Artificial decorative stone is a common building material that is characterized by high performance and versatility. It is used for cladding interior and exterior work surfaces. Such material can be made independently at home. This article will talk about the benefits artificial stone, the peculiarities of its receipt and stacking.

Content [Hide]

- 1 What is artificial stone for decoration?

- 2 Advantages and disadvantages of artificial stone for interior wall decoration

- 3 Overview of types of artificial stone for wall cladding

- 4 How to make a mold for an artificial stone with your own hands

- 4.1 How to make artificial stone: silicone mold

- 4.2 How to make an artificial decorative stone from plaster

- 4.3 How to make a decorative stone with your own hands from concrete

- 4.4 How to make an artificial stone with your own hands from acrylic

- 4.5 DIY liquid stone: manufacturing technology on gelcoat

- 5 Features of painting decorative stone

- 6 Wall decoration with decorative bricks: the preparatory stage

- 7 How to glue a decorative stone: instructions

What is artificial stone for decoration?

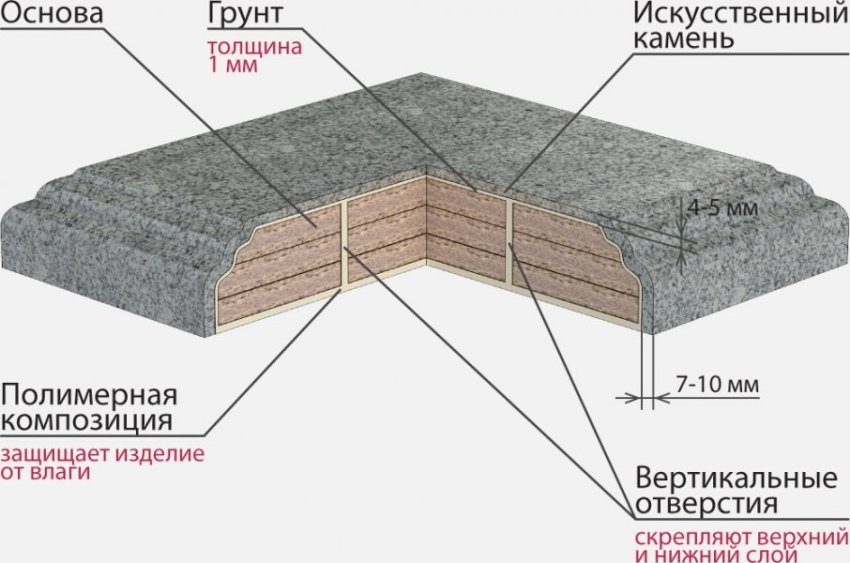

Today the range of stone for wall decoration is very wide. It can be easily purchased at hardware stores and markets. If necessary, this finishing material can be made by hand. The industrial production of such bricks is very similar to manual ones, since both cases involve the use of special injection molds.

You can decorate absolutely any room with artificial stone, it is important that the stone fits into the overall style of the interior, or becomes an interesting accent

Various materials are used for its manufacture. The most common of these are concrete, plaster and acrylic. For the subsequent processing of the stone, various technologies can be used: firing, glazing, etc. Liquid decorative brick, which looks like an uncured composition, is very popular. You can also purchase or make your own flexible type of artificial stone.

It is customary to use special plates for finishing external surfaces, which are characterized by low porosity and resistance to low temperatures. In turn, the stone for interior wall decoration is lighter, which facilitates its installation.

The ecological properties of this facing material depend on which components were used in its production. For example, cement and gypsum are distinguished by their natural properties, and their structure facilitates the penetration of air and moisture.

There are a lot of varieties in shape, size, color of artificial stone, so each interior can be supplemented with such a noble and luxurious finish

Helpful information! If acrylic is included in the decorative stone, it is not recommended to cover surfaces located in the immediate vicinity of heating devices. This is due to the fact that this material, when heated, emits harmful chemical compounds that can harm human health.

Artificial stone differs from the manufacturer at an acceptable cost, which undoubtedly makes it more popular among consumers than natural. If you choose a quality material or use the right components in its manufacture, then it will not be inferior to natural cladding.

Advantages and disadvantages of artificial stone for interior wall decoration

Decorative stone price per sq. meter ranges from 600 to 1500 rubles. The cost of finished products from the manufacturer depends on many factors, namely: composition, texture, color, etc.

An important advantage of artificial stone is its low cost compared to natural material, which makes it attractive for those seeking to manage their budget wisely.

Using an unnatural decorative stone for the walls, obtained on your own, allows you to save finances, as well as complete the required pattern or continuous installation without any difficulties. Such material has other positive qualities, which are recommended to pay attention to.

First of all, an artificial stone can be made independently in the same place where it will be laid. This eliminates transportation costs. Such a facing material is characterized by its small thickness and low weight, since it most often looks like thin plates. As a result, the overall weight of the structure is significantly reduced.

Decorative rock of unnatural origin is distinguished by good strength characteristics (especially if it has undergone additional processing). If necessary, you can make an artificial stone of any color. For this, the appropriate pigments are added to the mixture.

Artificial stone is in no way inferior in aesthetics, versatility, variety of assortment to natural material

The shape of the interior stone can be different. You can independently make both straight plates and plates with arbitrary dimensions. This property is very important, as it allows you to make cladding elements that are ideal for the installation site.

The mold for such a decorative brick can be purchased or made by yourself. On the construction market, you can easily buy products that have a very different texture (smooth, embossed). It should be noted that special polymer additives can be added to the composition of the mixture to obtain such a facing material. They allow you to make a flexible stone, which will allow you to change its shape even after laying.

From the point of view of decorative properties, artificial material is more acceptable. With the help of it, it is possible to cover not only walls, but also interior elements such as fireplaces, stoves, etc. However, in the latter case, it is necessary to select a material that has refractory qualities. To transform the appearance of arches, decorative stone trim can be used. Photos of such arched structures can be easily found on the Internet.

Artificial stone for decorative finishing does not need to be formed of complex structures from bearing profiles; it can be attached to the wall surface with glue

Helpful information! Due to its resistance to moisture, it can be used to organize ornamentation or solid construction in bathrooms.But in this case, it is recommended to pay attention to the composition of the artificial stone.

Self-made material does not need special care and can become a decoration for any interior. However, like any other product, artificial brick also has some negative sides. For example, a wild stone has a rather large mass. The surface for laying it must have high strength and endurance. In addition, products can have a rather complex, non-uniform shape, which complicates the selection of individual blocks during installation.

However, walls made of wild stone can decorate the interior of any room. It suits both classic and modern styles equally well. In order to determine the choice of material, you need to pay attention to the photo of a wild stone, since there are many of its varieties.

A variety of textures and a wide color palette of artificial decorative stone will suit any design solution

Overview of types of artificial stone for wall cladding

Such building material is classified according to two main parameters, namely: the method of production and composition. Depending on these criteria, decorative artificial brick is subdivided into:

- ceramic;

- plaster;

- concrete;

- polyester;

- acrylic;

- liquid.

Ceramic. The stone from this material is produced in several stages, and also undergoes a special heat treatment (firing). Self-production of such cladding is a rather complicated procedure, therefore it is rare. For production on an industrial scale, a rather large area and a large consumption of electrical energy are required.

Decorative stone made of gypsum polymer composition is a unique material, ideal for interior and exterior decoration works

Plaster. One type of decorative stone that is very popular in the modern construction market. It is carried out using special molds and casting technology. For making at home, as a rule, this type of decorative brick is used. However, the facing material made of gypsum is not resistant to low temperatures. Therefore, it can only be used for finishing interior surfaces in rooms with a temperature of at least +18 ° C.

Concrete. This kind of decorative artificial stone, depending on the components, is divided into two types. The first one includes ingredients such as cement and sand. It differs in a slightly higher cost than gypsum, but is also suitable for forming at home. Cement-sand facing material is resistant to low temperatures.

The second type of concrete stone is called monumental. The method for producing such products is called free forming. Thanks to this method, artificial boulders are produced for garden decoration, as well as whole concrete slabs.

Polyester. This type of wall decoration stone includes special mineral fillers. They differ in that they are able to pass into a solid state under the influence of high temperatures.

The stone containing polyester resin is similar in composition to acrylic analogues. It has good mechanical properties and surpasses even facing elements made of natural, natural materials in this indicator.

Note! Polyester resin is a fairly cheap product, so the cost of the finished product is low.

Among the disadvantages of such a building material, its specific smell should be noted. Over time, it erodes, but it is felt for a long time after installation.

Thanks to new types of artificial ceramic stone, there is no need to strengthen the walls, it can be easily laid on a plasterboard surface

For DIY manufacturing, polyester stone is not suitable, since the technology for its production is too complex. The process of forming products takes place in a vacuum under the influence of very high temperatures.

Related article:

Brick-like gypsum tiles: specifics of installation and operation

Styling methods. Features of working with various bases. How to make gypsum tiles with your own hands.

Acrylic. Manufactured by casting. It turns into a solid state without the use of high temperatures, therefore it belongs to cold-curing decorative facing materials. Has a presentable appearance. For clarity, it is recommended to study the photo of an artificial stone for interior wall decoration, made on an acrylic basis.

The scope of application of acrylic stone is practically unlimited due to excellent hygienic characteristics and the absence of pores in the structure

The process of forming an acrylic stone implies the same conditions as for a gypsum type. Differs in thermal plasticity, so there is a possibility of changing the shape of the finished material. Moreover, this does not affect its quality characteristics.

Liquid. A special kind of decorative artificial stone produced using a gel coating (gelcoat). Features of the technology for the manufacture of liquid stone affect the mechanical properties of finished products. It is also worth noting that cast decorative tiles are more resistant to temperature changes and moisture than liquid ones.

How to make a mold for an artificial stone with your own hands

The matrix for casting this decorative finishing material is not difficult to purchase in a specialized store. To save money, you can make such a template yourself. Another common reason for making a mold for a decorative stone with your own hands is the lack of the required type of facing material on sale.

As a basis for the matrix, as a rule, conventional patterns of decorative tiles are used. Sometimes the texture of the template is created using natural materials, which include not only natural stones. For example, templates made to imitate wood patterns are very popular.

There are two types of forms:

- homogeneous;

- complex.

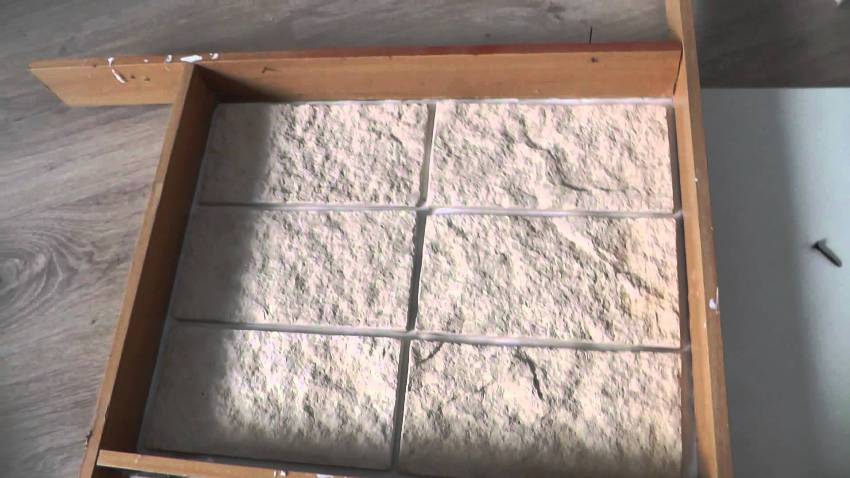

In the first case, the manufacturing procedure is less complicated. This is due to the fact that homogeneous matrices are smaller and do not require significant expenditure of silicone material. In turn, complex shapes allow the production of several finished tiles at once, which significantly speeds up the process. It is these matrices that are recommended to be used for making artificial stone on the wall.

Be that as it may, for the formwork you will need a wooden box that you can do yourself. Sometimes cardboard boxes are used for these purposes. When selecting or manufacturing formwork, one important rule must be remembered: the template must be designed a little larger than the original stone sample, both in width (10-15 mm) and in height (25-30 mm). This will allow you to achieve the required clearance between the products.

To complete the form itself, you will need a suitable material. To do this, you can use a silicone sealant or polyurethane. And there are also special sealants that consist of two ingredients and are sold ready-made.

How to make artificial stone: silicone mold

Silicone sealing compounds can be easily bought on the construction market or in a specialized store. As a rule, this mixture is sold in tubes or buckets. After the manufacture of the formwork, it is necessary to take care of the lubrication of its walls. For this purpose, you can use ordinary grease.

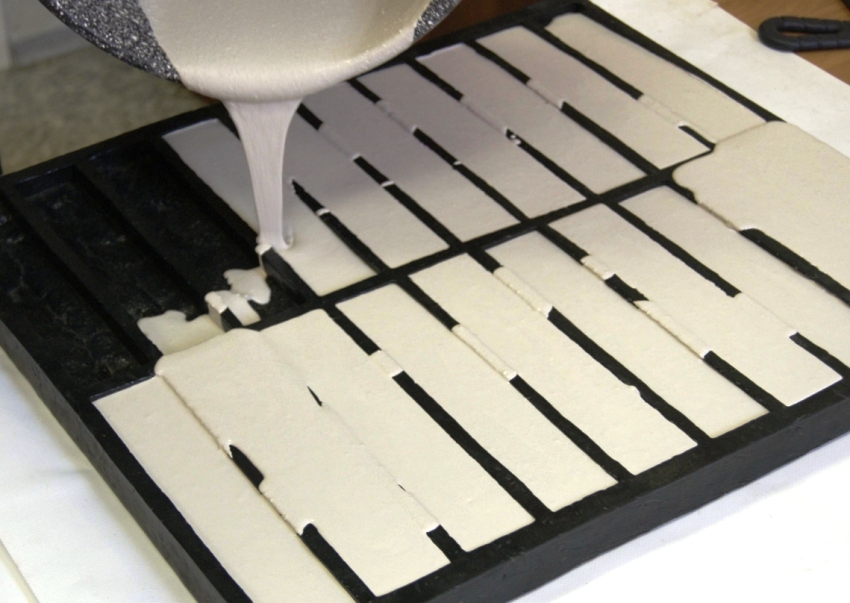

The material for the mold is poured carefully, slowly so that it can spread well around the workpiece and no air pockets are formed

Next, you need to take the original sample, according to which the template will be executed, and place it at the bottom of the formwork. As mentioned above, you can use ordinary tiles, stone or wood as it. Then solid oil is also applied to this sample. The fatty substance will allow you to easily separate the matrix from the product and will not spoil the shape pattern.

Note! If a gypsum element is used as a template for a stencil, then ordinary lubrication is not enough. Before laying it into the formwork, it is recommended to cover it with at least two layers of varnish. It is recommended to start making the matrix only after the varnish has completely hardened.

At the next stage, a soap solution is made. It is used to lubricate the tools (brush and putty knife) that will be used to dispense the silicone.

The silicone sealant must be evenly distributed over the entire surface of the facing specimen. During the formation of the matrix from this material, care must be taken not to form air pockets.

After filling the formwork with silicone, you can start leveling its surface. For this purpose, a second tool is used - a spatula. Then the mold for making the decorative stone is left for a while. This will allow the sealant to solidify in the formwork and acquire the desired shape for the sample.

It is worth noting that the longer the matrix takes to form, the better it will be. Its operational life will also depend on this. The approximate solidification rate of silicone is 2 mm per day. Thus, taking into account the thickness of the mold, you can easily calculate the time for which you need to leave the stencil. After the matrix is ready, it should be separated from the formwork and the artificial stone sample.

Even a pre-lubricated mold is quite difficult to detach from the rest of the elements, so it is recommended to slightly trim the contact points. If, after removing the matrix, shells remain on its surface, then this problem is solved with the help of an additional silicone composition. This is how a template is made for making an artificial stone. Photos of ready-made stencils will help you in their manufacture.

A do-it-yourself mold for an artificial stone is a great way to save on building cladding materials.

How to make an artificial decorative stone from plaster

To obtain finished decorative products, you first need to figure out how to make plaster at home. Before mixing such a material, it is advisable to immediately determine its volume. This is due to the fact that gypsum dough has a high setting rate. Therefore, its quantity must correspond to the number of forms. Consider what components are used to obtain a gypsum mixture:

- gypsum;

- water;

- sand;

- pigment.

Coloring powder is not used in all cases, but only when it is necessary to obtain decorative stones on the wall of a certain color. The process of mixing the composition itself is not difficult.

For the manufacture of artificial material, you will need special molds for the production of gypsum stone

First, you need to pour water into a previously prepared tank. Then you can start adding gypsum powder.The proportions may vary, but it is recommended that the amount of water be approximately 0.6 times the volume of the main component. Sand can increase the strength of the future finishing material, so it is advised to use it in any case. It should be no more than 10% of the total mass of the mixture.

Helpful information! It is recommended to use gypsum and acrylic products as facing stone for interior decoration. In turn, for outdoor use it is best to make concrete elements.

The amount of pigment can be different (from 2 to 6%). It is selected depending on what color you need to get decorative tiles. It is recommended to test a small amount of plaster beforehand to determine the shade.

Decorative gypsum stone has excellent properties and is therefore an irreplaceable material during renovation

To lubricate the mold, as a rule, a substance is used, which is made from turpentine and wax. The first component should occupy at least 70% of the volume, and the second - the remaining 30%.

After adding the last component to the mixture, it is distributed in forms and leveled with a spatula. The artificial stone production technology may include one more stage - vibration treatment. Thanks to this, the performance characteristics of the future tile are significantly increased. It is desirable to carry out such processing immediately after placing the mixture in the matrix.

Then you need to wait 15 minutes and remove the formed brick from the stencil. The final step will be to dry it outdoors. It is categorically not recommended to subject such products to heat treatment, since gypsum is not resistant to high temperatures.

How to make a decorative stone with your own hands concrete

For the manufacture of concrete finishing products, polyurethane or plastic forms are most often used. Consider what this type of artificial stone is made of:

- cement;

- sand;

- water;

- polymer resin;

- pigment.

The proportions for making artificial stone at home from concrete can be different. First you need to mix the above components. The proportions of cement and sand in this case are 1: 3. At the next stage, it is necessary to add water in such an amount that the consistency of the mixture reaches the state of thick sour cream. To give the cement mortar the required color, a small amount of pigment is used (2.5% of the total mass of the composition).

Now the resulting composition is distributed over stencils. At this stage, it is very important not to be mistaken. The mortar should fill the mold no more than halfway so that there is enough room for the reinforcing component. Often, to enhance the strength properties of decorative tiles, a metal net is placed over the cement. Then it must be poured with the remaining amount of solution.

Externally, artificial stone looks almost identical to natural materials, besides, the concrete that is used in their manufacture is many times cheaper than natural

Then it is necessary to compress the composition into forms by means of vibration. After vibration compaction, you need to wait at least 24 hours for the solution in the stencils to harden to the required state.

How to make an artificial stone with your own hands acrylic

To make acrylic decorative items, you will need an appropriate resin and special hardener. Consider what other tools and materials will be needed in the manufacture of artificial stone from these materials:

- electric drill (for mixing components into a homogeneous mixture);

- copolymer powder;

- ready-made or homemade lubricant.

Note! Using an acrylic base also allows you to make artificial marble with your own hands.Thanks to the combination of polyester resin with mineral chips and coloring compositions, you can get very beautiful elements for wall decoration.

The acrylic artificial stone contains polymer acrylic resin, natural mineral fillers and pigments to give the desired color

First of all, for the manufacture of decorative acrylic stone, you will need to mix polymer resin with a hardener. The proportion of these components in this case is 5: 1. It is important to remember that after obtaining a mixture of these ingredients, its amount should correspond to 25% of the total volume of the compound.

Next, you need to add a filler and a coloring pigment to the acrylic mixture, which will take up the remaining 75% of the weight. As the first, any mineral crumb (for example, granite) can be used. The texture of the future facing material depends on its size. The pre-selected pigment will give the color to the acrylic binder. The amount of dye in this case is 2-6% of the total volume of the mixture.

To obtain decorative bricks with your own hands, you will need to fill the matrices with an acrylic solution and wait about 24 hours. After this time, you can safely remove the finished tiles.

Making an acrylic stone with your own hands will not be difficult, the main thing is to master the technique

DIY liquid stone: manufacturing technology on gelcoat

Sure, cast artificial stones have better physical properties, but liquid ones have one advantage. Thanks to the gelcoat, it becomes possible to manufacture products that are complex in terms of shape. Such material can be done independently at home.

The components required to make such a facing material are quite expensive. Today there are two simple technologies for making this type of artificial stone:

- creation of facial composition;

- mixing the primer solution.

These methods differ from each other not only in composition, but also in the percentage of the filler. For the primer mix, you will need to take 20% gelcoat (based on the total mass of the solution). It is necessary to add one more ingredient - microcalcite, the share of which is 73%. Then 7% of an accelerator and 1% of a hardening substance are mixed with the above components.

Liquid stone is used in various fields, it can be finishing work, facade cladding, as well as the manufacture of sanitary ware

In turn, the facial composition will have to spend exactly 2 times more gelcoat, namely 40%. The proportion of accelerator and hardener in this case is also 7 and 1%. The mineral filler and colorant take up the rest of the solution. Solidification of liquid decorative stone occurs in 1 day.

Features of painting decorative stone

Today there are two common methods that allow you to change the color of a do-it-yourself decorative stone. The addition of special coloring agents is the most common method. Another option is to paint the finished finishing material. Some people perform this procedure after laying the veneer.

If everything is clear with the first method, then it is recommended to pay attention to the second. For painting finished stones for wall decoration, special iron oxide compounds are used. Their cost is fully consistent with the quality, which is quite acceptable.

Painting an artificial stone not only improves its aesthetic qualities after a certain time of use, but also provides anti-corrosion protection of the material

Helpful information! Experts recommend applying iron oxide paints using a special pneumatic spray gun. In the absence of it, you can use a regular brush, but this will complicate the work.

There are several rules that should be followed when performing this procedure. For example, the color of an artificial decorative stone should be lighter than the seams. It is strongly not recommended to use more than 3 shades for painting.

ABOUTwall decoration with decorative bricks: preparatory stage

Before you start laying the decorative stone, you must first prepare the wall surface. It should be not only strong, but also even, so that there are no problems with gluing the facing products. The permissible deviation in this case is 1 mm per 1 m of the wall. Masters are advised to adhere to this rule, regardless of the type of finishing material.

Before installing decorative stone, the surface of the walls must be thoroughly cleaned of unnecessary materials

Before you start decorating the walls with decorative bricks, you need to remove all old facing materials from them. These include the following: wallpaper, paint and plaster. To eliminate them, you can use a regular spatula. This tool is especially helpful when removing old wallpaper and paint.

Consider what tools and materials will be required for laying decorative bricks:

- glue;

- the reservoir in which the adhesive solution will be located;

- a spatula for applying glue to the wall;

- crosses for seams;

- building level;

- mixture for grouting;

- hydrophobic composition and a tool for its application (for example, a roller).

After acquiring all the necessary tools and materials, plaster the walls should be done. It is important to remember that in this case it may be necessary to install a reinforcing mesh, which will strengthen the base for the decorative tiles. However, such a measure is necessary only when the weight of the artificial stone is too large. For laying thin decorative stone tiles, there is no need to organize reinforcement. But in any case, you will have to eliminate wall defects.

If the surface has sufficiently visible defects and irregularities, then using plaster, you can easily eliminate them.

You will need to apply a primer to the wall surface. This will strengthen the surface and enhance the adhesion effect of the tiles. Experts advise to select a special primer for the plaster.

Preparing glue and sketching on the wall

This type of stone requires the use of a special adhesive. To prepare such a building mixture, you will need to use ready-made powder and mix it in a certain amount of water. As a rule, along with the glue, there is a detailed instruction containing not only the proportions of the components, but also the time it takes to make it. In turn, laying decorative stone for outdoor decoration is best done with a cement mortar.

You can also use liquid nails to mount a decorative unnatural stone. This mixture is capable of providing the necessary adhesion to the wall. Some masters even use cement mortar for indoor work. However, before applying to the wall, PVA glue is preliminarily added to it.

You can immediately buy a ready-made adhesive solution, which is diluted with water to the required consistency

Before you start laying decorative tiles with your own hands, you need to sketch a sketch on paper. He must take into account the area of the part of the wall set aside for a brick, as well as the following nuances: the presence or absence of a seam and the number of artificial stones. The best option is to transfer the sketch directly to the wall. This practically eliminates the possibility of mistakes when laying this facing material.

How to glue decorative stone: instruction

The laying of such a facing material is not particularly difficult, however, it requires appropriate care and accuracy.First of all, thick glue is applied to the wall. Its number should correspond to the width of the first row. After applying the adhesive, it is necessary to start laying the stone. To do this, each element is first applied to the wall, and then pressed down. Excess mortar released after pressing on the brick is simply removed from the wall.

Helpful information! If the laying of stone for the house is done end-to-end, then each next element must be tightly leaned against the previous one. To organize the required seam, there are special delimiting elements - crosses. If you need to organize a large distance between the facing products, then you can use drywall.

For laying decorative stone, you need, first of all, elementary skills and abilities, as well as a little creativity

The best starting point is the corner of the room. From it it is necessary to lay the tiles gradually, one row at a time. It is important to remember that it is better to glue the tiles from above, moving down. This will prevent the adhesion mixture from getting on the already laid elements. For cutting whole stones, as a rule, a regular grinder is used.

Some varieties of this decorative material are best glued to the wall with an offset. This simple action will allow you to achieve a more realistic result when finishing with artificial stone. Photos of various stylistic solutions will help you decide on the choice of colors and textures.

After laying this finishing material, you must wait a few days. During this time, the solution will completely harden and it will be possible to eliminate auxiliary elements. It is also advisable to prepare a grout solution in advance. It is made from cement-based adhesive paste and pigment substance. It is applied in two ways: with a special pistol or with a sponge.

At the last stage, it is necessary to wipe the tiles in order to eliminate the particles of the solution that got on them during installation. You can apply a hydrophobic composition to such a stone. Its use is recommended in cases where artificial material is placed in rooms with high humidity. After application, it forms a strong film on the surface of the cladding.

The technology is very similar to the process of laying natural stone for interior decoration. However, there are differences, since the structure and weight of the artificial material still differ from those of natural products.

Caring for this type of decorative elements is not difficult. All that is needed to remove dust and other contaminants is to wipe the tiles with a damp sponge.

Thus, artificial decorative stone can be purchased on the construction market or made on your own. The process of its formation is not complicated. But if you are not confident in your own abilities, then it is better to buy ready-made material.