Before starting construction, it is necessary to develop the appropriate documentation. This also applies to the construction of a gazebo with your own hands: drawings and dimensions, diagrams, sketches and projects of future buildings will give a clear idea of the shape of the structure, the materials required for construction, the location of all structural elements. A complex of graphic documents will allow you to calculate the cost of construction and avoid unreasonable financial costs.

Content [Hide]

- 1 Types of gazebos for self-construction

- 2 Diy gazebos: drawings and dimensions, diagrams, sketches and designs of structures

- 3 Wooden gazebo with your own hands. Photos and drawings of structures

- 4 Do-it-yourself metal gazebo. Photos, drawings and diagrams of structures

- 5 DIY polycarbonate gazebo. Photos of original models

Types of gazebos for self-construction

The appearance on the construction market of various materials with unique properties made it possible to move away from the usual models of arbors and give various non-trivial forms to light structures. The functions of modern gazebos have changed in many ways and today they are not just pavilions where you can relax, but also full-fledged summer kitchens or cozy guest houses.

Due to the ease of erecting gazebos from current building materials, many can assemble and install the building on their own. The complexity of such construction largely depends on the type of gazebo with your own hands. The photo confirms the variety of shapes and purposes of lightweight structures.

Given the various characteristics, the gazebos can be divided into several groups:

- open - easy to build, used mainly for summer vacations;

- closed - solid structures with walls, doors and windows. Can be used both in summer and winter;

- portable - seasonal demountable structures that are easy to dismantle and can be installed anywhere.

The list of materials used for the construction of gazebos is quite diverse. It can be products made of wood, metal, glass, plastic, stone, brick, as well as their combinations. Also very popular arbors from scrap materialswhere any, sometimes the most unpredictable, raw materials are used: glass and plastic bottles, wooden pallets, tree trunks and much more, depending on the imagination of the craftsmen.

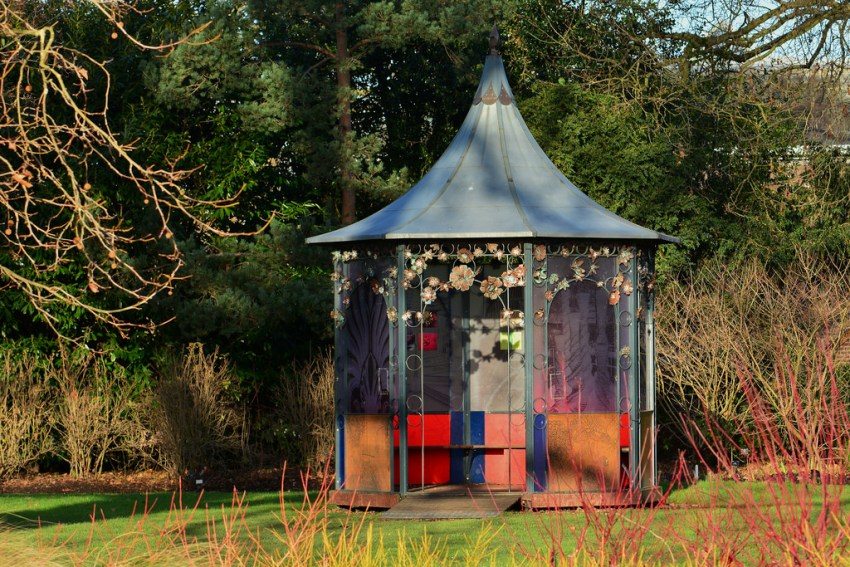

Closed gazebo made of wooden multi-colored boards

The shapes and sizes of the gazebos are chosen taking into account the dimensions of the site: if the area is small, then a structure of weighty dimensions will look inappropriate. As for the configuration of buildings, these can be structures of a square, rectangular, round, hexagonal, octagonal shape, as well as the construction of any other complex models, including in the form of a hemisphere.

Helpful advice! If you are doing the construction work for the first time, use the recommendations, photos, do-it-yourself arbor drawings posted by users on the Internet. This will help to avoid possible installation errors.

To cover the roof in gazebos, slate, corrugated board, cellular and monolithic polycarbonate, flexible tiles and other materials are used. Given the plasticity of many coatings, roof structures can be made in different ways: single slope, multi-slope, spherical, domed, hipped roof, arched and multi-level. Arbors with living climbing plants act as roofs and walls are quite common.

Recently, functional gazebos have been gaining popularity, serving as summer kitchens, with barbecues, barbecues or fireplaces. The presence of such equipment imposes certain requirements on the technology of their construction, observing which you can build gazebos with your own hands. Drawings and dimensions, diagrams and projects, sketches and ordinal plans for laying stoves will facilitate the construction of a building as much as possible and help to accurately calculate the cost of construction.

Arbor made of wood with equipped swing bench

Diy gazebos: drawings and dimensions, diagrams, sketches and designs of structures

How to build a gazebo with your own hands? Projects, photos, drawings of structures of various shapes and designs are available in countless numbers on the Internet. But you can develop your own individual version yourself. For those who are not sure that they will be able to competently prepare all the schemes or who have chosen a too complex design, it is recommended to use ready-made drawings.

Drafting a gazebo includes several stages: creating a sketch of a future building and drawing up working drawings. Schemes and sketches will make it possible, already at this stage, to plan the location of the gazebo in relation to the site, outline the arrangement of furniture and equipment, fix the places for supplying communications and determine the consumption of building material.

Some recommendations will make it possible to draw up a working draft as correctly as possible:

- choose the type of structure: open or closed;

- carefully think over the design of the gazebo, which should correspond to the style of the existing buildings and are determined with the materials of construction;

- choose a place for future construction on the site;

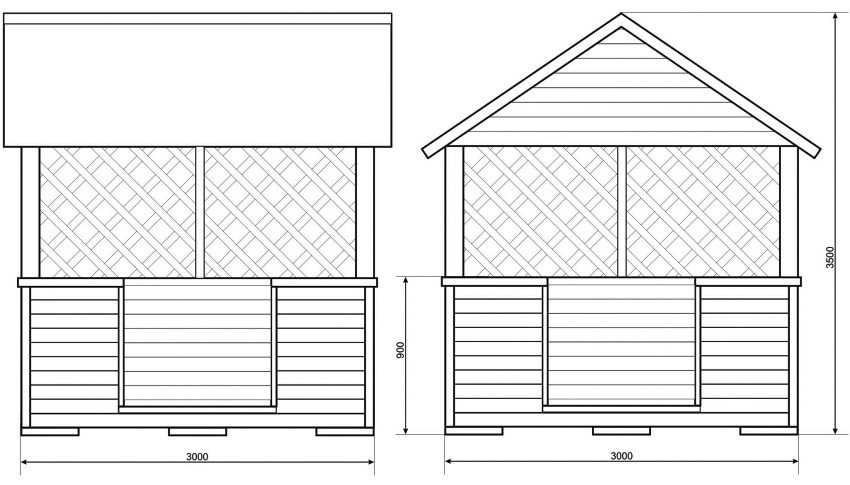

- the dimensions of the gazebo in the drawing must correspond to the dimensions of the allotted space. The drawing indicates the height, length, width of the structure, the location of the support stacks, the entrance, as well as the shape and height of the fence;

- include in the project drawings with projections: facade image, sections, layout and diagrams of technical units of the structure. Shows all sizes and shapes of the gazebo;

- if a closed building is assumed, a ventilation scheme is prescribed;

- separately develop a working plan of the foundation, indicating its type (strip, columnar or slab base);

- describe the diagrams of structural units: indicate the dimensions and installation locations of doors, windows, stairs;

- separately carry out the scheme of the roof with the designation of its size, configuration, angles of inclination, height, coating material;

- indicate the technology for the construction of walls, roofs, barbecue (if expected). For gazebos with fireplaces, stoves, barbecues, attach a plan for the sequential laying of bricks indicating all sizes of equipment;

- perform wiring and water supply schemes;

- develop a plan for the placement of lamps, furniture and equipment;

- make up a specification for building materials, including fasteners, processing impregnations and hardware.

The more thoroughly the project is completed, the more accurate the calculations of the required amount of materials will be, the easier it will be to construct and the higher the likelihood that the structure will be reliable and strong. Use in the preparation of the basic project photos, drawings of gazebos for giving with your own hands, which craftsmen share with pleasure.

Related article:

Gazebo: simple and beautiful, photos of the original pavilions. Lightweight structures made of different materials. Polycarbonate gazebos. How to properly arrange and decorate the gazebo. Review of the prices for gazebos.

Wooden gazebo with your own hands. Photos and drawings of structures

When choosing material for the construction of a gazebo, many people prefer wood. Wooden models fit perfectly into the exterior of the local area and look harmonious in the garden. In addition, wood is a fairly strong, environmentally friendly and durable material that is easy to process. As a rule, wooden arbors are made in an open version. For the construction, a bar, logs, a board, a lattice of planks and other wooden elements are used.

DIY rectangular gazebo made of wood

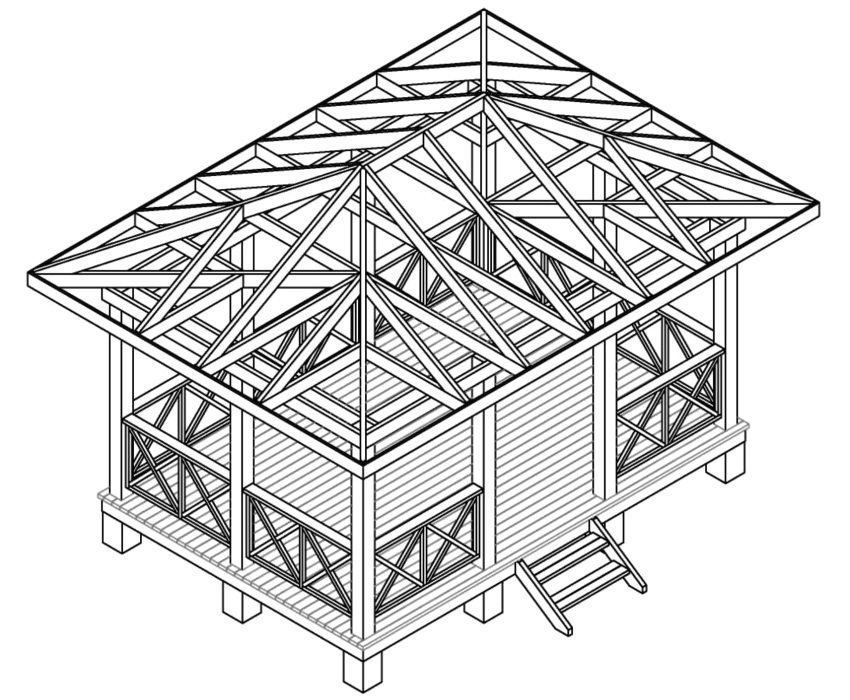

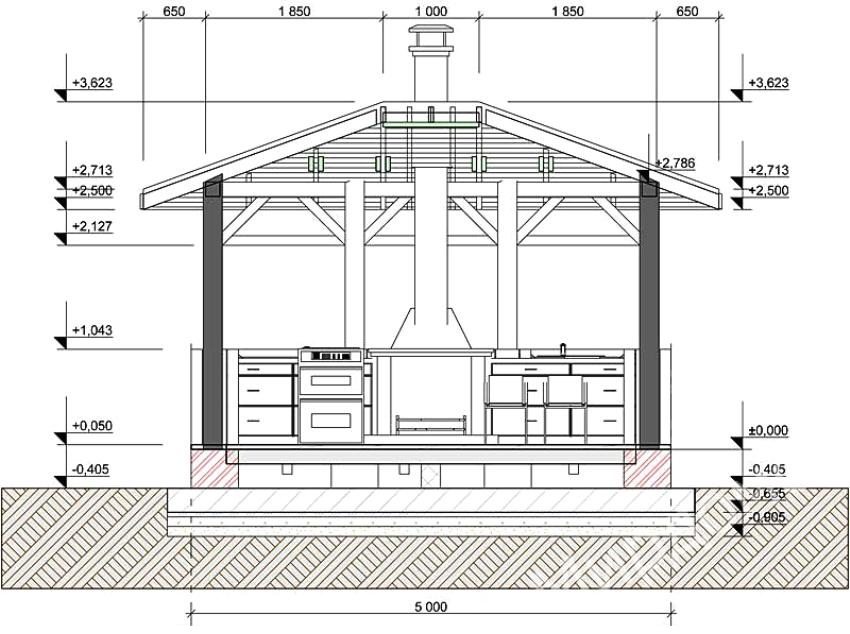

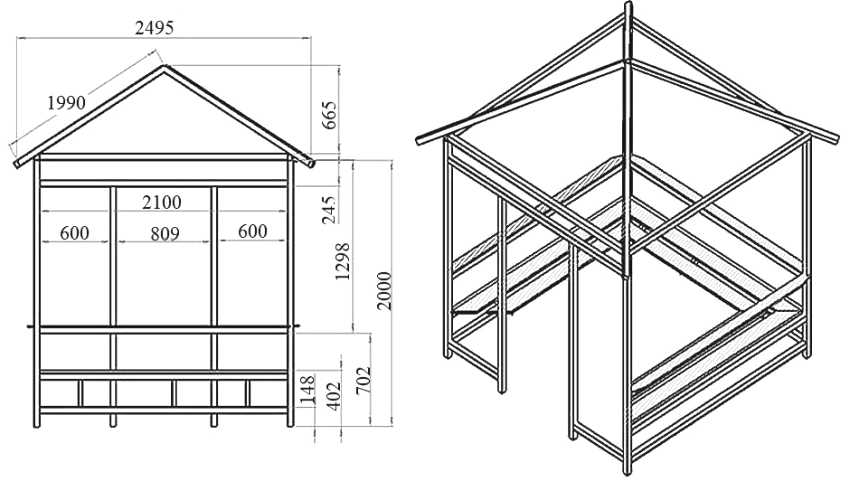

The simplest option for self-design and construction is a square or rectangular gazebo. It is a lightweight open structure consisting of support posts, roof and railings. The drawings show the dimensions of the structure, the height of the support posts, the configuration of the roof, indicating the height and angles of inclination, the height and drawing of the fence.

Drawings of the frontal and profile projection of the gazebo are being carried out. A separate diagram shows the foundation for the structure (usually a columnar base is used). This indicates the depth of the pillars and the distance between them, which depends on the size of the gazebo.

Helpful advice! For the convenience of the work, it is necessary to attach to the project detailed diagrams of technical units, where options for fastening the elements to each other will be indicated.

In the drawings of the roof, it is necessary to display the rafter system indicating the method of fastening the upper strapping, the lower support for the rafters (Mauerlat), and also set the step between the rafters.

When all the drawings and diagrams are ready, you can start building the structure yourself. First of all, they prepare and mark the site for construction. For this, pegs with a construction cord are used. After the perimeter is fixed, proceed to the foundation.

To complete the foundation, according to the drawings, holes are dug about 70-80 cm deep, the bottom is filled with a layer of sand, and then the support posts are inserted and concreted. When performing work, it is imperative to check the verticality of all supports and their equidistance from each other along the entire height.

Then they begin to carry out the lower strapping and the device of the floor from the log. For this, wooden beams are used. When the floor frame is assembled, plank flooring is arranged. Next, the upper harness is attached, the roof frame is assembled using the prepared schemes, the frame is sheathed with a board and covered with roofing material.

Installation of the fence is carried out when the structure of the gazebo is fully assembled and installed. First, the horizontal beams are fixed, serving as railings, and then the vertical supports (balusters) of the fence are fixed.If the project provides for a wooden lattice as a fence, then frames are prepared from a bar according to the specified dimensions, inside which slats are packed in the form of a grid.

Projects of gazebos made of wood with barbecue, barbecue

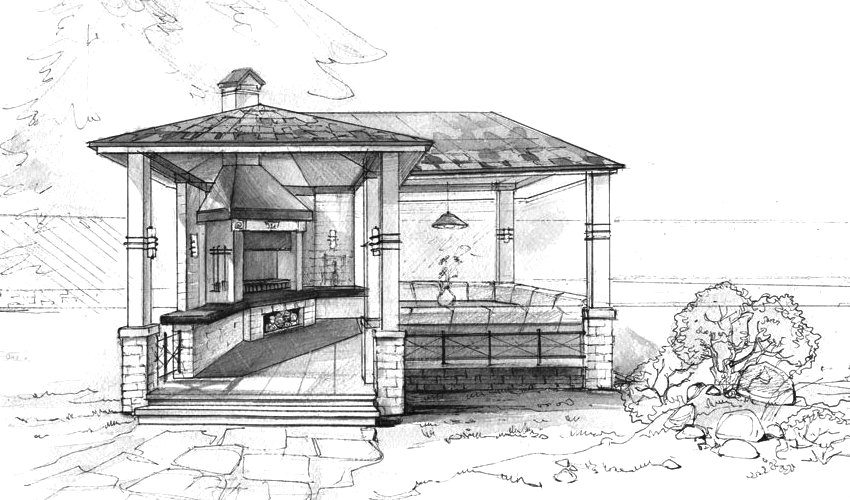

Before proceeding with the development of the project of the gazebo itself with a barbecue or fireplace, it is necessary to complete a sketch, which will indicate the location of the gazebo on the site. Due to the fact that water and gas are often supplied to such structures, it is necessary to correctly plan its installation site. In addition, the direction of the wind should be taken into account, in which the smoke from the stove would not spread to other buildings.

Spacious wooden gazebo equipped with barbecue oven

Wooden gazebos with barbecue, stove or fireplace usually replace summer kitchens in terms of functionality. Such structures can be erected both open and closed. Variants of closed buildings are often used in winter, therefore, at the design stage, wall insulation and the availability of high-quality ventilation can be provided.

Designing gazebos with barbecue, barbecue or fireplace is a rather complicated process. For such structures, it is important to take into account not only the foundation for the pavilion itself, but also directly for the furnace equipment, since the brick structure has a fairly large weight. Most often, a separate tiled foundation is arranged under a brazier or fireplace, and for the gazebo itself - a columnar or tape foundation.

Helpful advice! To avoid the appearance of cracks in the concrete base under the brazier or fireplace, it is necessary to reinforce the foundation with steel rods.

The drawings show all the dimensions of the gazebo, the layout with the designation of the location of the barbecue or fireplace. A diagram of the foundation and chimney is shown separately. The project also includes drawings of the barbecue itself, indicating the shape and dimensions of the brazier, the number of firing points and the orderly laying of bricks during construction.

When developing a plan for the gazebo, it is required to make the correct zoning of the space. It is necessary to provide for a safe location of the dining table and provide free access to the barbecue or fireplace for preventive and maintenance activities. It is also extremely important to indicate the dimensions of the floor area around the furnace equipment where the fireproof material will be laid.

Using gazebos with barbecue and oven as a summer kitchen, it involves connecting water, gas and electricity networks to them. In this regard, the project includes wiring diagrams indicating the location of electric points, as well as wiring diagrams for gas and water networks.

Competently executed projects of wooden gazebos with fireplaces, stoves or barbecues will avoid mistakes in the rather complicated construction of such structures.

Do-it-yourself metal gazebo. Photos, drawings and diagrams of structures

In addition to wood, metal is often used for the construction of arbors: iron or aluminum. This material is durable and products made of it do not need repair. The elements are connected using welding. Models of metal arbors can have a stationary or collapsible design. In the case of a collapsible version, bolted connections are used as fasteners.

Helpful advice! One of the conditions for the durability of a metal structure is surface treatment with anti-corrosion agents and timely painting.

When planning the location of the gazebo, it must be borne in mind that metal elements get very hot in hot weather. In this regard, it is recommended that such structures are open and installed in the garden.

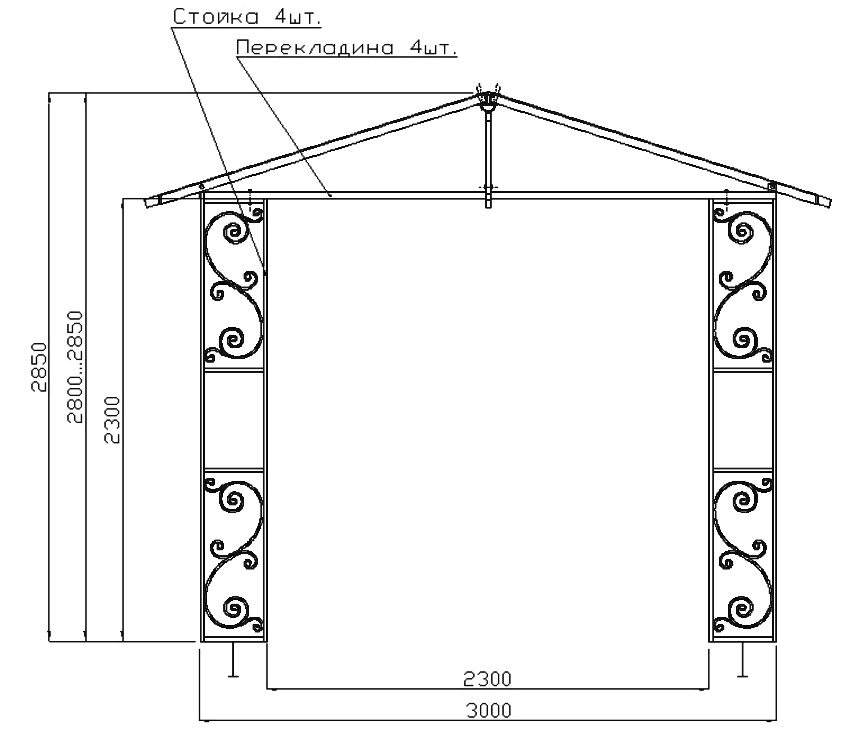

Before starting the project, you need to think over the design of the gazebo, which would match the style of the existing exterior. The dimensions laid down in the drawings of a metal gazebo with your own hands depend on the estimated number of people who can be inside it, as well as furniture and the availability of certain equipment (barbecue, barbecue).

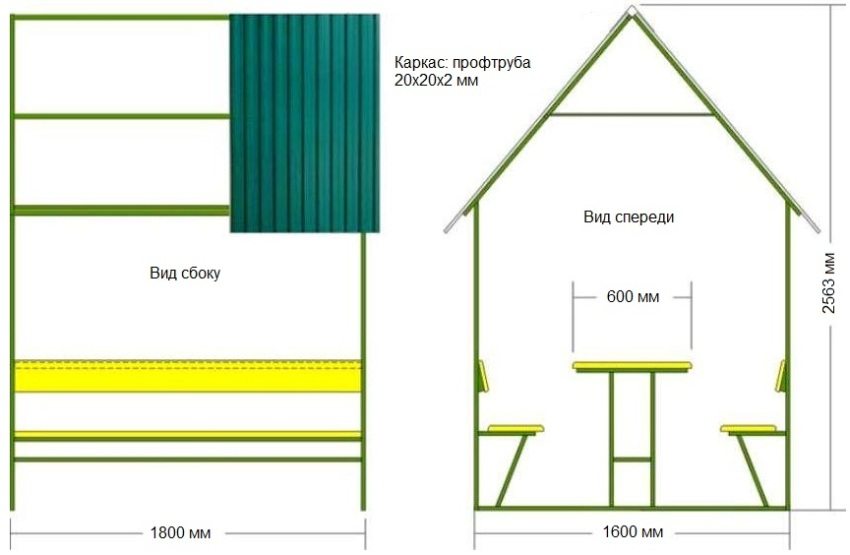

Many people use ready-made schemes for building metal gazebos with their own hands, photos of which can be found on the Internet. Relatively easy to install is a rectangular structure with dimensions of 2.5x3 m. This model will not be bulky and at the same time it is possible to place a table and several seats in it for a comfortable rest.

Do-it-yourself gazebos from a profile pipe. Drawings, photos of finished structures

Due to a number of properties of a shaped metal pipe, many use this material to build a gazebo. Structures from a profile are characterized by ease of construction, excellent resistance to weathering and durability. In addition, this material is relatively inexpensive, and the structures made from the profile have a decent neat appearance.

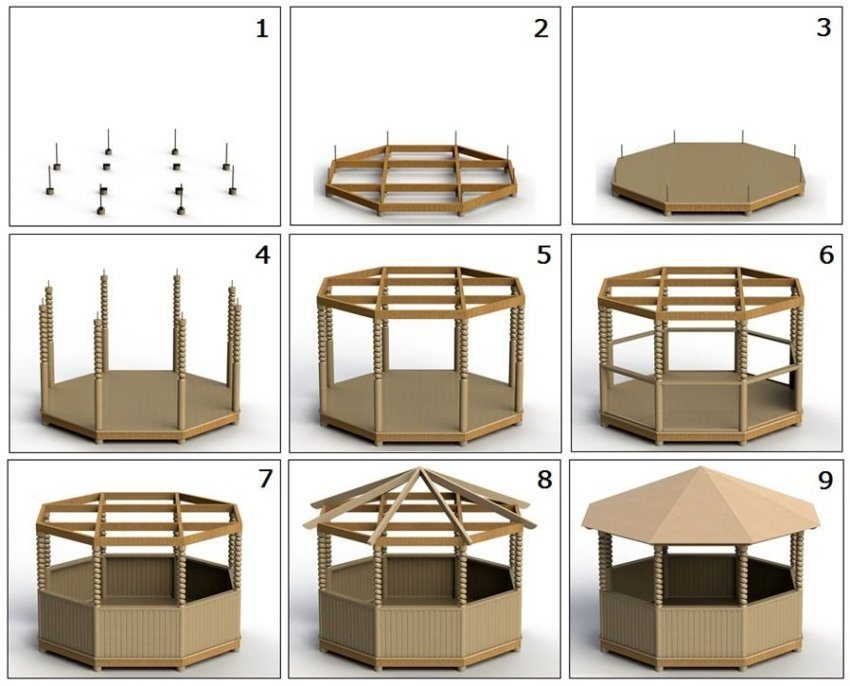

Before proceeding with the manufacture of the gazebo, it is necessary to select the type and shape of the structure, prepare drawings, check the availability of the necessary materials and tools for installation. A photo of arbors from a profile pipe with their own hands demonstrates various configurations of these structures: rectangular, hexagonal, square and other more complex shapes.

Helpful advice! For those who do not have sufficient skills in working with a welding machine, as well as for the first time installing a gazebo, it is recommended to choose designs of simple shapes.

Sketches and drawings of the gazebo can be done independently or you can use ready-made schemes, proportionally changing the dimensions for your option. In the drawings, it is necessary to indicate all dimensions, perform all calculations as accurately as possible, since the appearance of the structure and the selection of the necessary materials will depend on this.

For the construction of the structure, the following materials will be needed: concrete, a shaped pipe, a primer for processing metal surfaces, accessories, roofing material. Of the tools you will need: a building level, a drill with a set of drills, a grinder, a welding machine, a shovel, fasteners.

Having chosen and marked out the place for the structure, they proceed to the construction of the pits. Their number is determined by the number of supports, according to the drawings. The pits are made about 60 cm deep. The height of the support posts is taken taking into account this value. For the supports, a profile with a section of 80x80 mm and a wall thickness of 3 mm is used, to which the supporting metal heels are welded. This will give the structure additional stability.

The bottom of the prepared pits is covered with crushed stone, carefully tamped, support posts are inserted and concreted. At this stage, it is important to maintain the maximum verticality of the installed racks. To do this, as soon as the concrete hardens a little, the position of each support is checked and leveled.

After installing the supports, it is necessary to withstand about 2 days until the concrete has fully set, and then proceed to the lower horizontal strapping. For it, a profile of a smaller section is used, which is welded to the supports at a certain height above the ground. The distance from the ground to the horizontal harness is taken so that it is as comfortable as possible to enter the gazebo.

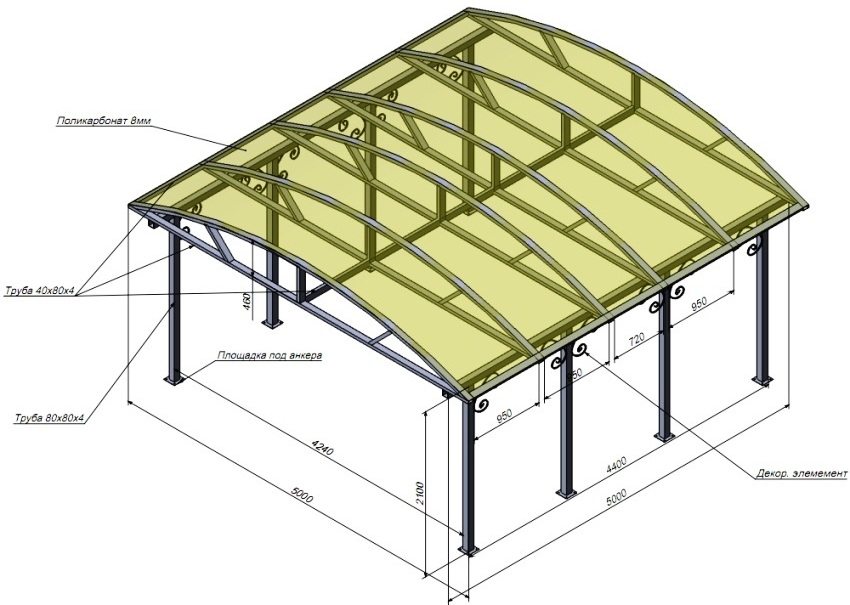

Next, proceed to the manufacture of the roof. A rafter system is formed from the profile according to the diagrams. For a gable form, a profile is welded at an inclination of 15 degrees.For the convenience of fastening the roofing material, a profile pipe is welded to the roof frame as a batten with a pitch of 45 cm. On this, the arbor frame is considered assembled.

DIY polycarbonate gazebo. Photos of original models

The main advantage of transparent polycarbonate is its compatibility with other materials. Polycarbonate gazebos can decorate any yard. Polycarbonate sheets can be used to decorate not only the roof of the gazebo, but to make the walls of the pavilion from it or use it as a fence.

Forms of polycarbonate arbors

Polycarbonate gazebos models are distinguished by an incredible variety of shapes. This is due to the ductility of the material, light weight and ease of installation. Arbor designs can be oval, round, rectangular, spherical, as well as asymmetric. The structures are of open or closed type.

The roofs of the gazebos covered with polycarbonate can be single slope, multi-slope, arched, semi-arched, hipped, spherical, domed and multi-level. A variety of colors of polycarbonate panels allows you to give the space inside the gazebo any shade, taking into account your preferences.

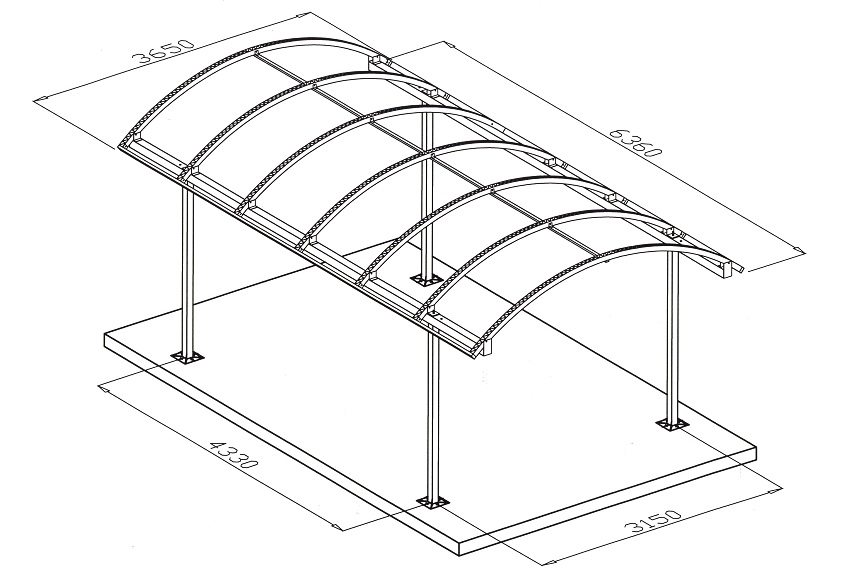

The structures of polycarbonate gazebos can be made in combination with a profile pipe, forged metal, wood, stone, brick, and also combined from several types of material. Quite often, you can find structures with an arched covering in the form of a canopy adjacent to the main house. The choice of a particular material for a gazebo with a polycarbonate coating depends on the presence of similar elements in the exterior.

According to the functional purpose, polycarbonate gazebos can be used as children's playgrounds, summer kitchens, lounges and guest rooms. The dimensions of structures can be voluminous, equipped with a brazier or barbecue, and completely miniature, under which a pair of small shops and a table.

Do-it-yourself photos of polycarbonate gazebos demonstrate original models of various shapes.

Do-it-yourself gazebo construction from metal and polycarbonate

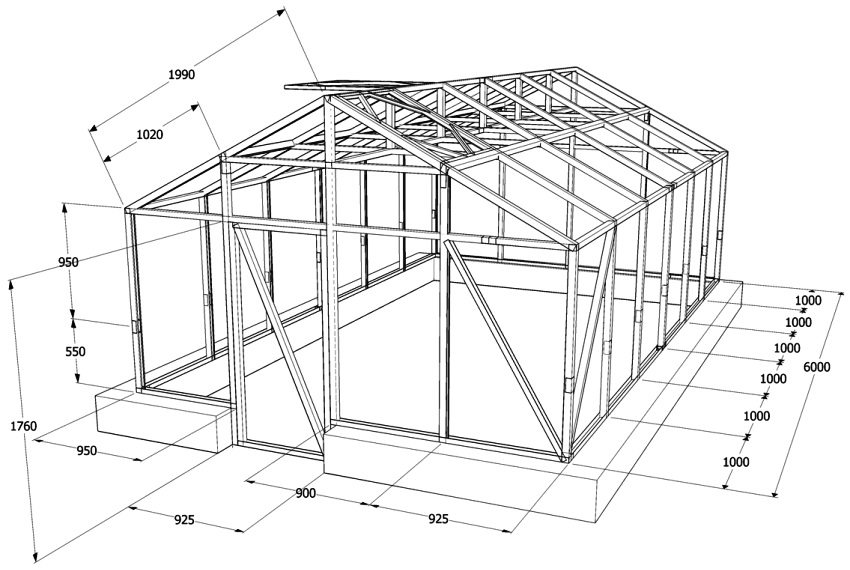

The construction of the gazebo should begin with the development of drawings and sketches of the structure. In the drawings, it is necessary to describe the structural diagram of the frame, all sizes and methods of fastening the elements. This will help to correctly calculate the necessary materials and accurately cut out the elements of the frame and coating.

Helpful advice! Cut polycarbonate with a saw with fine teeth or at low speeds of the grinder. This will help keep the cut straight and prevent the plastic from crumbling.

For the base, a concrete platform is suitable for the structure. For its device, a layer of vegetation is removed, crushed stone is laid with a thickness of 5-6 cm and poured with a solution of concrete with a layer of up to 10 cm.If you plan to supply electricity to the gazebo, you must first lay a wire under the tie placed in a flexible corrugated pipe for electrical wiring.

The installation of the frame supports is carried out simultaneously with the base device. Pits 60 cm deep are made at the corners of the perimeter and profile pipes with a cross section of 50x50 mm are inserted into them. After that, the racks are concreted, paying attention to the verticality of the installation and the identity of the depth of each of them.

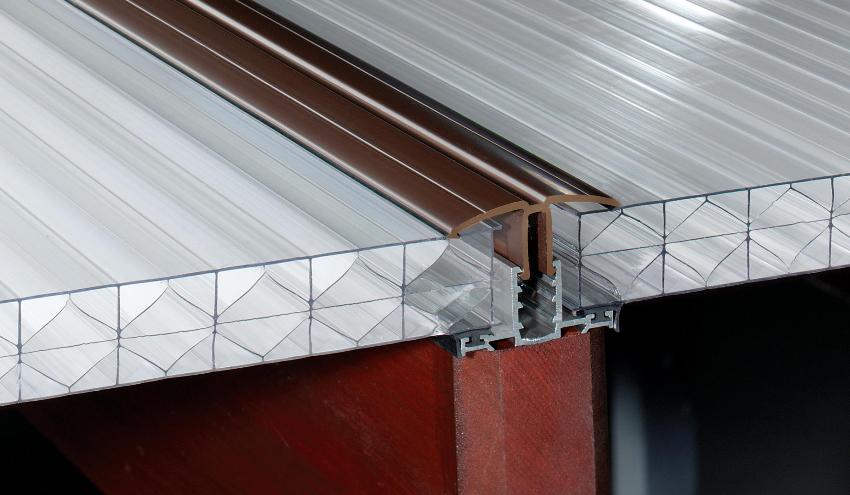

After installing the support pillars, the upper trim and horizontal beams (girders) from the profile pipe are attached to them by welding. These elements will subsequently serve as the basis for fastening benches and fencing made of polycarbonate panels.If desired, the fence can be made not only of plastic, but also of any other material, for example, natural stone, wood or forged elements.

The roof of the gazebo can be made in a single-pitched version. To do this, small pieces of pipes are welded to the profile of the upper trim, to which inclined pipes are subsequently welded. The height of the racks is selected in such a way as to provide a sufficient slope for precipitation from the roof. To give the roof structure rigidity, an intermediate pipe is welded in the middle of the slope, to which polycarbonate panels will be attached.

Installation of polycarbonate sheets

During installation, sheets of cellular polycarbonate are laid so that the channels (honeycombs) inside the sheet are located as vertically as possible: this will ensure the moisture removal to the outside. Please note that the marked surface of the sheets should be on top, where the material is treated with a protective film. Plastic panels are stacked end-to-end, interconnected with a special profile.

The holes for the fasteners are made with a slightly larger diameter than the screws. The distance from the edge of the sheet to the first joint should not be less than 40 mm. The panel joining line should be located along the frame elements. To ensure the tightness of the point connections, use thermal washers in the color of the plastic.

At the end of the work, the edges of the sheets should be properly processed. For this, the upper end is closed with a sealed tape, and the lower end with a perforated tape. Such processing will prevent dust from entering the panel and at the same time ensure the removal of moisture from the plastic channels.

Gazebos made of polycarbonate and other materials, assembled independently in strict accordance with the drawings and diagrams, will have a solid structure and will last for a long time. They will perfectly decorate the plot and become a favorite vacation spot for the whole family.