Any home workshop should be equipped with a vice. This simple tool makes it possible to perform a wide variety of operations. Vices have a wide or narrow purpose, depending on the variety and design. You can buy ready-made equipment or make a vice with your own hands. This article will tell you how to do this.

Content [Hide]

Purpose, installation and device of the vice

A vise is a very useful mechanical tool used to hold parts in place during machining. They are especially needed when it is necessary to rigidly and reliably fix the workpiece or set it at a safe distance.

The very design of the classic vise is two jaws. One of them is stationary and fixed on the body or on the bed, the other can change its position. The object is fastened between the jaws by compressing them using a locking mechanism, which consists of several elements:

- Metal lead screw with trapezoidal thread. The screw is set in motion using a special handle.

- Bases or slabs of cast iron or other heavy material to support. It can be made of steel or duralumin.

- Screw-fastened sponge. When the screw is rotated clockwise, the moving jaw approaches the bed. Thus, the part is fixed. When the screw is rotated in the opposite direction, the workpiece is released.

To fix the vise itself to the support, several methods can be applied:

- fixed installation in one place with continuous use;

- on a clamp, this assumes a less reliable fixation, but makes it possible to use it in different places;

- using suction cups - in this case, it is necessary that the surface is perfectly smooth and even.

Varieties of vise: which fixtures to choose for different jobs

There are several types of vise that are classified according to different parameters. One of the main identifying elements is the type of clamping mechanism. Based on this factor, the following types of vice are distinguished:

- screw;

- wedge-shaped;

- with installed diaphragm;

- eccentric;

- with pneumatic device.

Depending on the purpose, the vice is divided into the following types:

- carpentry;

- locksmiths;

- machine tools;

- manual.

Taking into account the material used, these devices are also divided into types. Joiner's vice for a workbench is most often made of wood, and locksmith's - of metal.

Interesting to know! Vices are also called yews - both definitions are correct. Construction dictionaries describe this tool as equipment for locksmith or carpentry work, used to fix workpieces during various types of machining (this can be drilling, planing or sawing).

A locksmith vise is the most common type of tool in question. These devices have their own subspecies, they differ in size, or rather, in the width of the jaws. This figure can vary from 63 to 200 mm. Small vices are used mainly for household purposes. They are fastened with a lower clamp screw on a small machine, but more often on a table or an ordinary stool. Larger vices are installed in industrial workshops and large workshops for the purpose of processing large parts.

Locksmith vices: price, features and varieties

A vise for locksmithing is a must-have item in any industrial workshop. Such equipment is necessarily present in the workshop of an experienced, self-respecting master. Moreover, depending on the shape, type of fastening and the material to be processed, they are divided into several types.

Pipe vise is used to fasten pipes or cylindrical parts.

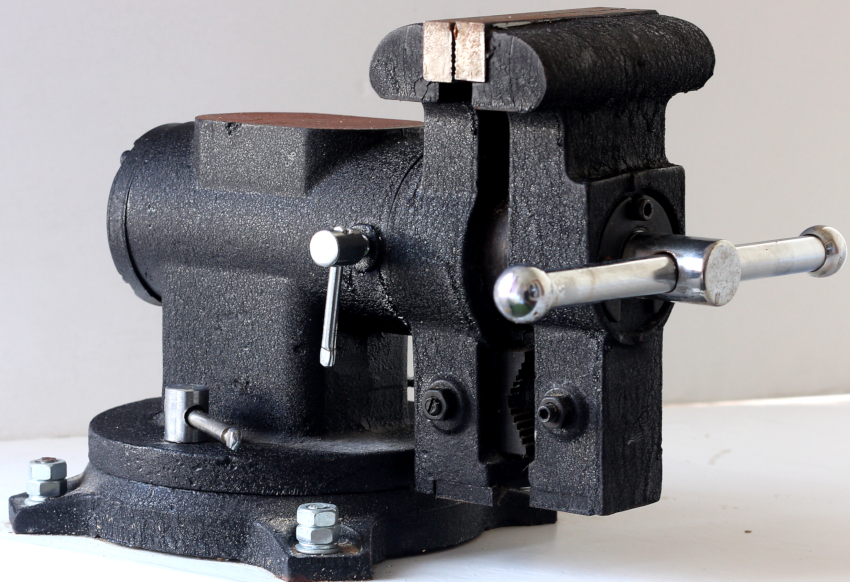

The main advantage of the rotary vise is the ability to fix the part in the required plane and at the right angle to organize the workflow. With their help, it is possible to process the most inaccessible parts and their areas. At the same time, it is almost impossible to do this on an ordinary vice. Like all installations of this type, rotary products can be stationary - these are bench joinery vices, which are attached to workbench tables. Another subtype is a vise with a built-in clamp for attaching to a table.

A vise for locksmith work is a necessary tool not only in the industrial workshop, but also in the home workshop.

Hydraulic vise is designed to provide more reliable fixation of particularly large parts. Clamping in them is carried out under the pressure of compressed air. Basically, such tools are installed in large industrial enterprises. The price of this type of joinery vice is high, and the device is rather complicated, so the tool is not intended for home workshops.

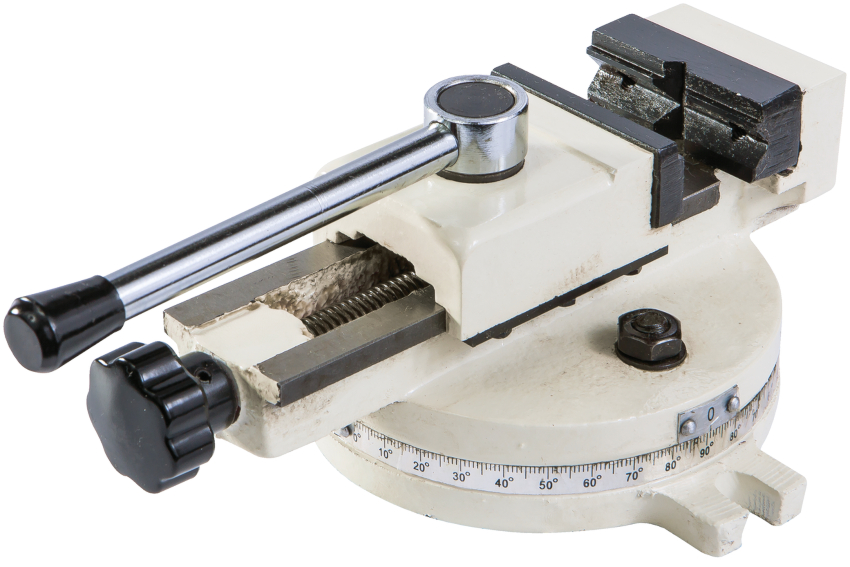

Self-centering vise is necessary in high-precision production, that is, wherever precise fixation of a part in a certain position is required. Typically, this type of vise design requires a bearing base.

Features and varieties of joinery vice

Joiner's vice is used for processing wood parts. This type of work is specific, therefore it assumes a special design of the tool itself, which is different from the device of a locksmith's vice. Most often, joinery vices are made from solid wood, and the fixing of the parts is done with wooden vise sponges. In this regard, they should be wider than that of a locksmith vice, in addition, they assume a significantly larger clamping area.

Joinery vice most often has one base, but with two guides. With their help, the movable jaw is held, which allows avoiding distortions. In this case, the guides can be an integral part of the workbench, or they can be removed if necessary.

Interesting to know! Even hand models of a certain design allow manipulation of elongated workpieces. For this purpose, a special wide anvil is used with the ability to mount the workpiece in a vertical position. Models are also produced for fastening round-shaped parts.

Joinery vices are also classified based on the technology used in the screw activation process. For this reason, they can be manual or pneumatic. If design features are taken into account in the classification, then the vice is divided into rotary and non-rotary.

As mentioned above, carpentry models are used to process wood and plastic blanks. Therefore, wooden parts are mounted on the jaws, which helps to avoid clamping marks. When the device is front mounted, there is a chance to work vertically with fixed parts.

Design and type of vise fastening: price and quality

A locksmith machine can be designed to be mounted on a workbench or table. For this purpose, special bolts are used. In this case, an all-metal vise design is obtained. Photos clearly demonstrate this.

Locksmith vice is designed to be fixed permanently on a workbench or on a table using a special bolt

You can also choose the option of the stationary or rotary type, which will make it possible to machine parts with the option of changing the angle. In this case, the width of the jaws will fluctuate in the range from 45 to 200 mm with the possibility of the jaw extending by 140 mm. The advantages of such equipment are the durability of the sponges, as well as a strong anvil, lightness and small size of the product. When it comes to a rotary model, it should be noted that it can be rotated 360 degrees. Do not forget about some disadvantages:

- during operation, the vise jaws require constant alignment of the position;

- the washers on the vice are distinguished by the presence of lock washers, which wear out quickly;

- it is difficult to clamp long workpieces;

- there is a backlash in the device.

Locksmith vices are divided into parallel and dining vices. In the first version, the jaw is displaced by the rotation of the vise screw, which is parallel to the stationary base.

The cost of a fully-equipped industrial vise is quite high, so it is better to make them yourself, especially if you have minimal knowledge and skills, as well as the necessary materials at hand.

Homemade vise: machine design and hand model

A machine vise is a more accurate version of a device for fixing parts. It is either completely devoid of backlash, or the magnitude of its run is the smallest. The vice is simply placed on the workbench. They differ in that they have a swivel mechanism.

The machine version has its own subspecies:

- stationary (with fixation perpendicular to the position of the vice);

- sinusoidal, where the part is installed at an angle;

- multi-axis, on which the workpiece can rotate in different directions along the axis.

Machine-type vise provides strong fixation, which is extremely important when processing metal parts. They have a robust body and are coated with an anti-corrosion layer. Clamping rigidity ensures high precision work. At the same time, if the clamping of the workpiece has curvatures, then traces will remain on it. For this purpose, you need a foil gasket, or you need to fix the part using only the upper part of the jaws.

Useful advice! The carpenter's vice, in comparison with other types of equipment, allows for better processing of parts made of soft materials, while with large products you can work in the same plane.

The manual model is a portable vise of a compact form that does not require stationary fixation on the base. They are designed for processing small workpieces and are of two types (based on design features):

- with jaws, screw and handles;

- a lever-type vise that resembles a locking mechanism pliers.

Such a vice is used to perform precise work, since they have a minimum level of backlash. The tool is designed for working with profiles made of aluminum and metal tiles, and also flat workpieces can be clamped on them. Therefore, if it is supposed to process miniature parts, it is enough to purchase or make a do-it-yourself manual vice at home.

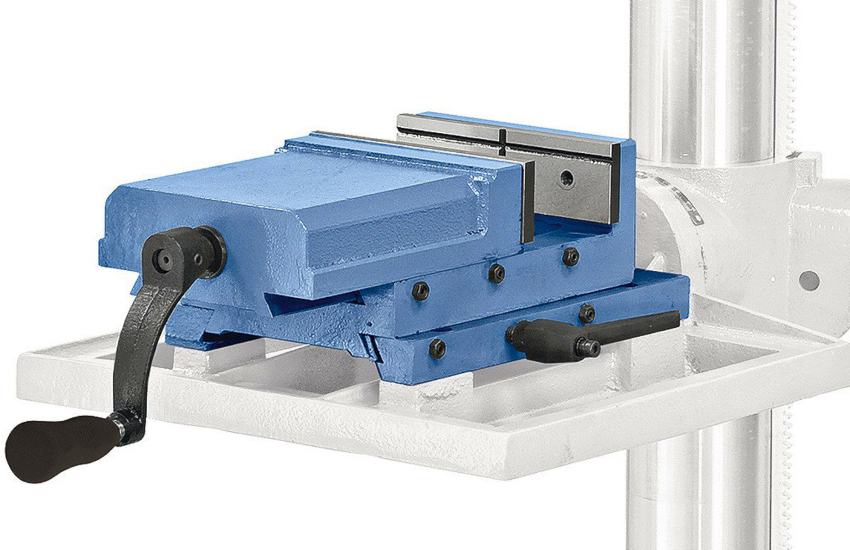

Drill vise: an integral part of the machine

The vise mounted in the drilling machine is not an additional part, but a necessary accessory to the installation. With their help, you can firmly clamp the part in relation to the machine chuck and perform the most accurate and even serial drilling operations.

When purchasing a vice for a drilling machine, you should immediately pay attention to the size of the jaws. Their width can range from 60 to 150 mm. Their depth and the indicator of maximum divergence are also important. Certain models of drilling vices have prismatic jaws that allow fixing workpieces and round parts.

A sub-type of vise for a drilling machine is a tool with an additional step, which allows you to fix a small-sized part so that a significant part is located above the surface of the drill vise jaws.

Related article:

A machine for sharpening drills and other tools: rules for selection and use

Main types, design, equipment. Machine tools for knives, discs, band saws. Homemade and factory options.

The main parameter is the distance between the grooves, which determines the possibility of mounting certain vices on the drilling machine. You can find models that have small ears instead of long grooves. Special attention should be paid to such a drilling vise.

The modern market offers a wide range of equipment of this type. It is best to give preference to the model with three-way installation. Such a vice can be easily installed not only on the edge of the lower level, but also on the other two. This feature makes them more flexible in their work. You can purchase a ready-made structure, and it is also quite affordable to make a vice for a drilling machine with your own hands.

How to make a homemade carpentry vise

Due to the variety of spare parts that the modern market offers, as well as thanks to the Internet, where you can find a large number of dimensional drawings, it is absolutely unproblematic to make a vice with your own hands. It should be noted right away that the price of a homemade tool will be an order of magnitude lower than the cost of a ready-made vice.

Useful advice! In order for the equipment to be convenient and to cope with the task at hand, before making a vice, it is necessary to select the dimensions in advance, think over the availability of tools and materials, and prepare blanks.

The first thing to consider when making a joinery vise is that the jaws must be made of soft wood to avoid damaging the soft parts.

To make the work as convenient as possible, the vice is screwed to the workbench.Then a simple furniture nut is attached to the fixed half for the subsequent screwing in of the stud. The latter, in turn, will be responsible for the mobility of the mechanism. The next step is to fix the washer on the movable jaw and attach the wrench to the handle. The sponge tips themselves can be made from plain plywood.

If you need to make a homemade vise for a drilling machine with your own hands, then you should mark the parts, and then cut out three identical beams. The frame is prepared from a thick board or from three sheets of plywood. On two fixed bars, two vertical holes are drilled, on the third - a hole for a hairpin, which acts as a clamping mechanism. Next, mount the nut in the timber.

A small patch with four holes for fixing is welded to the end of the stud. Next, the pin is screwed to the fixed jaw, and its end to the movable one. The finished structure itself is attached to the workbench.

Do-it-yourself bench vice at home: video, photo, diagram

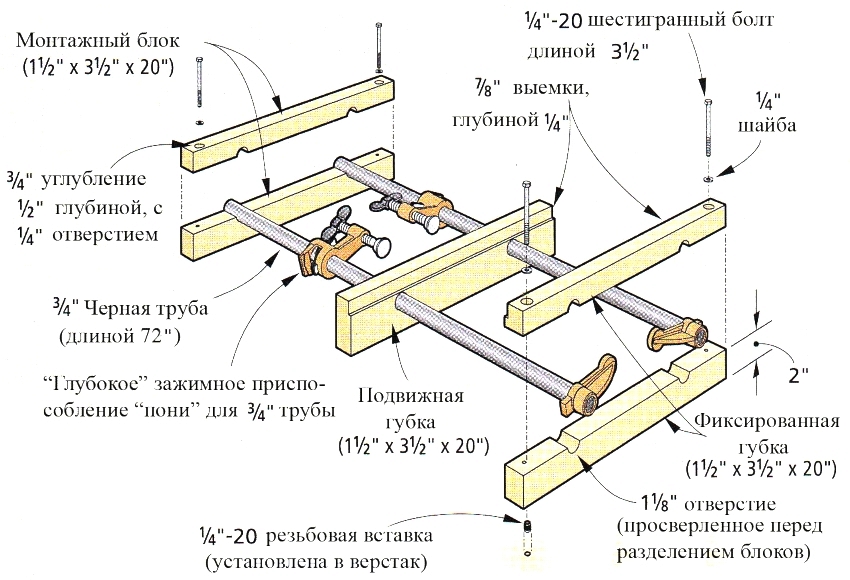

A subtype of joinery vices that can be easily made from wood are Moxon's vices, or bench vices, which allow fixing large and dimensional boards, plywood and panels. Moreover, they do not require a large area in the workshop, they are made of wood. To make a wooden vise with your own hands, you will need:

- hairpins - 2 pieces;

- nuts - 4 pieces;

- boards - 3 pieces.

Sequence of work:

- The boards are cut to the required size.

- Two holes are drilled in the fixed and moving parts.

- On a stationary part, nuts are inserted into the prepared holes, which are preliminarily greased with glue on both sides.

- On the edge of the hairpin, a knob is welded (for convenience) or a handle made of wood is attached.

- The bed for the fixed part of the vise made of wood with your own hands can be made in the form of a step.

- The finished product is attached to a workbench or to a special table. For fixing, you can use both bolts and self-tapping screws.

An important point in the manufacture of wooden vices is that the holes in the fixed part must be smaller than the nuts, which will prevent the nut from spinning in the hole.

Useful advice! Just like the joinery vice itself, you can make a workbench for them yourself. A do-it-yourself vise table is made in accordance with the required dimensions. In this case, the workpieces should protrude slightly beyond the support.

How to make a vise with your own hands from metal: materials and work sequence

Locksmith and milling vices are designed for working with metal, so a more reliable and strong material is required here. It is about durable steel or cast iron. At the same time, like wooden ones, you can make them yourself. The easiest way to do it yourself is to make a vice from a channel. To do this, you need the following set of tools:

- welding machine;

- electric drill;

- grinder with a circle for stripping;

- a square for the correct determination of the angles;

- drills of different sizes and diameters.

In addition, you will need the following materials and auxiliary means for making a vice from a channel with your own hands:

- blueprints;

- channel made of steel 6 mm thick;

- metal sheet with a thickness of 6 mm;

- corner 70x70 or 50x50;

- stud with a diameter of 16 mm, used as a clamping screw;

- bolts and nuts - 20 sets.

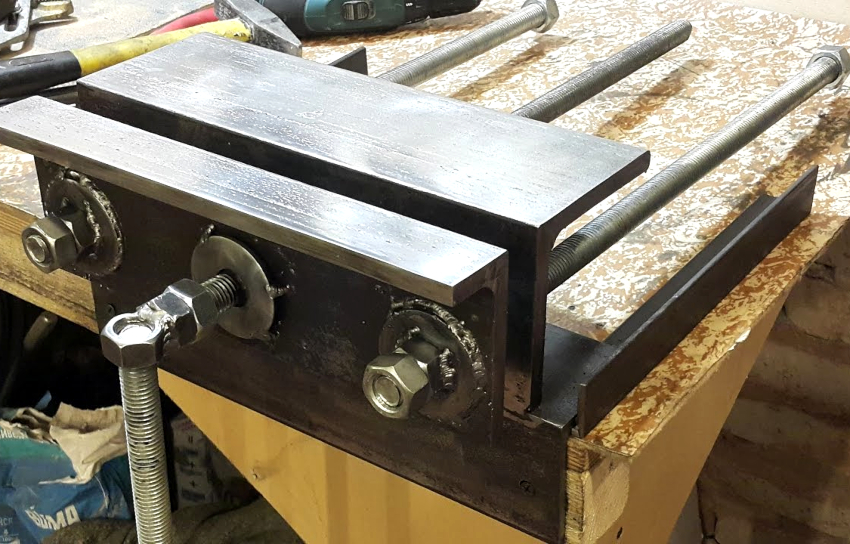

A couple of nuts, into which the screw is screwed, is not easy to do on your own; here it is best to use the services of a professional turner. The nut is welded to the channel as much as possible coaxially. The ends of the channel should be covered using pieces of metal sheets; a hole for the screw must be made in the strip.

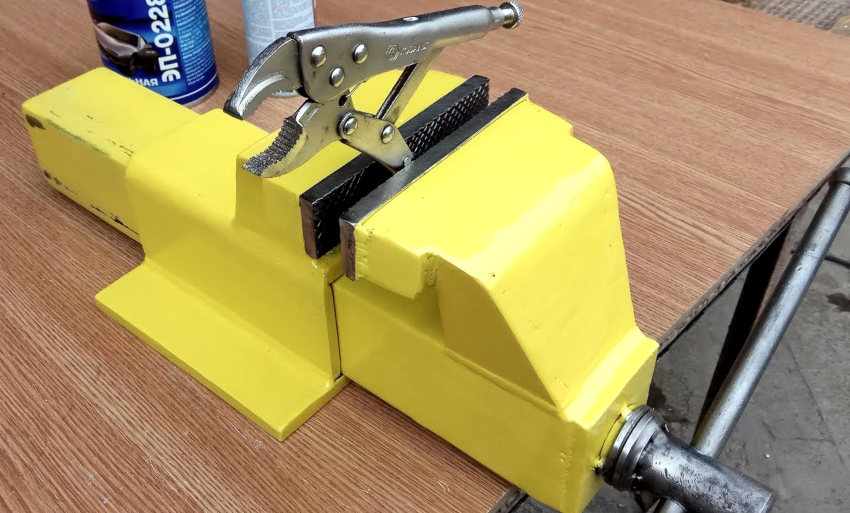

At the next stage, using a grinder, two corners and a plate are cut out.The finished corners are attached to the channel on both sides and covered with a piece of metal. Thus, a U-shaped structure is obtained, which is the basis of a hand-made vice from a channel.

To make the bed, you will need a sheet of metal 7-10 mm thick, in which four holes are drilled on each side, and 6 holes are made on the U-shaped element. One nut is welded to the bed, and two metal stoppers on the sides of it. They also make vise sponges with their own hands: they are cut out of steel. One part is welded immediately, and the second is attached to the moving part.

Do-it-yourself vise from the corner: step-by-step manufacturing instructions

You can make a machine vice from a metal corner with your own hands. This will require the same tools as for working with the channel, and the following materials must be prepared:

- metal corner 30x30;

- threaded stud;

- nuts for studs;

- small bearing.

A sample drawing of a vise from a corner can be found on the Internet. In accordance with the required dimensions, it is not difficult to make your own product. First, you should prepare two blanks by sawing the corner. Their size depends on the width of the drill bed. Next, two sponges are made from thick metal using a grinder and markings are applied along which holes are drilled to fix them to the base.

Useful advice! You can add an aesthetic look to the vice with paint. For this, a simple metal enamel is used.

Then you need to make a clamp with your own hands. You will need to take a part of the corner with a drilled hole for the stud. It is better to weld the bearing immediately. On the side opposite to the mounting with the bearing, it is necessary to fix the same corner and make a hole for the shaft. On the other hand, three nuts should be welded. For convenient rotation of the stud, a wrench is attached to the base of the nut. Such a vice will cost significantly less. In addition, knowing their device, you can independently repair the vice if necessary.

Experienced craftsmen know that it is quite difficult to drill and hold parts at the same time. As a result, the work turns out to be inaccurate, which affects the quality of the product. A vise of the appropriate type will greatly help to simplify the task. Using the recommendations given in the article, you can make them yourself. At the same time, such a vice will practically not differ in anything from those purchased in the store, but will cost much less.