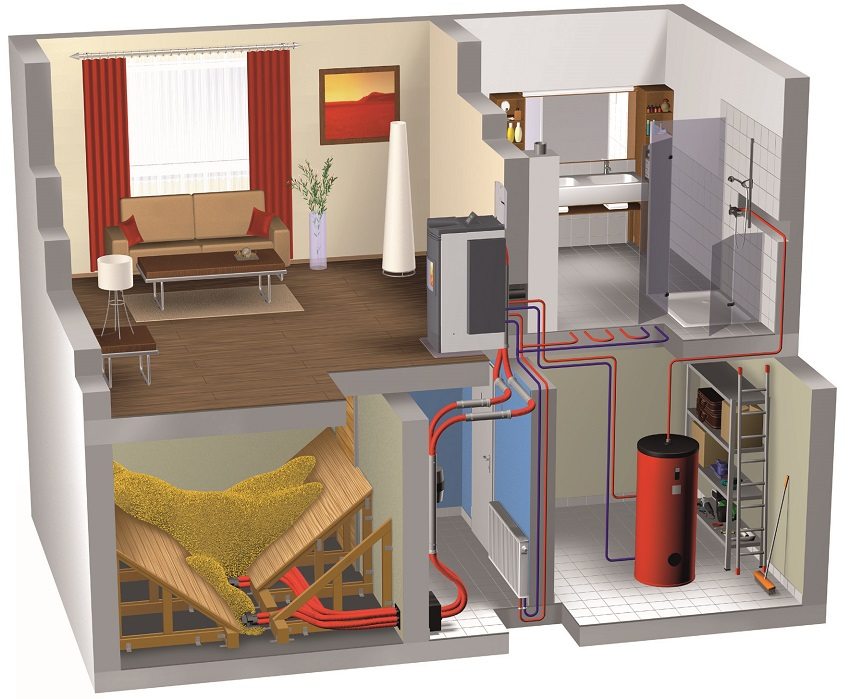

Solid fuel boilers for long burning with a water circuit for the house are heating units designed for use in non-gasified cottages, houses and summer cottages. The low price of fuel, their use as a reserve source of heat and the ability to burn garden waste in boilers made solid fuel boilers quite popular among owners of suburban housing. Such equipment is especially important in the context of the continuing trend of increasing gas prices.

Solid fuel boilers long burning - an excellent alternative to gas units

Content [Hide]

Solid fuel boilers for long burning with a water circuit for the house: types of units

Unfortunately, there are still many settlements and summer cottages where gas pipelines are only being planned. In such conditions, equipment becomes an alternative, the fuel for which is coal, firewood or fuel pellets (pellets). To ensure a comfortable microclimate and the availability of hot water for domestic needs, they resort to using long-burning solid fuel boilers with a water circuit for the home. The convenience of their use lies in the fact that the equipment is loaded once a day (in some models, it is loaded once a week). Long burning solid fuel boiler due to this, it has a high (up to 95%) efficiency.

Solid fuel double-circuit boiler of long burning will provide not only heating of the house, but also hot water supply

Single-circuit and double-circuit model device

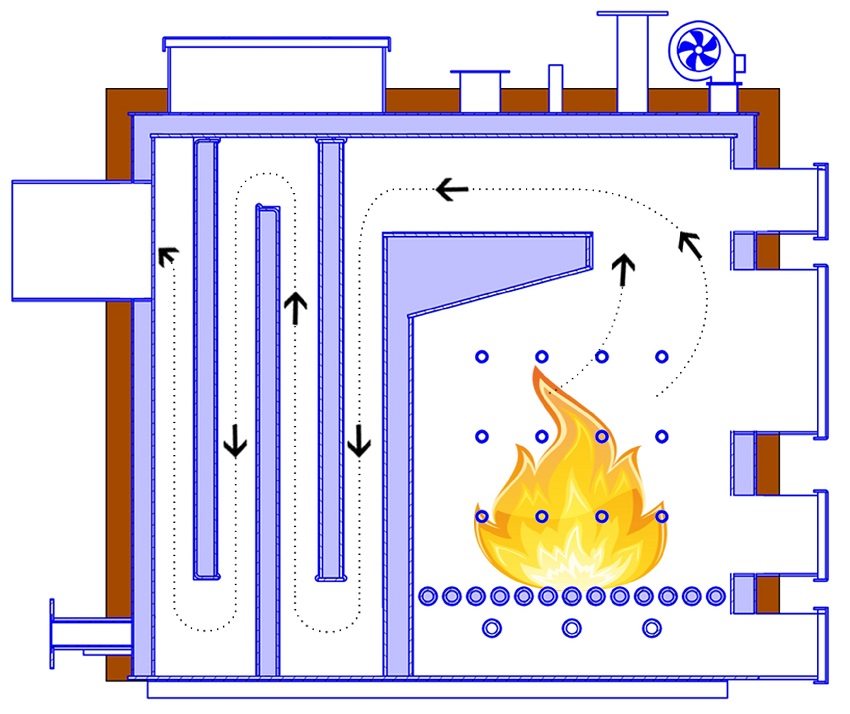

By their design, boilers with one combustion chamber using bottom blast and boilers with a two-part furnace with bottom and top blowing are distinguished (pyrolysis boilers). Types of body of a solid fuel heating boiler with a water circuit: cast iron or steel.

The device of a single-circuit boiler, providing for heating the coolant for the batteries of the heating system, has the following design:

- firebox - combustion chamber for solid fuels;

- ash pan - a collection of waste generated during combustion;

- chimney - a channel for the output of exhaust gaseous combustion products;

- shirt - a heat exchanger with water built into the firebox.

The principle of operation of the boiler is as follows: a fuel is loaded into the combustion chamber, which releases heat during combustion. The heat exchanger accumulates heat and gives it to the coolant, which circulates through the coil.Warm water enters the batteries, and the cooled one returns back to the boiler.

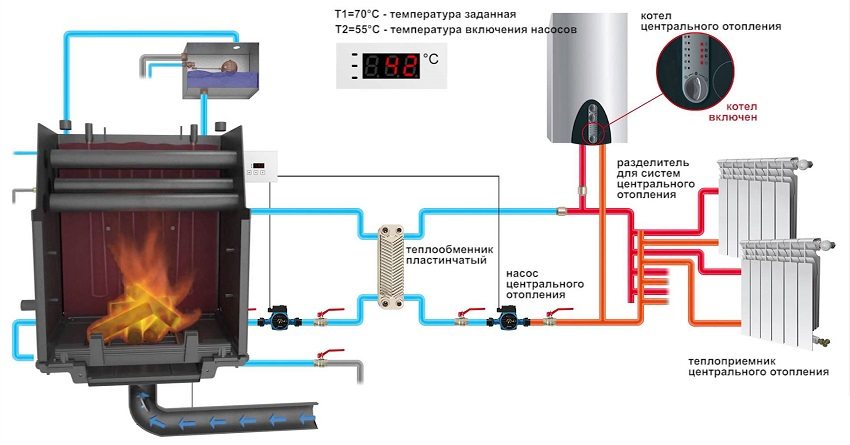

The difference between a double-circuit solid fuel boiler for a home is that it provides an additional heat exchanger (coil) used for hot water supply. This heat exchanger is connected to the water supply pipes, providing domestic hot water supply.

The modern boiler room is equipped with a double-circuit solid fuel boiler with a storage tank for hot water

There are two methods for connecting and locating the DHW circuit:

- Flow-through heating mode. With this method, the water heating coil is built into the jacket. The hot water coil is heated by the energy of the heating system coolant. The water transported along the coil is heated to 45 degrees. The efficiency of such a system is up to 8 liters per minute.

- Cumulative heating mode. Such a system provides boiler (hot water tank) built into the flue duct or main heat exchanger. Heating is carried out by hot air or heating agent of the heating system. Depending on the consumption of hot water, cold water is supplied to the boiler from the water supply and heated there to 90 degrees. With such a scheme, the DHW circuit is able to provide a volume of water 2 times the volume of the boiler, which will contribute to excessive fuel consumption.

Additional equipment for boilers

When water is heated, due to expansion, its natural circulation occurs: when heated, it moves up, and when it cools, it goes down. Long burning wood boilers able to heat only a certain amount of water. This parameter should be taken into account when choosing a boiler.

Related article:

|

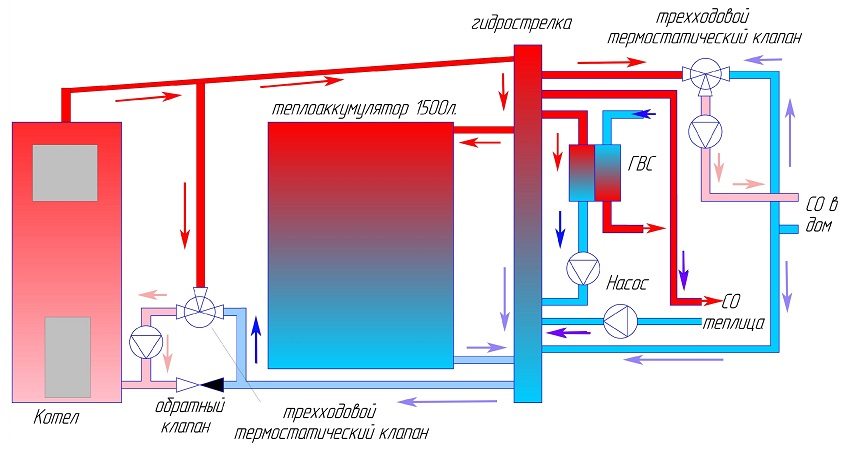

To increase the efficiency of the equipment, it is proposed to equip the boiler with a circulation pump. With its installation, the efficiency will double, but then the functioning of the boilers becomes volatile. If electricity is supplied intermittently, it is recommended to equip the boiler with a switch (bypass) capable of converting the forced movement of water into natural one.

Heating and hot water based solid fuel boiler and solar panels will provide your home with energy independence

Useful advice! When purchasing a boiler, you should choose a model that will provide domestic hot water supply without supplying water to the heating system. This will allow hot water to be used during the summer season.

So that the boiler for long-term combustion of fuel does not work to heat the radiators, but provides heating of water for domestic use, it is equipped with an electric heating element. Such a boiler is called hybrid and is a multifunctional equipment.

Equipping boilers with additional equipment (for example, a fan for providing draft in the chimney, a pump for pumping hot water in pipes) makes the equipment volatile, on the other hand, the connection to the network makes it possible to automatically control the process.

We offer to watch the video: "Do-it-yourself solid fuel boiler for long burning":

The device of a pyrolysis solid fuel boiler with a water circuit

A feature of the functioning of pyrolysis boilers is that the combustion chamber in them consists of two separate sections. Solid fuel burns in one section of the furnace, and combustion products in another. When in the cold season firewood (often damp) is laid in the first section, steam appears during their combustion. To eliminate its negative impact on the combustion process, use the second section of the furnace.It is into it that hot gas moves, which removes excess moisture using a secondary air stream. This method is called the double blowing method. The two sections of the chamber are separated by a grate, where firewood lies, through which the primary blowing passes. The functioning of the pyrolysis boiler is facilitated by the forced draft created by the smoke exhauster.

The procedure for the pyrolysis unit:

- solid fuel (firewood) is stacked on the grate;

- the boiler is fired up, the firebox door is closed and the smoke exhauster is turned on;

- during combustion, a high temperature is created inside the chamber, which contributes to the formation of charcoal, carbon monoxide and volatile formations of hydrogen and nitrogen;

- all these products enter the second section of the chamber, where a secondary air flow is added to them and these products are burned;

- the heat from the combustion of these products is re-fed to the first section of the chamber.

As a result of this design of the boiler, a sufficiently high temperature is maintained in it, the waste from the combustion of firewood is thermally decomposed, forming a pyrolysis gas. Thus, solid fuel is used rationally, and the heat from the combustion of waste is reused.

Comparative analysis of models of solid fuel boilers with a water circuit for the home

For the correct choice of a solid fuel boiler for heating a private house, it is necessary to analyze its characteristics:

- in pyrolysis units, a re-supply of air is used, which ensures the duration of the burning out of the fuel insert, extending it to 10-12 hours, and the burning time of a similar bookmark in a conventional boiler is 4 hours. From the point of view of efficiency, pyrolysis boilers are loaded less often and less fuel is consumed;

- in pyrolysis boilers, firewood is burned practically without waste. The ash remains at least. This, in turn, facilitates the maintenance of the equipment: it is not so often required to remove ash from the boiler and clean the flue;

In pyrolysis boilers, a repeated air supply is used, extending the duration of the burnout of the fuel insert up to 10-12 hours

- two-stage combustion, which reduces the excess air in the chamber, increases the performance of the pyrolysis boiler;

- in the presence of two combustion chambers, it becomes possible to control and regulate the combustion process. Pyrolysis boilers can be automated, which is completely impossible in conventional boilers;

- pyrolysis boilers can take quite large logs for lighting, which, in turn, saves time for chopping wood;

- easy and affordable installation - does not require permits, you can install the equipment yourself.

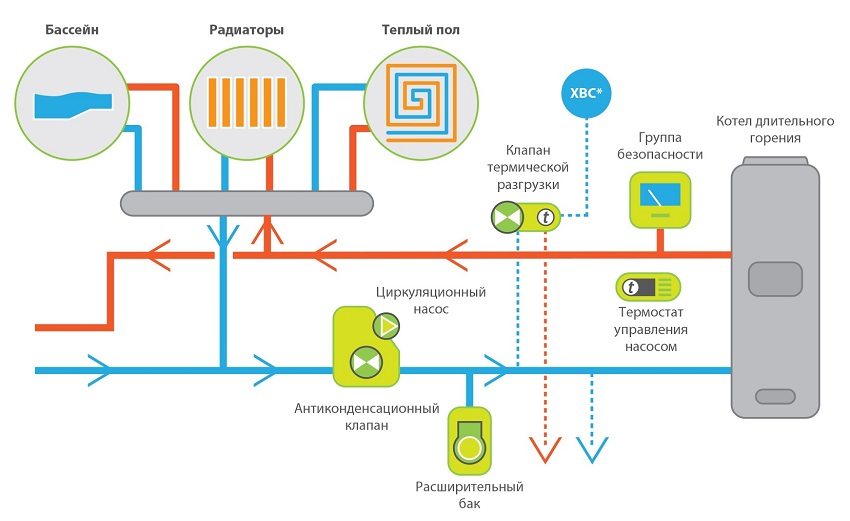

Simplified diagram of connecting automation to a heating system with a long-burning solid fuel boiler

There are many advantages of solid fuel pyrolysis boilers for heating a private house, but there are also some disadvantages that should be mentioned:

- high price;

- dependence on electricity - due to the use of a smoke exhauster;

- in some cases, non-compliance with the declared power characteristics;

Useful advice! Before purchasing a solid fuel boiler for long burning, read the reviews about its manufacturer. Very often there are models with an ineffective pyrolysis process.

- the use of boilers at partial capacity leads to the formation of tar clogging the gas duct;

- for the correct operation of pyrolysis heating solid fuel boilers with a water circuit, a mixture of hot water is required to the liquid entering the boiler again;

- the return temperature must be at least 60 ° C, otherwise condensation will appear in the gas path, which will lead to corrosion.

How to choose the right solid fuel heating boiler

What you should pay attention to when choosing a suitable solid fuel boiler model:

- unit power. If you purchase a double-circuit boiler to provide hot water supply, you should choose a unit whose power is enough to heat domestic water;

- hot water circuit performance. It is necessary to calculate whether the volume of water heated by the boiler is enough for the household needs of the whole family;

Useful advice! To provide hot water supply to a house where a large family lives, you should purchase a boiler model with a built-in boiler or provide for the installation of a heat accumulator.

- convenience and frequency of maintenance. Pay attention to how often you have to load wood and empty the ash pan. Give preference to models with a volumetric hopper, where cleaning is done once every three months, and the burning time reaches up to five days;

- the materials from which the boiler is made. Equipment made of cast iron is durable (service life is up to 30 years). The hot water coil must be made of steel or copper.

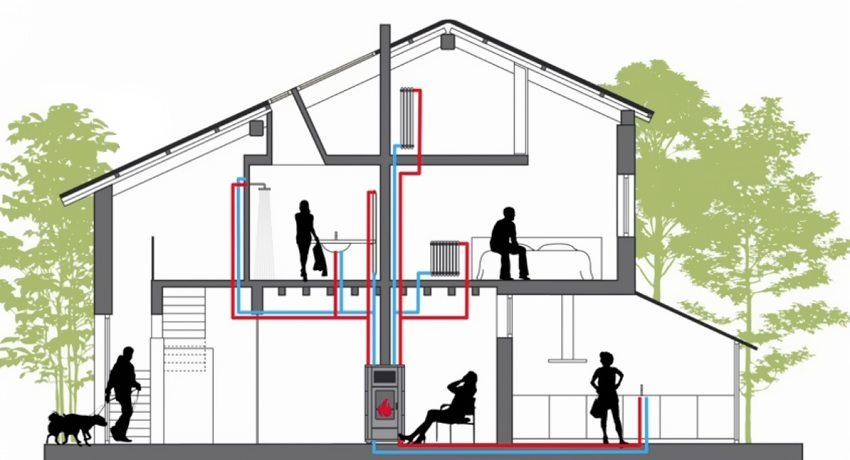

Modern models of solid fuel boilers for long burning can completely replace gas units in heating and hot water supply systems of a private house

Modern models of solid fuel boilers for long burning can completely replace gas. Moreover, due to their high performance, they are environmentally friendly and economical. The purchase of a solid fuel boiler with a water circuit will be beneficial if all the requirements and parameters of this equipment are taken into account.