A chair in the interior is the simplest model of furniture in the design, which is quite easy to choose and buy. However, if you want to have something exclusive, original, and sometimes just as cheap as possible in the country or in the house, the idea appears to make chairs out of wood in your own workshop. This article will talk about how to execute the conceived design, realize the ideological plan and where to start the carpentry work for the novice master.

Content [Hide]

- 1 Is it easy to make a wooden chair with your own hands?

- 2 What tree to use when making do-it-yourself chairs

- 3 Do-it-yourself chairs made of wood: drawings, assembly, design options

- 3.1 Log stool or stool: quick ideas for beginners

- 3.2 How to make a chair out of wood with your own hands: drawings, tools, assembly

- 3.3 Wooden chairs with upholstered seats, with armrests and armchairs

- 3.4 Solid wood chairs: reliable and solid

- 3.5 How to make a folding wooden chair yourself

- 3.6 Some useful ideas for folding chair designs

Is it easy to make a wooden chair with your own hands?

Chairs accompany people all their lives. They change with the interior, style, purpose and age of the owner, but they are always present in the room. The idea to start a furniture project usually arises from those who saw a photo of wood products on any resource and were inspired to their own experiment. If, for example, it is often necessary to repair chairs made of wood, then all the nuances of the design, the “weak points” of certain models are already familiar. Therefore, they have their own ideas about how to make a reliable and comfortable chair.

Already at the initial stage, a novice furniture master assesses the complexity of the work performed, his own practical skills in carpentry and creates a list of necessary tools. Newbies never start manufacturing complex products, realizing that a lack of experience can lead to poor execution and wasted resources and time on the project. However, experience appears only in the process of work. If you start with simple models and use inexpensive materials, it is possible that very soon your own exclusive furniture will become a matter of personal pride.

Woodworking, if desired, is easy to master. If the master has little experience, then there is no point in buying a full set of tools, including their electrical counterparts, or asking the price of woodworking machines. It will be enough to purchase the essentials, and the rest of the inventory can be rented.Time will tell whether carpentry becomes a long-term hobby or the enthusiasm for making furniture disappears with the first chair mockup.

What tree to use when making do-it-yourself chairs

Wood is a very generic name for the material used to make chairs. Not every kind of wood that is used in furniture production will be suitable here. The reason for this strict selection is in the loads acting on the chair in different planes. They dictate the parameters of stability and safety of use. If we consider the options for suitable wood, then you get a considerable list to choose from:

- soft species - pine, linden, cedar;

- moderately soft varieties - aspen, birch, mountain ash;

- moderately hard species - walnut, beech, pear, cherry, oak, larch;

- hard varieties - maple, ash, hornbeam and many types of exotic wood.

Helpful advice! Oak or beech are ideal for making chairs, but they are expensive. For the first own furniture samples, it is better to purchase dense wood, but financially less expensive, for example, rowan.

The most durable products are made from strong wood species. However, it is not easy to assemble such wooden chairs with your own hands, because machines will be needed for high-quality processing of the source material. The price of raw materials made from durable wood is never low. Soft rocks are easily processed even by hand, but the operational period of such products is not too long. Therefore, the assembly of chairs is usually planned in a combined design in order to achieve the desired strength and reduce the cost of the product. For example, you can use plywood for the seat or backrest.

Experts indicate all conifers as an undesirable material for the manufacture of chairs due to their straight-layered structure. Ignoring the warnings threatens with frequent breakdowns, the formation of chips and a short product life. The only use of softwood in chairs is plywood for seating. In other cases, even the highest quality of blanks does not guarantee the durability and safety of furniture. At the same time, conifers should not be excluded from the list of lumber if a stool design is planned. For such a simple chair model, pine or larch is suitable.

Wooden chairs: lumber recommendations

It is recommended to master carpentry skills on those materials that are available (left over from construction), and you can also use trees cut down on the site. For quality products, for example, the remains of fence boards are not suitable, because the types of construction and joinery wood differ. However, for the first experience of making chairs, unnecessary lumber or solid wood may well come in handy.

If wood is bought specifically for manufacturing, then you need to pay attention to the following aspects:

- tables and chairs made of wood can combine several types of lumber in their design: solid wood, logs, beams, boards;

- purchased boards or timber must be free of cracks, deformations, distortions, knots;

- the moisture content of lumber or blanks for chairs should not exceed 12%, that is, the wood is selected dry;

- lumber thickness rule: board <100 m

- the presence of rot, mold, mildew, holes is unacceptable.

Helpful advice! Buy lumber with a small margin, because when making pieces of furniture, there is a high probability of spoiling or breaking any part due to lack of skill and experience.

For chairs, wood is selected without visible defects. All the cutting features that can add texture to the manufacture of interior items do not play any role for chairs.In the vast majority of cases, they can even turn out to be a hindrance and significantly reduce the strength and operational capabilities of furniture.

Wood color and pattern: is it worth considering the features

To make wooden chairs in an apartment or for a summer residence, you need to take care of their organic entry into the existing interior of the room. If the main part of the furniture is made in dark colors, then light armchairs or chairs will look like an inappropriate detail against their background. Construction chemicals for wood processing can achieve different shades. However, it is worth knowing that walnut has a dark brown color, cherry wood will be a reddish hue. Light brown base in oak, cedar, teak, alder, larch, and the lightest tones are typical for beech, pine, birch, maple, ash.

The color of the wood is not important if the chairs are supposed to be installed in the dining area, using deep covers that completely cover the entire frame of the product. In this way, you can successfully hide small defects in the processing or quality of the selected wood. However, not all interiors involve the installation of chairs with covers, no matter how practical they are.

A well-chosen wood color can be further emphasized by the expressiveness of its structure. Sometimes the interior needs a bright or, conversely, restrained wood pattern. Beech and alder practically do not have a pattern. The teak can stand out with a striped structure. Growth rings are clearly visible in oak, maple, ash and cherry. There are various techniques for changing the pattern of wooden chairs, photos of the results of these works can be easily found on the Internet and, if desired, do the same.

Do-it-yourself chairs made of wood: drawings, assembly, design options

Before starting to manufacture, you should initially decide on the type of the intended product, and not select material or look for instructions on how to make a chair. All the following steps will depend on this: the search for drawings, the choice of wood, the purchase of tools, etc. You can make chairs out of wood with your own hands with or without a backrest (stool, bar stool), with a soft or hard seat, folding or convertible design, with or without armrests. Whether it is a comfortable chair or a modest wooden stool, an ordinary chair for the dining area or an exotic product - such issues are decided first of all.

When it is finally determined what the product will look like, they begin preliminary calculations, measurements and drawings. These steps are needed to calculate the material, select the optimal size and comfortable design of chairs. To do this, it is necessary to determine the height and inclination of the backrest, the width of the seat, the height of the legs, etc. At the same stage, it is worth considering which parts can be made cheaper without losing strength. For example, you can replace the boards with plywood or fabric, insert inserts from cheaper raw materials.

If you have experience in remodeling finished chairs or want to master the art of carving, then you can try to create semi-antique chairs. Various species are chosen from wood to implement such an idea. When there are carved elements in the project, the inserts are made from moderately soft rocks. You can artificially "age" a standard chair using special painting and processing methods: crackle technique, brushing, patina, coloring and other methods. The product turns out to be extraordinary, and for a certain interior design it can become one of the accents in the room.

Log stool or stool: quick ideas for beginners

The simplest type of chair is a regular piece of log set vertically.Such furniture is not placed in an apartment: because of the special strength and massiveness, it has a place in the country, in the garden, on the lawn. However, designers in pursuit of extravagance offer lovers of eco-style universal chairs made of logs that can serve as coasters, benches, coffee tables and other furniture attributes.

Instead of a drawing for such models, it is enough to have good photos of chairs and cut a log of that length that will be comfortable for sitting. The choice of logs also matters: the manufacturing process and product design depend on the diameter of the starting material. A fairly thick piece of log can serve as a base for a chair with a backrest. Smaller logs will require more cuts and other furniture stacking.

The simplest way of joinery work with a log as a starting material will look like this: take a log of a suitable diameter, measure the desired seat height and make a cross-cut in this place. The cut of the log is installed vertically, if desired, it is treated with impregnation from decay, polished, varnished, etc. It turns out an ordinary stool like a stump. The base can be made in the form of a chair with a one-piece back.

Related article:

Wooden chairs for the kitchen: elegance in harmony with practicality

The advantages of wood furniture. Species variety of models, their structure and purpose. Choice according to style. Review of manufacturers.

The number of stages of processing a log increases, and the requirements for the diameter of the source material increase:

- from the edge of the log, the desired seat height is measured, as in the first case, at this point a cross-cut is made, and not completely, but approximately 2/3 of the thickness;

- the height of the back of the chair is outlined, the necessary part is completely cut off;

- a vertical cut is made from the upper end of the cut to the border where the seat is indicated.

This is followed by cosmetic treatment and creative work on the product: leveling or deepening of the backrest, grinding, firing, impregnation, etc.

Helpful advice! To create a chair with a back from a solid log, a large diameter material is selected for cutting. Otherwise, an uncomfortable chair with a mediocre seat and an uncomfortable back will come out of a narrow log.

Huge logs from which a comfortable one-piece chair would emerge are rare. You don't have to look for wooden giants, but take a narrower material for work, saw it along and construct original wooden chairs from several parts. How to make such models, it is recommended to look on the Internet at a photo of wooden chairs with your own hands. You can get inspiration from the videos you watched, or make your own original sketch based on what is already in stock.

How to make a chair out of wood with your own hands: drawings, tools, assembly

A creative approach will be present in any projects involving the manufacture of products by hand. You can make a chair out of wood using templates and drawings from the Internet or, based on them, come up with your own interesting design. In any case, there are basic rules for the production, processing of wood and elements that must be followed.

For a standard hard chair you will need:

- measuring tools - a ruler or square, tape measure, a special construction pencil for marking, level;

- cut tools - hacksaw, jigsaw, miter box;

- processing tools - chisel, plane, mallet;

- assembly devices - screwdriver, hammer, self-tapping screws, wood glue;

- materials for finishing - sandpaper of different grain size, varnish or stain.

Initially, a blueprint is being searched for a chair of identical design. You can make developments on the basis of your own measurements, however, with insufficient experience in carpentry, there is a high probability of error or significant shortcomings. There are two main models of chairs on the Internet - with a straight back or a more ergonomic inclined part. The first option is easier to perform, but in the second case, a convenient and reliable product is obtained, similar to the factory one.

Helpful advice! When several symmetrical parts are prepared, the first sample is made according to the drawings, and the subsequent ones - according to the first sample (as in the template). In this way, an exceptional identity of parts can be achieved.

Let's get acquainted with the step-by-step instructions for making a standard chair with a back. First, you need to carefully study the finished drawing or think about your own. You need to prepare blocks of the required length for the front and back legs of the chair. There are options when all 4 legs are the same in height or the back legs can be much longer, combining their own height with the height of the back. The legs are cut from a flat profile or bent - it all depends on the design.

In each blank for the legs, it is required to drill holes at the same height from the bottom for installing the base and grooves for reinforcing horizontal lintels. Next, the jumpers themselves are cut, observing the length indicated in the drawing, plus be sure to add 2-3 cm from each end to organize mounting spikes. You should be careful about the same dimensions and make the connecting nodes as accurate as possible so that the structure does not "walk" during assembly.

The back of the chair is cut from the edged board. On the inside of the rear legs, grooves are made for its fastening. It is easier to fix the back with self-tapping screws, while the fasteners are not twisted immediately, but after preliminary shallow drilling, so that the timber does not split during assembly.

The seat for the chair is made, like the back, from edged board or furniture board. In size, it should protrude slightly beyond the edge of the installation frame. Before installing the seat, the chair frame should be additionally reinforced with diagonal slats.

The finished parts of the chair are sanded with sandpaper and varnished before final assembly. It is necessary to carefully distribute the varnish so that it does not flow into the grooves intended for the spikes, otherwise it will be impossible to glue the parts. When the varnish dries, you can finally collect the chair.

Wooden chairs with upholstered seats, with armrests and armchairs

There are several ways to improve the comfort of your own workshop chairs:

- complicate the design and make wooden chairs with armrests;

- slightly change the order of assembly and make wooden chairs with a soft seat and back;

- instead of a chair, you can make an armchair with your own hands, just not a massive, but a lightweight model, which, for example, will be appropriate in the interior of the Art Nouveau style.

It is not difficult to add armrests to the chair structure. They need to fit into the overall design, be at a comfortable height and not unduly restrict seat space. Perhaps, when adding armrests, it will be necessary to revise the entire assembly of the chair, radically change the drawings and think over a different type of connection of all parts. However, the armrests are well worth the consideration in the wood chair design project. Photos of original finds and ideas that have already been implemented can inspire your own non-trivial projects or show in which direction you should look for your own style.

You can make wooden chairs with your own hands as comfortable furniture with a soft seat and back. Plywood with a thickness of 4-6 mm is most often chosen as the basis. For the softening layer, furniture foam rubber, felt, polyurethane foam, latex, etc. are taken: 4-6 cm of total thickness will be enough, density - 30-50 kg / m³. It is better not to consider synthetic winterizer and batting as a filler at all, since these materials are quickly crushed. Cutting the gaskets is carried out according to the drawings of the chair and indent along all the cutting edges up to 20 mm in the direction of reduction. The casing of the product can be bright and decorative or serve a purely practical function. Special furniture fabrics, leatherette, eco-leather or natural leather are used as upholstery.

By combining a soft seat and a design with armrests, you can make a computer chair with your own hands. A novice craftsman will not be able to make a product with an adjustable back, but convenience, stability and reliability are quite achievable.

Helpful advice! The assembly of all parts of the chair is pre-assembled dry. Only after careful fitting of the parts is glue applied and the final assembly is carried out.

Solid wood chairs: reliable and solid

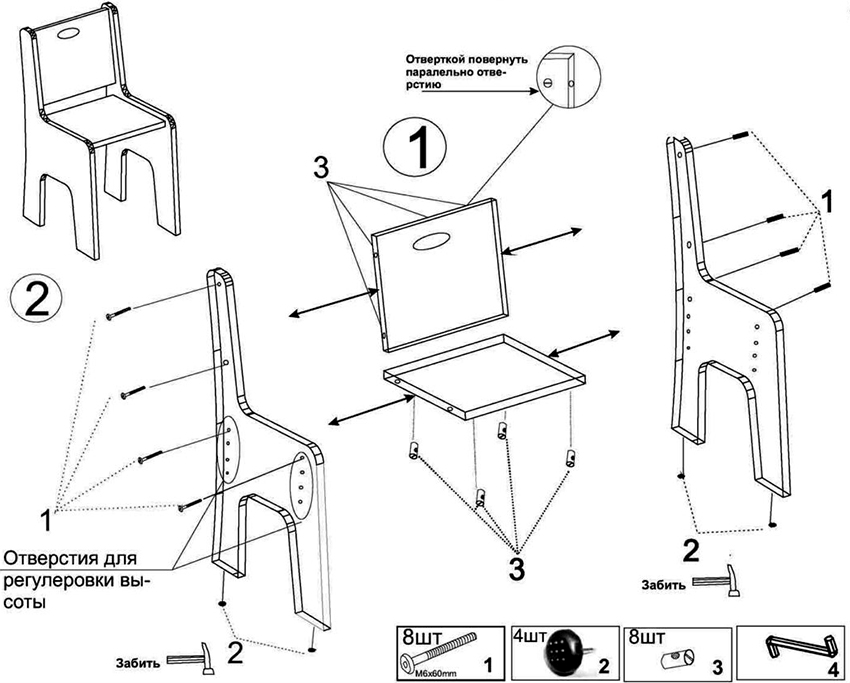

Making a chair made of solid wood with your own hands is financially more profitable than from lumber. The massif is cheaper, but it is required to take into account that the products from it are bulky and rough. For a country house interior, such furniture will be a good choice. It can also be placed in an apartment, but only in a reduced version - for children. Environmentally friendly material and sustainable construction are the primary characteristics of children's furniture. Solid wood is ideal for these requirements.

Children's tables and chairs are made of moderately soft wood. They usually try to use birch. The choice of material is due to the fact that all the corners of the furniture must be rounded off for the safety of the child, and with a wood species that is malleable to processing, it is quite easy to do this without specialized machines. Often, some elements of the array are replaced with plywood. It allows you to reduce the cost of furniture, make the product lighter in weight and add design details that will be of interest to the child.

Increased requirements are imposed on all surfaces of children's furniture. They are especially carefully sanded and treated with water-based varnishes without toxic odors. Similarly (in accordance with a high level of safety) paints are selected. Ideas and drawings on how to assemble a wooden highchair with your own hands can be found on construction and other thematic sites on the Internet.

How to make a folding wooden chair yourself

A folding chair is the second most practical and convenient seating device after a stool. You can use it at home, in the country, take it with you on a picnic or fishing. The product is easy to transport, easy to store. There are enough advantages in application, however, making a folding chair with your own hands may cause fear that incorrect calculations will not allow the structure to transform correctly.

Do-it-yourself folding chairs made of wood or plywood. The massif for such products is not purchased, since the advantages in lightness and mobility are lost due to its heavy weight. DIY folding chair drawings are very popular on the Internet. If you wish, you can watch a video demonstrating the manufacturing process and choose a model with a backrest of various shapes or without it at all. To assemble one of the popular samples, you need to prepare:

- legs 4 pcs. from a bar or board (40x20 mm), 470 mm long;

- crossbars for sitting 4 pcs. from a bar or board (40x20 mm) 320 mm long;

- props 2 pcs.- cut out the same as the crossbars for the seat (40x20x320 mm);

- seating boards 2 pcs. (90x20 mm) + 2 pcs. dimensions 60x20 mm, the length of all 4 blanks is the same - 350 mm;

- fastening tool - 6 pcs. bolts (6x40 mm), self-tapping screws 45-50 mm long.

Assembly of the chair begins with processing all the parts and rounding the ends. Then the chair legs are bolted crosswise. The connection point is located 60-100 mm above the middle of the parts to make the structure more stable. Pay attention to symmetry so that both hind legs are outside and the front legs are inside. Bolt caps and nuts are recessed. The seat crossbars are bolted to the assembled crosspieces: to the external parts - from the outside, to the internal ones - from the inside.

At a level of 100 mm from the lower edge of the legs, they are fixed with transverse strips (projections), securing with self-tapping screws on each side. The seat is formed from boards that fit in the following sequence: wide, narrow, narrow, wide. The distance between the boards is 15-20 mm. At the final stage, the product is varnished or painted.

Helpful advice! To make sure that the drawing and calculations are correct, make a preliminary model of the chair from cardboard.

Some useful ideas for folding chair designs

A folding chair can be made with your own hands like a chair. This requires finding a suitable design and choosing a more comfortable one from several models. It will be a seat and backrest not with soft filling, but the issue of comfort is completely solved by additional pillows and small mattresses.

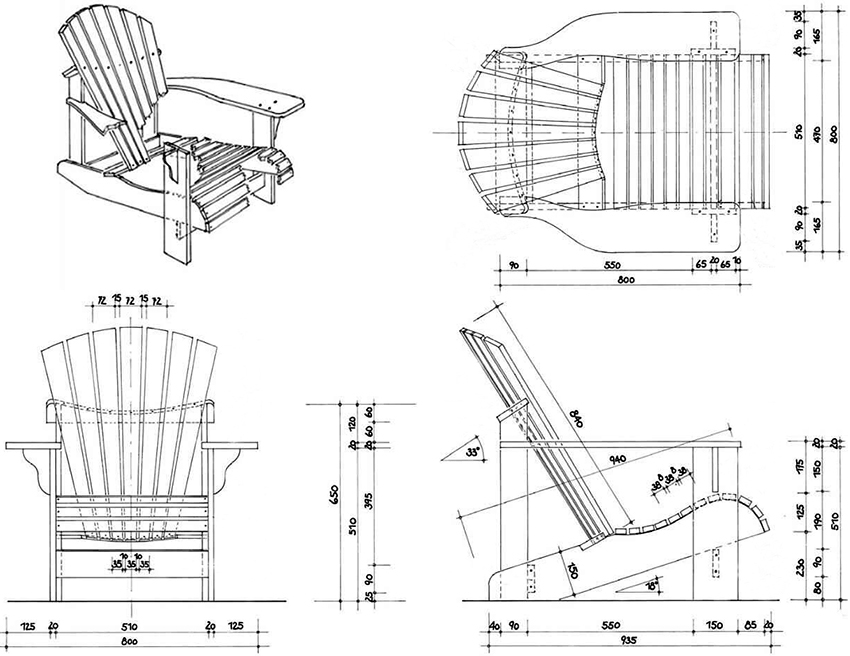

You can assemble an original garden chair made of wood with your own hands. The drawings of the folding model are very simple. Materials will require a bar of the same cross section (45x30 mm), strong galvanized wire and brackets for its fastening. It is required to carefully cut the workpieces of a given length, maintaining symmetry:

- seat - 6 pcs. length 375 mm + 2 pcs. length 875 mm for the back legs of the chair;

- dividers - 9 pcs. 228 mm long to create a transition from seat to back;

- backrest - 4 pcs. length 787 mm + 2 pcs. 745 mm long + 2 pcs. 1050 mm for front feet.

Assembly of the chair consists of combining parts in a checkerboard pattern. To fix all the blanks into a single structure, holes are drilled at the same distance from the edge into which the wire is threaded. Its free ends are fixed on the outer part of the chair with metal brackets.

The frame of a folding chair made of wood is always made, which contributes to the reliability and stability of the furniture. Material combinations are available for the backrest and seat. The most commonly used fabric is very thick. The result is an ergonomic, lightweight recliner-like chair.

There are other options, when holes are made at the same distance along the backrest guides. A strong twine is threaded through them, and the free space for the back is filled with weaving from this twine.

You can make your own wooden chair without having any carpentry experience at all. Modern tools, ready-made drawings and instructions allow you to perform work accurately enough. Over time, skill will increase, which means more sophisticated and exclusive models will be obtained.