HDPE pipes for water supply are made from low pressure polyethylene (hence the abbreviation) by continuous extrusion at the molecular level. This gives the material special properties that allow it to be used in wide areas of human management.

Content [Hide]

HDPE pipes for water supply: basic characterizing information, scope of use

Pipes, which are made from polyethylene at low pressure, are produced in five variations - SDR9, SDR11, SDR13.6, SDR 21 and SDR 26. The SDR indicator determines the degree of resistance to internal pressure. It is equal to the ratio of the outer diameter of the product to the thickness of the material of its wall. In this regard, increasing the wall thickness entails a decrease in SDR. That is, the lower this indicator, the stronger the pipe.

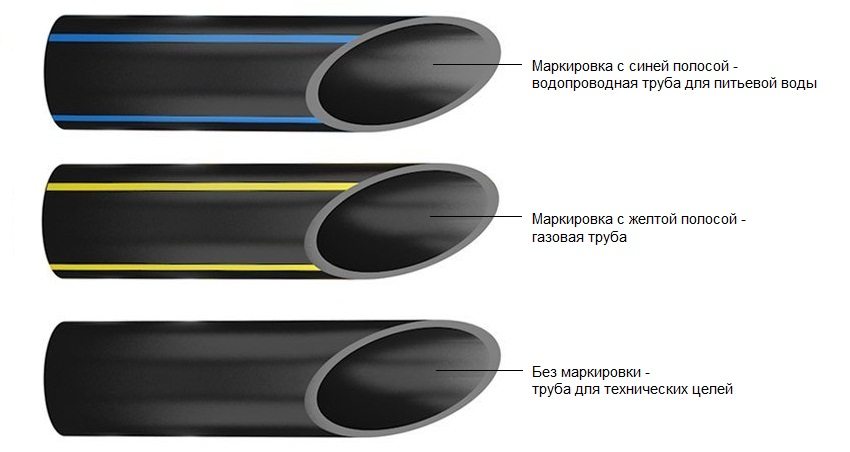

All HDPE pipes for water supply can be of two grades - these are PE 80 and PE 100. At the same time, PE 80 pipes are used for the installation of water supply and sewerage systems with a cross section of up to 90 mm, and PE 100 in main pipelines. In addition, the plastic used in the manufacture of pipes can be food grade and technical. The second is made from secondary raw materials, so its use in domestic water supply systems is not allowed.

Helpful advice! Be careful when purchasing pipes for organizing drinking water supply. They must be made of polyethylene, which is approved for contact with drinking water.

Manufacturers supply polyethylene pipes in coils of 100, 200, and sometimes 1000 m. In some cases, you can find products 12 meters long.

Polyethylene pipes are widely used in the construction and reconstruction of water pipelines, for the equipment of hydraulic structures and swimming pools, irrigation plants and artesian wells. Polyethylene pipes are used to transport various liquid and gaseous fuels in industry or in the domestic sphere.

Quality control of polyethylene pipes for water supply

All pipes produced are subject to strict quality control according to the following parameters:

- condition of the inner and outer surfaces of products. The walls must be absolutely smooth.Only the presence of insignificant longitudinal stripes and some waviness is allowed, which does not exceed the permissible deviation standards;

- inner, outer, and also end surfaces cannot have cracks, foreign inclusions and cavities;

- The water supply plastic pipe is only black. Longitudinal blue marking stripes can often be present, of which there should be at least three pieces. Their distribution around the circumference must be uniform.

Since the tightness of the water supply system depends on the quality of the material, it is worth paying special attention to this circumstance and purchasing products from only well-known trusted manufacturers.

What Makes Polyethylene Plumbing Pipes So Attractive

If we compare with some other materials for the production of pipes (steel, cast iron, asbestos), then polyethylene will surpass them in many respects:

- manufacturers give a fifty-year warranty period only for polyethylene pipes;

- a plastic pipe with a diameter of 20 to 110 mm wound in 1000-meter coils allows you to save all the consumables that are required for installing the pipeline, and also significantly speed up the process of laying the pipe;

- the use of thermistor fittings simplifies and speeds up the work of connecting pipes to each other;

- training of qualified welders who can work with polyethylene is much easier and faster than metal specialists;

- HDPE pipes for water supply are quite possible to mount repeatedly with low costs for re-installation. They can be easily disposed of and recycled;

- a polyethylene pipe can be pulled inside an existing old water supply system without even disassembling it.

Positive physical and chemical properties

Polyethylene possesses several chemical and physical properties that make its consumer properties attractive:

- chemical neutrality of polyethylene contributes to the absence of corrosion in contact with water or even more aggressive media;

- the material has a lower specific weight, which significantly reduces the cost of all production processes and transportation of products;

- very high elasticity (linear expansion up to 7.5%) allows the products to withstand not only minor ground movements, but even earthquakes. It was this circumstance that pushed the Japanese at one time to the production and widespread use of such pipes;

- ideal smoothness of the inner surface allows the use of thinner pipes while maintaining the hydraulic parameters at the same level as that of thicker steel counterparts;

- due to the low modulus of elasticity of polyethylene, the possibility of water hammering, as well as destruction when water freezes, is significantly reduced.

Polyethylene pipes also have several disadvantages: they are destroyed by ultraviolet radiation, deformed at high temperatures (more than 65 degrees), which makes it impossible to use them in the heating system.

Helpful advice! When using polyethylene pipes in industrial processes, do not run nitric acid solution through them. This substance is capable of reacting chemically with polyethylene, destroying the pipe walls.

Methods for connecting polyethylene pipes

It is customary to connect polyethylene pipes to each other in two ways: one-piece and detachable. One-piece connections are used when operating a pipeline at high pressures, that is, in trunk systems. In everyday life, mainly detachable connections are used.

One-piece connection method

In practice, the permanent connection of polyethylene pipes is carried out in two ways:

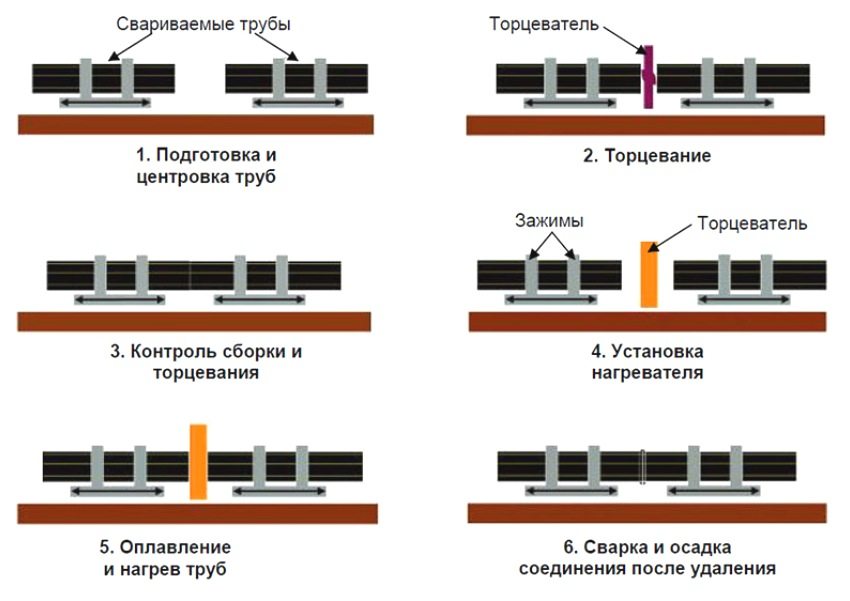

- butt welding with a polyethylene welding machine;

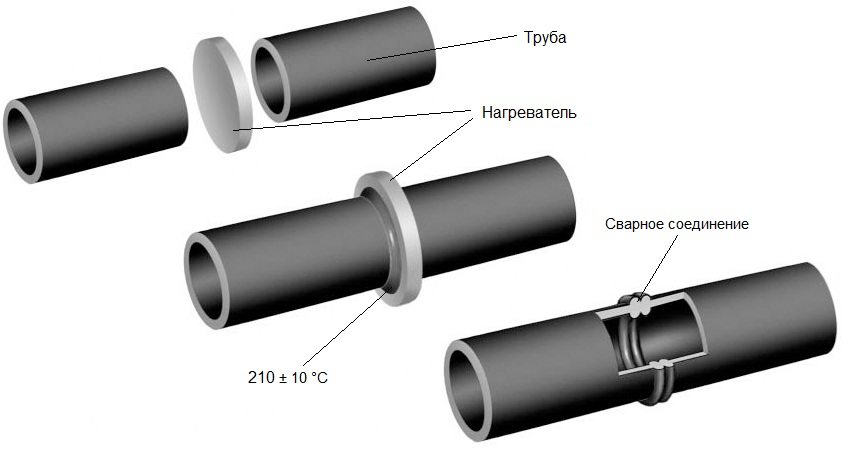

- use of electrofusion connectors.

Butt welding is the most complex technological process that requires trained personnel and special-purpose welding equipment.

Helpful advice! For butt welding to be of good quality, you only need to use one weld seam. It must necessarily be the same strength as the rest of the pipe.

With everything you need, pipe welding is very convenient, since it does not require the use of additional parts. It allows not only to connect two pipe sections, but also to qualitatively attach fittings to them.

With electrofusion coupling, a polyethylene electrofusion coupling with embedded electric heaters is used. Such a connection can withstand pressures up to 16 atmospheres. It is more expensive than butt welding, so it is used in cramped conditions where welding cannot be performed.

The use of detachable connections when installing the pipeline

The most common type of detachable connections are flanged. Their elements include: bushings that are welded to the end of the pipes, as well as metal flanges. Thin (less than 50 mm in diameter) pipe can be connected with compression fittings if flanges are not possible or beneficial.

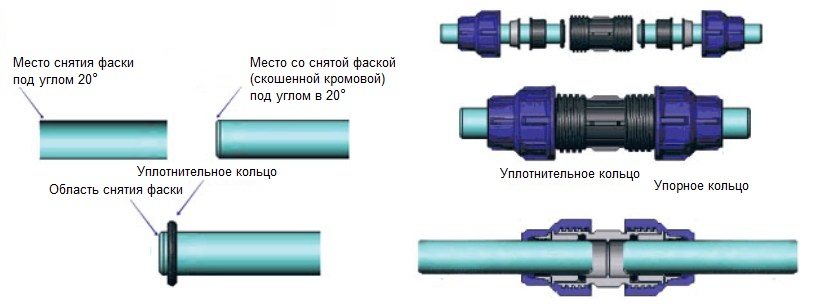

Installation of compression fittings when connecting pipes using the split method

Collet connections of the crimp type can withstand high loads (up to 25 atmospheres), which allows them to be used not only for joining pipes together, but also for connecting products from other materials to them.

HDPE pipes for water supply, connected correctly and competently, form a low-cost water supply system, which will not require repair for a long time and will not lose its original quality characteristics.