In modern construction, laminate flooring has gained great popularity. Laminate looks like a tree, but several times cheaper than it. In addition, due to its sufficient thermal conductivity, it is ideal for creating a "warm floor" heating system. The warmth emanating from the floor creates comfort in the house, even in the coldest weather. What is a warm floor under a laminate on a wooden floor and is it suitable or not? These questions are asked by everyone who has decided to arrange this system at home.

Content [Hide]

What is a warm floor under a laminate on a wooden floor or on a concrete base

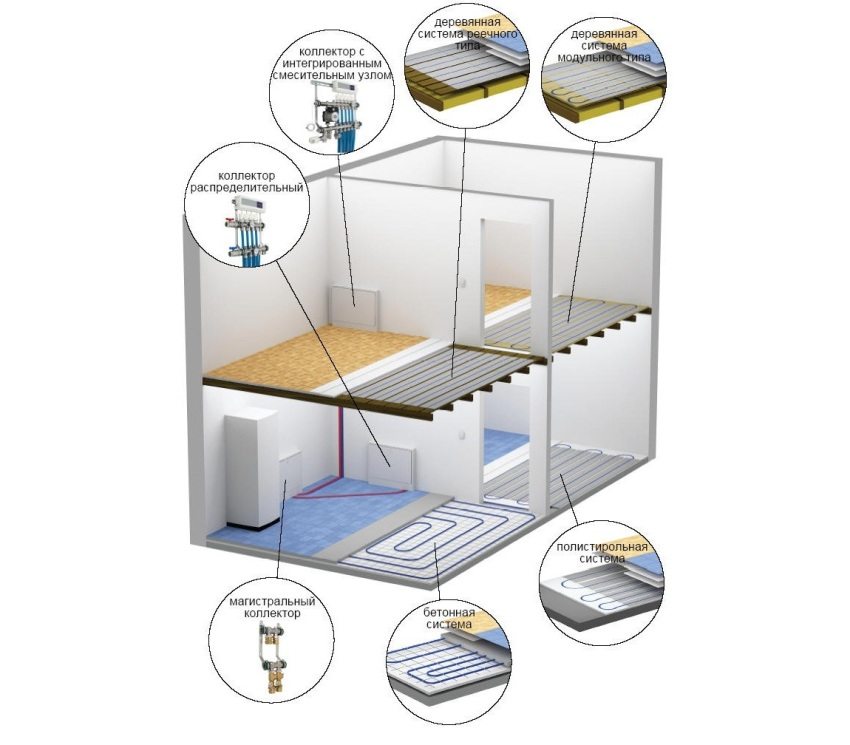

Today there are 3 types of underfloor heating. They are all based on completely different principles:

- Water system.

- Electrical cable.

- Infrared electric.

Film infrared warm floor goes well with laminate

The main feature of this system is that the heat sources are located under the surface of the floor covering. The heat generated by them warms the coating, which transfers energy to the surrounding air. For each species, any of the following is true:

- heat is distributed evenly;

- the system is very efficient;

- lack of heating elements in prominent places;

- dust does not circulate through the room, as is the case with radiator heating.

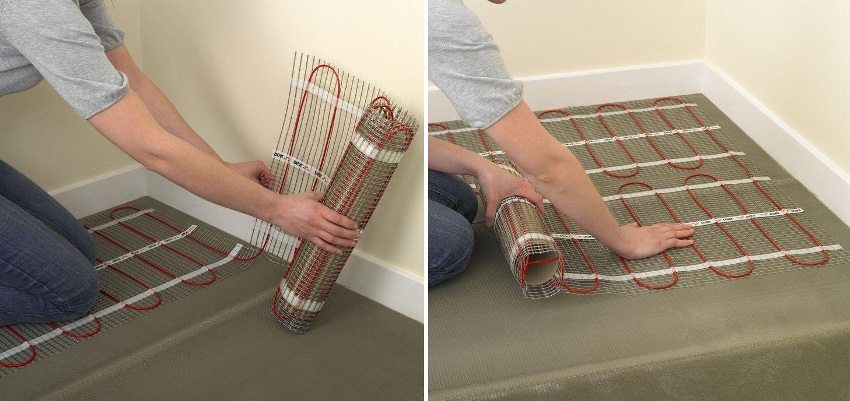

Electric underfloor heating mat is compact and lightweight, but it is able to effectively heat spacious living spaces

Any of them can be mounted on a concrete base or on wooden floor... Underfloor heating under the laminate of each of these types has its own advantages and disadvantages.

Helpful advice! In order for the water floor to function more efficiently, you need to create not one circuit, but 6 or even 8. This will allow a more even distribution of heat. The tubes will be shorter, so the heat loss will be reduced.

Warm floor: pros and cons (video)

Installation of a water-heated floor on a wooden floor is absolutely safe

The heat source for such a device is heated water circulating through tubes that are located directly under laminate... Modern industry produces pipe products for these purposes, made of the latest materials using innovative technologies.Thanks to this, polyethylene and metal-plastic pipes ensure complete safety of the system. Any water leaks are excluded.

The initial stage of arranging a water-heated floor is laying a cross-linked polyethylene pipe on an insulating substrate

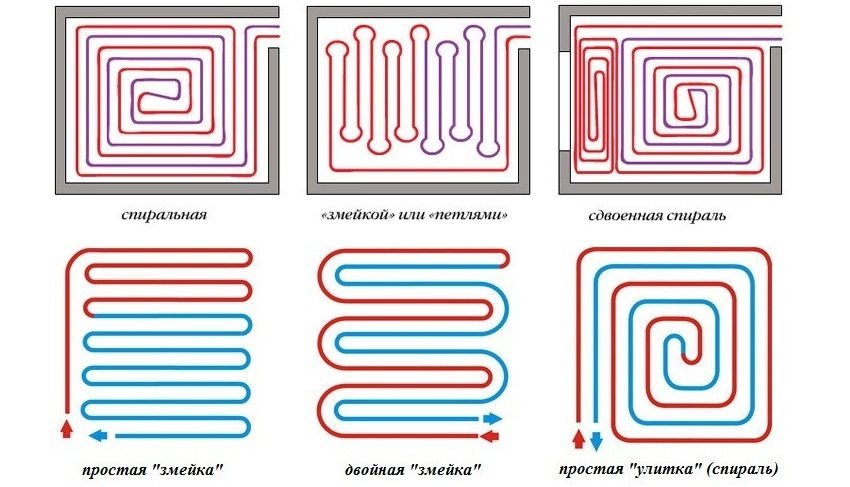

For laying water floor heating it is necessary to lay a damper tape around the perimeter of the room. Then, on top of the rough base, arrange hydro and thermal insulation, lay out the reinforcing mesh. Then the pipes are laid in a parallel or spiral manner. In the first case, the drawing looks like a snake, and in the second, like a spiral. The ends of the pipe are closed to the heating circuit, so that water circulates freely inside.

The next stage is filling the entire structure with a sand-cement mixture. The resulting screed is leveled under laying laminate... In the process of circulation of the coolant through the pipes, the cement will warm up, evenly transferring heat laminate.

This type of underfloor heating has several advantages:

- safe operation;

- reliable functioning;

- no power supply is needed if the circulation of the coolant occurs naturally.

Combination of various options for arranging a "pie" of a water-heated floor within one living space

It also has some drawbacks:

- complex installation;

- the height of the ceilings is reduced due to the device of the concrete screed;

- if the pipe is damaged, it will be quite difficult to repair the system.

Such a system is absolutely safe for installation on a wooden floor. The warm floor under the laminate, arranged in this way, will last a long time.

Do-it-yourself water floor heating (video)

Electric type underfloor heating device

The principle of operation of the system is based on the property of conductors to heat up when an electric current passes through them. The heating element is a special self-regulating electric cable. It is able to automatically change the resistance in those areas where overheating is detected. This is necessary to avoid burnout. The cable is available in single-core and two-core.

Before starting installation, the surface is leveled and a thin sand-cement screed up to 0.3 cm thick is made. If necessary, heat insulation is arranged under it. Drying will take place after 3 days. Only then can the mounting tape be attached. Then you need to fix thermostat in a convenient place and lay the cable according to the instructions on the package.

Upon completion of the installation, the screed is again made from 3 to 10 cm thick. It will reach complete drying only after a month. Only then can the flooring be laid. For this very well suited, produced in Germany Waterproof Laminate 33 Grade 12mm thick.

Main advantages:

- operational reliability;

- long service life, more than 20 years;

- easy installation and maintenance;

- electronic control of the optimum temperature.

Among the shortcomings, the following should be indicated:

- the presence of, albeit weak, but electromagnetic radiation;

- high cost of electricity.

Made in Germany, 33 grade 12mm waterproof laminate is perfectly matched with the electric type warm floor.

Helpful advice! For a warm floor at home, it is better to buy a two-core cable. It is much easier to stack it.

The peculiarity of using an electric type of warm floor is to select the optimal mode, which ensures sufficient heating with optimal use of electricity.

DIY electric underfloor heating (video)

Infrared film warm floor

This is the most innovative floor heating system.It is a film that, as a result of exposure to an electric current, is capable of emitting the infrared range of electromagnetic waves. This range of the spectrum is invisible to the human eye, but is felt by the skin as warm. Half of the sun's energy is infrared rays. The absence of glowing elements is the main feature of this material.

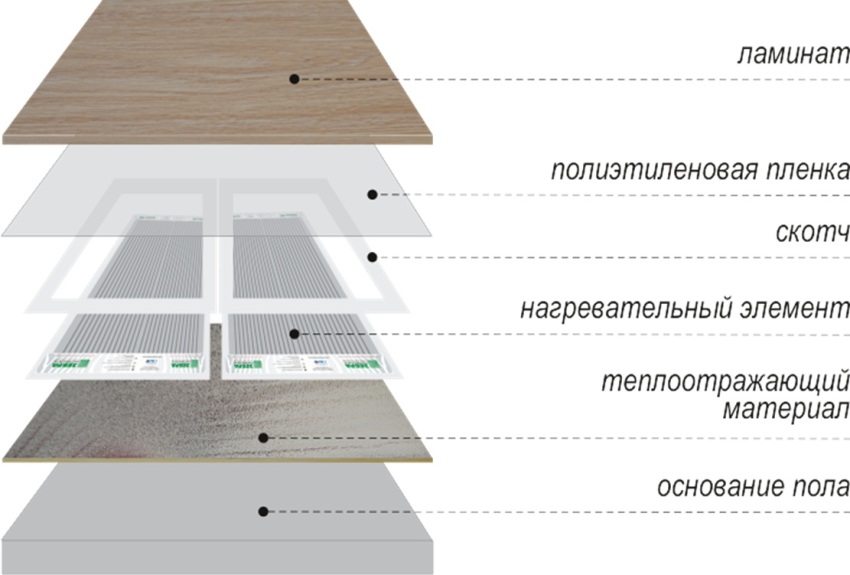

In installation, such a system is the most convenient. It is enough to lay a heat-reflecting coating on a leveled base, and already on it an infrared film. Topcoat that can be made in Germany waterproof laminate 33 class 12 mm thick, stacked directly on the film itself. No need to arrange screed, which is a long and laborious process.

Helpful advice! Under laminate it is better to lay the backing not made of foamed polyethylene, as is most often done in normal conditions, but duplex or isoplate. These materials are waterproof.

Advantages infrared film:

- very reliable and durable system;

- installation of such a system is the easiest of all types of underfloor heating;

- the absence of incandescent elements reduces energy consumption very significantly.

The disadvantages are:

- too high a price;

- fear of moisture;

- risk of damage during installation.

Laying laminate on a film infrared warm floor

A feature of the operation of such a floor is extreme caution. He is afraid of rough mechanical stress. Therefore, do not put heavy furniture on such a surface. This could damage the film and render it unusable. It is better to use such a system in open spaces.

Each owner independently chooses the type of underfloor heating for the device at home. The decision is made depending on preferences and availability of financial resources.