The arrangement of the personal plot is carried out by various methods: sheds and gazebos are installed, paths are laid, flower beds and flower beds are broken. The finishing touch is the garden furniture. A garden bench with a backrest with your own hands is suitable for arranging a small recreation area: drawings and diagrams of beautiful structures, as well as recommendations for their creation, you can find in this article.

Content [Hide]

- 1 Types of designs and photos of garden benches

- 2 Do-it-yourself examples and technologies for creating garden benches and benches

- 3 Making garden benches from wood with your own hands in the ethno style

- 4 Do-it-yourself bench as an alternative to a bench for a summer residence

- 5 Drawings of benches for a summer residence with your own hands: photos and descriptions

- 5.1 DIY garden bench with a back: design drawings for two persons

- 5.2 DIY wooden bench: step by step instructions

- 5.3 DIY garden bench from scrap materials: the use of pallets

- 5.4 Drawings of a garden bench with a back made of wood with your own hands: "Transformer" design

- 5.5 Manufacturing technology of a transformer bench

- 5.6 The final stage of the construction of the transformer bench

Types of designs and photos of garden benches

The modern range of garden furniture is quite extensive. The classification of products is carried out based on the following features:

- specifications;

- material;

- functionality.

Photos of garden benches with your own hands, their functional side

The functional features of the furniture are valued along with their practicality and durability. All products are divided into two large groups:

- benches used exclusively for seating;

- multifunctional benches (the product can perform several functions - be a bench, rocking chair or table).

Useful advice! Use the unusual design of the transforming bench to save space in the garden. It can be easily converted into a writing or outdoor dining table.

Many homeowners install swing benches.To create them, materials of different types are used, and the structures themselves can be given an interesting shape. To make such a bench convenient to use, it is imperative to build a canopy on top of it. It will provide protection from the sun and precipitation.

A swing bench is a great option garden furniture

Benches with a backrest, which have a stationary type of placement, are popular for making their own hands. Most often they are made of concrete or brick, and a special place is selected for the installation. Such products are not afraid of the influence of the sun and moisture.

There are folding benches with small dimensions and a mobile design. They will come in handy if the summer cottage is rarely used. During the absence of the owners, the folding benches are removed to the garage for storage or to the house.

Photo of country benches with your own hands made of wood and metal

Metal products have the highest strength characteristics. They are reliable, durable and can be used all year round. Metal structures are unpretentious in terms of maintenance. It is enough to periodically cover their surface with an anti-corrosion agent, which will protect the benches from the harmful effects of moisture.

A bench made entirely of metal will have a very massive appearance, so modern designs are made using forged patterns. It should be remembered that for this you need to acquire a welding machine.

Most of the owners of suburban areas who decide to make a bench for a summer residence with their own hands prefer wood. This material becomes the basis for creating benches with a beautiful design, excellent performance and a warm texture. Regardless of the design of the garden or yard, wooden products can always harmoniously fit into the landscape.

Useful advice! Take oak or larch for work.

For protection purposes, the surface of the product must be coated with a varnish or paint. This will prevent damage to the wood from insects, fungi, mold, moisture and the sun. Using a lacquer as a finish will help preserve the natural grain of the wood.

Photo of benches with your own hands made of stone

If you prefer practical options for benches, you should pay attention to products made of stone. This type of material is notable for its low cost and long service life, and the structures are durable, reliable and aesthetically attractive.

The stone belongs to the category of materials of natural origin. Despite this, the designs of such benches will not always be able to support every design and style of the garden. On the site, stone elements must be present as an addition. The benches look especially advantageous against the background of a residential building, partially made of stone.

A good ensemble will be made of stone:

- steps;

- tracks;

- reservoirs;

- gabions;

- flower beds.

Supports for fences, gazebos and awnings can be made of stone partially or completely. If at least one of these elements is present on the site, stone benches will always be in place. However, it should be remembered that such products do not have a back.

Do-it-yourself photo of garden benches: successful homemade plastic and other materials

Plastic products have a number of advantages, which include:

- simplicity and low weight of the structure, due to which the transportation of the material does not cause difficulties, and the bench itself can be moved from one place to another;

- profitability;

- an extensive selection of color schemes, which allows you to make a product that will subsequently fit well into the garden design;

- practicality (collapsible structures are easily disassembled and placed in the trunk and are also easily assembled on site).

Useful advice! Use do-it-yourself garden benches drawings to create composite structures. You will be able to endow your product with positive performance characteristics that are inherent in each type of raw material used.

Combined combinations of materials different in texture, texture, color and origin are used not only for decorative purposes. The most common option is a combination of stone and wood.

Structures made of wood and complemented by stone or metal elements look original. In such projects, wood creates a soft and beautiful texture, while stone and metal are responsible for strength.

Do-it-yourself examples and technologies for creating garden benches and benches

Bench and bench designs have some distinctive features. Building a bench is the easiest way to organize a seating area in your garden. The product has no back and, unlike the bench, has a simple outer design.

A do-it-yourself wooden bench with a back can have a more complex decorative design:

- non-standard shape;

- armrests;

- a structure decorated with carved and forged elements.

Simplest ideas for creating garden benches

To liven up the design of a simple bench, you do not have to come up with a complex drawing and puzzle over creating additional accessories for the garden. It is enough to use two wooden boxes and several boards.

In this case, the boxes will function as supports. After making the bench, you can fill them with earth and organize a small flower bed. A seat is made of boards, which is installed between the boxes. The material must be sanded well with sandpaper, remove all irregularities and burrs.

Useful advice! From benches based on boxes, you can make a garden bench with a backrest with your own hands. It is enough to install the structure to the wall and nail several boards in the required place as a backrest on its plane.

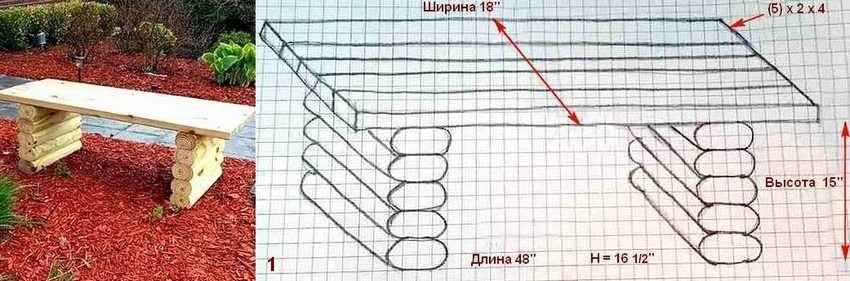

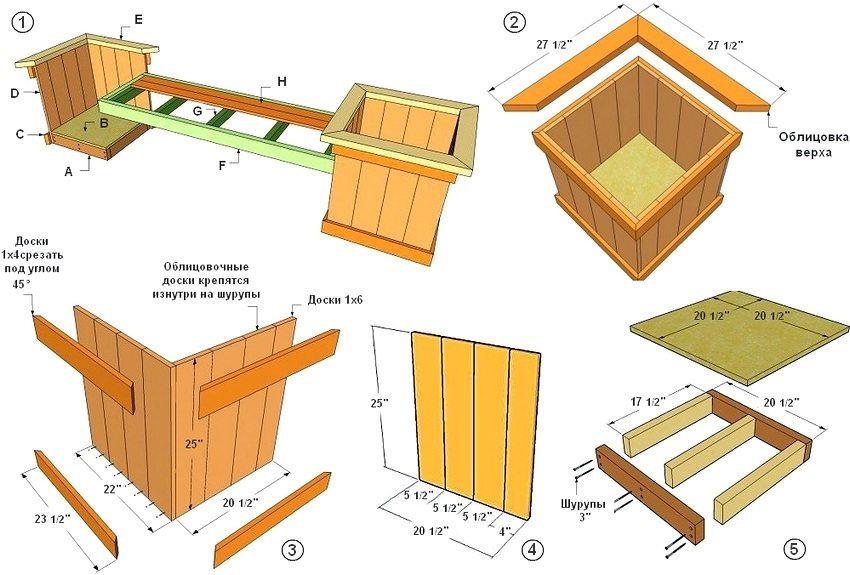

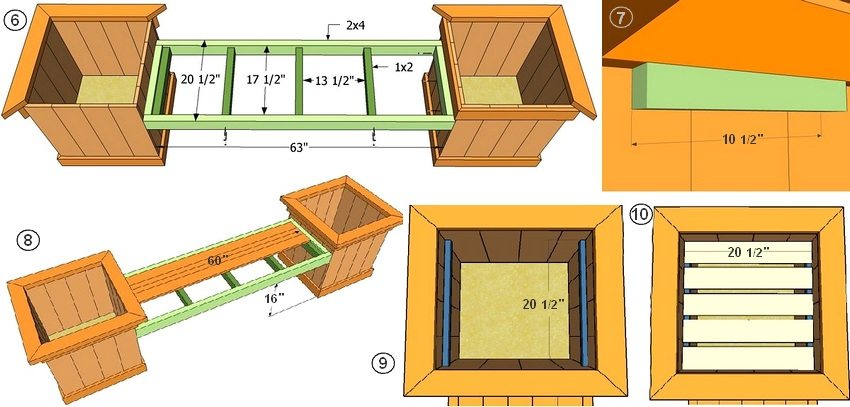

Figure: 1-1. Scheme of a bench with wooden boxes for flowers: 1 - design of a bench and calculation of materials: A - logs (2x4 boards 17 1/2 "long - 6 pcs., 2x4 boards 20 1/2" long - 4 pcs.); B - the bottom of the box (3/4 plywood 20 1/2 "x 20 1/2" - 2 pcs.); C - trims (1x4 boards, 23 1/2 "length - 16 pcs.); D - side lamellas (boards 1x6, 25 "long - 32 pcs.); E - trims for top cladding (2x4 boards 45 "long - 8 pcs.); F - seat frame (2x4 boards 63 "long - 2 pcs., 2x4 boards 17 1/2" long - 2 pcs.); G - transverse strips (1х2 boards 17 1/2 "long - 5 pcs.); H - seat (boards 1x4 60 "long - 5 pcs.); 2 - side facing; 3 - installation of the walls of the flower box; 4 - mounting dimensions of the box walls; 5 - diagram of the device of the bottom of the box for flowers

Wood structures have a certain drawback. The material itself requires constant care, and in this case, the tree also comes into contact with the soil, it is periodically necessary to water the plants. To make the bench more practical, wooden boxes can be replaced with concrete or stone pedestals. Concrete flower beds can be made independently or purchased at a store.

For the seat, use treated boards or half a round log. The choice of raw materials depends on the style of the garden or courtyard design.It is recommended to fasten the seat with metal corners, fixed to concrete using dowels, and to wood using through bolts or self-tapping screws.

Figure: 1-2. Scheme of a bench with wooden flower boxes: 6 - mounting dimensions of the seat frame; 7 - strengthening the structure of the bench; 8 - installation of the seat rails; 9, 10 - box installation

Vases with bonsai or ornamental bushes can be used as supports. The only, but very important requirement is that the container must be very strong. A hole is cut into the seat in the shape of a flowerpot in the place where the legs of the benches are usually located. The size of the hole must be large enough to create conditions for plant growth and maintenance, however, it must not exceed the size of the container. In fact, the plank seat is placed on top of the flowerpots and is fixed by the force of gravity and the weight of the seated.

Making garden benches from wood with your own hands in the ethno style

Ethno and rustic style design trends are often used in interior design. A country house, cottage or summer cottage is a great place to create an eco-friendly and natural corner suitable for family vacations. This design can be continued in the garden. To do this, it is enough to make a bench with a backrest with your own hands from logs (Fig. 1) and other natural materials.

Useful advice! For the construction of the structure, you can use logs with or without bark. To process the material or leave it in its original form - depends on your wishes and the design of the site.

DIY technology for making a country bench from a log

To form a seat, it is enough to saw the tree trunk lengthwise. This can be done exactly in the middle (in the diameter zone) or by moving the saw closer to the edge (in the middle diameter zone). The backrest is made from a thinner tree trunk, or you can cut it closer to the edge. As a result, this element should be thinner and lighter than the seat part.

Legs can be made from the remains of a log. They are connected to the seat part using metal pins. This is done like this:

- In the parts to be connected, holes are made for the pins in the appropriate places. The hole diameter should be slightly smaller than the fastener diameter.

- The pin is driven into one of the holes at about the middle of its length.

- On top of the free edge of the pin, the second connected part is pushed and also hammered. In this case, the blows do not fall on the pin, but on the wood.

The fasteners are hammered in with a sledgehammer or hammer. Since wood is a fairly soft material in structure, hammer blows can damage its surface. To avoid this, you need to place an unnecessary board under the tool.

The pins ensure a secure connection of all parts. To strengthen the fixation, 2-3 pins can be installed.

Ethno style in garden benches with a backrest with your own hands: additional ideas

In the ethno style, you can create a design with a non-standard performance. A highlight can be, for example, making a bench using curved branches of different diameters. Before assembling the product, these branches are processed and sanded. In other words, the bark is removed from them, and then the surface is sanded with sandpaper. An unedged board must be used to assemble the seat. It is handled in a similar way.

Note! All elements of this structure have rounded shapes, and the seat boards are facing forward.

If your summer cottage has a wicker fence, you can use the same design option with some changes. Short seat boards can be replaced with long ones by placing them lengthwise. The back is formed according to the principle of weaving from branches of medium thickness, which bend well.

You don't need to have any special skills to make a wicker back. You may not get a very neat result, but you don't need to. The back should be simple and unobtrusive, rough weaving will only increase its decorative properties. The branches can be placed tightly or, conversely, leave gaps between them so that your bench "breathes".

Do-it-yourself bench as an alternative to a bench for a summer residence

Despite the absence of a backrest, this scheme (Fig. 3-1) for making a bench looks quite attractive due to the peculiarities of the material from which it will be made. The structure itself has a very simple structure, so everyone can cope with the technology of its creation.

For the legs, you will need a rounded bar. If you have small diameter logs, you can save on purchasing material and trim them yourself. The original appearance of the bench is obtained due to the fact that the bars are stacked one on top of the other and fixed. The result is beautiful product supports.

Calculation of parameters and required materials

The bench height can be adjusted to suit your needs. This indicator also depends on the diameter of the timber that will be used in the work. To calculate the amount of material, you need to determine how many bars will be stacked one on top of the other to form the required height of one of the legs.

Dimension table:

| Product parameter | Indicator, cm |

| Length | 120 |

| Height | 38 |

| Width | 45 |

| Seat board (section) | 4x9 |

In our case, 5 bars are required, the length of which is 0.45 m. Calculation formula: 5x0.45 = 2.25 m. Based on this, for the construction of two supports, 4.5 m of timber (2.25x2) will be required. The seat will consist of five boards 1.2 m long.To make it, you will need the following amount of material: 5x1.2 = 6 m.

Figure: 3-2. The procedure for making a simple wooden bench: 2 - sawing wood for the legs of the bench; 3 - drilling holes in the details of the legs; 4 - preparation of boards for the seat; 5 - processing the edges of the seat parts

Useful advice! To round off the edges of the timber, you can use cutter or purchase ready-made profiled material. Its cost is higher, but profiled timber is much more convenient in work.

Initial stage: material preparation

To begin with, the boards for the seat are prepared. The material is cut into the required number of boards of the appropriate length and processed. Sharp corners should be rounded. Take advantage of the opportunities milling cutter or a sander. If you do not have such a tool at hand, it will be enough to sand the edges with sandpaper.

Figure: 3-3. The procedure for making a simple wooden bench: 6, 7 - marking the details of the legs; 8 - drilling holes at the designated points; 9 - applying a protective coating to the seat parts

Sanding with sandpaper is a long and laborious process. To make your job easier, you can order material grinding at a sawmill. After the boards are prepared, they need to be opened with a varnishing compound. It can be a completely transparent varnish or a tinted composition (the choice of a top coat depends only on you).

The bars, designed to form the legs of the bench, are tightly stacked next to each other so that their edges form a straight line. Use a pencil and square to mark the areas where the fasteners will be installed. The lines should be distributed along the entire length in increments of 7-10 cm.

Figure: 3-4.The procedure for making a simple wooden bench: 10, 11 - fastening the legs to the seat; 12 - view of the finished product

Assembling a wooden structure: mounting fasteners

Metal pins will be used as fasteners. An alternative replacement for them can be pins made of wood. For the installation of fasteners, holes are made, the diameter of which is slightly less than the diameter of the pins, and the depth is half the length of the pin.

To fix the parts, the fasteners will be hammered into one of the bars, and the next element will be pushed through the hole on top of it.

Useful advice! Assembling a structure using pins is a reliable method of fastening. To increase the strength of fixation, you can use an adhesive during installation, but this technique will make the structure non-separable.

The pin connection is also used in the process of creating, according to the drawings, a do-it-yourself garden bench made of wood, the design of which is equipped with a back. A quality result can be achieved only if all holes are located strictly one above the other. As a result, all parts during assembly should form an even edge line.

After drawing the marking lines, you need to measure the distance from the edge, which should be the same. It is recommended to create a template for these purposes. It is enough to take a piece of plank, the width of which is 1.5 cm. It will serve as a kind of limiter. In other words, the holes from the edge will be separated by a distance equal to the width of this strip. Apply the template straight along the edge line and mark the intersections with the perpendicular markings already in place.

Related article:

DIY metal garden benches: drawings and photos of structures. A detailed description of the technological process of creating a convenient structure based on a shaped pipe. Drawing of a transformer bench.

The installation of the pins should be staggered, so you should place the holes not at every intersection of the lines, but one after another. Holes are also made on the other side of the bar. They should be staggered in relation to the holes that were made earlier. As a result, when the legs are connected to the seat, there will be a pair of pins for each bar.

The final stage of creating a wood bench

From a technological point of view, the previously described type of connection can be considered correct. However, the scheme of its installation is rather complicated for a person who does not possess the necessary skills.

There is an easier way to fasten the structure:

- The bars are stacked on top of each other.

- The folded parts are fixed with clamps.

- Through holes are made at three points (in the center and at the edges).

- Through the holes, the parts are fastened with a long hairpin (do not forget to put washers under the nut and head).

After that, the seat boards are nailed to these legs (from above), or you can make a pin connection at this point.

Useful advice! To hide the placement of nails, prepare a concealer with a mixture of very fine sawdust and mastic intended for wood. Choose mastic to match the shop. Coat all joints with this mixture. After drying, the surface should be sanded.

When the assembly is complete, sand all parts. Their surface should be as smooth as possible. The topcoat can then be applied. For these purposes, use a varnish or wood paint intended for outdoor use. It is better if the topcoat is translucent. This way you can leave the natural pattern of the wood visible.

Drawings of benches for a summer residence with your own hands: photos and descriptions

The bench, due to the presence of the backrest, has a more comfortable design than the bench. You can lean on it and relax your back. The capacity of such products may be different, but usually do-it-yourself drawings of garden benches made of wood are drawn up for 2-4 persons. This is done for the reason that a long structure needs additional support. As a result, the process of creating a product becomes more complicated. In fact, there is enough space for 2-4 persons, so you can limit yourself to making the simplest structures.

The bench, due to the presence of a backrest, has a more comfortable design for sitting in comparison with a bench

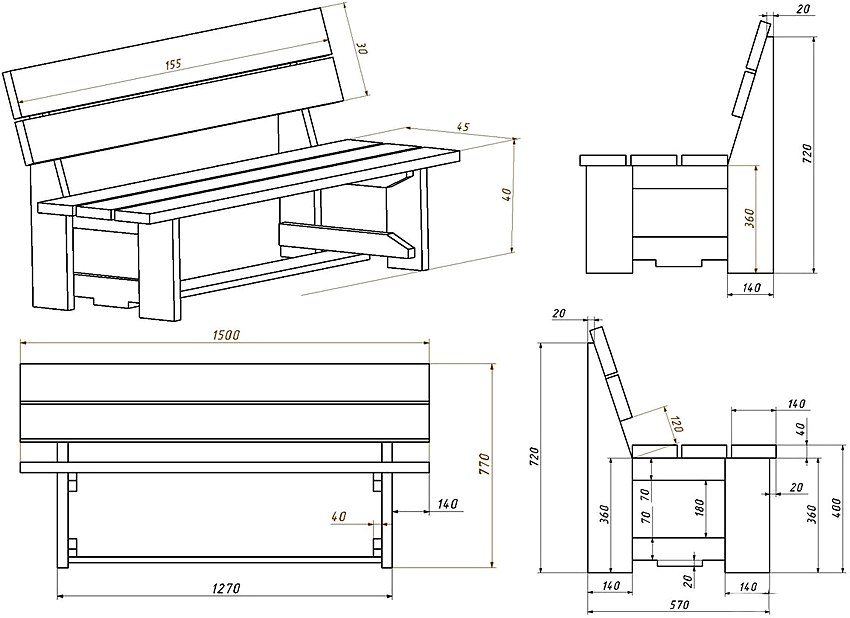

DIY garden bench with a back: design drawings for two persons

To make a do-it-yourself bench with a wooden back according to this project (Fig. 4), you need to acquire the following tools:

- drill;

- a set of drills;

- hacksaw;

- plane.

Note! The structure is designed for installation in a garden, balcony or terrace.

It will take you no more than one day to complete all the work on creating a bench. The main material will be a square block made of pine. The parameters of its section are 6x6 cm. You will also need "twenty" boards. Before cutting these boards, they should be sharpened until parts with dimensions of 5.8x5.8 cm are obtained.

DIY wooden bench: step by step instructions

Assembling a bench from pine blocks is carried out in the following sequence:

- using dowels and adhesive, we assemble the legs for the U-shaped sides. Then, using the same method of fastening, we fix the slats (5.8x2 cm) and projectile bars (3.5x3.5 cm) mounted on the sides;

- use a marker to mark the location of the response holes for the installation of dowels;

- connect the sidewall and the longitudinal rail. In order to mark the position of the sidewall, a 2 cm thick spacer should be used;

- fix all elements while drilling holes with clamps. This will allow you to achieve accurate mating between the connected structural parts;

- sand all parts well before final assembly.

The last stage of construction is the application of a protective agent and a top coat.

DIY garden bench from scrap materials: the use of pallets

An interesting design of a bench can be created from such scrap materials as pallets (Fig. 5). It can be installed not only in the garden, but also on the terrace and even inside the country house. Three pallets are required for work.

Manufacturing steps:

- one of the pallets is divided in half. These halves will later be the back of the product. Cutting must be done so that after assembly, the back and seat parts form a geometrically regular shape, and all the edges coincide;

- knock the other two pallets together with nails. We fix the backs-halves to them;

- a mattress of the appropriate size should be placed on top of the structure. You can use cushions from an old sofa, replace their upholstery first, or sew new ones. You can also place several small pillows on the back.

Using wooden pallets is a fun way to create an original garden furniture

Useful advice! You can leave the mattress quiet or secure it with straps. For more functionality, wheels can be added to the design.

Drawings of a garden bench with a back made of wood with your own hands: "Transformer" design

For the manufacture of the structure, you will need to purchase pine lumber.

Materials for work:

| Material type | Quantity, pcs. | Section size, cm | Length, cm |

| Board | 6 | 3x10 | 100 |

| Board | 2 | 3x10 | 32 |

| Bar | 4 | 3x6 | 80 |

| Bar | 2 | 3x6 | 50 |

Manufacturing technology of a transformer bench

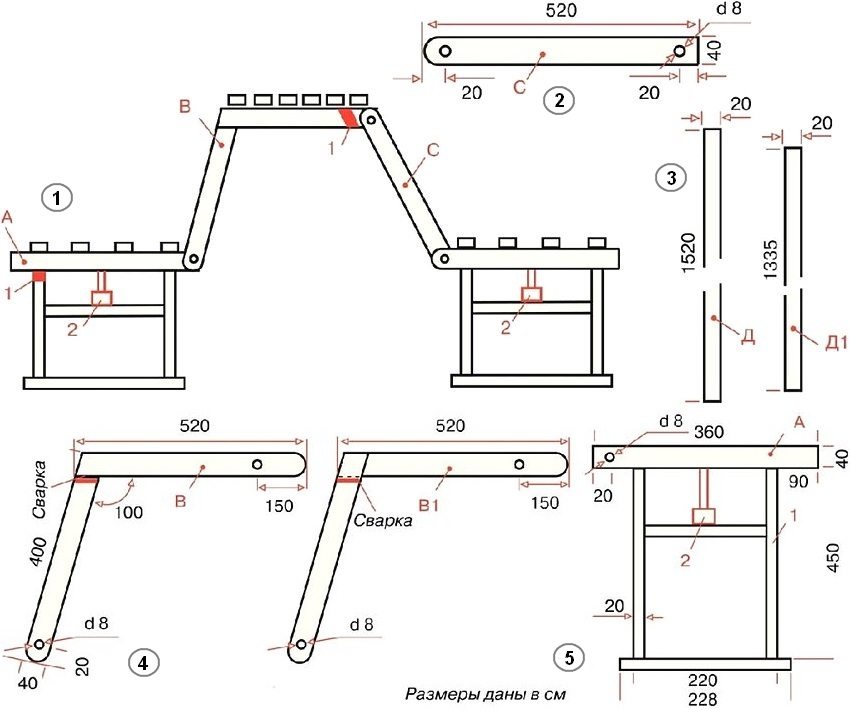

Following step by step instructions, you can create an interesting bench, the design of which can be transformed into a table with two benches (Fig. 6).

The main stages of making a bench:

- After creating the supporting parts according to the drawing, attach 3 boards to one of them. The seat will be formed from these boards. Do not forget to step back from the end part by 5 cm. 4 self-tapping screws must be installed in each board. Two of them will fix the seat to the support on one side, the rest are designed to fix the seat to the other support (on the other side of the product);

- for each nodal assembly zone, you will need to install 4 fasteners;

Useful advice! Apply wood glue to these areas when assembling. The adhesive composition will increase the fixing strength and durability of the entire structure.

- after all the parts are prepared for work, the legs with the backrest and seat support should be sawn from the end at an angle of about 75º. Using self-tapping screws designed for working with wood, connect the legs in pairs with the middle bars. The optimal length of the fasteners is 5 cm;

Figure: 6. Scheme of creating a bench-transformer: 1 - kinematic diagram of the transformer in the "table" position (1 - limiters of position B (pipe 20 × 20 mm, length 35-49 mm), 2 - support rod); 2 - detail C (pipe 40 × 20 - 2 pcs.); 3 - connecting jumpers (pipe 20 × 20 mm). D - for an external bench, D1 - for an internal one; 4 - parts B, B1 (pipe 40 × 20 mm). B1 is mirrored with respect to B; 5 - bench leg (4 pcs.), Where: A - steel pipe 40 × 20 mm, 1 - jumpers (pipe 20 × 20 mm - 4 pcs.), 2 - support rod

- then the back is performed. In the process of transformation, it turns into a tabletop. Find the longitudinal edge of the backing board. Its length is 32 cm. Here you need to attach three boards 150 cm long. In this case, the indent from the end in this case will already be 8 cm;

- boards are mounted so that a gap of 1 cm is formed between adjacent elements;

- in the support board, you need to make 3 holes, the diameter of which is 0.8 cm. It is better to perform this procedure in advance. These holes will be used to fix the bench back in a horizontal position.

The final stage of the construction of the transformer bench

To create the axes of rotation, make 2 holes in the top of the rear leg. The backrest will be fixed to the base of the product using a pair of M8 bolts.

One of the holes made will be axial, the other will be regular. To simplify the operation of the bench, equip the bolt in the area of the axial hole with a nut with 6 faces; for the second, a wing nut is suitable. She should bend her antennae. Due to this simple manipulation, the fastener can be turned off / on without the use of additional tools, but only by hand force.

Upon completion of all work, you need to check the structure for performance. Tilt the backrest and bolt it in place. Remove the fastener from the hole and move the backrest to a horizontal position. To fix it, place the bolt in its original place and secure with a nut. The structure is completely ready for operational use.

When creating benches, you can experiment. The main thing is that the product is durable and practical.