Quite often, amateur craftsmen ask themselves how to properly install vinyl siding. A video instruction of this simple, but having many subtleties, process is in this article. Facade cladding with such material has recently gained more and more popularity, but the cost of refurbishment is often quite high. Having studied the basic rules of cladding, and using some tips, you can easily install vinyl siding with your own hands.

Content [Hide]

Tools

To create a high-quality cladding with plates yourself, you will need the following tools and additional components:

- drill, mains or cordless screwdriver;

- building level, plumb lines;

- electric circular saw;

- scissors designed for cutting metal;

- screws and self-tapping screws;

- crabs, special mounting brackets;

- aluminum profile or timber from wood 50x40.

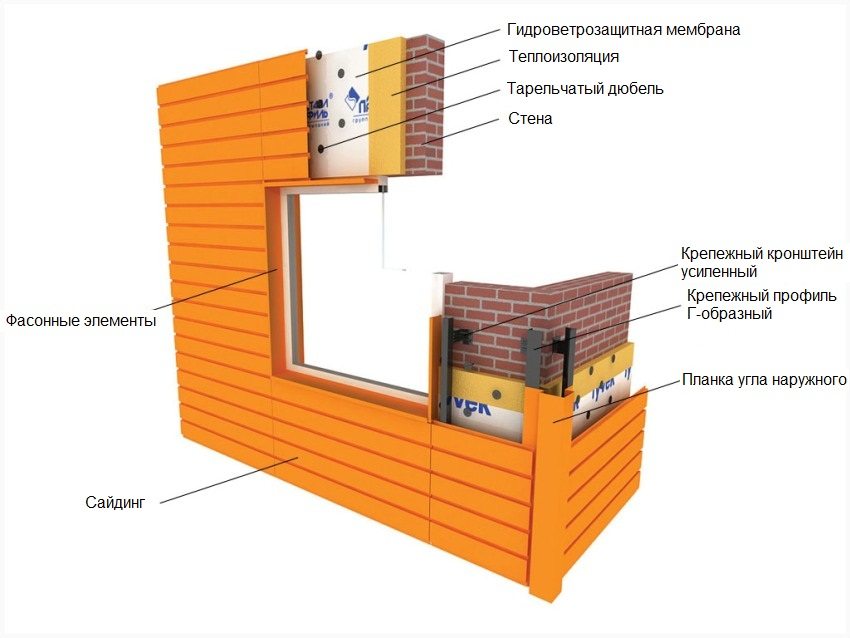

A profile or timber is required to create the frame on which the vinyl siding will later be installed. Manufacturing a structure for cladding is necessary if you plan to equip a ventilated facade. This system allows the walls to breathe.

Important! Before starting work, vinyl elements must be allowed to soak for a while at outside temperature.

Surface preparation and frame assembly

If on the outside walls there are irregularities in the form of protrusions from the masonry, protruding reinforcement, then they must be removed. They can interfere with the creation of an even frame or the laying of insulation in its niches. There is no need to remove common plaster imperfections or small dents, as they will be hidden by the cladding.

There are two different approaches when assembling a framework. The lathing for siding can be vertical or horizontal. The vertical frame is suitable for siding panels such as a shipboard or block house.

Create a vertical wireframe

To start arranging such a structure, it is necessary to draw a vertical line along the corner of the house, using the level prepared by plumb lines. After that, holes are drilled along it for attaching the mounting brackets.When installing suspensions, it is required to observe vertical symmetry, since they will serve as a kind of hollow for a profile or timber. After fixing the carrier at the opposite corner of the building, a construction thread is pulled between them, which will serve as a starting point for other crossbeams. The distance between the profiles should be no more than 0.4-0.5 m.

Creating a horizontal wireframe

The lathing horizontally is carried out if used for cladding siding, similar to the lining. A horizontal line is drawn with the help of the building level. The top carrier is attached in the same way as the vertical one. Then, after fixing the first profile, the location of other structural details is marked from it. The distance between the profiles should not be more than half a meter.

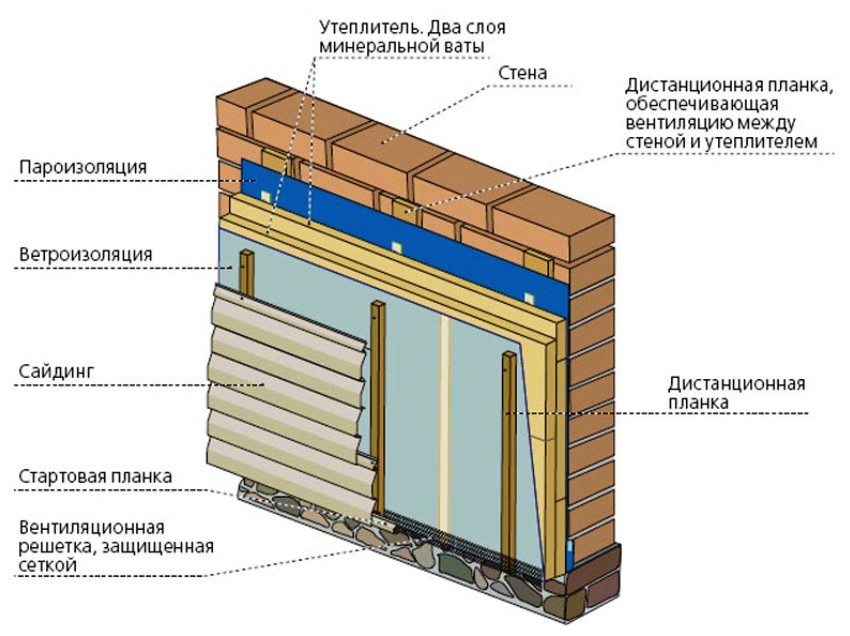

Warming

If, in addition to creating the original appearance of the facade, it is required to carry out thermal insulation of the walls in parallel, then inside the resulting frame is attached insulation for siding... For these purposes, mineral (stone) wool, foam are ideally suited. The insulation plates are fixed with fungi or special assembly glue.

The distance from the plane to which the siding will be fastened and with insulation should not be less than 1 cm. Also, when arranging thermal insulation, it is required to protect the walls of the house from moisture. For this, special hydro and vapor barrier films are used. Read below how to install vinyl siding. The video instruction will help you understand the many subtleties of the sheathing.

Installation of vinyl siding: video instruction

After assembling the frame, the sheathing process can begin. Cladding panels from different manufacturers usually have different designs of locks, additional elements. Usually, the kit includes instructions for installing vinyl siding, which describes in detail how to connect the plates.

However, there are basic principles for fixing panels:

- corner profiles or bars should only be fastened vertically;

- the first screw is screwed in at the highest point, then all the others;

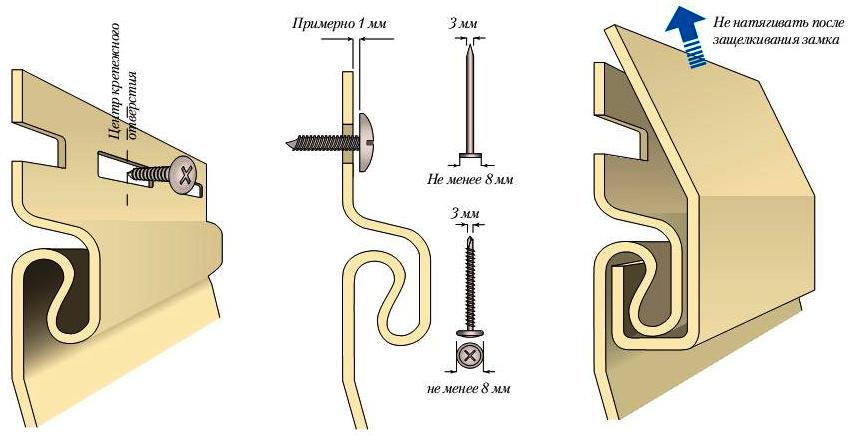

- the panel cannot be screwed on tightly, it must be free to hold onto the fasteners.

Important! When fixing the panels, screws or self-tapping screws must not be screwed in to the very end. It is worth leaving 1-2 turns so that the siding cannot deform during temperature fluctuations.

Arrangement of the corner

First of all, corner strips are installed, ordinary vinyl panels will be inserted into them. The angle should be set a few millimeters above the lowest point. The fastening process starts from the upper hole, the self-tapping screw is screwed into its upper half. The rest of the fasteners should be in the middle of the hole.

Advice! If, when installing vinyl siding with your own hands, you need to lengthen the corner elements, then the upper part should be mounted on the lower one. The overlap in this case will be about 2-2.5 cm.

Thanks to the flexibility of the vinyl corner strip, obtuse and sharp corners can be accommodated. To create an obtuse angle, the plank needs to be pressed down a little, and for a sharp one - slightly squeezed. You can replace the finished corners with regular J-profiles.

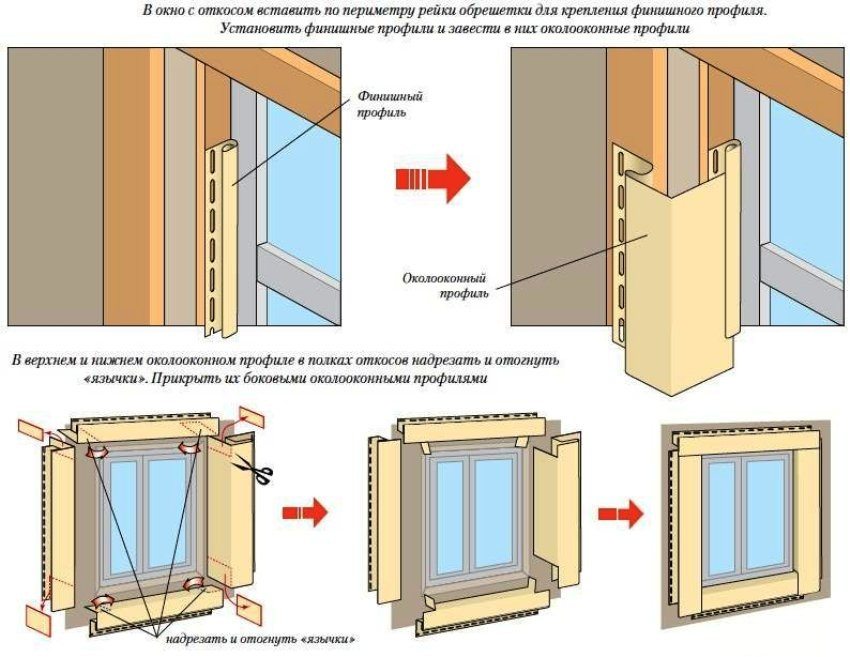

An example of the correct design of windows and external slopes when house cladding with siding

Installation of H-profile and starter strips

The H-connector is intended for joining ordinary vinyl panels, if their length is not enough to completely cover the wall. It must be fixed in the same way as the corners. It is possible to do without installing an H-profile, but then the plates will need to be overlapped. After that, the starting strips are attached. Their installation is carried out strictly according to the level around the entire house.

When the preparatory stage is completed, you can proceed with the installation of vinyl siding.Video materials allow you to see the whole process in subtleties.

Installation of vinyl siding: instructions and basic rules for fastening

In order for the cladding to be of high quality and to serve for a long time, it is necessary to follow the rules for fixing the panels:

- the gap between fasteners is usually 25-30 cm;

- you need to tighten the self-tapping screw exactly perpendicular to the wall;

- the screw should be located in the middle of the special hole for fastening. Thanks to this, the plate can be displaced during expansion;

- in order not to tighten the screw to the end, you can use two methods:

- attach a coin when screwing;

- tighten the screw completely, then loosen one turn.

- there should be a technological gap of 0.5-0.6 cm between adjacent starting strips. It is also designed to provide freedom of the plates during linear expansion;

- use special corner elements for arranging corners;

- it is also necessary to maintain a gap of about 1 mm if you are installing vinyl siding using brackets. The instruction usually indicates such important points.

Installation of vinyl siding: video of assembly of ordinary panels

The first plate is inserted into the slots of the corner or H-planks. In the center of the panel, the first self-tapping screw is screwed into a special hole, the next are placed from the middle to the edges. The next bar is started from above in relation to the first, it is lowered until it clicks. If the lock snaps into place, then the plate will lie flat, and you can proceed to its further fastening.

After installing all the panels, the finishing and near-window strips are attached. First, the finish strip is attached, and only then the last plate is inserted into it. As you can see, there is nothing complicated in the process of installing vinyl siding. The video instructions presented in the article will greatly facilitate understanding of all the intricacies of the cladding process.