A fence on the territory of a private house or in the country can be built using different materials. For these purposes, wooden boards, bricks, and metal mesh are suitable. Today, the development of industry makes it possible to make a fence from more technologically advanced and durable materials. One of them is polycarbonate. It becomes more and more popular every year. In order to build a polycarbonate fence, you need to familiarize yourself with its types, as well as installation features.

Content [Hide]

Features of a polycarbonate fence and its differences from products from other material

Structures made of iron and wood have many drawbacks that modern materials lack. Metal fences are corrosive and therefore require painting and other protective measures. In turn, wooden structures have weak strength, and are also prone to cracking and rotting.

Polycarbonate is lightweight, which is incomparable even with the weight of the most popular material in construction - wood

Polycarbonate is a modern synthetic polymer that is highly durable and flexible. Products made from this material transmit light and at the same time hide everything that happens on the site from prying eyes. Fence polycarbonate looks presentable and impressive, especially in combination with metal and brick elements.

Helpful information! If necessary, a fence made of this material can be given a non-standard shape, since it has good plasticity.

Polycarbonate serves as a sound insulator because it is able to absorb sound vibrations. Separately, it should be said that Plexiglas products do not transmit ultraviolet radiation, which can harm the plants in the area.

You can build a fence from such a canvas with your own hands. However, it is necessary to clearly understand the technology of work and know how to fix polycarbonate, and you also need to figure out how to do it correctly. This material is lightweight, which greatly simplifies the transportation and installation of sheets.

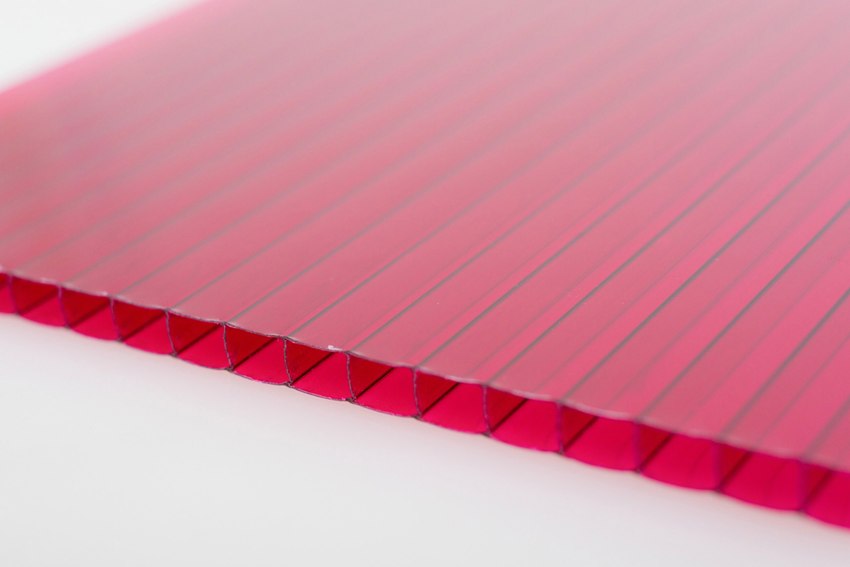

Polycarbonate with a honeycomb structure also has high strength due to stiffening ribs, which create a honeycomb structure

Advantages and disadvantages of polycarbonate

The arrangement of such fences has become widespread recently, and such fences are used not only in private plots. Administrative buildings, schools, factories and other facilities often use polycarbonate structures. The broad operational scope of this material indicates its many benefits.

Polycarbonate is resistant to moisture. Wooden fences swell and collapse from water, and metal fences rust. Polycarbonate does not grow moldy and is also corrosion resistant.

Another plus of such a fence is resistance to temperature fluctuations. This also applies to sharp changes that can cause quite significant damage to structures made of familiar materials. A polycarbonate fence for a summer cottage will not heat up when exposed to sunlight.

PCB sheets are resistant to heavy loads. The same property is inherent in iron fences, but polycarbonate, in contrast, has good flexibility. This allows not only to simplify installation, but also to bring to life unique design options. The plasticity of these products can be different, and it is usually indicated in the instructions that come with the sheets in the kit.

Polycarbonate sheets can be easily formed into any shape, which allows you to create fences of the most incredible geometric shapes

Polycarbonate fence can have different transparency. For example, if you need to create a shade that will have a beneficial effect on the plants in the garden, then it is best to choose a translucent option. Such a sheet is an ideal material for the construction of a fence, and is also suitable for arranging polycarbonate doors.

Note! A very important advantage of this material is that there is no need for finishing. Caring for this product is quite simple: it is enough to periodically wipe it with a damp cloth.

Experts advise using such fences if you live near a motorway, airport or railroad. The honeycomb material has a honeycomb structure, which allows it to absorb technical sounds.

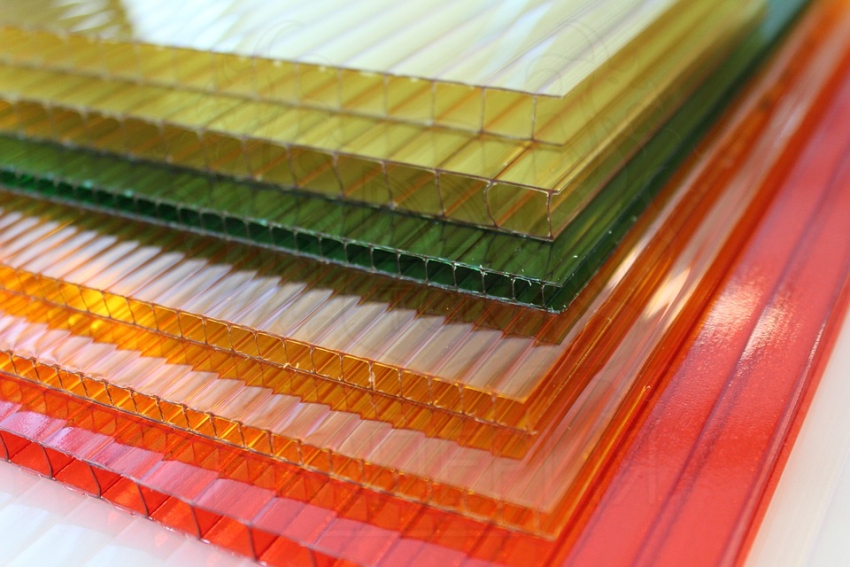

Another plus of this building material is the variety of shades. If necessary, you can choose the most suitable color for combination with a metal frame or brick. The combination of PCB with wrought iron fence... Forging with polycarbonate requires a fairly large expenditure of funds, but it is not only pleasing to the eye, but also a very durable structure.

Polycarbonate sheets transmit up to 90% of sunlight, while the crystal structure refracts it in such a way that the fence allows you to hide behind it from prying eyes

Of the disadvantages of polycarbonate sheets, one can single out the need for organizing metal fixing elements. Without them, the fence will have weak stability, and plasticity will only aggravate the deformation process. The canvas has good strength characteristics, but it is not as resistant to mechanical stress as, for example, iron.

And also it is worth noting the expensive cost of polycarbonate fences. The price for such structures depends on many factors, but most often it is higher than for standard fences. This is due to the fact that PCB is often combined with forging metal, brick and wooden elements.

Varieties of polycarbonate fences: photo

Today, such products are divided into several types. All polycarbonate fences are differentiated depending on their structure. On this basis, two types of material can be distinguished:

- cellular;

- monolithic.

Monolithic polycarbonate does not have any empty spaces inside the sheet, therefore it is heavier and stronger than cellular

Cellular.The structure of such a material is presented in the form of interconnected cells. The outer plates are joined by means of stiffeners, which can be straight or diagonal (X-shaped). The geometric parameters of these sheets are different and vary depending on the type of canvas. A fence made of cellular polycarbonate can have various thicknesses - from 3 to 40 mm.

Monolithic. Unlike cellular PCB, this material is one-piece and comes in two types: transparent and translucent. The thickness of homogeneous polycarbonate products can reach 12 mm, but no more.

There is another factor by which experts classify polycarbonate products - the type of installation. The fact is that today there are several options for mounting such sheets:

- sectional;

- on brick pillars;

- forging with PCB.

In the first case, polycarbonate sheets are fixed in a special frame, which is prepared in advance. For its manufacture, profile pipes or metal corners are used. The sheet is fixed by means of self-tapping screws or special fixing elements. The result is a section that is easy to transport and install due to its low weight. This option is one of the most popular when installing a polycarbonate fence. The welded sections can be easily installed by yourself.

Installation of PCB sheets in combination with brick pillars is also a common option. The main disadvantage of this method can be considered the complexity of the organization (including the foundation).

Helpful information! In some cases, this canvas is used in combination with a 3D mesh. A polycarbonate fence of this type is highly durable. The plastic material itself has a decorative function.

Cellular polycarbonate consists of two, three or more sheets of transparent polymer, the space between which is divided by stiffeners

This design has quite a few positive aspects.

Brick-polycarbonate fence is resistant to temperature fluctuations, long service life and presentable appearance. Separately, it should be said about the versatility of these structures. There are many options for their outdoor decoration. In combination with brick, you can use both a monolithic polycarbonate fence and a cellular one.

The most interesting way to use carbonate is to install such a forged fence. Depending on individual conditions, you can choose transparent or translucent polycarbonate sheets. Experts advise using the second option in combination with forged metal rods. There is a possibility of installing the PCB behind the sections (from the inside).

And also another combination is possible, which is less common, but is also popular. It is a polycarbonate sheet fence. Such a fence is more difficult to do with your own hands.

Polycarbonate perfectly complements forged structurescreating spectacular design solutions

Installing a polycarbonate fence: material selection

Since the cost of the PKB today is quite high, it is necessary to carefully approach the calculation of the amount of material that will be spent on the installation of the fence. First of all, you need to measure the perimeter of the site in order to understand how much distance the fence will take.

As for the material itself, first you need to choose its thickness. This indicator is very important, as it affects the durability of the future fencing. For the fence, it is advisable to buy sheets with a large thickness. The choice of structure depends on where exactly you equip the fence.For example, a monolithic PCB is suitable for installation in quiet areas, since it is not able to provide a high degree of sound insulation.

Before installation, you need to decide on the design of the polycarbonate fence. Reviews on specialized forums will help you make the right choice. It is also recommended to study the composition of the sheets that you decide to purchase. Some manufacturers add various additives to the material in order to reduce the cost of its manufacture. Such sheets do not differ in quality and are not suitable for the installation of fences.

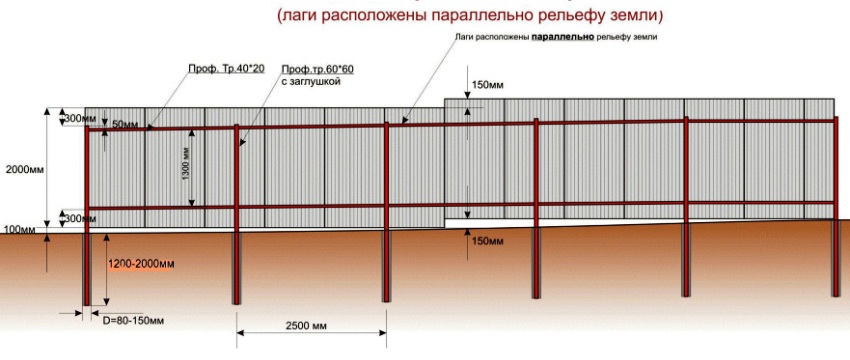

The simplest option for installing a fence from a PCB is sectional. For the frame of the sections, it is customary to use professional pipes with a square section of 60x60 mm and rectangular ones - 20x40 mm. This structure is assembled by welding. The most difficult option is a forged fence with polycarbonate.

Related article:

Metal profile fences: photo and video instructions for self-installation

Self-installation of the fence: a list of tools, installation of pillars, sheathing of the frame with corrugated board.

Polycarbonate fence: preparatory work

The first point of preparation for the installation of a polycarbonate fence is the acquisition of the necessary tools. Consider what is required for this event:

- hand drill (for holes);

Having made a preliminary marking, it is necessary to mark the points in the places of the future erection of support pillars with wooden pegs

- sledgehammer;

- Bulgarian;

- screwdriver;

- level;

- nylon thread.

Note! Before direct installation, it is recommended to mark the site. This is necessary to simplify work and prevent mistakes during the construction of a polycarbonate fence.

The marking of the territory is carried out as follows: first, you should evaluate the perimeter, examine the soil surface. It should be flat. Otherwise, it is recommended to fix the problem. Then the direct markup is done. To do this, you need to mark the points at which the pillars will be installed.

To prepare for the installation of a polycarbonate fence, you need to drill holes in the ground using a drill

Preparation for the installation of the fence from the PKB takes into account the work with the drill. This tool must be selected in such a way that it can be used to drill a hole with a diameter of 200-250 mm. It is important to remember that the bottom of the pit should be about 20 cm below the level of freezing of the soil. This rule will preserve the stability of the future structure.

Before installing a polycarbonate fence, you must also take care of the safety of the sheets themselves. Experts advise keeping them indoors. However, this possibility does not always exist. If the PCB slabs will be stored outdoors, then it is recommended to cover them with a dense cloth that does not let the sun's rays through. It should be noted that PCB sheets cannot be stored together with polyvinyl chloride products.

Organization of the foundation for the fence for polycarbonate

The level of soil freezing on the site is the main factor that affects the depth of the organization of holes for metal posts. However, not every owner knows about this parameter and can independently determine it. As a rule, the depth of the hole for the post is from 80 to 120 cm.This is due to the fact that the soil in most regions does not freeze below 70 cm.

It is better to reinforce the strip foundation, otherwise over time it will begin to exfoliate, which will lead to the destruction of the fence

The type of foundation depends on the composition of the soil. For example, for difficult soils that tend to be unstable, it is recommended to use a full tape backing. This option is also suitable for combined fences (corrugated polycarbonate, etc.). The depth of such a foundation should be at least 100 cm, and the width should be about 30 cm. The overall dimensions of the recess should exceed the dimensions of the metal pillars.

Installation of a foundation for a combined polycarbonate (or standard) fence includes another procedure - reinforcement. This event is necessary in order to give the structure additional strength and reliability. For reinforcement, you will need to purchase reinforcement with a diameter of 10-16 mm. Individual elements, as a rule, are welded together or use wire for joining. Reinforcement must be continuous.

Polycarbonate fence on a metal frame: start of installation

Installation of polycarbonate fencing begins with fixing the pillars, which will serve as a frame for the sheets. The distance between the metal supports varies, but the recommended and most common option is 2 m. This process requires the use of a level. Each post should be perfectly flat, which in the future will affect the overall characteristics of the structure.

After leveling, the supports are poured with concrete. Then you need to wait for the cement to dry. After the solution has dried, the guide elements are joined to the posts. Welding equipment is used for the connection. Rectangular pipes with dimensions of 20x40 mm are most often used as guides.

It doesn't matter which section of the fence is mounted. This can be a polycarbonate fence between neighbors in the country or a fence separating the site from the street. In any case, certain rules must be followed. One of them tells that two corner supports and two logs (professional pipes 20x40 mm) determine the plane for all subsequent sections. Thus, you need to be very careful in the first steps.

Helpful information! The tops of pipes used as supports should be closed with plugs or welded. This will protect them from getting into and accumulating inside the water.

To organize the frame, it is customary to use shaped pipes. And you can also use the profile that is used to fix plasterboard sheets. A polycarbonate fence on a metal frame is not a complex structure, however, it is recommended to observe the proportions during operation.

In order for the support pipes not to change their geometry over time, they must be plugged from above

Before starting the assembly of the frame, it is necessary to mark the vertical supports. It should correspond to the places where the horizontal jumpers will be fixed. The step between them is from 60 to 100 cm. Then you can start fixing the jumpers. For this, welding equipment is used. If you do not have the opportunity to fix the crossbars by welding, then you can use self-tapping screws.

After welding, the joints are cleaned, then anti-corrosion protection is carried out. Those places that can rust are covered with a primer and (if necessary) painted. This is enough to protect the frame from rusting.

How to fix polycarbonate: step-by-step instruction

Before direct fixation, it is necessary to prepare the material. First of all, all sheets are cut into parts, the parameters of which may be different. They are determined depending on the width and height of the fence sections. An electric jigsaw is great for cutting polycarbonate sheets. It is advisable to choose a tool with teeth that are of medium size and are used for woodworking.

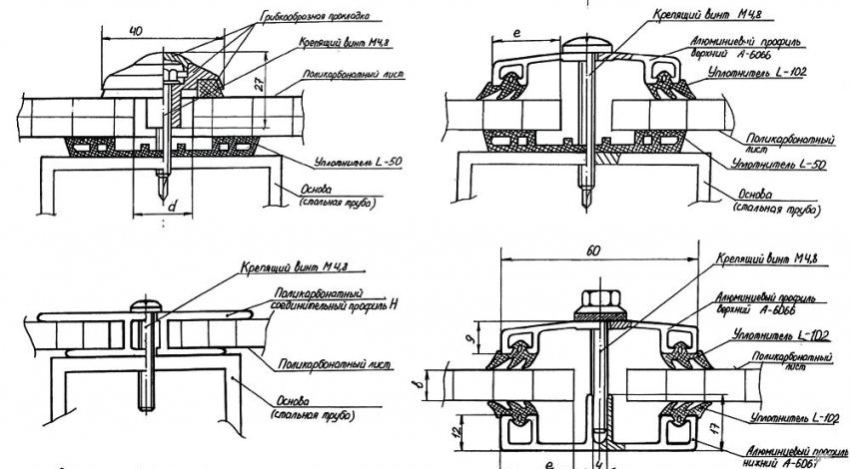

It is not recommended to remove the factory film from the sheets before fixing the polycarbonate. During installation, it will protect the sheet from minor scratches and other minor damage. At the next stage, it is necessary to equip the ends of the PCB plates with special plugs. Such elements have the shape of the letter "P".

Next, the sheets are attached to the frame.This is a major step in building a fence. Fixation is performed using self-tapping screws. It is important to remember that polycarbonate can crack during installation on the frame. To avoid this, experts recommend making all holes in advance.

The diameter of the holes that need to be drilled in the PCB plate must be 2 mm larger than the self-tapping section indicator. Then the gap is closed with a special sealing nut. The distance between the self-tapping screws should be no more than 30-40 cm. Thus, the fastening for polycarbonate is made.

Experts advise to remember one more important rule: you cannot screw the locking elements to the end. A small margin needs to be left. This is due to the fact that polycarbonate can deform when exposed to temperature. As a result, this can lead to the fact that the sheet will burst.

A gap must be formed between polycarbonate and other elements of the protective structure for thermal expansion

Helpful information! It is also advisable to leave a small (about 2 mm) gap between the plates and other elements of the frame.

It is required to sheathe the fence with polycarbonate along its entire length, except for those places where the gates and other passages will be installed. At the last stage, it is necessary to remove the factory film that protects the sheets.

Polycarbonate fence cost: price overview

The final cost of organizing a fence from this material depends on several factors. First of all, these are the characteristics of the material itself (thickness, height, structure). The price is also influenced by individual factors, which include the length of the structure.

Sheets that have a honeycomb structure are cheaper than solid material. The most expensive is a monolithic PCB sheet, equipped with UV protection on both sides. Cellular boards are produced in various sizes. For example, their thickness ranges from 4 to 32 mm. The same indicator for monolithic products is slightly less - from 2 to 12 mm.

It is worth noting that the price of a colored polycarbonate fence will be higher than the cost of a transparent fence. When choosing the height of the fence, it is recommended to take into account that material overruns should be minimal. This will save finances.

The cost of 1 sheet of transparent polycarbonate 4 mm thick is approximately 1800 rubles. Moreover, its dimensions are 2100x6000 mm. Products with a length of 12 m, as a rule, cost 2 times more. Colored polycarbonate plates are sold at a higher price - an average of 150 rubles. more expensive than a transparent material with the same dimensions.

Sheets with a thickness of 6 mm and a size of 2100x6000 cost about 3100 rubles. for 1 pc. And slabs 6 m long, having the same dimensions, are about 6400 rubles. PKB slabs, the maximum width of which is 32 mm and the length of 6 m, cost approximately 14,000 rubles.

In turn, products with a length of 12 m and a width of 32 mm can be purchased for 28,000 rubles. The price of a polycarbonate fence for a summer residence with such characteristics will be maximum.

Do not forget that other auxiliary elements will be required for the installation of the fence. The steel spigot, the base material and the fixing elements are also expensive. The price with the installation of a polycarbonate fence ranges from 2000 to 2800 rubles. and depends on factors such as the method of mounting the poles, the characteristics of the material.

Polycarbonate is a modern material, which in its qualities is not only not inferior, but also surpasses the usual iron and wooden fences. It does not require special care and is resistant to external factors.When choosing a PCB, it is recommended to pay attention to its dimensions and colors. Self-assembly of a polycarbonate fence does not require special building knowledge.