be girded around the perimeter with rods located in a horizontal plane.

In order to simplify the installation of fittings, each block has special grooves, which are located in the jumpers (internal). Horizontal bars are mounted in such a way that each subsequent element overlaps the previous one (overlapping). Further, the rods are connected to each other, as well as to the vertical elements using a special wire.

Before starting the casting of the formwork, you need to take care of laying communications inside the forming structure

Note! Reinforcement allows not only to increase the strength of the structure, but also to reduce the cement pressure on the mold.

Pouring solution. Before you start pouring permanent formwork with your own hands, it is recommended to take care of laying communications inside the forming structure. The cement mortar used for forming the formwork must not contain foreign additives and impurities (for example, crushed stone). The operation itself is quite simple. Pouring is carried out step by step, and the height of the concrete layer should not exceed 1 m. This figure corresponds to the size of 3-4 fixed blocks of the structure.

The price of permanent formwork for the foundation is lower than the cost of standard counterparts, which involve the use of plywood and boards. It is important to remember that the poured solution requires leveling. For these purposes, a special tool is used - a vibrator. In the absence of the necessary electrical equipment, you can use a conventional bayonet shovel.

Permanent wall formwork: casting technology

Independent use of such a wall casting technique requires an understanding of the technological process. Most often, this type of construction is used by non-professionals in the case of the construction of private one-story houses, as well as garage structures. The construction of the formwork made of expanded polystyrene can be carried out alone. However, a few people will complete the wall installation much faster.

The advantage of using polystyrene foam molds is that they are lightweight. Thus, physical activity in this case is reduced to a minimum. Before starting construction, it is necessary to study a step-by-step algorithm of actions and nuances that allow you to answer the question of how to make the formwork correctly.

Walls made using this method are recommended to be installed on a strip foundation. This base is best suited for construction using non-removable foam molds. It is important to remember that the use of cement mortar for filling walls often imposes a certain limitation on the number of rows of blocks. Experts advise to have 4 rows of forms, and they must be reliably connected to the base of the building by means of reinforcement.

When installing non-removable polystyrene foam blocks, special attention must be paid to their joining

Helpful information! It is not recommended to pour all the concrete at once. Partial pouring should be done first and wait a while for the mortar to settle. As a rule, this procedure takes no more than 3-4 hours. Next, the cement slurry is added.

When erecting monolithic structures for casting walls, special forms are often used - shields. They are connected by means of special tie bolts and form a gap into which the concrete is poured. Such products can have different dimensions. For example, their maximum height is 3.3 m, and the width indicator ranges from 0.25 to 2.4 m. After the mortar has solidified, this structure is dismantled. The size of the formwork panel is selected depending on the individual characteristics of the structure being erected.

It is worth noting that another feature of the fixed formwork used to fill the walls is its instability. This is due to the fact that concrete poured into molds has a large mass. Thus, even blocks, laid in 4 rows and equipped with fittings, need to wait for 24 hours. This time is quite enough for the solution to settle and thicken.

When installing non-removable blocks made of expanded polystyrene, special attention should be paid to their joining. Individual structural elements must be connected with particular care so that the surface of the first rows is as flat as possible. Otherwise, when adding the next rows, the walls may collapse due to their skew.

The alternative to expanded polystyrene is plastic. Plastic formwork for monolithic construction is used when it is required to ensure good strength and rigidity of the structure. The advantage of such products is that they are highly durable.

Finishing the walls after pouring them: recommendations

Facing works allow not only to give the wall, cast in a formwork, a complete look, but also to enhance its protective characteristics. Finishing is carried out on almost all types of structures. Once the wall has been poured, there is usually no need to level it. This is due to the design of the forms. Thus, there is no need to apply a thick layer of plaster.

It is not worth saving on finishing walls and other surfaces, since the total cost of work is already reduced due to the use of expanded polystyrene. The price of this material is much lower than the cost of traditional formwork options.

Most often, a special mesh is sufficient for wall decoration, which can be made of fiberglass or metal. Such a mesh is joined to the concrete surface with the help of an adhesive, after which it is sealed with plaster or putty.

In this way, not only standard rectangular walls are processed, but also round columns. The formwork for such structures is most often made of plastic. There are also cardboard forms.

Note! In addition to standard methods for finishing the outer surface of concrete, there are other equally popular options. For example, tiles and artificial stone are often used as cladding.

For interior wall decoration, as a rule, plasterboard material is used. Installation of plasterboard is carried out in two ways - using profile elements or glue. This cladding method is very popular not only because of its simplicity and efficiency, but also because this material provides good sound insulation.

Racks for the organization of non-removable floor forms

The traditional option for organizing floors in monolithic or any other buildings involves the use of special telescopic (sliding) racks. These products are used to fix temporary decking, which is made of moisture-proof plywood for formwork. This method is not convenient, as it requires a lot of time and quite a lot of physical exertion.

The rack, which plays a supporting role, consists of several structural elements. The lower part of the telescopic product is equipped with a tripod, which ensures the stability of the pipe. In turn, in the upper part there is a special attachment, which is necessary to grip and hold the construction beam - the crossbar. All slab formwork props are divided into two categories depending on the location of the threads. Some of them are equipped with open threads, while others are closed.

The pipe, which has a smaller cross-section, is distinguished by the presence of special holes along its entire length. The hole pitch can be different - from 11 to 17.5 cm. The outer pipe is equipped with a support nut. As a result, when it becomes necessary to fix the rack at a certain level, a special earring is threaded through the holes in the pipes. This element has a support (nut), therefore it is held in the desired position.

The organization of floors in monolithic and not only buildings, provides for the use of special telescopic sliding racks

Telescopic formwork props can vary in length. This figure ranges from 1.7 to 4.5 m. They can withstand quite heavy loads (up to 4 tons). It is worth noting that such support products are made of metal, therefore they are covered with special anti-corrosion compounds, since the steel can rust.

Fixed slab formwork: features and characteristics

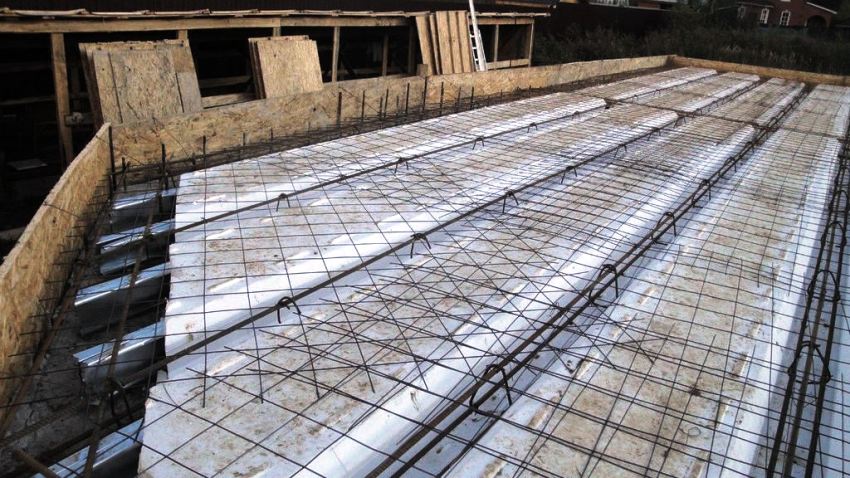

In contrast to the standard method, which assumes the presence of support posts, expanded polystyrene slab formwork has a completely different installation technology. As a basis for such a system, special matrices are used, which are made from dense and durable polystyrene foam.

Such matrices should be laid on load-bearing walls. The advantage of this method is that these elements are lightweight, so no serious physical effort is required to install them.

Note! Before starting work, it is necessary to calculate the floor formwork.

As a basis for formwork, special matrices are often used, which are made from dense and durable polystyrene foam.

Docking matrices with each other is quite simple. Each product is equipped with a tongue and groove system for connection. Thus, any person with no experience in this area can perform such an installation. Thanks to the tongue-and-groove system, it becomes possible to quickly organize a continuous flooring.

Such formwork for a monolithic slab is capable of withstanding a layer of concrete up to 15 cm thick. As a rule, this value is quite enough to organize a reliable structure.Before proceeding with the pouring of concrete, it is necessary to place the reinforcement between the joint zones of the floor elements. The metal frame should be assembled into a continuous beam that occupies the entire width of the gap.

Then, on top of the matrices, it is required to place a reinforcing mesh. It is made of rods with a diameter of 10 to 15 mm. The reinforcement is knitted in the traditional way - by means of a special wire.

The final stage of creating a volumetric slab formwork involves pouring concrete, after which it is required to wait for it to harden. Thus, the organization of the floors is carried out using polystyrene foam matrices. The result of this process is a robust construction that can withstand significant loads.

Any design errors or displacement of blocks during their laying can lead to the collapse of the structure

After the cement mortar hardens, the formwork made of expanded polystyrene is not dismantled. It remains in the pie of overlap and from that moment begins to perform a thermal insulation function. This method of organizing the structure is more technologically advanced when compared with the traditional method, which takes into account the use of removable beams for slab formwork.

It is important to remember that the independent application of such a technology requires an understanding of its nuances. The main thing is that even before starting work, you need to know that laying floor elements requires accuracy. Any design errors or displacement of blocks during their laying can lead to the collapse of the structure.

Fixed formwork: prices in today's market

Block cost is an important point to pay attention to. The price of the building blocks used for permanent formwork is influenced by two key factors:

- density of expanded polystyrene;

- dimensions of parts.

Fixed forms are a good cost-effective alternative to standard structures that are assembled from wood and plywood

The price of a permanent formwork for a foam polystyrene foundation must be taken into account in the construction estimate. When choosing individual elements of the forming structure, it is recommended to pay attention to their density. This indicator affects the resistance of the structure to pressure. The higher the density of the parts, the correspondingly higher loads they can withstand.

Note! Experts advise to purchase blocks with density ranging from 25 to 35 kg / m³.

The average cost of a block made of expanded polystyrene is approximately 160 rubles. It should be noted that such a price corresponds to products with dimensions of 1500x250x250 mm, having a density of 30 kg / m³. Structures with a length of 1.5 m have the function of adjustment due to the installation of jumpers of different sizes (15-25 cm). Products with a length of 1 m are cheaper - from 130 rubles. for 1 pc.

If you plan to use standard construction technology, then it is recommended to study the cost of various materials. The price of telescopic racks depends on the features of their design and the manufacturer's company. Currently, these support elements can be purchased for 500-5000 rubles. It is not recommended to buy the cheapest materials and tools, as they often have low technical characteristics.

The price of the blocks from which the permanent formwork is made is influenced by two factors: the density of expanded polystyrene and the dimensions of the parts

The supporting elements are used to support the timber structure, which is made of film faced plywood for formwork. The price of 1 sheet of such material varies from 600 to 3000 rubles.

Fixed forms are a good alternative to standard structures that are assembled from wood and plywood.Such formwork allows not only pouring concrete, but also serves as a reliable thermal insulation material. It is actively used in private construction, however, it requires studying the installation instructions and observing safety rules.