Aerated concrete house is an excellent solution to the problem associated with the construction of suburban housing. Many land owners use blocks for the quick construction of budget buildings, which explains the popularity of the material. This article displays all the advantages and disadvantages of buildings made of aerated concrete, takes into account all the nuances of technology, which allows you to fully assess the characteristics of the material and understand how expedient its use.

Content [Hide]

- 1 Characteristics of aerated concrete: photo and material properties

- 2 Houses made of gas silicate blocks: classification and technical characteristics of the material

- 3 Pros and cons of aerated concrete houses, an overview of negative opinions

- 4 Aerated concrete house: operational features of buildings

- 5 Myths about the construction of houses from aerated concrete: reviews from the forums

- 6 Design features and average prices of turnkey aerated concrete houses

- 7 Prices for the construction of two-story and one-story houses from aerated concrete, ways of saving

- 8 Timing and calculation of the construction of country houses from a gas block

- 9 How to independently build a house from gas blocks: photo and step-by-step technology

- 9.1 Organization of the foundation for a house from blocks: photos and technology features

- 9.2 Installation of ceilings and walls in a house made of aerated concrete blocks: photo and construction process

- 9.3 Arrangement of a roof for a house from aerated blocks: photo and description of the process

- 9.4 Finishing work in a house made of aerated concrete blocks: photos and recommendations

Characteristics of aerated concrete: photo and material properties

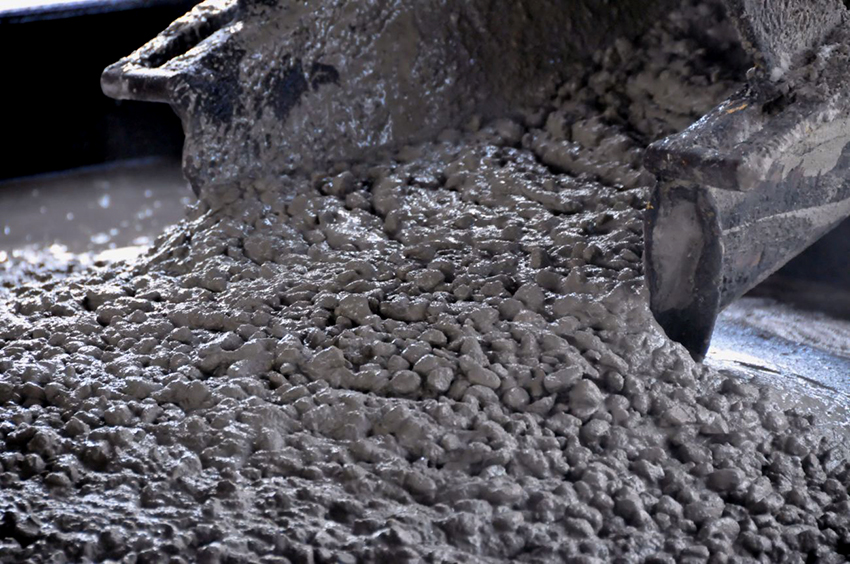

Aerated concrete is one of the types of cellular concrete used in building construction. It has the same porous structure, low density and light weight. This is where the similarities end, since each type of aerated concrete has its own properties and performance characteristics. In the production of aerated concrete blocks, the following components are used:

- Portland cement - provides viscosity.

- Quartz sand is used as a filler.

- Aluminum powder or paste - gas-forming materials.

- Industrial purified water.

- Additives that improve the composition - gypsum, lime, industrial waste (ash, slag).

At the factory, all of the above components are thoroughly mixed, after which the solution is poured into molds.As a result of a chemical reaction between the ingredients, hydrogen is formed. Due to it, the mixture swells and increases in volume. Under the influence of this gas, pores are formed in the material. When the reaction stops and the mixture sets, the aerated concrete is removed from the molds and cut in accordance with standards. Manufacturers produce gas blocks of two types for the construction of houses:

- Autoclave - obtained as a result of synthesis hardening. During the drying process, the blocks are steamed in autoclaves in an environment saturated with steam under the influence of high pressure.

- Non-autoclave - the blocks are hardened in drying chambers under the influence of atmospheric pressure.

In fact, this is one and the same material, which is dried in different ways, due to which it acquires certain properties.

Helpful advice! The use of homemade scaffolding will greatly facilitate the installation work.

Houses made of gas silicate blocks: classification and technical characteristics of the material

In accordance with generally accepted standards, three types of blocks are manufactured in production:

- Structural - the density index of products is in the range of 1000-1200 kg / m³.

- Thermal insulation - the density of the blocks varies within 200-500 kg / m³.

- Structural and thermal insulation - the density level ranges from 500-900 kg / m³.

If aerated concrete is marked with the D500 mark, it means that 1 m³ contains 500 kg of solid material, and the rest of the volume consists of air filling the internal voids.

Aerated concrete optimally combines the most advantageous technical characteristics:

- High level of strength - despite the low density of the material, you can safely build load-bearing walls from aerated concrete blocks.

- Light weight - due to the porous structure, about 85-90% of the volume is occupied by air, therefore, aerated concrete blocks are quite light.

- Low thermal conductivity - the thermal conductivity of the material in a dry state is 0.12 W / m ° C.

Why you can't use home-made aerated concrete for building a house

On the Internet, you can find hundreds of recommendations and step-by-step technologies that describe the process of creating aerated concrete at home. From the outside, this task looks quite realizable, so many craftsmen are trying to start production on their own. In the process of making gas blocks with their own hands, a gross violation of technological standards occurs, which affects the quality of products. However, despite this, there are still people who want to purchase building material at a reduced cost.

In factory production, specialized technical equipment is used and high-quality raw materials are used, so buyers can expect to buy products with the necessary characteristics:

- correct block shape and exact dimensions;

- the minimum percentage of manufacturing defects;

- physical and mechanical parameters corresponding to the declared ones;

- uniform density of the material throughout the volume, which can be seen even during visual inspection;

- chemical inertness of the material, achieved through laboratory control, which is carried out at all stages of production.

To make the house beautiful and reliable, you must use only high-quality gas blocks for construction

Helpful advice! It is very easy to distinguish handicraft aerated concrete: the geometry of the blocks is broken, the structure of the material is uneven, the products emit an unpleasant chemical odor, most often lime.

Homemade material can significantly reduce the cost of building a house from aerated concrete, but the use of such blocks is fraught with many unpleasant consequences.

First, blocks with uneven density (structure) do not meet quality standards. Such products are less durable and within a year after the start of operation, the house may become cracked.

Secondly, it is impossible to perform high-quality aerated concrete masonry. Blocks with disturbed geometry cannot be fixed with an adhesive composition; for this you will have to use a conventional mortar. As a result, the seams between products are very thick (within 10-20 mm), which reduces the thermal efficiency of the house and the walls freeze.

A home made from self-made blocks will be cheap, but this can have a bad effect on many characteristics of the building.

Thirdly, if the lime in the blocks is not completely decomposed, the material will exude a persistent chemical odor. This will not only create inconvenience, but can also affect the health of the residents of the house. In addition, an excessive amount of lime in the composition of gas blocks can provoke corrosive processes that damage the walls.

Pros and cons of aerated concrete houses, an overview of negative opinions

The pros and cons of aerated concrete can be considered on the example of houses built using this material. The porous structure provides these blocks with many advantages:

- high construction speed;

- profitability;

- fire resistance;

- low thermal conductivity;

- simple processing system;

- low cost of aerated concrete houses;

- environmental friendliness;

- excellent level of vapor permeability;

- durability;

- frost resistance.

The low price of aerated concrete houses is due to several factors. On the one hand, this is the cheapness of the building material itself. For the manufacture of blocks, a small amount of cement is required, because the bulk of the products are pores filled with air. On the other hand, the construction time is short. The block sizes are large enough to shorten the duration of this process, and therefore, to reduce the cost. In addition, a brick in the same volume weighs much more (about 3-5 times). As a result, building materials and working hours are used more efficiently.

Note! If we compare the speed of building houses from aerated concrete and brick, then in the first case 1 m² of walls can be folded in about 20-25 minutes. The use of bricks does not give such results.

The low level of thermal conductivity allows you to maintain a comfortable temperature in the house even in winter. Aerated concrete retains heat in the house about 2-3 times better than brick. The energy efficiency of a 37.5 cm thick wall made of gas blocks is the same as that of brickwork, which is 60 cm thick. Blocks lend themselves well to any kind of processing: chipping, sawing, milling. Products can be easily cut even with a hand tool, which is why you can see beautiful buildings with complex architectural shapes in the photo of aerated concrete houses.

Aerated concrete belongs to the group of non-combustible materials. If a wall made of such blocks is exposed to a flame with a temperature above 100 ° C for 2 hours, the surface will be covered with cracks only 30-40 mm deep. This time will be enough to evacuate all tenants of the cottage from aerated concrete before the building's floors fall. A wooden house in similar conditions will burn out to the ground.

If the blocks are made without violating the technology, they do not have unpleasant odors, are environmentally friendly and perfectly let the air through. There are cases when the service life of aerated concrete was 40-50 years.

What are the disadvantages inherent in aerated concrete: material cons

The same porous structure, which provided so many advantages to aerated concrete blocks, has become a source of some disadvantages. One of the weaknesses is the low level of flexural strength. The ultimate deformation coefficient of this material is in the range of 0.5-2 mm / m. If deformation changes go beyond these indicators, the walls of the house may become cracked.

To exclude the likelihood of such an outcome will help the construction of a solid foundation for a house made of gas silicate blocks, reinforced with mesh reinforcement or monolithic strapping. In addition, it is advisable to reinforce the masonry and strapping the floors.

Due to the porous structure of the material, the installation of fasteners (screws, anchors, nails) is very easy, but the reliability of its fixation leaves much to be desired. For aerated concrete walls, you need to select special parts. Better to give preference to frame, nylon or steel fasteners. In such conditions, the installation of door and window structures deserves special attention. If the technology is violated, they can loosen over time.

Important! It is not recommended to build houses from aerated concrete above three floors.

The adhesive properties of the material are not up to par, therefore, surface reinforcement is performed before plastering on aerated concrete walls. The priming also helps to solve the adhesion problem. Among the disadvantages of aerated concrete buildings, there is also a large shrinkage. The displacement of non-autoclave blocks reaches 2 mm / m. The indicator of autoclaved aerated concrete is slightly less - 1 mm / m.

Aerated concrete house: operational features of buildings

In order for the house to stand throughout the entire operational life, it is imperative to take into account some of the features of gas blocks. First of all, we must not forget about the hygroscopicity of the material. Porous blocks, like wood, absorb and release moisture well. Wall cladding will help protect the front of the building. In addition, it is advisable to organize a high-quality ventilation system in the aerated concrete house.

Aerated concrete is quite energy efficient, which reduces the cost of heating the house. However, when buying a material, it must be borne in mind that its thermal insulation properties depend on the brand. The higher this figure, the worse the blocks retain heat. To improve the energy efficiency of your home, you can cover the walls with plaster.

In order for a building made of aerated concrete to serve the entire operational period, it is necessary to take into account the characteristics of the material

Aerated concrete building blocks are large, therefore, the likelihood that the installation will be performed poorly increases. Such a result is possible even if geometrically correct products are used. If glue of a thick consistency is used in the work, through gaps may form in the masonry of gas silicate blocks, since in this state the composition is unable to completely fill all the voids.

Helpful advice! Experts recommend to study it after building a house. A thermal imaging survey will determine if there are seams or joints in the building that need to be repaired.

Myths about the construction of houses from aerated concrete: reviews from the forums

Before building a house from aerated concrete, many owners of summer cottages look at reviews on the Internet. Most of them are positive:

Related article:

House project from foam blocks with a description: from planning to finishing

Turnkey houses: from getting to know the peculiarities of building materials to putting the facility into operation. Properties, advantages and characteristics of foam blocks.

“As a builder with many years of experience, I have learned well the characteristics of various materials.Aerated concrete blocks are in great demand among the population and, in my opinion, it is difficult to find a more suitable option if you need to build a house in a short time and at minimal cost. The material is quite lightweight, environmentally friendly and earthquake resistant. Aerated concrete, unlike wood, is not flammable. It's easy to work with him. In addition, the material saves on finishing work, since the blocks have the correct geometry. "

Stanislav Mokry, Yekaterinburg

“Especially for the construction of a house made of aerated concrete, I purchased a land plot within the city. I used D500 blocks in my work. This material is of good quality and practicality. The price of aerated concrete is also acceptable. I had to additionally insulate the underground part of the foundation, but the installation of insulation on the walls was not needed. I did everything according to the technology, so the house turned out to be warm, with ideal living conditions.However, there is one caveat. A comfortable microclimate is maintained only on condition of constant heating. Otherwise, no complaints. I have been using the house for three years already. "

Evgeny Starostin, Moscow

On the forums, there are often negative reviews about building blocks. Common opinions:

- The walls are cracking fast.

- The building needs mandatory insulation.

- Aerated concrete is too fragile.

- Blocks are destroyed by moisture.

- Aerated concrete is hazardous to health.

The myths about the construction of aerated concrete often arise due to ignorance of the characteristics of the material

In most cases, this is due to a lack of understanding of the technical and operational characteristics of the material, as well as the intricacies of the technology itself, which may be violated during the construction process.

Myths about the technology of building houses from aerated concrete

Over time, cracks appear in any material, even in brickwork. In most cases, the reason for the premature destruction of a building is not the quality of building blocks (the exception is handicraft products), but a violation of the technology for arranging the foundation under the house made of aerated concrete. Negative consequences arise if, at the design stage, the features of the soil at the site and the nature of the location of groundwater were not taken into account.

Note! The reason for the appearance of cracks can be mistakes made in the process of reinforcing masonry from aerated concrete blocks. Moreover, this rule applies to both the foundation and the walls of the building.

If the building project was developed in accordance with the requirements of SNiP, then there is no need for additional insulation. However, many developers, when decorating a house made of aerated concrete, perform installation of insulation materials "at the same time".

There is an opinion that aerated concrete block can be broken with a hammer blow. However, even a brick can be broken with a certain amount of force. According to the provisions of SNiP, it is recommended to use blocks marked D500 in the construction of cottages made of aerated concrete. This type of material is considered to be quite durable for the construction of low-rise buildings (up to 3 floors). However, it combines characteristics such as lightness and warmth. If all technological features are taken into account during the construction of a house, the building will be able to withstand any load.

D400 building blocks are considered warmer than D500 but less durable. Aerated concrete marked D600 has an increased strength index, but retains heat much worse.

Myths about the operation of houses from aerated concrete blocks

Some users also express their mistrust regarding the operation of aerated concrete structures, fearing that the blocks, like a sponge, absorb moisture. This type of material does have similar characteristics to wood.Aerated concrete is able to absorb moisture and give it back to the building, affecting the indoor climate. However, if you live all year round and if there is a finish that does not interfere with the natural circulation of moisture, water will not be able to damage the blocks and destroy the building.

The opinion that aerated concrete, when wet, is immersed in water is also erroneous, and therefore it is unsuitable for housing construction. The fact is that the porous structure provides the material with buoyancy, which is completely unrelated to how much water the blocks have absorbed. Therefore, a small house made of aerated concrete is considered an acceptable option for building a suburban area.

In the presence of high-quality finishing of a building made of aerated concrete, a comfortable microclimate is formed inside

The composition of aerated concrete contains aluminum, as well as lime, which sometimes smells like in the rooms of a building after construction, which causes some land owners to fear the safety of this material. These components are indeed present in the initial mixture, but after the completion of the chemical reaction, they are absent in the finished product.

Note! In industrial production, they adhere to precise dosages. In addition, aerated concrete undergoes high-quality drying. The result is an artificial stone composed of safe silicates. If aerated concrete smells like lime, it means that it was made in a handicraft way.

Design features and average prices of turnkey aerated concrete houses

If we compare the price of aerated concrete and brick cottages, then it should be noted that the first option will definitely be cheaper. The cost of building a turnkey aerated concrete house can be influenced by several factors:

- Features of the project - clients can purchase a standard project with pre-prepared documentation or order the development of an individual solution that will take into account personal wishes.

- The brand and quality of building materials - the cost depends not only on the volume of purchase, but also on the manufacturer, which can be foreign or domestic.

- The complexity of architectural design - this factor takes into account the area and number of storeys of the building (the construction of a house with an attic made of aerated concrete will cost less than the construction of a two-story building), the type of roof and foundation.

- Relief features of the site - if the area has a slope or the soil on the site is too specific, the typical project will have to be finalized for an additional fee.

The advantages of building turnkey aerated concrete houses

Having given preference to the construction of a residential building from turnkey blocks, the owner of the land plot can fully appreciate all the advantages of professional service. From the moment the customer signs an agreement with the contractor company, the firm takes over the solution of all issues:

- the need to change or adjust the project;

- performing geological and geodetic studies of the site;

- selection of a team of workers;

- quality control of work performed;

- implementation of all construction work described in the contract (starting with the arrangement of the foundation, ending with the laying of communication systems and the completion of finishing).

The quality of the work performed also depends on how correctly the contractor was chosen. When choosing a construction company to implement a project on a site, you should pay attention to the following points:

- time of existence of the company;

- the number of completed projects (photos of houses made of gas silicate blocks in finished form and in the process of construction will be useful);

- quality of work;

- real customer reviews.

Experienced contractors have at their disposal a reliable supplier base, in-house design office, multidisciplinary teams of professional workers.

Note! The customer has the right at any time to carry out personal control of the construction process, cost estimates, and also receive a report from the contractor.

When choosing a construction company, you need to pay attention to the quality of their work, customer reviews and the life of the company

Reputable construction companies serve customers according to a well-established scheme. They strive to maintain optimal prices and often offer customers a profitable system of discounts on the purchase of materials.

Prices for the construction of two-story and one-story houses from aerated concrete, ways of saving

To build a house from gas silicate blocks with minimal costs, it is very important to think over all the nuances, up to the purchase of materials, their shipment and even a thorough study of the contract before signing.

The purchase of materials makes up a significant part of the total costs, so this task should be given special attention. In this case, it is necessary to think ahead, since any hitch can freeze the construction for a long time. The accelerated pace of construction is not without surprises and unplanned difficulties. There may be fluctuations in the cost of building materials by 150-200%, both in one direction and in the other direction.

This table will allow you to find out how much a house made of aerated concrete (one-story buildings) costs:

| Area, m2 | price, rub. |

| 61,79 | 827950 |

| 104,48 | 1398700 |

| 127,05 | 1700900 |

| 156,45 | 2094500 |

| 165,9 | 2221000 |

Choosing a store with the best prices, you should also take care of an acceptable system of delivery and unloading of materials. If these works are not included in the general estimate, such a service can significantly increase costs. Moreover, this is possible even when the material is purchased at a very low price. Another reason for the leakage of money can be inconvenient access roads to the construction site. It will probably be more profitable to lay the paving slabs to the site once than to rent a manipulator every time you need to transport materials.

Problems can arise even if a contract is signed with the contractor, which spells out all the terms and prices. Without experience, it is impossible to foresee all the nuances and completely secure yourself against additional costs. The contract may stipulate the installation of rafters and roofs, but insulation work is not indicated. In this case, you will have to pay extra for them.

Note! There are no universal workers. Even the most experienced bricklayers will not be able to correctly install the communication system or electrical wiring. Therefore, it will be necessary to involve several teams with different specializations.

Table with prices for two-story houses made of aerated concrete:

| Area, m2 | price, rub. |

| 89,25 | 831600 |

| 111,09 | 1223500 |

| 134,4 | 1480205 |

| 176,51 | 1943900 |

| 236,67 | 2606500 |

Timing and calculation of the construction of country houses from a gas block

The construction time can be influenced by factors such as the area of the building, the type of foundation and roof, the complexity of installation work, etc. However, there are average indicators that can be taken as a basis for performing preliminary calculations.

Average construction time table:

| Type of work | Timing |

| Arrangement of the foundation | 1.5-2 months |

| Erection of walls and ceilings in a house made of aerated concrete | 1-2 months |

| Installation of the rafter system and roof | 2-4 weeks |

| Installation of door and window structures | 10-15 days |

| Installation of electrical wiring | 8-15 days |

| Installation of communication systems | 25-30 days |

| Installation of finishing | 2-4 months |

Aerated concrete house calculator: calculation formula

Even if it is planned to build a small single-level house from gas blocks, you will have to make a lot of calculations before starting work. Moreover, the more floors a building has, the more accurate the calculations must be.

To calculate gas blocks, all walls must be divided into three groups, taking into account their thickness. One of them will include external walls, the second - internal load-bearing, and the third - internal partitions. For each group, its own calculations are made. As a result, it is necessary to determine the length of the walls, as well as the area that falls on the door and window openings.

Then you need to calculate the volume of the wall surfaces. To do this, multiply their main indicators: length, width and height. The area of door and window openings is subtracted from the result. After that, it is necessary to divide the volume of wall surfaces by the volume of one building block. Thus, you can find out how many gas blocks are required to build a house.

Before starting construction, it is necessary to make a careful calculation to determine the amount of materials

For the construction of external load-bearing walls, it is advisable to use products with parameters 20x30x60 cm. The volume of such blocks is 0.036 m³. Internal load-bearing walls are most often built on the basis of a material that has the same dimensional characteristics, and aerated concrete can be laid flat. Less stringent requirements are imposed on internal partitions. For their construction, products with a size of 10x30x60 cm are suitable. The volume of these blocks is 0.018 m³.

Helpful advice! It is better to buy materials with a margin, which is 6-7% of the total number of gas blocks.

How to independently build a house from gas blocks: photo and step-by-step technology

In the process of developing a project involving the construction of a country house, it is imperative to take into account the characteristics of the material. The thickness of the walls made of aerated concrete blocks for the house is selected taking into account the structural features of the building. If the construction site is located in latitudes with moderate climatic conditions, then products with a thickness of 30-40 cm can be used for the construction of load-bearing walls.For interior partitions, this figure is 10-15 cm.

Aerated concrete building needs a stable and reliable foundation. Most often, experts recommend using a slab foundation, which has a monolithic structure. It is suitable for the construction of residential buildings on all types of soil. The roof can be flat or pitched, however, regardless of the design, its installation must be done correctly. It is preferable to choose a lightweight roofing option:

To build a high-quality house from gas silicate blocks, it is necessary to take into account all the features of the material

- profiled sheet;

- metal tiles;

- bituminous shingles.

In the cold season, the unfinished house needs conservation. Do not lay aerated concrete in winter if the outside temperature is below -5 ° C. With the onset of cold weather, the building is preserved. For this, a waterproofing film is used to cover the walls. It is desirable that by this moment the floors, which are located above the first floor, are already ready. In addition, the pallets are covered with foil where the gas blocks are stored. It is recommended that you do not remove the factory shrink tape.

Organization of the foundation for a house from blocks: photos and technology features

The durability of the house primarily depends on the quality of the foundation. Most aerated concrete building projects involve the use of monolithic structures. The ideal option is considered to be a shallow tape-type foundation. It optimally combines qualities such as reliability and reasonable cost. The shallow foundation is laid to a depth of 0.5-0.6 m.

Note! The depth of laying the base does not depend on the level of soil freezing.

The thickness of the foundation is selected taking into account the thickness of the walls of the building. When creating a house from a gas block with your own hands, you need to form a basement.This can be achieved if the base is 0.2-0.3 m above the soil line.

A shallow foundation needs reinforcement. This procedure is required. For this it is necessary to make a frame with a longitudinal-transverse structure. Corrugated reinforcement with a diameter of 1.2 cm is suitable as a building material. The frame will consist of upper and lower longitudinal belts (3 rods in each), interconnected by transverse bridges, which are placed in increments of 0.3-0.4 m. For pouring it is desirable to use concrete grade M300 or M400.

Installation of ceilings and walls in a house made of aerated concrete blocks: photo and construction process

Walls can be built only after the foundation has gained strength. The drying process takes at least 20 days. The first row of gas blocks must be waterproofed. For this, a cement screed is formed on the surface of the foundation tape. Interlayer thickness - 10 mm. Next, the waterproofing is laid. Glassine is also suitable, but it is better to refuse to use roofing material. After that, a cement-sand mortar is again applied, and a foam block is installed on top of it.

All subsequent rows are laid using special glue. Each 4th row is reinforced with a welded mesh with steel rods 0.4 cm thick. For these purposes, fiberglass reinforcement can also be used. Before laying the mesh, grooves must be formed on the surface of the blocks. They can be done using a wall chaser.

The technology for installing floors in aerated concrete house depends on the type of floors. If these structures are formed from beams, then the floors are also made of wood (according to the standard scheme). If porous concrete slabs are installed for the house as floors, do not use wet concrete screeds. Such structures will significantly weight the floor. Aerated concrete slabs do not need insulation.

Important! Since aerated concrete absorbs moisture, before finishing the floors, the surface of the slabs should be carefully primed with polymer compounds. This is done multiple times.

Before creating an interfloor overlap or installing a roof, an annular armored belt with a monolithic structure is equipped on the upper row of masonry. Thanks to him, the loads are evenly distributed between the blocks. The recommended height of the belt is 0.15-0.2 m. Its thickness should be less than the thickness of the walls by about 0.1 m. The voids that remain must be filled with insulation. If this is not done, then the armopoyas will become a cold bridge.

The use of reinforced concrete slabs as floors is possible only if the distance between the load-bearing walls is not more than 6 m.To stay on the surface of the armopoyas, the slab must rest on it at least 1 cm.The remainder is covered with a smaller gas block.

If there is no more than 6 m between the bearing walls, then it is recommended to use iron plates for the overlap

Arrangement of a roof for a house from aerated blocks: photo and description of the process

To prepare the basis for mounting the roof, metal studs should be embedded in the armopoyas. They will be used to fix the Mauerlat. It is recommended to use fittings as studs, or you can purchase finished products with threads. The second option greatly simplifies the process of installing the Mauerlat. At the next stage, the rafter system is installed. The technology in this case is individual, and it depends on the characteristics of the selected type of roof. For a house made of aerated concrete, you can build a roof with your own hands in different ways:

- Organize a pitched roof - this option is very rarely used in residential buildings, since such a structure is more suitable for outbuildings and sheds.

- To build a gable type roof is an ideal solution for country houses.

- To build a hip or attic structure is the most acceptable option for a residential building made of aerated concrete.

Whatever type of roof you choose, you should insulate it. For this, a layer of waterproofing material, insulation and vapor barrier are laid.

Note! If, when building a house from a block with your own hands, a residential attic will be arranged under the roof, it is also necessary to organize sound insulation.

Metal tiles, slate, corrugated board, bituminous or ceramic tiles are suitable for the roof of a house made of gas blocks.

The waterproofing is fixed to the rafters with wooden slats, which will later be used to fix the batten structure for the installation of the roof. The space between the slats under the waterproofing is filled with insulation. Mineral wool is most often used for these purposes, although other materials are also suitable, for example, foam or expanded polystyrene. Next, a vapor barrier film is attached using rails. Then the roofing is installed.

The most common materials:

- professional flooring;

- metal tile;

- slate;

- ceramic tiles;

- bituminous tile.

To prevent sedimentary moisture from accumulating on the roof, the installation of the roofing material should be started from the bottom.

Finishing work in a house made of aerated concrete blocks: photos and recommendations

Aerated concrete walls look unsightly, so finishing is required, and the house is plastering both inside and outside the building. You can start facing the front part only after the eaves have been installed, the roof is equipped and the installation of engineering systems has been completed. For these purposes, experts recommend using plaster compositions intended for aerated concrete blocks, in combination with fiberglass.

Interior finishing works are carried out as follows:

- The walls are covered with an inexpensive putty. You can use a gypsum composition.

- Fiberglass is glued over the plaster.

- A finishing layer of putty is applied to the walls.

Thanks to this technique, cracks that may appear on the walls will not go over to the finish.

Do-it-yourself gas-block houses, like any other buildings, have both advantages and disadvantages. There are many positive and negative reviews on the Internet. Therefore, the choice should be made based on budget opportunities. If the construction is carried out by turnkey professionals, you don't have to worry about the quality of the work performed.