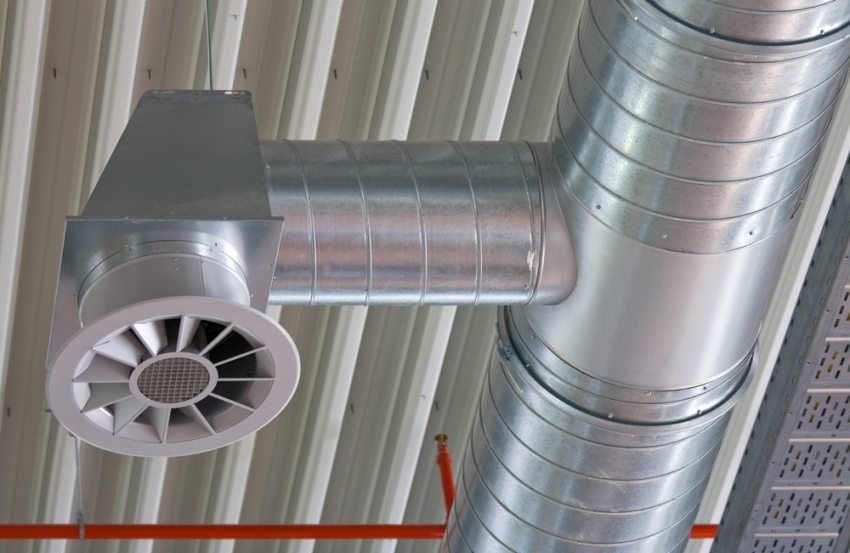

When planning your own houses, high-rise buildings, various buildings and institutions, as well as industrial buildings, great attention is paid to ventilation. One of the important points when installing ventilation systems will be the correct choice of pipes for ventilation. In this case, it is necessary to take into account its dimensions, the material from which it is made, and the features of operation.

When choosing a pipe for ventilation, you need to take into account its dimensions, material of manufacture and operating conditions.

Content [Hide]

- 1 Certain parameters of high-quality air ducts

- 2 Metal pipes for ventilation: types, advantages and disadvantages

- 3 Plastic pipes - reliable, simple and easy

- 4 Sewer pipe ventilation

- 5 Sandwich pipe - the right solution for smoke ventilation

- 6 The use of corrugated pipes for ventilation

- 7 High-quality ventilation: correct selection of parameters and compliance with operating conditions

Certain parameters of high-quality air ducts

For the device of natural and mechanical ventilation, high-quality air ducts are required. They are required to meet certain requirements. These parameters include: tightness, the ability to hold the air pressure calculated according to the project, the ability to ensure the free passage of air masses through them, the ability to maintain the necessary thermal insulation.

Related article:

|

Two main characteristics underlie the classification of pipes: the shape of the section and the material from which they can be made. In any multi-storey or private house, rectangular or round air ducts are installed. Exhaust and supply ventilation is provided with pipes, the cross-sectional diameter of which can be in a fairly wide range. For round - from 100 to 2000 mm, for rectangular - from 100x150 mm to 1600x2000 mm. The sectional shape is selected according to several important parameters, which must be suitable for the size and purpose of the room. The main materials from which pipes for ventilation are made are metal and plastic. It is impossible to mark any of them as the best. That is why both types are presented on the market in sufficient assortment.

Metal pipes for ventilation: types, advantages and disadvantages

Metal pipes can be made of the following metals: galvanized black, thin-sheet black, stainless and galvanized steel, aluminum. The indisputable advantages of their operation are:

- long service life, strength;

- smooth surface will provide good aerodynamics;

- there is no accumulation of dirt, dust, soot on the surface;

- can withstand high temperatures and pressures;

- resistant to aggressive influences.

Galvanized pipes for ventilation

Exhaust ventilation in a private house must be properly designed. The choice of material for the ventilation pipe is always a responsible and controversial issue. Often consumers are inclined to choose such a pipe as galvanized.

Important! The galvanized pipe, having a low weight, retains all the important temperature characteristics inherent in all metal types.

Plus, it's inexpensive and easy to assemble. Installation of the system is not difficult to do with your own hands. A zinc layer saves such a pipe from corrosion, and during operation it does not need additional painting.

Metal pipes: stainless steel and black steel

In most cases, air ducts made of stainless steel and black steel are installed in factories. They are distinguished by their ability to withstand high temperatures, increased fire resistance. Stainless steel is also suitable for transporting aggressive air masses through it.

Plastic pipes - reliable, simple and easy

Many experts unanimously believe that exhaust pipes for ventilation in a private house, when self-assembled, should be plastic. There are several types of polymers for making pipes of this type. Especially popular are PVC or PVC pipes for ventilation... They have a lot of advantageous advantages over others, which explains the high demand for them:

- pricing policy: cheaper than metal;

- ease of installation: they do not require the use of special fastening devices, they are most often mounted using certain devices of their own design;

- PVC pipes have a wide range of sizes, which will allow you to assemble a structure of any complexity from component parts;

- they pass the air moving through them well, since they have a smooth inner surface;

- soundproofing;

- have a pleasant appearance and can be used after finishing finishing the premises;

- low weight, which makes it possible not to firmly fasten the entire system;

- long service life.

It is very important to choose the right option, especially if you intend to do everything yourself, without the help of a qualified master. Many buildings are equipped with PVC pipes ventilation, but in most cases these are private houses.

Sewer pipe ventilation

In terms of their technical qualities, sewer and ventilation PVC pipes are very similar. Most often, consumers are concerned about the question: is it possible to arrange a ventilation system from sewer pipes with their own hands, while obtaining the desired result? Nobody can give an unequivocal answer to it. You can only briefly consider it, and the decision will remain with the owners.

The biggest difficulty in this process is the mismatch in the sizes of the component parts. The diameters of the pipes of one and the other type do not coincide in their range. If the ventilation system, for example, natural, will be installed from scratch, then such a device is quite possible. But if the consumer wants to supplement the already existing system with sewer pipes in his private house, then he is unlikely to succeed. The discrepancy between the sizes of the pipes themselves, the connecting elements will not make it possible to implement the plan.

Many are of the opinion that sewer pipes made of plastic which emits harmful fumes. Putting them not on supply system, but on the exhaust, you can solve this issue.In this case, all harmful vapors will be drawn out of the room. Aesthetics of appearance is not suitable for many. PVC ventilation pipes are more attractive and suitable for any interior.

Decisions on the device of ventilation in a private house from sewer pipes are made by the owners themselves, weighing their skills and capabilities.

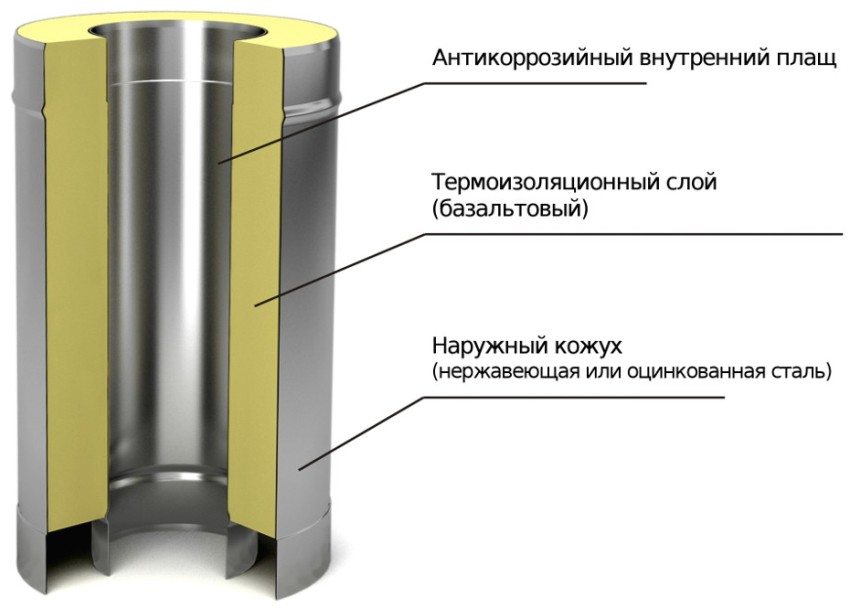

Sandwich pipe - the right solution for smoke ventilation

The sandwich pipe for ventilation has a device and characteristics that provide a high level of thermal insulation and fire resistance. They are an integral part of heating devices such as stoves, heating boilers, fireplaces in a private house... The name itself has already defined the basic idea of their design: two pipes of different diameters are one in one, and the space between them is filled with a basalt seal. Insulated sandwich-type chimneys have high thermal insulation performance. The exhaust air with combustion products does not have the ability to cool down and, according to all the laws of physics, quickly rises up and is evacuated from the room.

The place of their application determines the source material for manufacturing. If solid fuel is used for heating, then only a sandwich will do. stainless steel pipes with a high coefficient of heat resistance. If gas is used for heating, then it is enough to install ordinary steel chimneys.

The diameter of the sandwich pipe can be of different sizes. This allows you to easily match the chimney to any heating device. When marking, use the writing of numbers through a fraction. For example, 120/150. The first is the diameter of the inner working tube and the second is the outer diameter.

Important! In order to calculate the diameter of the ventilation pipe, it is necessary to know the power of the heating equipment and the size of the section of its outlet.

The use of corrugated pipes for ventilation

Pipes of this design are classified as flexible ducts. They have a large list of advantages:

- high elasticity and flexibility;

- make the entire ventilation system as a whole flexible, which is very important when solving some complex issues during installation and reconstruction;

- durable;

- easy to use, easy to assemble by hand;

- do not require special devices (adapters, tees).

Any corrugated pipe, regardless of the complexity of the configuration of the premises in the house and what diameter it has, bends easily at any angle.

The flexible pipe can be galvanized, PVC and aluminum. Each type has the advantages of the material from which it is made and the advantages of flexible ducts directly. It is widely used both in factories and in a private house, easily assembled by hand.

Installation of a duct for a kitchen hood from aluminum corrugation

High-quality ventilation: correct selection of parameters and compliance with operating conditions

All its further performance depends on the correct selection of the ventilation system parameters. The main parameters are dimensions. It is possible to calculate the diameter of the ventilation pipes after the entire system has already been designed and the choice of the material for the ducts has been made. It has a different bandwidth, which affects the size indicators.

When making calculations, it is important to consider where the pipe is located in a private house: a residential or utility room. Since they have different rates of air exchange rate. We take this indicator from the regulatory documents (L). For a natural type of ventilation system, the speed of the air passing through its channels is 0.5-1 m / s, and for a forced ventilation system - 5-7 m / s (V). Then it will not be difficult to calculate the channel cross-sectional area using the formula:

S = L / 3600V,

with which the diameter is easily determined.

The second important point in the operation of ventilation ducts will be insulation. Ventilation pipes - metal and plastic - need insulation. This is a hot issue in attics in the house. Galvanized, PVC and any other pipe are covered with condensation in cold weather. This is due to the fact that the temperature inside and outside the ventilation duct is very different.

Important! Insulation of pipes for ventilation is certainly necessary, constantly accumulating condensate leads to various types of destruction.

Warming can be carried out using such materials: foamed rubber, basalt fiber, polyurethane foam, polypropylene, mineral wool. Sandwich-type channels have a basalt fiber layer inside, and do not need additional insulation. Insulated ventilation pipes will last much longer. Their service life directly depends on the timely and high-quality performance of this procedure.