Owners of private households, in order to protect their homes from the penetration of unauthorized persons and from prying eyes, frame the territory with a solid, strong and reliable fence. The best option is a concrete sectional fence, which has a number of distinctive advantages, attractive appearance and affordable cost.

Content [Hide]

- 1 Sectional concrete fence: product characteristics

- 2 Varieties of precast concrete fences

- 3 Pros and cons of concrete sectional fences

- 4 Characteristics of concrete fence posts

- 5 Caps on concrete fence posts

- 6 Installation of concrete sectional prefabricated fence

- 7 Installation of type-setting fencing

- 8 Decorative finishing options for a fence made of concrete panels

- 9 How to make concrete fence sections

Sectional concrete fence: product characteristics

The concrete sectional fence is a modular structure, the individual elements of which are manufactured using vibration casting technology. The working solution is prepared from cement with a strength grade of at least M500, pure river sand, fine gravel or granite filler up to 5 mm in size, water, colored pigments and modifiers. The resulting mixture is filled with special forms, which are located on a vibrating table, where a reinforcing mesh made of steel not lower than BP-1 is also placed. The solution is evenly distributed and compacted, which allows you to achieve a smooth surface of the products. The concrete must harden within 2 days.

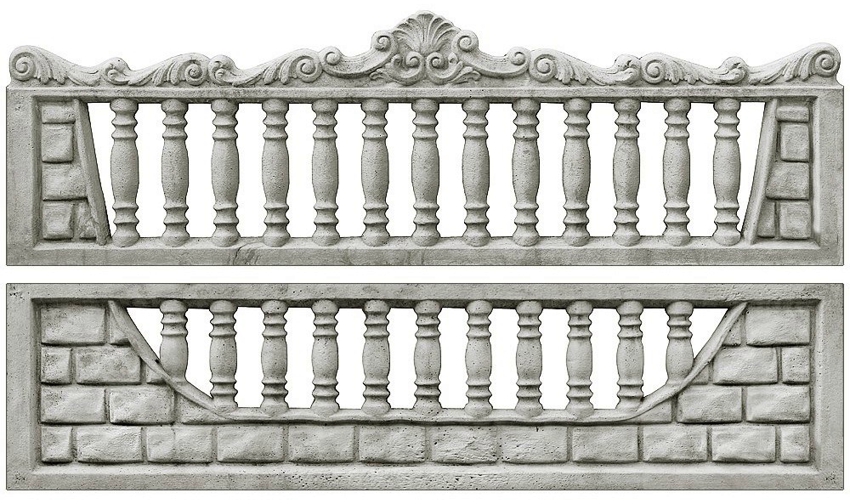

Fence concrete slabs can be made in the form of solid or lattice products or braids with voids. The sections are one- or two-sided. More than 300 types of products can be obtained depending on the forms used. The use of vibration casting technology allows to obtain durable products with an even smooth surface that does not allow moisture to pass through, providing increased frost resistance. The minimum service life of concrete sections is 25 years.

Modular concrete slabs are produced in a standard size of 50x200 cm. Upon individual ordering, products may have other dimensions. The weight of one element is 40-75 kg, depending on the thickness, which can be 4-6 cm, which affects the price of the concrete sectional fence. The cost of one plate can vary between 300-700 rubles. When installing the fence, the number of sections is selected based on the height of the fence. If the fence is installed for the purpose of dividing the territory or as a decoration, one or two sections are sufficient. A fence that performs a protective function must have at least 3 sections.

Varieties of precast concrete fences

Fences from concrete sections are produced in different designs and for various purposes. They are presented in five variations:

- Monolithic.

- Monolithic self-contained.

- Blocky.

- Typesetting.

- Euro fences.

Each of the types of concrete fence is subdivided into separate subspecies, where the products differ in the method of production, installation location and design, which also affects the cost of a concrete fence. A monolithic concrete fence is the most durable option. However, such a fence is very heavy, which complicates its installation. When installing monolithic sections, it is necessary to prepare a strip or columnar foundation, without which other fencing options may well do.

Important! For the installation of a monolithic fence, you will need to attract construction equipment.

Monolithic fences consist of reinforced concrete slabs 5 m long, 2.2 m high and 12 cm thick. The weight of one element reaches 3 tons. Plates in the manufacturing process are reinforced with plastic or metal fiber to increase the sound insulation characteristics of the product.

A monolithic self-contained fence is mounted without a foundation, which is carried out due to the presence of a wide base. It can be installed on a horizontal wide base or inserted vertically with spikes into glasses. Thanks to this feature, fences can be installed in places with a high level of groundwater. Such fences are not decorative. They can have a flat or ribbed surface. They are mainly installed in industrial areas.

Decorative, block and type-setting concrete fences

Block concrete fences are made from monolithic or hollow blocks. When installing such a fence, there is no need to use intersectional concrete fence posts. Concrete blocks are laid out according to the brickwork principle. The elements are connected to each other using cement mortar. The disadvantage of such fences is the need for decorative finishing of products using textured plaster or tiles.

Type-setting concrete fences are distinguished by high decorative qualities. Each set consists of 2-4 elements measuring 50x200 cm, which are made in different variations of texture and color. They can be homogeneous, with imitation of stone, wood or brick, contain images and patterns. Plates can be blind or through with an ornament. The sections are produced with a matte or glossy surface.

Euro fences are distinguished by their high decorative effect and good technical characteristics. Products are presented in a wide variety of textures, shapes and colors. You can choose options that mimic the look of natural stone, brickwork, wood or balustrade. The price of a decorative concrete fence starts at 500 rubles. for one plate.

Helpful advice! Eurofence can be purchased in a combined design using forging and decorative stone.

Euro fences can be one-sided and two-sided. The first option includes structures in which the texture or pattern is applied only to the front part. The reversible versions have decorative trim on both sides.

Pros and cons of concrete sectional fences

Fences made of concrete slabs are very popular among owners of private territories, due to the fact that they have a lot of advantages. Concrete enclosing structures are robust, reliable and durable. The products are equipped with a metal base, which is reliably hidden in concrete layers. Such a fence is capable of withstanding significant mechanical loads.

Concrete structures are characterized by increased moisture and frost resistance, resistance to strong gusts of wind, fire resistance. They are not subject to corrosion and decay. Sectional concrete fences are easy to install. They can be installed on any ground. Due to the mobility of products, the fence can be disassembled and moved to another place. The sectional structure of such a fence eliminates the formation of gaps. Such fences do not need special care and additional costs associated with their operation.

Thanks to the variety of product designs, a fence created from prefabricated elements can become a real masterpiece that will stand out with an individual and unique appearance, which is confirmed by photos of concrete fences. The sections are available in various textured designs. There are options with imitation wood, stone, forging, stucco molding, tiles. Various color variations can be selected to create interesting aesthetic compositions.

Note! The concrete sectional fence is suitable for any style of decoration of the local area, ideally combined with various finishing materials.

Among the disadvantages of concrete fences, one can single out the large weight of the products, which requires the involvement of special equipment for the installation of slabs or several persons with sufficient physical strength. Also, monolithic barriers are characterized by air tightness. They will block the light from nearby plants.

Characteristics of concrete fence posts

Support pillars are important structural elements of a concrete fence, which provide strength, reliability, resistance to mechanical stress and durability of the structure.

They produce solid and type-setting concrete fence posts. The first type is distinguished by its high strength and ability to withstand significant loads. The prefabricated posts are represented by hollow decorative elements that are strung on a metal base. They are connected to each other using concrete, which is poured into the internal cavity. Such products are highly aesthetically pleasing. Individual elements can have patterned or embossed decorations. The price of concrete pillars for a fence starts at 600 rubles. per unit of product, and the cost of monolithic supports starts from 700 rubles.

Support structures can be round, square, triangular or multi-faceted. Based on the method of securing sections to them, the pillars are produced with longitudinal grooves, metal hinges and embedded timber bars. The fixing option depends on the type of fence. When installing monolithic fences, mainly supports with groove joints are used.

For the fence, you can pick up monolithic pillars, devoid of aesthetic appeal, or products stylized as marble, stone, wood and other materials. You can make concrete fence posts with your own hands. To do this, you should prepare a frame made of wooden planks, into which a concrete solution is poured with mandatory reinforcement.

Helpful advice! For the manufacture of concrete pillars of circular cross-section, you will need a pipe of a suitable diameter.

Caps on concrete fence posts

On the pillars of a concrete fence, caps are often installed, which are also called covers, tips, tops or protective lights. They are made on special equipment using vibration casting technology. Frost-resistant additives are added to the working cement mixture, which increase the moisture resistance of products, and fiberglass, which increases the strength characteristics of the caps.

To obtain a certain color of the caps for the fence posts, special dyes are used, due to which the products retain their original appearance and rich color, without fading in the sun. Concrete caps on pillars protect the supporting structures from moisture penetration, which gradually flushes out the binder, erodes the seams, promotes the occurrence of deep cracks, thereby reducing the duration of the structure's operation, and it gradually collapses.

In winter, at negative temperatures, water crystallizes, increasing in volume, which contributes to the disruption of the integrity of the support column. The protective effect is achieved due to the inclined arrangement of the outer surface of the hood, which ensures free drainage of water. Covers for concrete fence posts have a decorative function, providing a presentable appearance of the fence. Products are presented in a variety of shapes and colors.

Important! Caps for concrete poles are susceptible to shock loads, which requires compliance with certain measures during their transportation.

Depending on the design, concrete parapets for the fence can be:

- pyramidal, with a large number of faces;

- spherical, which are distinguished by a large radius of a spherical part and large sizes;

- conical, which have a ribbed or smooth surface;

- made under the tiles.

The outer contour of the protective lights can be made in the form of a circle, rectangle or square. Products can be pitched, flat, ribbed, stepped, with peaks, decorated with balls.

Installation of concrete sectional prefabricated fence

Before installing a concrete fence with your own hands, you must correctly determine the number of concrete sections. The length of the products is 2.06 m. When calculating the number of sections, you should also take into account the cross-section of the support posts and the presence of technological gaps.

The first step is to determine the perimeter of the fence. Subtract the width of the gate, wicket and leaf supports from this value. Next, you need to calculate the number of supporting structures. Here it should be borne in mind that two pillars are dug in at the corners. The value obtained after subtraction must be divided by the length of each section. Thus, the total number of panels for the fence is determined.

When buying parts of a concrete fence, it is necessary to perform a test measurement of its elements by measuring the thickness of the slabs and the parameters of the mounting grooves. Before marking the perimeter, a trial assembly of the structure should be performed. The slabs are laid flat on a flat, dry area, so that they do not touch the ground. For this, bars or boards are used. On both sides, pillars are put on the sections with their feet up so that the ends of the concrete panels are completely inserted into the mounting grooves. The distance between the axes of the support pillars is measured, which will be the mounting dimension of the concrete fence.

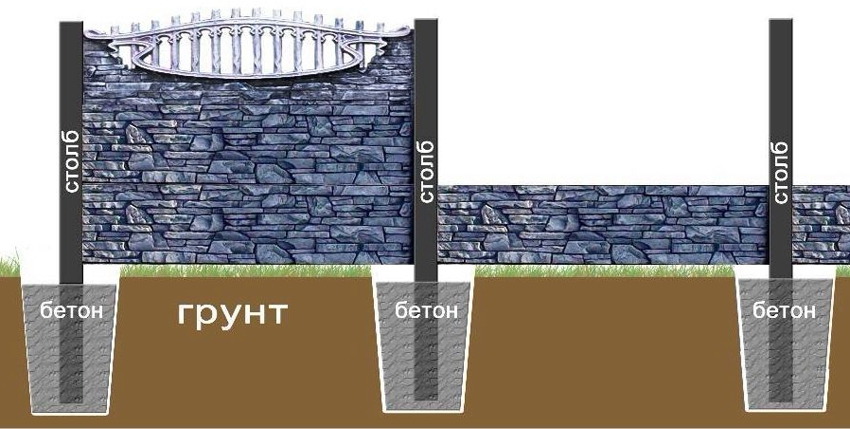

Before installing a monolithic concrete sectional fence, it is necessary to prepare the base, represented by a shallowly buried tape. For this, the territory is marked along the perimeter of the site to determine the dimensions of the sectional concrete fence. Further, a trench is dug out by marking. A sand cushion is organized at the bottom. Formwork is mounted in the trench. Next, the installation of concrete pillars for the fence is carried out. With the help of a building level, the verticality of the elements is checked. It should be borne in mind that there must be a distance of 2 m between the supports. The trench is filled with concrete.

Modular concrete slabs are inserted into the corresponding grooves between the supporting elements.When installing a gate or wicket, it is necessary to mount separate pillars to which metal inserts for the leaves will be welded.

Installation of type-setting fencing

When installing a type-setting concrete fence, there is no need to arrange a foundation. The territory is marked using a cord. Next, you should prepare wells for supporting pillars, which can be solid or prefabricated. The distance between them should be 2 m. The depth of each well is 0.7-0.8 m, the size is 50x50 cm. A cushion of rubble and sand is arranged at the bottom of the pit, at least 20 cm high, which should be tamped with water.

Installation of supports starts from the corner. Each support is deepened no more than 0.5 m with obligatory fixation with props. Free space around the support is covered with rubble. The element is reinforced with cement mortar in a 3: 1 ratio of sand and cement, which is done after the final installation of the fence. Slabs are inserted into the grooves between the supports. After installing each element, it is necessary to check how level the fence is. Immediately set up the first level of concrete blocks for the fence posts. After some time, you can move on to the second, which will eliminate the likelihood of its bevel.

The final stage of installing a concrete fence is the installation of concrete covers on the fence. First, it is necessary to clean the end surface of the column and apply soil to it. Then it is covered with a layer of glue mixture intended for outdoor use. A decorative cover is installed on the post, which should be located strictly horizontally. Before the binder hardens, the safety lantern should be immobile.

Important! When installing the hood, ensure that the product hangs over the support along the entire perimeter.

After the protective cover is fully fixed, decorative elements can be attached to its surface.

Decorative finishing options for a fence made of concrete panels

There are several options for decorative design of a concrete sectional fence. To do this, you can use tiles, polycarbonate or wooden inserts, forging elements, plaster or paint. Slabs of a concrete sectional fence, (the photo clearly confirms this), can be arranged under the texture of wood, chipped natural stone, imitate brick or masonry from logs, a lattice or a baluster. The spatial openwork structure, weaving from bamboo and vine looks original and unusual.

Related article:

Wrought iron gates: photos of elegant metal structures

Designs and their features. Varieties of forged gates and their photos. The choice of material, style and decor. Making a forged gate with your own hands.

A boring monolithic concrete fence can be painted in any color that can be combined with other landscape and architectural elements of the area. To do this, it is necessary to use special paints and varnishes, which consist of pigment and polymer components. Such dyes are characterized by environmental friendliness, wear resistance, excellent moisture-repellent properties, and resistance to negative environmental influences.

To paint a concrete fence, you can use acrylic compounds for concrete, water dispersion, latex, rubber paints, special silicone dyes. In order for the fence to be in harmony with other elements of the landscape, it is important to choose the right shade of paint for the concrete fence. Do not give preference to too bright contrasting colors. The shade of the fence should match the tone of the roof. If the buildings on the territory are painted in a warm palette, you should not choose blue or gray for the fence.

Important! To paint the fence, it is enough to use no more than three colors.

Prepare the surface before painting. It is cleaned of dirt and primed. Next, a special impregnation is applied to the concrete. The surface is painted with paint using a brush or roller, moving from top to bottom.

Helpful advice! The fence must be painted completely in one day so that there are no differences in tone.

After the first layer is completely dry, apply the second one.

How to make concrete fence sections

To make sections of a concrete fence, you will need a vibrating table and several forms. A concrete mixer is required to mix the finished solution. To obtain high-quality products with high strength and performance characteristics, it is important to correctly make a working solution. For it you will need concrete of the M400 or M500 brand. Sifted river sand without clay inclusions is used as a filler. It must be sieved twice before use.

The working solution is prepared in the proportion of cement, sand and crushed stone 1: 1.1: 2.5 when using M450 Portland cement. If M400 grade material is used, then the ratio of the components should be in a ratio of 1: 1.2: 2.7. The mortar is mixed in an electric concrete mixer. Water should be introduced gradually until a solution consistency is obtained that resembles thick sour cream. In order to make colored sections that will not need additional coloring, a special pigment must be added to the batch, in the amount specified by the manufacturer.

After mixing, the ready-mixed concrete is poured into fiberglass molds for concrete fences, which are located on a vibrating table to compact the mortar. For the production of slabs, two technologies can be used: exposure and instant stripping. In the first case, the mortar must remain in the molds until the strength gains, and in the second, the formwork is removed after the completion of the concrete compaction process.

The sections made by the exposure method are characterized by greater durability, absence of defects and high decorative qualities. Products made using the instant demoulding technology may have minor defects. Such sections are not very aesthetically pleasing. They are mainly used in the installation of fences for industrial areas, vehicle fleets and warehouses. At the stage of pouring, the sections are reinforced, which will make it possible to obtain durable and reliable products that exhibit increased resistance to mechanical and shock loads. For this, metal rods with a smooth or corrugated surface are used.

Concrete sectional fences are very popular due to their high technical and operational characteristics, ease of installation, a variety of textures, designs and colors of components. An indisputable advantage is the affordable price of concrete pillars and slabs, as well as the durability of the structure.