Structurally gable roof structure the easiest to manufacture. It can have several different types: broken line, asymmetric and symmetrical, but in general, its design looks about the same in all cases. Unlike other types, the device of a gable roof rafter system with their own hands can be performed by anyone with construction skills.

The gable structure is the most popular for arrangement house roofs

Content [Hide]

Gable roof rafters

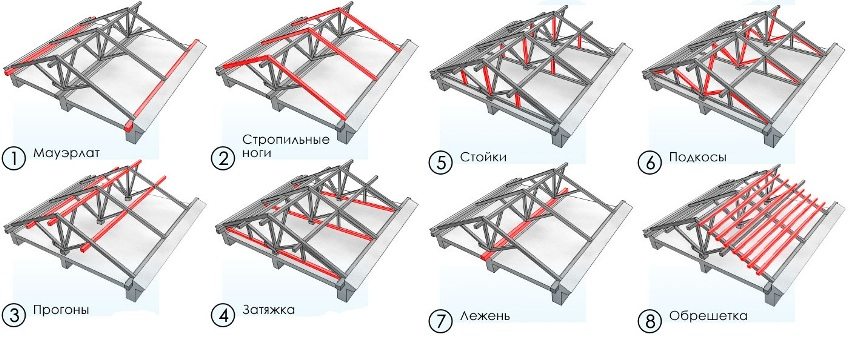

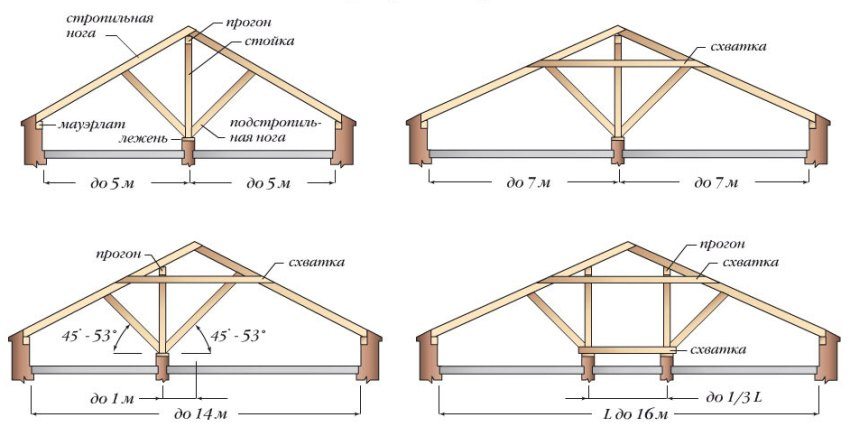

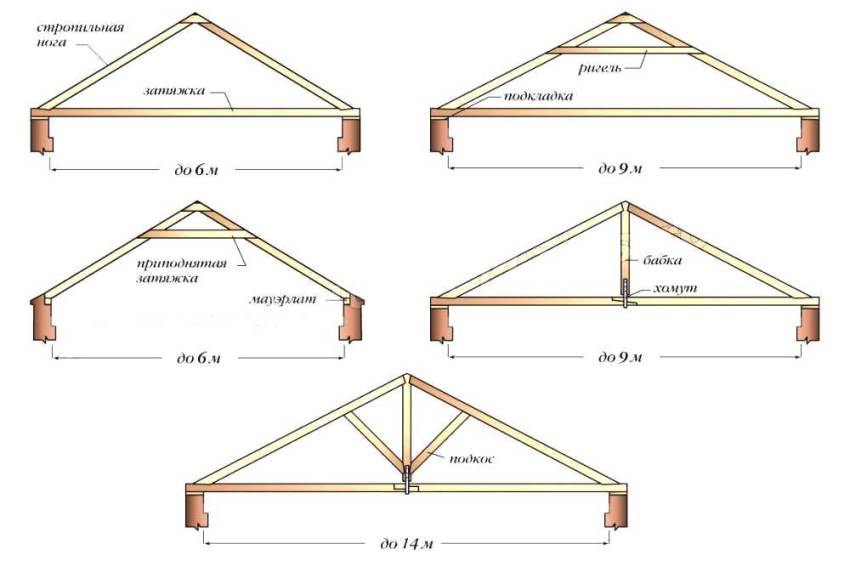

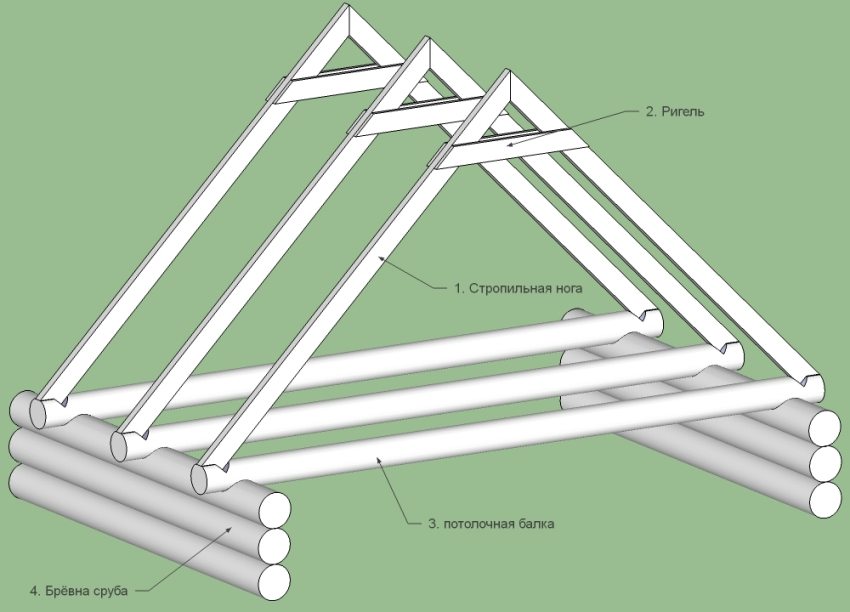

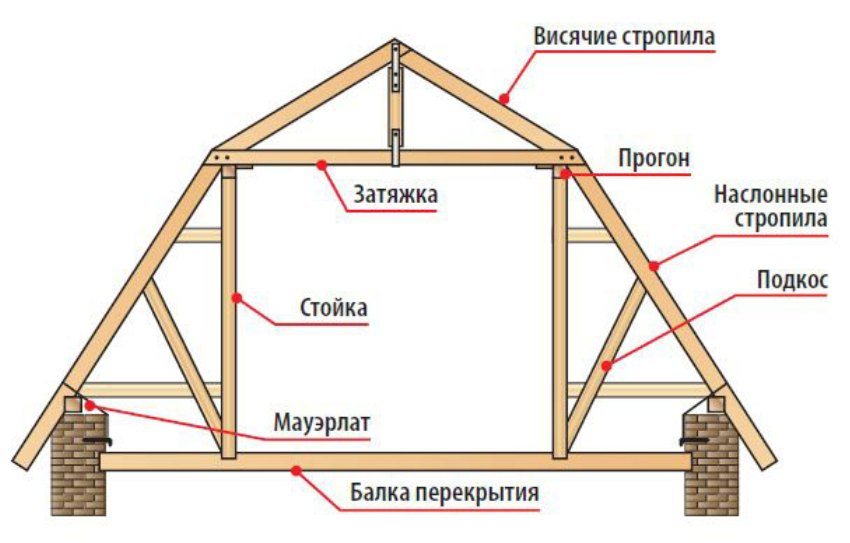

There are two main types of rafter systems for a gable roof: layered and suspended. In the first case, there are central supports abutting against the longitudinal internal partition of the building. In the second case, there are no such supports and the attic space is free. In the device of the rafter system of a gable roof, some basic parts can be distinguished, made of bars of various sections:

- Mauerlat serves to transfer the load of the entire roof to the outer walls of the building. It has the form of a square bar with a side from 100 to 150 mm. It is attached to brick or concrete walls using anchors, and in the case of wooden walls, the beams or logs of the upper row of external walls can play the role of a mauerlat. In such a situation, the rafters are attached to the Mauerlat immediately without additional elements;

- a rafter leg is an inclined beam made of a bar with a section of 150x50 mm, connecting the ridge and the Mauerlat. This element bears the main load of the entire roof, therefore, the rafter legs should be placed at a distance of 60-120 cm between themselves, depending on the type of material for the roof and the planned loads;

- The bench is a bar, similar to a Mauerlat, lying on the inner partition. The central pillars rest on it. In the hanging rafter system of a gable roof, the device of which is somewhat different from the layered one, this element is absent;

- a puff connects two opposite rafter legs in a hanging system, forming a triangle with them. Serves so that they do not disperse;

- racks support the ridge and rest against the central load-bearing wall of the building. They take part of the load of the entire roof and transfer it to the wall. Racks are made of timber;

- struts connect the rafter legs with rigid supporting elements: uprights and puffs. This increases the rigidity of the structure several times;

- the crate is stuffed onto the rafters of the gable roof from above. It is made of boards up to 30 mm thick.It can be solid, thin and sheet materials. The lathing serves as a support plane for the roof, and also gives additional rigidity to the entire rafter system of a gable roof. The sheathing device of one type or another depends on the requirements for the roofing material;

- the ridge is a bar that connects all the rafter legs at the points of their attachment to each other in the upper part of the roof. It has a horizontal layout;

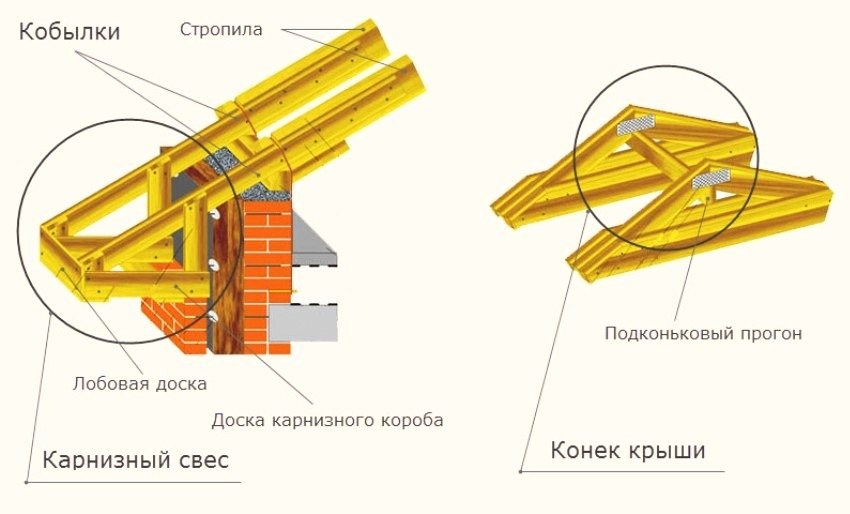

- overhang is called, protruding beyond the walls up to 40 cm, part of the rafter legs. It is needed so that rainwater does not wet the walls;

- filly are planks nailed to the rafter legs in the absence of an overhang. They play the role of extension elements.

Useful advice! Using filly is preferable to making long rafter legs. It is much easier and cheaper to replace a rotten filly. Indeed, in this case, you do not have to disassemble the entire roof.

DIY gable roof rafter system

Before you start the device of the gable roof rafter system with your own hands, you need to determine its type and calculate the need for materials. The hanging system is suitable in cases where an internal load-bearing wall is not provided for in the building structure, or if a spacious attic space is needed, for example, for the construction of an attic. The amount of lumber is calculated based on the floor area and roof height.

Useful advice! Rafter legs can be fastened together on the ground, and not "in place". This makes it possible to more accurately maintain the corners according to the template. In the case of a hanging structure, this method is the only one possible. Ground-mounted triangles are simply positioned in place and secured.

The procedure for carrying out work during the construction of a rafter structure may be as follows:

- installation and fastening of the Mauerlat on external walls. It fits on the side where you plan to tilt the roof. Preferably, these walls are parallel to the inner load-bearing wall of the building. It is necessary to put a layer of waterproofing of any type under the timber;

- laying the bed is done similarly to the construction of the Mauerlat;

- racks are vertically installed on the bed. You can fix them in a groove or metal corners. The angle at which the roof is inclined directly depends on the height of the racks, so if you want to make a roof with a given angle, you can calculate the height of the racks using the simplest trigonometric formulas. For example, for an angle of 45 degrees, it is necessary that the height of the posts be equal to the distance between the Mauerlat and the bed. The distance between the posts must correspond to the desired distance between the gable roof rafters;

- all racks are interconnected with a skate, which should lie strictly horizontally.

On this, the device of the main supporting elements can be considered complete. The next step in the construction of a gable roof rafter system with your own hands is the installation of rafters.

Diy installation of gable roof rafters

As mentioned earlier, the rafter legs can be fastened together below on the ground. For this, a template is made from small bars with a given angle and length. Then the required number of rafter legs is made on it. If the system is hanging, then they are still connected with puffs. After that, the rafters of the gable roof are installed with their own hands in place and fastened to the ridge.

Related article:

How to build a gable roof with your own hands. The main elements of a gable roof. Step-by-step instructions for installing a gable roof. Types of gable roofs.

In the case of the device of rafter legs "in place", they simply fit on the ridge in the places where the racks are located and are connected to each other in their upper part. At the bottom, they are attached to the Mauerlat. After that, the rafters can be stiffened with struts. When installing the rafters of a gable roof with your own hands, it must be borne in mind that these structural elements bear the greatest load.

Fastening the rafters to the Mauerlat

The reliability of the entire structure can be ensured only if all connections and fastenings are made competently and efficiently. One of the most critical places in the entire structure is the point where the rafter leg contacts the Mauerlat. At this point, the resultant of all the forces acting on the roof is directed in the direction of the rafter leg, "looking" at an angle downward. Therefore, the rafters can part with time. The task is such that this resultant is directed perpendicular to the walls, that is, in the direction of gravity.

This can be done in two ways:

- Place the rafter leg at an angle on the Mauerlat and nail it in. In this case, you will need to make filly, since the overhang is not formed.

- Make a rectangular cutout in the rafter leg, with which it will rest against the Mauerlat. This design is more reliable.

Attaching the rafters to the Mauerlat in any of these ways will avoid deformation. truss structure.

Sheathing and small elements

When the entire basic structure has already been installed and there is no doubt about its reliability, you can proceed with the installation of the remaining elements. At first, you can close the gables with boards. This will allow you to trim the lumber in place more evenly. If the installation of fillies is required for the overhang device, then these works are also performed. A cornice board is attached to the filly and the cornice is hemmed.

The lathing is made of boards with the required step or solid. Starting from the bottom, the boards are nailed at the right distance from each other. The first board should be nailed strictly parallel to the cornice.

Useful advice! If it is not possible to purchase a large amount of edged material, then the crate can also be made from unedged board. It is only important that the bark is removed, and the first board is still edged.

The installation of rafters of a gable roof is a responsible matter, since the strength and durability of the entire constructed structure depends on it. This work needs to be done efficiently.