Different types of gates are used for the same purpose - restricting access to a private area. When choosing a product, you can be guided by different motives, but the main ones are simplicity in opening and closing, as well as saving space. Roller models correspond to both of these characteristics, while it is quite simple to mount sliding gates with your own hands: drawings, diagrams, sketches of structures are easily found on the Internet.

Content [Hide]

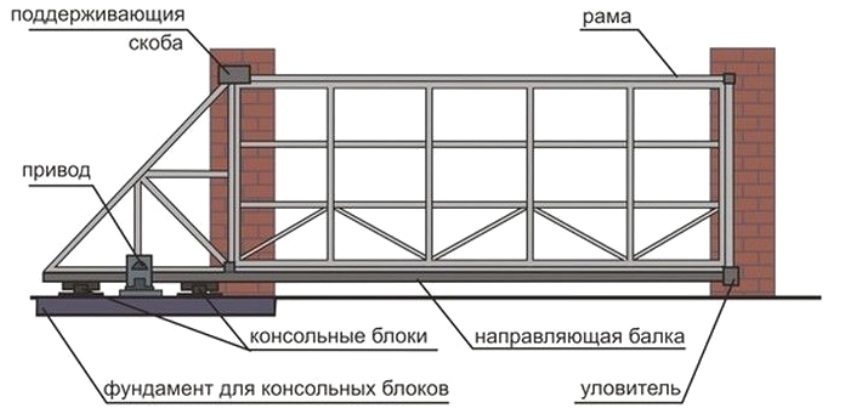

Sliding gate device

Sliding gates can be of two types - roller and rail. The first type of construction involves the use of roller bearings and is fairly easy to manufacture. Rail gates are considered obsolete today and are rarely used.

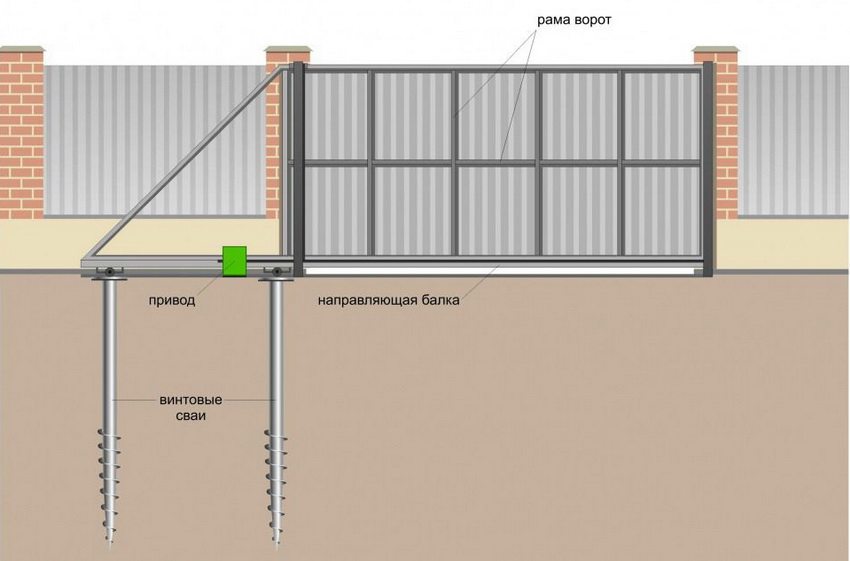

On the Internet you can find a large number of articles on how to make a sliding gate with your own hands. This will require minimal construction skills, some specialized tools, and patience. First you need to know that any roller sliding gates consist of the following elements:

- support or trolley - the console part is installed on two supports;

- guide beam - takes the load of the door weight;

- lower catcher - takes the load of the support roller when the gate is closed;

- upper catcher - reduces the level of windage of the structure;

- removable roller - is a support for the edge of the gate when it is closed;

- top lock or bracket - prevents the sash from sliding sideways;

- stand - the basis for the supports along which the sashes move.

You need to start installing the gate with the construction of the foundation, which will take on the main load of the structure. From above, supports are installed on it, along which the guide beam moves, the latter is welded directly to the sashes.

Sliding gates can be driven manually or by means of an electric motor. Both types of construction imply the same installation pattern.

Useful advice! When choosing a material for the sashes, keep in mind that it must be quite rigid and durable, since the entire structure is exposed to the wind.In addition, the canvas should not bend under its own weight.

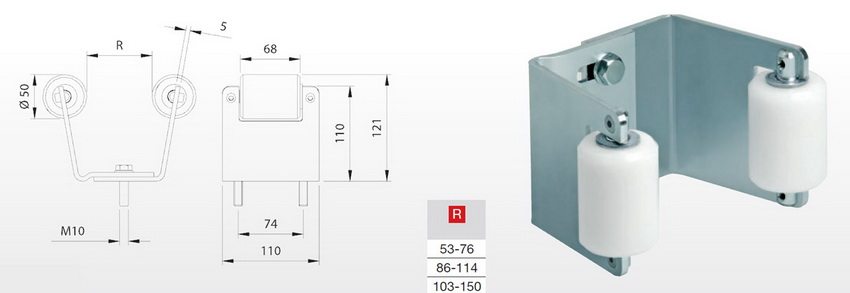

How to choose rollers for sliding gates and other accessories

In the modern market, there are a huge number of spare parts from which you can assemble a sliding gate with your own hands. The main selection criteria are the width of the opening, the height of the sashes and the total weight of the structure. You can also select component parts using special programs on the websites of manufacturing companies.

Particular attention should be paid gate, the opening width of which exceeds 5 m. In this case, the load will be more than 600 kg, and this requires a special set of accessories for increased loads.

If you decide to assemble a sliding gate from the video with your own hands, then you need high-quality components. First, according to the drawings, photos and videos of sliding gates with an average beam with your own hands, you need to calculate the maximum load and other parameters, and then pick up sets of spare parts from the manufacturer you need. Below you can familiarize yourself with the parameters of the mounting kits of different companies:

| Manufacturer | Sash weight, kg | Opening width, m | Beam length, m |

| Roltek MICRO | up to 350 | until 3 | 4.5 |

| Alutech | up to 450 | up to 4 | 6 |

| Roltek ECO | up to 500 | up to 4 | 6 |

Useful advice! When choosing accessories, contact an experienced specialist with ready-made calculations and a drawing. This way you will not only save your time, but also get the best spare parts.

Installation procedure for sliding gates

Doors should always be installed in a specific sequence:

- Creation of the foundation.

- Installing the cabling if you are installing the motor version.

- Installation of the gates themselves and the response post.

- Installation of automatic devices and check of the gate in action.

For each of the stages of installing a sliding gate with your own hands, photos and drawings in large quantities can be found on the Internet.

Tools required for the installation of sliding gates

To install a sliding gate, you will need a number of specialized tools:

- Welding machine - it is better to give preference to the inverter model, it ensures good quality of the seam and does not spoil the metal.

- Air compressor - used to paint the gate evenly. You can paint with a brush or roller, but with a compressor, the paint layer will be as uniform as possible.

- Grinder and a set of discs - for cutting metal blanks.

- Hammer, drill, pliers, tape measure, level, riveter.

Drawings, diagrams, sketches, designs of hanging gates with your own hands can be downloaded from many professional construction sites. There you will also find a list of specialized tools required for the manufacture of a particular type of gate.

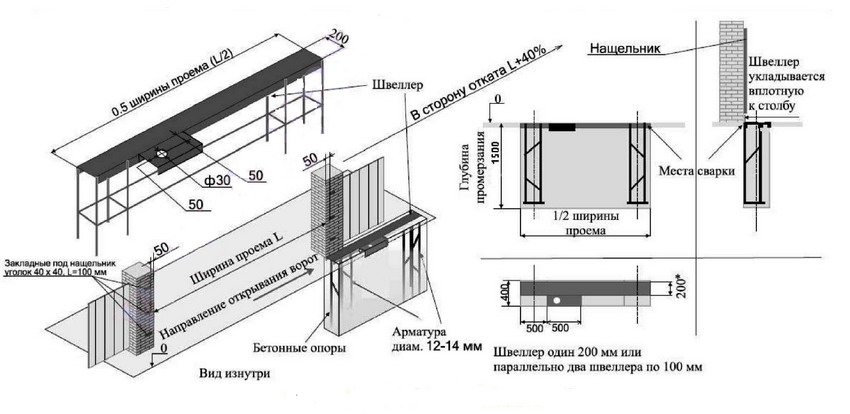

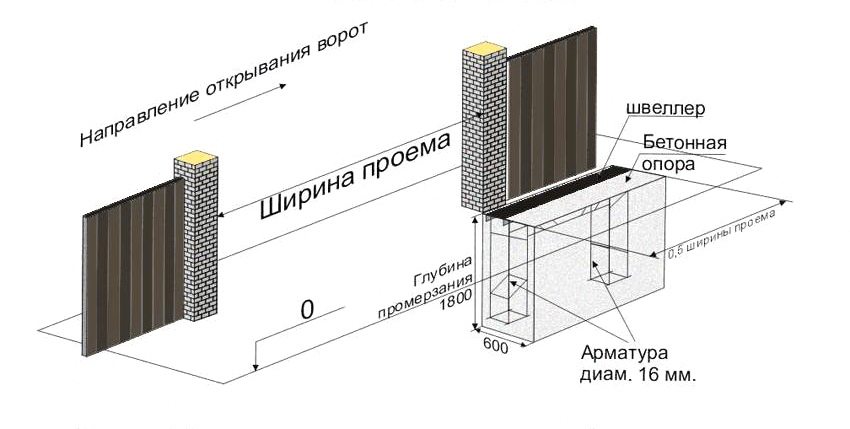

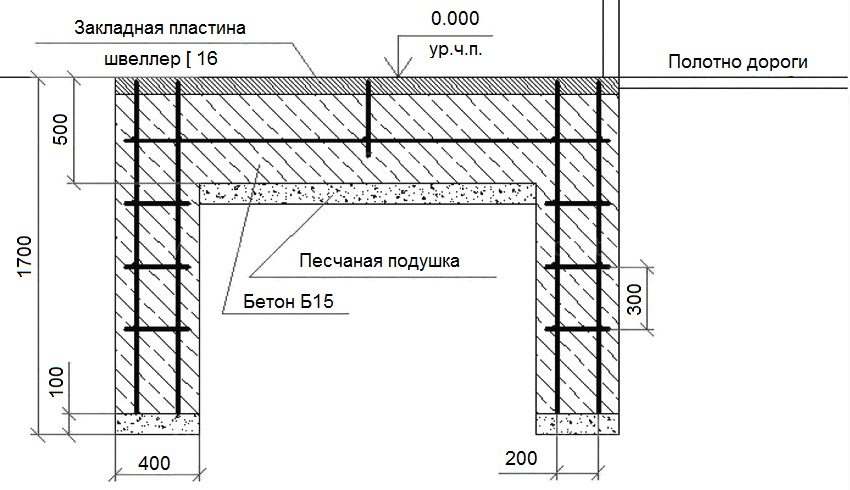

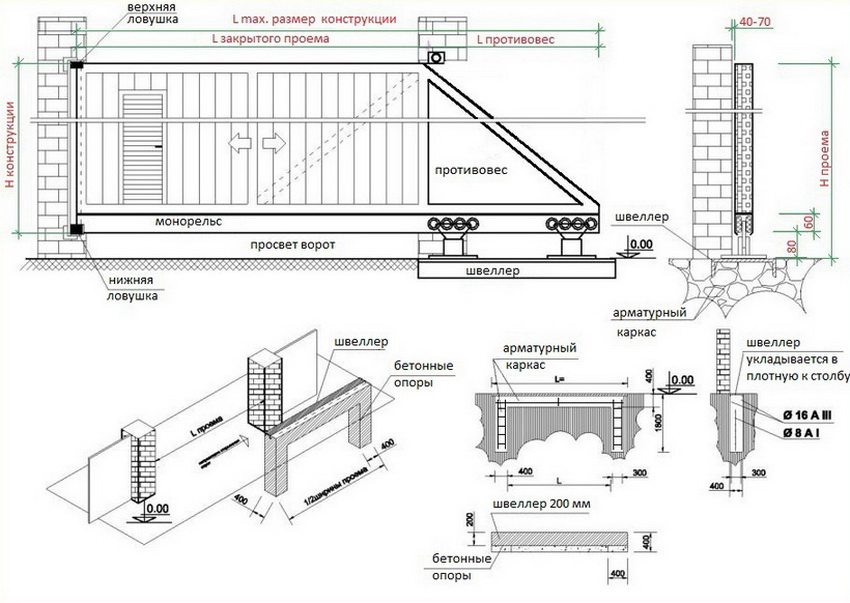

Foundation device

The first stage in the construction of the foundation is the marking of the pit. For this, a distance is measured along the fence of the site, which is equal to 1/2 of the width of the gate opening. The width of the pit for the concrete base is about half a meter towards the site.

If possible, it is recommended to use pillars as support pillars fence... Otherwise, a response post is mounted, the pit for which is located opposite the pit for the foundation, and on the opposite side of the opening. In the case of installing automatic gates, it is imperative to provide a place for laying the electrical cable. A metal or PVC pipe with a diameter of about 25 mm can be used as a casing.

Useful advice! The soil in the pit is taken out to the depth of soil freezing, that is, not less than 2 m.

The embedded element is made of a channel, to which the reinforcement pieces are tied from below. The element itself is placed in the pit so that the channel fits as tightly as possible to the post fence... The horizontal position of the channel parallel to the door opening direction should be checked with a level.

Concrete is poured over the embedded element, the level of which should be slightly above the surface of the element. After that, the concrete must be allowed to harden, it takes from 6 days. After the concrete foundation has solidified, you can proceed directly to the installation of the gate.

The method described above is the most common, but there are a number of other options on how to equip the foundation:

- Installation of a monolithic pile foundation - two reinforced pillars are driven into the ground, connected by a channel. This method is the most economical, as it does not involve the use of a large amount of concrete. For digging with this method, you can use the most common garden drill. The depth of the holes for the supports should be at least 2 m and 20-30 cm in diameter. Each of the holes should be located as close as possible to fence, and connect with each other with a small trench.

- Pile screw foundation. For its installation, it is not necessary to carry out earth and concrete work, it does not take much time. As the name implies, such a foundation consists of piles that are driven or screwed into the ground. In order for the piles to last as long as possible, they must be coated with epoxy or galvanized.

Gate installation

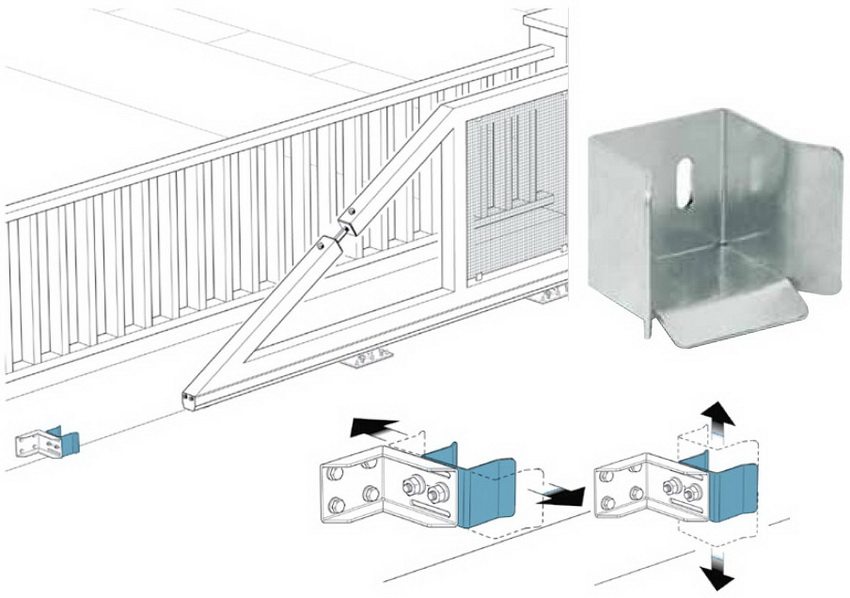

When installing the gate to the dacha with your own hands, you first need to do the markup. To do this, a lace is pulled along the line of the opening, indicating the trajectory of the sash movement. Then the adjustment pads are fixed.

After installing the platforms, you need to determine the extreme positions of the roller supports. To do this, you need to step back 15 cm from the edge of the opening along the embedded element and draw a tangent for the first trolley. The extreme position for the second trolley is calculated using the following formula: 100 mm is subtracted from the length of the door (with the console part) along the plane of the embedded element.

After carrying out all the calculations, you can proceed with the installation of sliding gates with your own hands, a video of this process, if necessary, can be found on the network. With the help of a welding machine, the adjusting platforms of the second carriage are welded, after which it is rolled into the opening and the sash is adjusted.

The sequence of actions looks like this:

- The canvas is removed from the roller carts.

- The carts are removed from the adjustment platforms.

- The pads are welded to the embedded element.

- Roller carts are fixed on the platforms.

- The door leaf is pushed onto the carts.

- Goal close.

- With the help of a wrench, finishing and final adjustment of the sashes is carried out.

In order for the carts to be properly attached inside the bearing profile, it is necessary to loosen the upper nuts at the points of their attachment to the platforms, and open and close the gate several times. If the sash moves freely enough, then the nuts must be screwed back. If, after that, the canvas moves with difficulty, then it is worth correcting the distortions of the trolleys in the perpendicular plane to the movement of the canvas.

When the blade movement is adjusted, you can begin to install the end roller. It is placed inside the support profile, fixed with fixing bolts, after which the element cover is welded to the door profile. It can also be bolted, but the welding will be safer in this case.

Useful advice! In winter, snow can enter the bearing profile, hindering the movement of the sash. To prevent this from happening, a cover of the bearing profile is welded on the inside of the door.

DIY drawings of sliding gates also imply the installation of an upper retainer with rollers.In this case, the rollers should grip the top of the web, and the bracket should be directed with holes towards the support post.

In some cases, for strengthening, the canvas can be sheathed with profiled metal sheet. Fastening the sheet to the canvas is carried out using self-tapping screws or rivets, the second method is more reliable. If you need to mount several sheets, then they overlap.

An important element of the gate design with your own hands (drawings, diagrams, sketches confirm this) is a catcher. The bottom catcher reduces the load on the roller carts when the gate is in the closed position. Therefore, it is mounted with the gate fully closed. The bottom catcher is brought under the end roller in such a way that its support surface is above the level of the end roller.

The upper catcher in the closed position of the door with its upper brackets must touch the protective corner of the front edge of the curtain.

Painting the gate

If desired, after installing the structure, the gate leaves can be painted in different colors. The paint must be durable and resistant to all kinds of adverse natural influences. In order for the paint layer to last as long as possible, the surfaces must first be cleaned with a grinder or sandpaper, and then degreased with acetone.

After stripping, the gate is primed. This can be done with a brush, roller or spray gun. The latter option is preferable, as it avoids irregularities and streaks. After priming, a paint coat is applied. After it dries, the staining is repeated. Different types of paint and under different weather conditions can dry from several hours to several days.

Diy drawings, photos and videos of sliding gates: selection and installation of automation

To install automatic sliding gates, you will need specialized electrical equipment. The choice of automation is a rather difficult question, since it depends on the weight of the structure, environmental conditions and many other factors. Particular attention should be paid to the following characteristics:

- The material of the gears in the gear - metal is the most reliable and best of all withstands harsh environmental conditions. In addition, they are characterized by their durability.

- Engine power reserve - in severe frost, the load on the engine is greater than under normal conditions, therefore, the power reserve in this case should be solid.

- Switch type - a metal limit switch can junk in the cold season, so for use in harsh climates, it is better to choose a magnetic one.

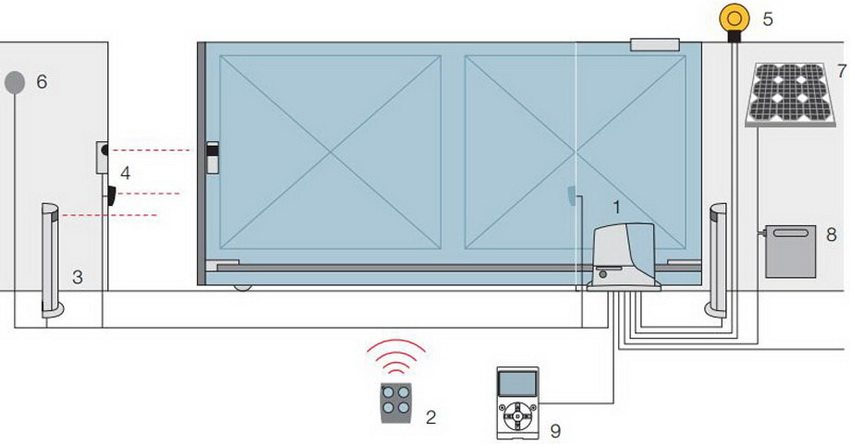

Automatic scheme for sliding gates: 1 - electromechanical drive, 2 - control panel, 3 - photocells on the rack, 4 - photocells, 5 - signal lamp, 6 - switch, 7 - solar panel, 8 - battery pack, 9 - O-View multifunction device

Another important parameter when choosing an automation is the sash weight. If it does not exceed 500 kg, then you can safely choose a drive for lightweight gates, and if it reaches 1 ton, then you need automation for weighted structures. A separate type of equipment is used for industrial gates.

Related article:

Do-it-yourself gate. Drawings, photos and videos. Description of the self-installation process. Advantages and disadvantages of swing and sliding gates, features of their installation.

As for the popular manufacturers of sliding gate automation, you can pay attention to the following companies:

- Came is a French manufacturer whose products are very popular in warm regions. In winter, ice can freeze on the gear rack and limit switches, so models from this company are not recommended for use in severe winter conditions;

- Nice - high-quality automatic equipment for lightweight gates. It is relatively inexpensive, characterized by durability and wear resistance under normal operating conditions. Internal gears are made of plastic, therefore, if the permissible weight is exceeded, they can very quickly become unusable;

- Faac - Italian automatic equipment for operation in all weather conditions. A distinctive feature is a large reserve of engine power, which allows it to function even in a harsh winter, as well as magnetic-type switches that prevent ice from freezing. The gears are made of steel and brass, so they boast a large margin of safety;

- An-motors is one of the most affordable electric motors with high quality. This automation is produced in Belarus, therefore it can boast of a democratic price.

Useful advice! When choosing a gate automation, rely on the maximum load on the mechanism, as well as on the harshest weather conditions in your area.

Self-assembly of automation is quite simple, since the kit includes installation instructions.

Review of finished models of sliding gates

If you do not have the time, desire or necessary skills to make a gate with your own hands, you can pay attention to a number of ready-made models from well-known manufacturers:

| Manufacturer | Features: |

| Hormann | Europe's largest manufacturer of garage and other types of doors, as well as accessories for them. Doors from the company are very popular and are characterized by a high level of reliability. |

| CAME Group | Doors from this manufacturer are characterized by reliability, safety and ease of use. The company's products are constantly being improved, and the model range is expanding. |

| ROLTEK | A domestic manufacturer of sliding gates, whose products are distinguished by affordable prices and high quality levels. One of the best manufacturers of doors and accessories on the market. |

| DoorHan | One of the favorites in the fencing market, specializing in the manufacture of a full range of spare parts for all types of gates. The company is actively developing and constantly improving the quality of its products. |

Do-it-yourself sliding gates: drawings, diagrams, design sketches. Advantages and disadvantages

Like any other design, sliding gates have their own advantages and disadvantages. The positives include the following points:

- Safe for people, especially small children.

- They are characterized by high values of strength and bearing capacity, as well as good rigidity.

- During the cold season, there is no need to clear the snow in front of the gate in order to open it.

Sliding gates for the entrance area can be made of metal, wood, corrugated board and have their own exclusive design

Negative sides:

- Most models do not have a wicket door, i.e. you can enter through such gates only by opening them completely.

- Sliding gates take up space from fence.

- It is quite difficult to choose the right type of guide grids, for this you need to carry out a large number of calculations.

You can talk about other advantages and disadvantages of sliding gates for a long time, but one thing is worth knowing for sure - this type of fence is quite reliable and takes up little space, which can be a decisive factor when choosing a beautiful and functional design for a suburban area.