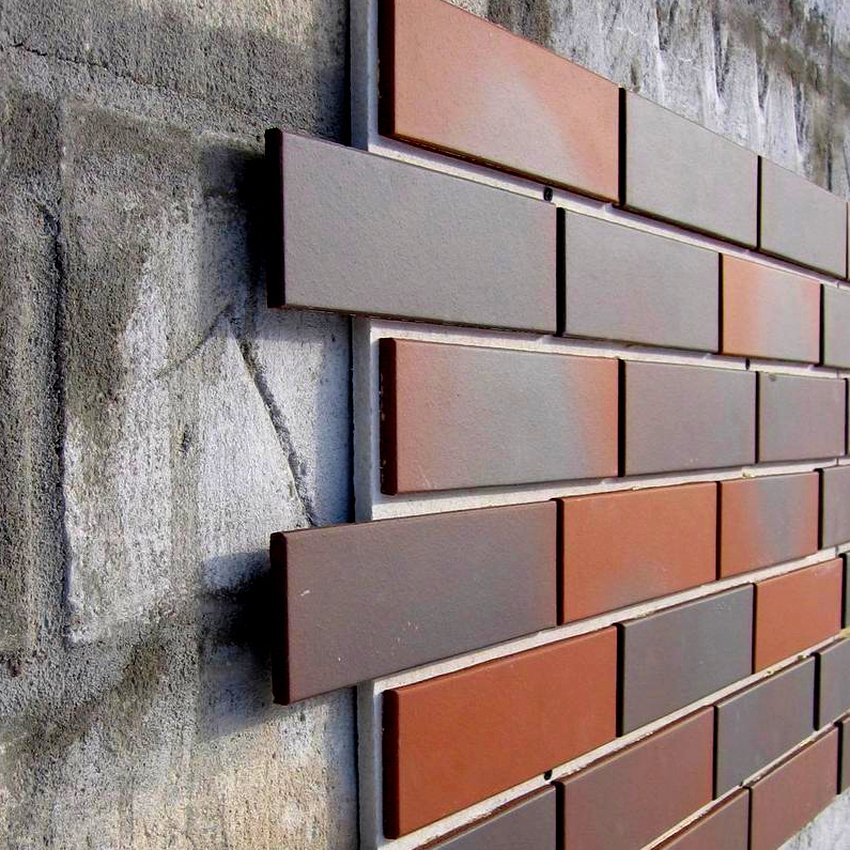

Increasingly, brick facade panels are used in the construction and repair of houses, which are considered an excellent option for exterior wall decoration. The material is a solid board or sheet of a certain size. The installation is secured thanks to the tongue-and-groove connection system. In addition to the fact that the panels imitating brick look attractive, they serve as additional protection for load-bearing walls and insulation.

Brick imitating panels not only look attractive, but also serve as additional protection for load-bearing walls

Content [Hide]

- 1 The main advantages of using brick facade panels for exterior decoration

- 2 Types of brick panels: fiber cement, polymer sand slabs

- 3 What makes Döcke and Wandestein facade panels stand out

- 4 Popular manufacturers of facade panels: Fineber, Alta-Profil and others

- 5 Characteristics of TechnoNIKOL brick-like soft facade panels

- 6 Facade panels for brick: basic installation rules

The main advantages of using brick facade panels for exterior decoration

Brick decoration always looks expensive and attractive, but, in addition to the fact that the material itself is considered quite expensive, its installation will also result in a decent amount. Additionally, you will have to spend money on transportation and storage, if necessary. Another disadvantage of using natural bricks is the lengthy installation process that requires the involvement of qualified bricklayers. Even despite the high cost, cracks may appear on the finished masonry over time, and the brick itself may lose its original color.

Brick facade panels have a lot of advantages, one of which is the ability to use sheets on any surface

Helpful information! In contrast to facing bricks, facade panels are characterized by lower weight. Therefore, the material can be used regardless of the bearing capacity of the foundation.

Brick imitation panels have a lot of advantages, among which the main one is the ability to use sheets on any surface. It is equally appropriate to attach the material to the walls of wooden, stone or brick houses. At the same time, the installation of sheets can be carried out almost at any time of the year. Due to the peculiarities of manufacturing, the panels not only play the role of finishing, but are also considered an excellent insulation. Many builders pay attention to such an important fact as a small amount of waste during installation.As a rule, this figure does not exceed 5%, which significantly reduces purchase costs.

On trading floors, you can find a large number of different options for decorative brick panels: sheets can imitate new brickwork, old or burnt bricks. You can also show imagination and when performing masonry seams, choose surfaces of different appearance, which are smooth or embossed.

What else distinguishes brick facade panels: photos of houses with beautiful finishes

Even despite the fact that facade panels for the house began to be used relatively recently, they quickly gained popularity among consumers, because they are distinguished by high quality and a large number of advantages:

- Convenience and ease of installation. The process of laying the panels does not require a lot of experience or any special skills that are absolutely necessary when carrying out brickwork. If you have a little experience, cladding a house with brick panels is easy to do without the involvement of professionals.

- High speed of work. The finished panel is characterized by a rather large surface, which allows revealing the facade as soon as possible.

- Good performance parameters. Manufacturing features allow the material to be used at high humidity and in conditions of large temperature differences. It is possible to finish with facade panels with constant exposure to sunlight.

- Long term of use. In terms of durability, the material is not inferior to natural brickwork.

- Lack of the likelihood of salt stains. Natural building material is characterized by its ability to absorb the surrounding moisture, which contains a certain amount of salts. After a while, salt deposits appear on the surface of the bricks, which spoils the appearance, and in the case of using front panels, such a problem will not arise.

- Light weight of the material. Facing brick is characterized by a significant mass that affects the foundation, therefore it is not recommended to use it when repairing an old house. Facade panels for facing bricks are lighter, which also reduces the load on the supporting structure.

- Large selection of products. You can create a beautiful facade by combining panels of different colors and textures.

- High strength indicators. Panels, in contrast to the same siding, are designed to withstand heavy loads, as well as resist mechanical damage.

Facade panels for facing bricks are lightweight, thereby reducing the load on the supporting structure

Helpful information! On trading floors, you can find a wide variety of cladding panels, which differ not only in the material of manufacture, but also in the installation technology, performance, and cost. It is also available to purchase ready-made panels with a layer of insulation.

As for the size of the facade panels for brick, the parameters are quite varied. Products can be both small individual elements and large-sized sheets, differing in three-meter height. Some manufacturers practice the sale of narrow, stacked panels of increased length, sheet profiles and sandwich panels, stacked in several layers.

Types of brick panels: fiber cement, polymer sand slabs

A large selection of various panels allows you to choose the best option for facade cladding in any of the modern or classic styles. The basis of brick panels for outdoor decoration is made up of components of natural origin, among which the following materials stand out:

- wood fiber;

- various minerals;

- glass;

- fiber cement or cement fiber material;

- aluminum and steel;

- copper;

- zinc;

- PVC and other polymers.

Due to the peculiarities of the materials used and production technologies, fiber cement panels for brick are distinguished not only by good flexibility, but also by bending and compressive strength. The manufacturing process consists of three stages. All the necessary components are mixed first. The finished solution is poured into molds, where it remains until completely dry. The last step is the application of a finishing coat and a protective layer.

A large number of positive characteristics are provided due to cellulose, which is necessarily present in the mixture. It is this component that gives the material strength and moisture resistance. The main characteristics due to which fiber cement facade panels for outdoor decoration are widespread:

- low flammability and lack of the possibility of spontaneous combustion;

- high bending strength - about 24 MPa;

- linear deformation not exceeding 2%;

- the ability to withstand 100-150 freezing and thawing cycles;

- the level of water absorption does not exceed 20%;

- residual strength - not less than 90%;

- density - 1550 kg / m³.

The main advantage of polymer sand wall panels for brick is low cost relative to other types of facing slabs. The second important advantage is increased strength, which makes it possible to use building materials for finishing not only the front part, but also the basement floor. An indisputable advantage is that the sheets belong to the class of self-extinguishing.

Fiber cement panels for brick are distinguished by good flexibility, bending and compressive strength

All popular manufacturers of polymer sand slabs offer customers a large selection of color variations. Wall decoration can be done using any shades of the red spectrum, and it is also easy to choose the right texture. Many firms use fine-grained marble or stone chips to decorate the surface of the panels, which, in combination with the incident sunlight, creates a unique and spectacular appearance.

Metal and plastic facade panels for brick: photos of examples of building design

Metal facade panels imitating brickwork look especially attractive. In fact, this type of panel is an ordinary siding, the surface of which resembles brickwork. Often, the imitation looks so believable that it can only be distinguished from the original upon closer inspection. The main advantages of using metal panels for exterior decoration of a house under a brick:

- incombustibility;

- resistance to temperature extremes;

- shape retention in dry or too wet weather conditions.

Important! In addition to the advantages, before buying, you should familiarize yourself with some of the inconveniences of using siding. The main thing here is considered to be the large weight of the sheets, which entails a longer and more laborious installation process.

Vinyl plastic facade panels for brick are made from various components, where the main one is polyvinyl chloride. The sheet consists of two layers. The first of them gives strength to the material, due to which the panels are characterized by the minimum indicators of thermal expansion. Even at low temperatures, the cladding does not deform. The outer layer protects from direct sunlight, and the presence of antistatic agents in the composition prevents the deposition of dirt and protects the material from destruction. A special advantage is the ability to self-clean the facade in rainy weather.

The attractive appearance of the products is ensured by the different textures present on the surface of the PVC panels.At the same time, experts recommend mounting sheets with some offset for an ideal imitation of masonry. A large selection of colors and patterns of facade plastic cladding panels for brick allows you to combine different options and create attractive homes.

Sandwich brick finish, thanks to the three-layer construction of the sheets, has many advantages. A distinctive feature is the presence of a heat-insulating layer up to 70 mm thick, which is located between the 5-mm facing layers.

Also, to prevent the formation of condensation, some types of panels are equipped with a vapor barrier film. This prevents the appearance of humidity inside and outside the room, even if there are frequent and strong fluctuations in temperature. Another characteristic advantage of sandwich panels is their increased sound insulation properties, which makes the material in demand when decorating houses located near busy roads or airports.

The main component for the manufacture of vinyl plastic facade panels for brick is polyvinyl chloride

Other popular options for facade panels: photos of houses

Facade panels for brick with insulation have another common name - thermal panels. The basis of the design is polyurethane foam or expanded polystyrene, which act as a heater. Imitation of brickwork is done using clinker tiles, which are a natural material. The main component (clinker) consists of clay that has been fired at the highest possible temperatures - about 1200 ° C.

The thickness of the base of the facade panel under a brick with insulation, depending on the manufacturer, varies from 6 to 10 cm, while the thickness of the clinker does not exceed 1.5 cm. thinner and higher quality expanded polystyrene, the density of which reaches 40 kg / m³... Installation of thermal panels is carried out using special polyurethane glue.

Facade panels that imitate stone are most often used for finishing the basement and are combined with brick-like sheets. Thus, it turns out to create a coherent and attractive picture of the house. The main component in the manufacture of panels is polyvinyl chloride, which is mixed with biochemical reagents and stabilizers. Such a composition allows the panels not to lose color for a long time due to various atmospheric influences, and also helps to withstand high temperatures.

The production of brick-like basement panels is carried out on automatic equipment with special molds. The panel of the finished basement siding closely resembles natural brickwork with the smallest chips, protrusions and irregularities on the surface.

Depending on the manufacturer, the thickness of the facade panel for a brick with insulation varies from 6 to 10 cm

Plinth sheets intended for cladding a house under a brick are thicker than other types of finishes. This allows the material to be more resistant to ultraviolet light, high humidity, as well as mechanical and chemical influences. The average service life of sheets reaches 50 years, and the panels do not require any special maintenance.

What makes Döcke and Wandestein facade panels stand out

On the trading floors you can see that the facade sheets are offered by a large number of different manufacturers. Each of them uses different technologies and gives the finished sheets an attractive appearance. One of the most popular brands is the Docke company. Facing sheets of the company are called "lightweight stone". Despite the outward simplicity, the sheets beautifully laid on the facade transform the building.The use in the manufacture of polyvinyl chloride makes it possible to endow the material with lightness, which, when installing the panels, greatly facilitates the work.

Docke facade panels look as natural as possible thanks to a high-tech process, which is followed throughout the entire production period. The company offers a wide range of colors and textures. So, panels that imitate ceramic bricks, sandstone and other natural textures are available for purchase. Due to its attractive appearance, it is easy to combine sheets with any other finishing materials, both natural and artificial. The price of facade panels for brick starts from 435 rubles at a size of 1015×430 mm.

Useful advice! Experienced builders recommend checking the strength of the finished sheets before buying, for which the edge of one of the panels is recommended to be bent at right angles. If the material is of high quality, then it will not break.

Facade panels for Wandstein bricks do not fade in the sun for a long time and do not lose their integrity

Another popular façade cladding company is Wandstein. The company focuses on the production of high-strength basement panels. Compliance with technology allows finished products to not fade in the sun for a long time and not to lose their integrity due to exposure to large temperature differences.

Related article:

Facade panels for exterior home decoration: types and installation

Facade panels can significantly improve the exterior of the building. At the same time, facing work allows you to insulate the structure.

Besides the fact that Wandstein panels will help to highlight and refine the base / plinth, they are also distinguished by their reliability and high quality. The most popular collections of the manufacturer are considered "Tuff" and "Skol". In the manufacturing process, the technology of automated dyeing is used, which allows the finished product to stand out among the products of other manufacturers. Distinctive features of Wandstein panels:

- The standard size of the facade panels corresponds to the height of the basement level and is 59.5 cm.

- Upgraded lock connection, rigidly and reliably fixing elements to each other. This technology can significantly speed up and simplify the installation process.

- The improved horizontal panel connection prevents even the slightest deformation of the sheets.

- Environmental safety, which is ensured thanks to high quality materials. The finished panels do not emit toxic substances and have hygienic and fire certificates.

Popular manufacturers of facade panels: Fineber, Alta-Profil and others

When cladding a house with brick panels, Fineber products are often used, which offers a wide range of products, which allows you to embody any design ideas regarding facades. The standard size of the panels is 1100x500 mm. According to the texture of the front surface, the following options are available for purchase:

- under a stone;

- brick;

- slate.

In order to ideally imitate brickwork on the facade, it is recommended to use small segments of the panels. In terms of technical and operational characteristics, Fineber facade panels stand out for their high quality and long service life. Even after 15-20 years, the manufacturer guarantees the preservation of the attractive appearance of the building - all thanks to the use of high-tech equipment and competent adherence to the stages of work. A distinctive feature is the absence of glare on the surface of the facade in sunny weather, because the outer surface is matte.

The optimal combination of cost and quality of finished products has brought Alta-Profil products to the leaders of the domestic market.In addition to good quality indicators, the company's products have other advantages:

- good ability to withstand aggressive environmental influences;

- the ability to operate at high temperature drops and constant high humidity;

- non-susceptibility to the absorption of chemicals, which often settle on the foundation;

- the absence of the likelihood of delamination and cracking even under the influence of high temperatures;

- low cost, for example, the price of a front panel measuring 1130x468 mm is 480 rubles.

Useful advice! Before buying branded sheets, you should pay attention to the presence of a hurricane lock, which looks like a slight bend over the main fasteners. It is thanks to this castle that it will be possible to protect the material from sharp and stormy gusts of wind.

Nichiha products are composed of wood fiber, silica sand, cement with the addition of mica and inorganic additives. The product is sold in the form of flat relief tiles, presented in various colors and textures, which allows it to imitate brick or masonry. An important advantage of the panels is the absence of synthetic components in the composition.

For reliability and long-term use, the outer side of the sheets is covered with acrylic in 6 layers, and the facade paint is applied to the inner part, which is characterized by a water-repellent effect. Nichiha fiber panels have minimal tendency to expand or contract even when exposed to high or low temperatures. Thanks to the acrylic surface, the facade is self-cleaning, and dust and dirt do not linger on the facade. If you look at the photos of the facade panels, you can pay attention to the absence of visible joints or seams.

Depending on the quality and price of the material, the estimated cost of the installation work also changes. The average price per square meter of facing with facade panels varies from 200 to 360 rubles. The cost will vary depending on the location of the building. The closer to the big city, the higher the installation price will be.

Characteristics of TechnoNIKOL brick-like soft facade panels

Technonikol Hauberk uses only high-quality materials and fasteners for installation in production. A large number of the advantages of the panels are due to the fact that they consist of four layers, where each plays an important role:

- The inner layer is bitumen, which does not allow moisture to pass through and acts as an antiseptic, preventing the development of pathogenic microorganisms. Helps to retain heat inside the building.

- The second inner layer consists of fiberglass, which increases the strength of the sheets. It is this substance that allows the panels to maintain their appearance, despite the shrinkage of the building.

- The third layer, adjacent to the facing surface, is quartz sand, which provides good adhesion.

- The fourth layer is quartz, which improves the adhesive properties of the board and increases the level of fire resistance. In addition, quartz reflects heat radiation.

Main technical characteristics of sheets:

- width - 100 cm;

- height - 25 cm;

- thickness - 3 mm;

- optimal temperature range - from -50 to +110°FROM;

- the number of defrost / freeze cycles for which the material is designed - 100;

- service life - 20-30 years, depending on the ambient climatic conditions;

- number of panels in one package - 20 pcs .;

- total packing area - 2 m².

Important information! Many people mistakenly think that the number of freeze / thaw cycles corresponds to the number of years of operation.Depending on climatic conditions during the cold period, such cycles can be up to 10. In this regard, sometimes the maximum service life of the panels does not exceed 15 years.

The weight of one square of cladding is about 12 kg, which greatly simplifies the work. Due to the fact that the kit contains all the necessary fasteners, you will not have to spend additional funds on their purchase. The ductility of the sheets allows you to accurately finish the convex and concave parts of the facade, as well as to easily cut the panels without using a special tool.

The presence of bitumen and fiberglass in the composition provides the sheets with good tightness, and the basalt granulate creates the effect of a three-dimensional image. Another advantage is the low price of soft facade panels for Tekhnonikol brick: the cost of one square starts at 400 rubles.

Facade panels for brick: basic installation rules

Before starting work, one should not forget that finishing the house with facade panels presupposes the presence of ventilation, which will protect the base surface. Installing the front panels should start from the corner of the first row, and each next sheet is laid in a circle. The upper row is fastened only after the completion of the installation of the lower one.

Most sheets have pre-cut holes. If there are none, you will need to make them yourself before fastening. It is important to control the curvature throughout the execution of facing under a brick, because even one incorrectly installed sheet can disrupt the whole picture.

Builders with experience do not recommend focusing on measurements when fixing a new sheet. It is better to attach the panel directly to the desired place - this is how you can avoid mistakes. To get the perfect imitation of brickwork, you need to grout the joints.

The next stage is the facing of boxes and slopes to ensure the tightness of the structure. Upon completion of the work, the seams should be treated with polyurethane foam. In order not to spend money on extra panels, it is preliminarily recommended to lay out the material on graph paper, taking into account the parameters specified in the characteristics of the product. When calculating the number of sheets, the following parameters must be taken into account:

- total size of the wall minus door and window openings;

- length from corner to all openings;

- distance between windows and door;

- height from plinth to top edge.

Useful advice! Before installing the facade panels, the lathing should be done. The finished frame must cover the entire facade and surround the window and door openings. It is necessary to install a vertical profile with a maximum step of 100-120 cm. The first and final posts are placed along the line of the corners of the facing surface.

How to install facade panels for exterior decoration using insulation

If you need to make a heat-insulated facade, you should start by laying a heat-insulating layer, for which it is recommended to purchase building materials of correct geometric shapes. The most popular options are foam, expanded polystyrene and mineral wool. Whatever the reliable adhesive mixture, for better adhesion, you need to fix the insulation with the help of umbrella dowels, characterized by a large round cap. In general, the decoration of walls under a brick with facade insulation consists of the following stages:

If there are no ready-made holes in the sheet, you will need to make them yourself before installation

- careful examination of the surface;

- leveling irregularities if necessary;

- installation of brackets;

- gluing insulation to the wall;

- making holes for dowels using a drill with a victorious tip;

- driving in "umbrellas" - at least 5 pieces per sheet;

- installation of a vapor barrier film using a construction stapler;

- securing the lathing;

- installation of facade panels for brick.

It is important to know that if not polystyrene, but mineral wool is used as insulation, then in general the course of work looks the same. The only distinguishing point is the elimination of the stage of gluing the heat-insulating material.

Every owner wants to make a facade that looks attractive and fits perfectly into the environment. Not everyone can afford to use natural brick or stone for cladding, and not every foundation can withstand such a load. Facade panels that imitate brickwork are cheaper and easier to install, which is why they are widely used. And most importantly, they practically do not require maintenance. The only thing that needs to be done is to check the reliability of the fasteners at least once a year and remove dirt as necessary.