Clinker brick for the facade is one of the most durable and reliable materials. Due to its unique physical and chemical properties, it is far superior to traditional ceramic bricks. High technical, mechanical, performance and aesthetic properties make this material an ideal solution for creating a presentable and durable building facade. All the characteristic features of clinker bricks are detailed in this article.

The clinker can be used for cladding building facades, laying paths and ebbs, or for interior wall decoration

Content [Hide]

- 1 Clinker brick: history of creation

- 2 Clinker brick: what is it?

- 3 Clinker brick production

- 4 Type and typical dimensions of clinker bricks

- 5 Scope and varieties of clinker bricks

- 6 Technical indicators of facade clinker bricks

- 7 The main advantages and disadvantages of the material

- 8 Rating of world famous manufacturers of clinker bricks and product price

- 9 Clinker brick cladding technology for the facade of the house

- 10 Varieties of clinker brick masonry

Clinker brick: history of creation

Clinker brick is a type of ceramic brick, characterized by a high density of the structure, which is obtained as a result of a special manufacturing technology. The material got its name due to the unique property of emitting a sonorous sound when tapping on it with any metal object. The word "klink" literally translates as pure ringing.

Due to its excellent decorative qualities, clinker bricks can be used for exterior and interior decoration of buildings.

For the production of clinker bricks, special clays with unique properties are used. The material is fired at a temperature of 1000-1400 ° C until the clay is completely sintered, which turns it into a glassy mass.

For the first time, clinker bricks began to be produced in 1743 in Holland. This was due to a shortage of other materials that occurred as a result of the construction boom in Europe at the turn of the 18th-19th centuries.The first fired brick was used for paving roads. In terms of technical and operational indicators, it was similar to cobblestone, which was widely used for road surfaces, but the clinker was easier to install and had a lower cost. Therefore, the paving of the streets and roads of large cities with clinker bricks became more and more popular.

The first half of the 19th century is characterized by the rapid development of industry and the growth of large European cities. The old quarries could not provide the required amount of building material for the construction of new buildings and road paving. This became a prerequisite for the search for a material that would be similar to natural stone in technical properties, and its production would be possible in any quantity.

Clinker tiles have high strength characteristics, due to which they are considered one of the best facing materials.

This period gave impetus for a more detailed study of the question of what a clinker brick is. Gradually, enterprises began to emerge that produce this material, which over time turned into large corporations with a worldwide reputation and successfully occupying leading positions today.

Clinker brick: what is it?

Based on GOST, it can be said that clinker brick is a high-strength product that has low water absorption, which gives it high performance properties and makes the material resistant to aggressive environments. Due to its excellent decorative qualities, it can be used for exterior decoration of the building.

Clinker is a brick of a regular shape in the form of a parallelepiped with certain dimensions. The outer surface of the product has a rough structure. The color palette of the material, which is due to the introduction of special additives, has more than a hundred shades, from light yellow to dark brown.

Clinker brick can have a different texture of the front side, which allows you to embody many design ideas for cladding a building

When choosing a material, you should know how the clinker brick differs from the ceramic one. To make clinker, a special type of clay is used, called skinny. Mineral components of igneous rocks are used as a charge. The mass is fired at temperatures above 1000 ° C. until the required amount of glass phase is formed. While conventional bricks are fired at temperatures up to 1000 ° C.

Thanks to the unique manufacturing technology, the level of strength of the material and its resistance to abrasion exceed those of high-quality concrete. The conditions and mode of firing make it possible to create a product with low hygroscopicity, which ensures low moisture absorption, which is only 8%. In contrast, brick absorbs up to 15-25% of water.

Important!Products with a glazed surface are completely moisture resistant, which significantly increases their frost resistance.

For humid regions of the country, it is better to use clinker bricks or tiles with a glazed surface.

Clinker brick production

For the production of clinker, special refractory refractory clay rocks are used. They should contain a significant amount of aluminum oxide (17-23%), which reduces the viscosity of the clay mass. This contributes to low deformation of the product during firing. If clay with a lower aluminum oxide content is used in production, it is pre-enriched with kaolin clays.

The presence of a certain amount of iron oxide, which should not be more than 8%, gives the finished product a peculiar shade. However, the amount of this component should not exceed the norm. Otherwise, this will serve as the formation of a dense layer on the surface of the brick, which prevents the release of carbon dioxide from the product, which will cause swelling and irregularities.

The amount of calcium should be in the range of 7-8%. An overabundance of the component will lead to a decrease in the sintering time of the product, which can cause deformation of the clinker. The likelihood of the formation of a significant number of pores also increases, which reduces the moisture resistance of the product and shortens the life of the material.

The content of magnesium oxide in clay should not be more than 3-4%, which can lead to clay shrinkage and deformation of the finished product.

The technology of manufacturing clinker bricks and tiles in many factories has not changed for a century

Features of the technology of manufacturing clinker bricks

Clinker bricks can be made by extrusion or semi-dry pressing. In the first case, the raw mass is mixed to a homogeneous consistency and fed into the container-extruder, where it is squeezed out onto the tape in the form of a rectangular strip with clearly formed geometric dimensions under pressure through a molding hole of a certain configuration.

Then, the volumetric strip, moving along the tape, is cut into separate products. Raw bricks go to preliminary drying, after which the moisture content of the products should not exceed 3%. The dried material is sent for firing.

The main advantage of this method is the production of high quality bricks with clear geometric dimensions. However, the technology requires high energy costs, which increases the cost of the product.

Modern production of clinker makes it possible to produce high-quality bricks and tiles with clear geometric dimensions

The second method allows you to reduce energy costs, while at the same time degrade the quality of the finished product. The essence of the semi-dry pressing process is as follows. The clay mass is cleaned, dried, crushed to a powdery state and moistened. Then the mixture is poured into molds where it is pressed. Finished products enter the chambers for final drying for 24-48 hours at a temperature of 80-85 degrees. Then the dried bricks are fed for firing.

The firing of the formed bricks is carried out in continuous firing tunnel kilns, with a length of more than 200 m, where dried products stacked on pallets are fed. The pallet conveyor moves slowly inside the chamber. Clinker products pass through several zones with different, clearly defined temperatures, the maximum of which reaches 1400 degrees.

Thanks to this technology, the clay is completely sintered. The result is a durable monolithic clinker block with a definite decorative appearance.

Type and typical dimensions of clinker bricks

Clinker bricks can be manufactured in the following standard sizes:

- single 1NF measuring 250x120x65 mm;

- one and a half 1.4NF measuring 250x120x88 mm;

- double 2.1NF measuring 250x120x140 mm;

- Eurostandard 0.7NF in size 250x85x65 mm;

- modular 1.3NF measuring 288x138x65 mm.

For convenient installation, clinker bricks are produced, the sizes of which are called fractions: 3/4; 1/3; 1/2; 1/4. The accuracy of the dimensions of Russian bricks is regulated by GOST, which allows deviations of no more than 2 mm in thickness, 3 mm in width and 4 mm in length.

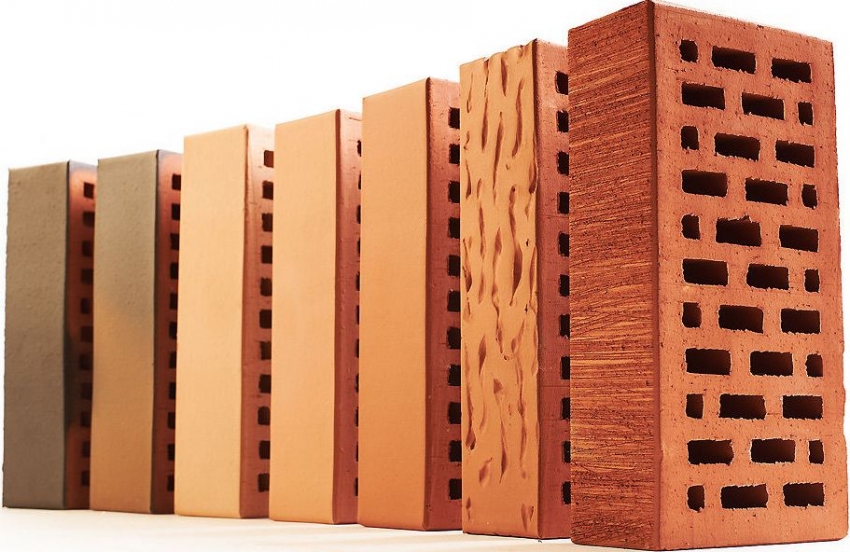

Facing clinker bricks can be solid in the absence of voids, and hollow, with through holes of various sizes and shapes. Their number and size affects the weight of the product, which is 35-40% less than that of a full-bodied product.

Therefore, clinker facade finishing is carried out using hollow bricks, which do not create unnecessary stress on the walls and foundation of the building.In addition, due to the immobilized air gap, a high thermal insulation of the surface is created.

The front side of clinker bricks can be:

- glossy;

- matte;

- corrugated;

- glazed.

Clinker bricks can be produced in various shapes and on order for a specific project, which allows you to embody the most daring design idea. Products can have rounded, semicircular cuts and internal roundings.

Thanks to a wide range of sizes, clinker can be used to decorate not only the facade of the building, but also the steps

Scope and varieties of clinker bricks

Today the industry produces several types of clinker. Each type of bricks has a specific purpose.

Related article:

Clinker tiles for steps: the right choice of material

Characteristics and distinctive features of the material. Varieties of the product. Laying clinker tiles on the steps. Material cost.

Construction single or ordinary clinker bricks are used for the construction of supporting structures such as pillars, columns, foundations, plinths and stair treads. These load-bearing elements, erected with clinker, are distinguished by their durability, resistance to external influences and mechanical strength. The cost of clinker bricks varies between 35-100 rubles. a piece.

For interior decoration, clinker bricks are rarely used. It is often used to create separate fragments that complement the overall concept of the interior. It can also be used for cladding a stove, fireplace, erection of an interior partition. For interior wall cladding, colored or white brick-like clinker tiles are most often used, which retain their color for many years. Due to the unique manufacturing technology, it does not show the consequences of the negative impact of external negative factors.

Facing or facade clinker bricks have high decorative properties and a wide range of colors. Thanks to the glazed outer surface of the product, maximum resistance to weathering and sunlight is achieved, which prolongs the life of the material while preserving its original appearance.

Facing clinker is produced not only in the form of rectangular products with strict geometry, but also shaped parts. The price of clinker bricks per piece averages 35-40 rubles.

Sidewalk clinker bricks are used for paving roads, pavements, park alleys, garden and footpaths. Clinker brick for paths has increased resistance to abrasion and mechanical shock, which allows you to get a durable coating that will retain its original appearance for a long time.

Clinker bricks for the facade: types and scope

Today, manufacturers produce several types of clinker bricks for the facade, each of which has its own advantages and distinctive features.

The most aesthetic is hand-molded brick. Thanks to the unique manufacturing technology, it is possible to obtain a product of a unique shape and size with a different texture, which surprises with its diversity. This effect is achieved due to the fact that the initial raw material, clay, remains in its natural form, and then is pressed with the preservation of all channels and pores of the material. The result is a unique texture.

White clinker brick is a unique material. For its manufacture, clay of the highest grade is used, which is mined near the location of limestone.The finished product is able to retain its original whiteness for many years, despite the negative impact of weather conditions. This effect is achieved by firing the clay to a sintered state, resulting in a dirt-repellent and waterproof effect.

Solid clinker brick is mainly used for facing steps of external stairs. It is a reliable and durable material that, thanks to the ribbed surface, has an anti-slip effect. The product is made from refractory slate clay, which is exclusively mined in northwestern Germany, and is the benchmark for clinker production.

Decorative clinker facing bricks have the same technical characteristics as conventional finishing bricks. However, it has a more attractive aesthetic appearance, which is clearly displayed in the photo of the facade of houses made of clinker bricks.

Clinker ceramic bricks withstand significant temperature changes, several cycles of freezing and thawing, and have increased moisture resistance.

Helpful advice!This material can be used for construction in regions with high humidity and low temperatures.

For facing the facade, hollow bricks are used to reduce the load on the foundation and walls of the building

Another variation of clinker is clinker tiles, photos of the facades of houses made of this material clearly demonstrate the popularity of a product that looks like an ordinary brick. However, the weight of the tiles is much less, which does not make the supporting structure heavier. It can be used for cladding an old building. The cost of the product is much cheaper, which makes the material the most affordable and in demand.

Technical indicators of facade clinker bricks

The resistance of the material to external influences and the durability of the coating depend on the density of the product, which is formed during the clinker firing. For facade clinker bricks, this figure is 2000 kg / m³, which indicates a high density of bricks, which can withstand significant mechanical loads without destruction.

Having low porosity, the material has a low hygroscopicity, which is only 3-5%. Due to this quality, clinker bricks absorb a very small amount of moisture, which is not capable of destroying the internal structure of the product and the facade of the building.

The clinker has increased thermal conductivity, so it is worth taking care of proper thermal insulation

Helpful advice! For buildings located in areas with high humidity, it is advisable to use glazed clinker bricks, which are not able to absorb moisture.

Due to its high density and low moisture absorption, clinker facade bricks are characterized by increased frost resistance. It is able to withstand more than 75 freezing cycles without visible damage, making it indispensable for buildings located in latitudes with cold climates.

To reduce the load on the foundation and walls of the building, facade clinker bricks are produced hollow, that is, as lightweight as possible. Through holes of various configurations are formed as a result of the use of special shapes during the pressing stage.

Due to its low porosity, the material has an increased thermal conductivity, which is 1.17 W / m ° C. Therefore, before facing the walls of the building, they must first be insulated.

Facing brick clinker is not afraid of frost, so it can be used in cold regions of the country

Possessing a high density, clinker bricks have a low vapor permeability, which is only 0.07 mg / (m / h / Pa), which refers it to an undeveloped facing material. However, due to this property, the material reliably protects the structure from moisture penetration.

Helpful advice! When using clinker cladding bricks, a good ventilation system must be considered to protect the walls of the building from condensation.

Due to the presence of refractory components in the composition of the product and firing the material at high temperatures, its good fire resistance is ensured. The structure remains stable without destruction or deformation even at very high temperatures.

The clinker does not have sound insulating properties. Due to the low porosity and high density, sound vibrations penetrate into the room without hindrance. Therefore, when using clinker bricks, it is necessary to provide reliable sound insulation, which can be created using thermal insulation material.

Manufacturers offer customers clinker of various shapes and configurations, which makes it possible to use the material for finishing door and window openings.

Clinker bricks are made from natural materials. Therefore, the products are environmentally friendly and free of harmful compounds.

Interesting! Raw materials and finished products are subject to mandatory radiation background control.

The main advantages and disadvantages of the material

The main advantages of clinker bricks include the following characteristics:

- material resistant to aggressive environment;

- the brick is resistant to sudden temperature changes and low and high temperatures;

- is dirt-repellent, eliminating the need for regular cleaning to maintain an attractive appearance;

- the service life of bricks is over 100 years;

- finished products are available in various shapes, textures and colors;

- does not lose its original color when exposed to UV rays, atmospheric phenomena;

Clinker brick is able to withstand significant mechanical loads and negative effects of atmospheric phenomena

- the material is able to withstand significant mechanical loads;

- universality of application;

- does not undergo biological degradation;

- the likelihood of efflorescence and "shots" formation on the surface of the material after its laying is excluded;

- has increased moisture resistance;

- has a stylish and effective appearance.

The disadvantages of clinker include the following factors:

- high thermal conductivity of the material leads to significant heat losses;

- installation of the product requires certain skills of a bricklayer;

- high cost of the product;

- to perform installation work, it is necessary to use a special masonry mortar, which is suitable specifically for clinker bricks.

Helpful advice! Each sample of clinker bricks has a unique pattern, so products from one batch may differ significantly. Pre-sorting should be done before starting work.

Rating of world famous manufacturers of clinker bricks and product price

Today clinker bricks are very popular, therefore, a significant number of manufacturers offer it in the construction market, of which the leading ones are:

- LSR Group is the first Russian manufacturer of clinker bricks, which holds a leading position among world companies;

- the international corporation CRH Group has established its own production in 25 countries of the world. Produces high quality products appreciated by professionals;

- German manufacturer Wittmunder Torfbrand Klinkerwerk has been making the classic version of clinker bricks for over a century;

- the German company Feldhaus Klinker produces attractive clinker bricks in a wide range of colors;

- German company ADW Klinker produces clinker bricks in bold color variations;

- the Russian manufacturer Rauf produces clinker facing bricks of natural shades;

- the Dutch company Daas Baksteen has been making clinker for 120 years, which has a unique color;

- the Polish company Roben is also famous for the unique shades of the product;

- the German company Terca has been known on the world market for over 200 years. The best materials for landscaping and landscaping are made here;

- Russian manufacturer Alfa-profile produces high-quality products in various variations;

- Ukrainian company Kerameya produces high quality, durable and expensive products.

German clinker bricks are now leading the way among products from other manufacturers. However, these products are the most expensive. The average price of clinker bricks for a facade made in Germany is about 80-95 rubles. a piece. While the cost of a domestic product will vary in the range of 25-35 rubles. a piece.

LSR Group: clinker bricks from a Russian manufacturer

The LSR Group includes four high-tech modern plants located in the Moscow and Leningrad regions. They produce a wide range of ceramic bricks. Facade products take pride of place and compete with foreign counterparts in the field of design.

For the manufacture of clinker, high-quality Cambrian blue clay is used, which gives the finished products high mechanical and operational properties. As a result, you can get a strong, durable and aesthetic product at an affordable cost.

Raw materials and materials that are produced at the factories of LSR Group undergo strict control in accordance with the requirements of the current legislation. The variety of color variations and textures ensures the growing demand for clinker bricks from domestic producers.

The Russian manufacturer LSR produces clinker tiles for various purposes - to cover facades, fireplaces or chimneys.

Clinker cladding bricks for outdoor decoration are produced in nine basic shades, which became the basis for creating a collection of products with their own names: dark red "Edinurgh", red "London", dark red flushing "Nottingham", cream "Marseille", white " Venice ”, snow-white“ Naples ”, straw“ Valencia ”, light gray“ Uppsala ”, brown“ Munich ”.

The average price of clinker bricks for a facade per m2 is 1300-1500 rubles. depending on the type of product.

Concern CRH Group

The CRH Group Corporation consists of several companies that produce various building materials. One of them is clinker bricks. Modern technology and high-quality equipment allows us to create a quality product that occupies one of the leading places in the world.

Depending on the location of the manufacturing plant, the clay deposit and the material production technology, the appearance of the finished products is characterized by uniqueness and originality.

The most popular model lines are:

- Miraz - deep red clinker bricks with a corrugated surface can give a building a noble and perfect look;

- Wega - smooth dark chocolate clinker bricks are ideally combined with white grout, which makes the facade of the building lively and emphasizes the neatness of the brickwork;

- Orion - clinker with a smooth surface in milk chocolate color can be used with lighter jointing, for example, ivory or light gray, which favorably emphasizes the architecture of the building;

- Gozdnica - clinker bricks with different shades of yellow, starting with a light matte and finishing with a thick sandy one, are able to create an optimistic mood and fill the atmosphere of the site with sun, even in rainy weather;

- Ochra - products of traditional brick color are able to emphasize the neatness and respectability of a building made of another building material;

- Cherry - deep, noble, rich shades of red are able to advantageously decorate any building facade.

Classic clinker from Wittmunder Torfbrand Klinkerwerk

The German company Wittmunder Torfbrand Klinkerwerk is the only manufacturer of the classic version of clinker bricks. Products have been manufactured using ancient technology for over a hundred years. Brick firing takes place in a ring kiln - the only one of its kind that has survived in Europe. The sintering process is carried out at a temperature of 1400 degrees. for two weeks. This makes it possible to obtain a strong, durable and unique in appearance product.

Clinker bricks have natural, natural shades of fired clay. Dyes and chemical additives are not used in the production technology of products. At the plant, all work is carried out mainly by hand, which reduces the likelihood of defects. All these factors make the final product environmentally friendly and safe, but also very expensive. The price of facing clinker bricks averages 120 rubles. a piece.

Clinker bricks are produced in three formats, which have their own names: thin, Hamburg and Oldenburg. The color scheme is very diverse. Here is the largest and most varied palette of shades that can be boldly combined with each other. There are also almost plain products. Red clinker bricks are very popular, which add some liveliness to the building.

The visiting card of the company is clinker bricks, the photos clearly reflect this, in gold and silver colors, which are not produced by any manufacturer.

Helpful advice! If the building needs to be given an antique look, it is worth using the company's exclusive collection of facade clinker, which can turn a house into a medieval castle.

The company creates unique bricks, among which no two products are alike. Individually, the bricks do not look very aesthetically pleasing. They become especially attractive in masonry with beautifully executed seams, as clearly shown in the photo of a clinker brick house.

Clinker bricks from ADW Klinker

The German company ADW Klinker is one of the trendsetters in the clinker production. Its products differ from other counterparts in a bold and varied range of colors, which is obtained as a result of a special production technology and due to the use of special raw materials. Clinker products are made exclusively from white clay. This allows you to create a variety of shades of the product. But this is achieved without the use of dyes. Certain mineral additives are added to the raw material, which, as a result of heat treatment, give the clinker a unique characteristic color.

The company offers many inimitable line collections featuring unique and unusual color combinations created by experienced design artists. Of these, three of the most popular options can be distinguished. The Hamburg collection is represented by products in the color of malachite and its shades.Bricks are produced with a smooth surface and a deformed shape, which allows you to create a special facing of the building.

Another, somewhat coldish option is the Fubsortierubg collection, where gray-silver shades prevail, smoothly turning into a rich black color. This cladding is ideal for a solid massive structure. She favorably emphasizes its monumentality and grandeur.

If you need to create a warm, sunny and fresh atmosphere, then you should opt for the Sintra sabioso collection, which combines a delicate beige-sand shade and a discreet brown color, complemented by a wavy line and textured brick surface.

Today, many designers, creating their masterpieces, give preference to ADW Klinker products, which allow them to embody bold design ideas that will not lose their original appearance even under the influence of harsh winter conditions. The average cost of a brick is 60-75 rubles. per unit of product.

The clinker collection "Fubsortierubg" has a gray-silver shade, smoothly turning into a rich black color

Clinker from Daas Baksteen

The Dutch company Daas Baksteen has been manufacturing clinker products for over 120 years. The clinker facing brick produced, the photo of the houses is a clear confirmation of this, has a unique and inimitable pictorial color, where several shades in the form of streaks and brush strokes are harmoniously combined.

Important! The company grants the right to create its own sketches of clinker bricks with the subsequent release of products, which makes it possible to realize an individual design idea.

“Baksteen 051-Cedarwood” can be distinguished among the most spectacular and unique collections. Here, the front side of the product has a textured structure that imitates cedar bark. Light colors seem to shine through rich dark shades, which allows you to create a three-dimensional effect. Such cladding will look the most aesthetically pleasing with snow-white door and window frames and other facade elements.

The clinker collection "Baksteen 051-Cedarwood" by Daas Baksteen is distinguished by an original texture that imitates cedar bark

Another warm and playful collection, Baksteen 035-Dalby, creates a welcoming atmosphere with a harmonious blend of peach, red and ocher, complemented by splashes of dark brown through which warm tones can be seen. This cladding will create a cute fairytale house.

Another unusual option is the Baksteen Sussex Multi collection. Here are presented clinker bricks of non-standard size 240x90x50 mm, the surface of which resembles a rocky structure in color. This is ideal for a chalet that needs to be ennobled with lots of shrubs and trees after construction is complete. It is also a good cladding for an office building and a country house. You can buy Dutch clinker facing bricks for an average of 70 rubles. a piece.

Russian manufacturer of clinker bricks Rauf

Clinker bricks at domestic Rauf factories are manufactured using modern European technologies, using high-quality raw materials and reliable foreign equipment. This company belongs to the LSR Group, which has been producing quality products for a very reasonable price for 20 years. Russian-made clinker bricks, photos clearly reflect this, are produced in a variety of textured and tint variations of red, brown and ocher colors. However, the products cannot yet compete with foreign counterparts. But production is moving forward rapidly. The price of the material is on average 30 rubles. per unit of product.

Among the offered assortment, you can choose clinker bricks, which are able to create an aesthetic appearance of the building.One of these options are vanilla products, which in combination with white or brown grout, window and door openings, gables and a hinged roof of the same color, are able to create a harmonious and attractive structure.

Another interesting option is the brown MIX rustic clinker brick. It is painted in various shades of chocolate, which favorably emphasize the shallow relief pattern that resembles a woody texture. Such a brick will be ideally combined with white or beige grout, which will create a respectable facade that will stand out favorably against the background of other buildings.

The White Venice collection is represented by products painted in a pale pink color, thanks to which, in natural light, the effect of a perfectly white facade is created. The clinker is harmoniously combined with dark brown or black joints, façade elements or roofing.

Clinker brick cladding technology for the facade of the house

Clinker brick is recognized by many experts who have noted its high strength, durability and reliability. However, this elite building material is very expensive, therefore, when laying it, it is necessary to strictly observe all technological processes that must be performed carefully and carefully so as not to end up with a marriage.

The surface must be cleaned before laying. It is recommended to start laying dry from the first row. This will allow the vertical seams to be placed evenly and correctly and eliminate unnecessary cutting of the brick. Now you need to measure the height of the clinker bricks installed on the construction site. This is necessary in order to determine the average height of the brick layer, taking into account the horizontal joints, which should be the same for each new row.

The next step is to determine the lowest horizontal level from which the installation of the first row begins. Further, it is necessary to strictly vertically mount using anchors a pair of vertical slats along the entire length of the facade, which are used as side edges of the facade. A mooring cord is pulled between the slats, which determines the height of the layer. Now you need to prepare stacks of facing material and containers for masonry mortar.

Useful advice! When performing cladding, it is recommended to alternate bricks from different batches in order to obtain an even color distribution and achieve a neat and aesthetic appearance of the facade.

In order for the color of the finish to be uniform, it is necessary to lay bricks sequentially from different packages

Features of laying clinker bricks

After completing all the preparatory work, you can proceed directly to laying the material on a special solution. The thickness of the seams should be no more than 10 mm.

Useful advice! The working solution should be divided into several parts, which correspond to the work areas. Installation must be carried out in whole layers in order to withstand the average thickness of the joints.

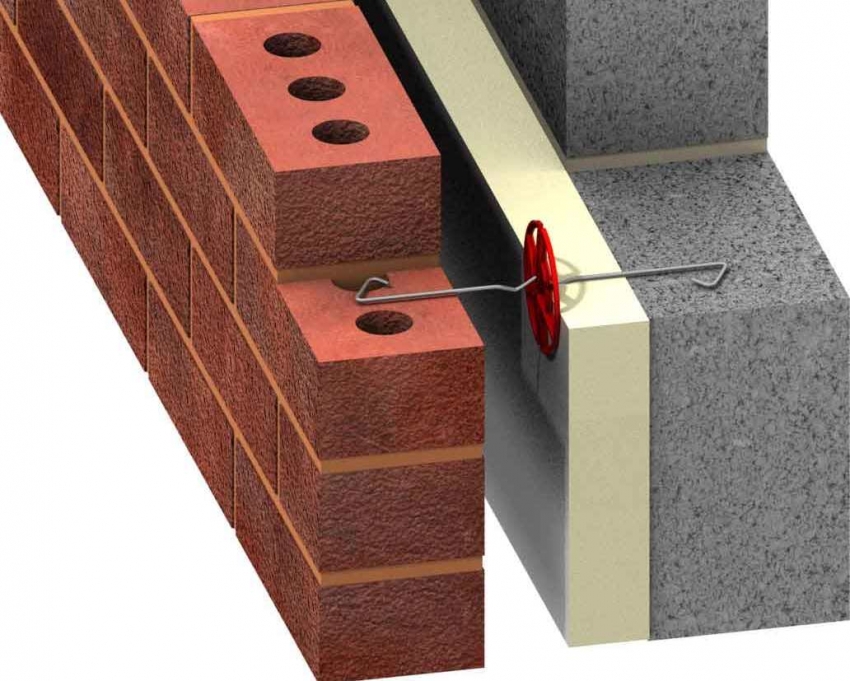

If it is necessary to provide a ventilating air void in the wall, which is especially important for wooden structures, a vertical joint should be left empty every 4 rows, which should be filled with thermal insulation material. When laying bricks, it is necessary to strictly ensure that no mortar penetrates into the air space between the facing material and the wall. To do this, it is recommended to press it with a trowel on the clinker from the side of the air gap.

Due to the fact that clinker bricks have a low water absorption rate, for better installation, the product should be moistened before laying. Each new layer is laid down to the level of the mooring cord, which determines the average layer height.The classical dressing of the seams when laying a brick must be taken equal to a quarter of its length. Expansion joints are placed as close to the corners of the building as possible. The distance between the seams should be 10-13 m.

Lay no more than 5-6 rows at a time. To align the structure of the brickwork, it is necessary not to beat it off, but to saw it off. Excess solution should be removed immediately, and if it has already grabbed, remove it very carefully, using a stiff brush or wooden spatula.

For a reliable connection of the cladding layer and the supporting structure, it is necessary to use anchors made of alloy steel, which must be implanted into the wall at a certain angle to the facade layer, in order to avoid wetting the insulation when condensation forms on the surface of the anchor.

Methods for finishing the facade with clinker bricks

Depending on the material of the bearing walls of the house, the need to create an additional heat-insulating layer, the variety of clinker bricks, the technology for finishing the facade may be different. There are three ways:

- wall decoration with clinker bricks creating an air space between the wall and the material;

- facade cladding without air gap arrangement;

- wall decoration with the installation of a heat-insulating layer between the wall and the facing material.

High-quality finishing of the facade of the building assumes free air circulation between the wall and the clinker

The most common option is considered to be a method that involves the creation of an air space, the distance of which is 2-4 cm.This is necessary to ensure free air circulation between the load-bearing wall and the finishing material, which simultaneously protects the building envelope from precipitation without interfering with their ventilation. This technology significantly increases the service life of the building. This is especially true for prefabricated or timber buildings.

The technology of this method provides for the creation of ventilation ducts for free air circulation. This is every 3-4th vertical empty seam in the brickwork in the lowest and top row, not filled with mortar. It is necessary to install a special ventilated mesh in it to eliminate the penetration of rodents.

If the construction object is located in a cold climatic zone, before facing clinker bricks, it is necessary to create an additional heat-insulating layer, which is covered with a vapor-permeable film on top. Next, the surface is plastered using a reinforcing fiberglass mesh. Mineral fiber mats or polystyrene are used as insulation.

When facing a building with clinker, you must adhere to the rules for creating a facade insulation cake

Useful advice! When using mineral wool, it is necessary to leave a distance of 2 cm to the facing material in order to exclude the possibility of condensation in the insulation.

When using facade panels for clinker bricks, the need to install an additional layer of thermal insulation is eliminated, since the material already contains insulation.

Necessary tools and materials for clinker brick finishing of the building facade

To perform facing work on the facade of the building, the following tools must be prepared:

- a trowel for laying clinker bricks;

- a pickaxe hammer, which is used to hew and cut bricks into pieces;

- vertical wooden slats with a section of 10x10 mm;

- scraper for horizontal seams;

- mooring cord to check the correctness and evenness of the brickwork;

- a wooden spatula or stiff brush to remove the frozen solution;

- sponge;

- special pencil;

- V-shaped metal sheet to widen the vertical seams.

Useful advice! For the installation of clinker bricks, an elastic trowel should be chosen, with a thickness less than the thickness of the joint.

For the installation of clinker bricks, it is necessary to use a special dry mixture, from which the working solution is prepared. The finished material has undeniable advantages over self-prepared cement-sand mortar. In the composition of ready-made dry mixes, there are no water-soluble salts, which subsequently form a white coating on the masonry.

The prepared solution from the dry mix has a homogeneous consistency, due to which it does not exfoliate, which eliminates the clogging of the air space. In addition, much less time is spent on laying bricks using a special solution than when using a cement-sand mixture.

Masonry mixture for clinker bricks

Today, a specially developed composition for clinker bricks of the Polish production Kreisel 130 is very popular. It can be used for both exterior and interior decoration without the use of additional grouting, which allows you to create a uniform and uniform color of the joints. After hardening, it has increased moisture and frost resistance. With its help, the formation of efflorescence can be prevented.

The material is available in 5 colors: brown, gray, brick, graphite and black. To obtain a ready-made solution, it is necessary to mix it in the proportion of 25 kg of the mixture and 2.9 liters of water. You can use the ready-made solution at an air temperature of 5 to 25 degrees. The consumption of the masonry mixture depends on the thickness of the wall and is 17 kg at a thickness of 6.5 cm, 45 kg - 12 cm and 110 kg - 25 cm. The cost of a 25 kg bag is 245 rubles.

Another popular masonry mixture for clinker bricks is Baumit Klinker S dry mortar. It is an environmentally friendly, modified material that consists of trass cement, mineral fillers and additives to improve the performance of the product. Available in gray, light gray, dark gray, anthracite, black, brown and beige. It can be used for interior and exterior decoration without using a joint.

When laying clinker bricks, it is important to take into account the temperature regime of the masonry mixture

The mixture is mixed with water in a ratio of 4.5 liters per 25 kg of dry matter. The ready-made solution has high adhesion. It can be used at temperatures ranging from 5 to 30 degrees. for 1-1.5 hours. The average cost is 220 rubles. per bag weighing 25 kg.

Clinker grout

A special grout is used to seal the joints that are formed as a result of laying clinker bricks and create a decorative effect. It can be made from cement or resin. The first option is used for exterior cladding, and the second for interior work.

Useful advice! If wide joints are to be filled, a cement-based grout with sand should be chosen.

Before grouting, it is necessary to prepare the facing surface. Dry the brickwork thoroughly, which may take several days. It depends on the weather conditions. At this time, the surface must be reliably protected from exposure to sunlight, precipitation, and excess moisture. Grouting works should be carried out under favorable weather conditions at a temperature of at least 5 degrees.

In order for the lining seams to be neat and of high quality, it is worth carefully preparing the surface

The grouting mixture is produced in the form of a dry powder, which must be combined with water to obtain a working solution of the required consistency.To do this, you must strictly follow the instructions on the package.

To check if the mixture is of a suitable consistency, you need to take a little material in your hand, squeeze it in your fist and then roll it between your palms into a roll. If there are traces of solution on the palms, it is too liquid. If the roll crumbles, the mixture is too thick.

The grouting process is quite simple and is performed 4-5 days after the completion of installation work. Using a special tool, the mortar is pressed against the horizontal and vertical joints in such a way that it completely fills the space and comes into contact with the mortar for laying bricks. After the fugue is completely dry, its excess is removed with a soft brush. This should be done very carefully so as not to damage the integrity of the surface of the seams.

Varieties of clinker brick masonry

There are three main ways to lay facing clinker bricks:

- Direct masonry allows you to create a pattern using different brick dressing options using an even distribution of joints.

- Decorative masonry involves creating an ornament using a specific pattern of seams and using bricks of different colors.

- Artistic masonry, or patterned relief, makes it possible to create a pattern using not only various seam patterns and alternating brick colors, but also using complex architectural elements in the form of grooves, protrusions, pilasters, slopes and other volumetric patterns.

The masonry can be single-row and multi-row, also bonded, spoon or combined. The masonry got its names from the names of the brick surface. The spoon is the long edge of the brick. The short, end portion is called a butt. Poke masonry is a cladding consisting of only pokes. In spoon masonry, every four rows of spoons are alternated with poke ones.

Non-standard cladding of a building facade with clinker bricks requires the professionalism of a bricklayer

Combined masonry involves various options for binding bricks, where spoons and pokes are harmoniously combined in different interpretations that have their own names.

The aesthetic appearance of a clinker brick facade also largely depends on the quality of the processing of the seams, which should stand out on the surface of the cladding and favorably set off a kind of binding of bricks. Depending on the type of brick and the design concept, the seams can be: convex, concave, single-cut, undercut, hollow, double-cut, concave or convex, which can be clearly seen in the drawings on the Internet.

Classic straight version of brickwork

Depending on the location of the butt and spoon bricks, various patterns can be obtained on the facing surface of the facade, which are characteristic of a particular type of masonry:

- Old Russian, or Gothic masonry assumes alternation of spoons and pokes in each horizontal row, where each poke is located strictly in the center of the spoon laid below;

- cross masonry provides for the alternation of poke and spoon rows, where the spoons should be located symmetrically vertically between two pokes;

- the masonry "path" is a pattern where 5 rows are laid with spoons, which in each new row are shifted by half a brick or a quarter of a brick, and alternate with a butt row;

- American dressing consists of 4-6 spoon rows, which are stacked with an offset seam, alternated by a row of bonded bricks;

- in the English masonry, butt and spoon rows alternate;

- Flemish dressing assumes a different alternation in each row of butt and spoon bricks, with which you can get a spiral, cross, diagonal or double butt simple masonry;

- in savage masonry, an irregular and asymmetrical change of spoons and pokes is provided;

- Brandenburg ligation involves laying three spoon bricks in each row, which alternate with one butt bricks, where the joints are located every 1-3 rows strictly vertically;

- herringbone dressing involves the creation of spoon rows, where the bricks are located at an angle of 45, mirrored in every second row.

Clinker brick laying depends on the architecture of the building in order to emphasize the elements of the facade

In the photo of houses made of clinker bricks, laid out on the Internet, you can clearly see various options for straight masonry, which is used for facing the facade of the building.

Decorative masonry using colored and textured bricks

Decorative masonry involves the creation of a facade cladding, where a geometrically clear pattern of seams is observed in combination with textured, colored or embossed finishing elements.

The texture of the brick is aimed at emphasizing the expressiveness of the brickwork. With the help of a grooved surface, you can create the atmosphere of an old building that has survived several centuries. Clinker bricks for plinths, pylons, retaining walls are usually used with a rough textured surface that resembles chipped stone. For cladding multi-storey buildings, cornices, walls, brick with a rough texture is often used.

Useful advice! To enhance the decorative effect in the brickwork, it is necessary to include inclusions of glazed bricks located in a certain or random order.

Using bricks of different colors, which are harmoniously combined with each other, you can create unusual decorative ornaments on the facade of the building. The most popular flat patterns can be obtained as a result of the implementation of one of the masonry: Flemish colored, chaotic, chain colored, Dutch, bonded, spoon with different brick displacement options, Gothic, Silesian, cross, Brandenburg and English. They can be seen more clearly in the photo of beautiful houses made of clinker bricks.

Today, straight Bavarian masonry is very popular. A unique pattern is obtained by alternating different shades of bricks laid in spoon rows, which is clearly displayed by photos of clinker brick houses located on the Internet.

The classic version of the Bavarian masonry involves the use of bricks of four colors: dark red, brown, red and black-brown. The first row is laid out in a chaotic order from all colors. The laying of the second row is carried out in the same order, where the adjacent finding of two bricks of the same color is not allowed. After one row, it is necessary to observe the vertical arrangement of the seams.

When the question arises, which finishing material is better to use for facing the facade of a building, many experts prefer natural, environmentally friendly, durable, wear-resistant, durable and aesthetic clinker bricks. Despite the high cost of the product, you can forget about repairing and sealing cracks on the surface of the cladding for many years, enjoying the pristine appearance of an aesthetic and presentable facade.