To ensure an acceptable temperature in your unheated garage in winter, you can build a working oven with your own hands. It is not expensive, and fuel can be obtained for it at a bargain price if you try. There are several options for the construction of such a structure of varying degrees of complexity. Let's consider some of them.

To save on heating a small utility room, you can build working furnace do it yourself

Content [Hide]

- 1 The operating principle of waste oil furnaces

- 2 How to make a working oven with your own hands is the easiest way

- 3 Do-it-yourself furnace for working off (video)

- 4 Using capillary technologies in the manufacture of a furnace

- 5 Organization of additional features of the waste oil furnace

- 6 Advantages and Disadvantages of Oil Furnaces

- 7 How to make a furnace for working out with your own hands (video)

The operating principle of waste oil furnaces

Fuel oil has long been used by humans as fuel. Being one of the heaviest components of oil, this substance is used not only for fuel, but also for the production of various oils and other liquids for petrochemical production. Like all components of oil, fuel oil and its derivatives have good flammability with the release of a large amount of heat. Used car oil must be disposed of using complex technological processes. However, you can benefit from it by carrying out combustion in a homemade furnace for mining. A drawing of the simplest version of such a design may look like the one shown below.

Waste oil is a very complex substance composed of a mixture of various hydrocarbons. If you set it on fire, then only volatile substances will burn out, and everything else will go to waste. Moreover, they are very toxic and it is forbidden to throw them into a regular landfill. When heated without combustion, the mining begins to disintegrate into many components, most of which are gaseous. Here they are, with sufficient access of oxygen, burn completely, leaving no harmful substances. For such a process to occur, it is necessary to build a furnace for working off. You can do this with your own hands, for example, from an old gas cylinder.

How to make a working oven with your own hands is the easiest way

In order to independently make a stove for a garage, which will consume used car oil as fuel, you need to find an old gas cylinder. Before you start cutting it, you need to release all the residual gas and drain the condensate. After that, the balloon is rinsed with water to exclude even the very possibility of ignition. To disassemble the cylinder, you need to release gas from it by pressing the valve.

Helpful advice! To make sure that there is no gas in the cylinder completely, it is necessary to lubricate the valve with liquid soap.Press the valve until the soapy water stops bubbling.

After the gas is completely drained, the valve must be unscrewed. If this is not possible, you will have to drill a small hole with a diameter of 10 mm in the bottom of the cylinder. To do this, take a drill and drill in the center of the bottom, without pressing hard, so as not to get sparks. To be sure, the drilling site is constantly watered. As soon as the hole is ready, ordinary water is poured into the container and rinsed. Then the water is drained and the places of the cuts on the cylinder are marked.

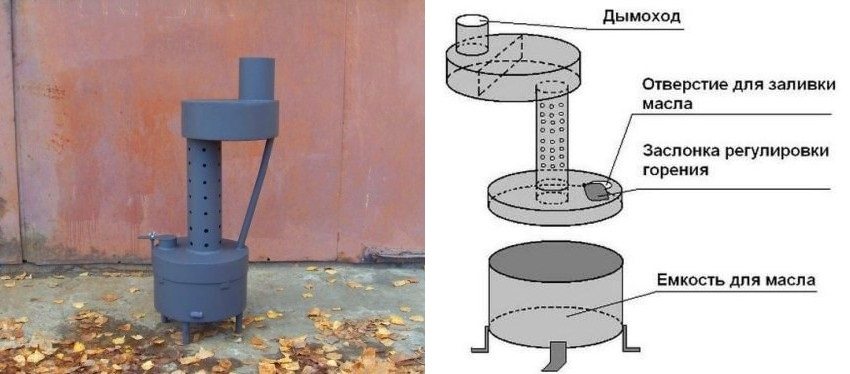

When making a do-it-yourself furnace from a gas cylinder, a drawing of which was presented earlier, it is necessary to cut off the lower part. Its height is 20 cm. Legs are welded to it, which can be adjusted for ease of installation on any surface.

The primary combustion chamber is made from the bottom. Waste oil will be poured into it, which in the process of controlled combustion will heat up and decompose into volatile fractions. The top of this chamber is covered with a 4 mm thick round steel lid. It must necessarily be easily removed if necessary, since the inner surface of the chamber needs to be thoroughly cleaned from slags every week.

A hole with a diameter of 10-15 cm is cut in the middle of the lid. A pipe 50 cm long is welded onto it, in which a set of 10 mm is drilled. holes. The pipe must be thick-walled, at least 4 mm. In the same cover, a hole is made on the side of a smaller, up to 5 cm diameter. A small tube with a shutter is inserted into it. It plays the role of a throat for filling oil and a throttle to control the flow of the air mixture into the furnace.

Since a self-created furnace for working off needs to remove smoke without exhausting fire, another chamber is made from the top of the cylinder, in which the exhaust gases cool before flying into the pipe. There is a baffle inside this chamber to prevent direct fire from entering the exhaust pipe. The incandescent gases have time to completely burn out in this chamber while they bend around this partition.

Helpful advice! The height of the chimney should be 4 m. This is the optimum size for proper draft. It should be strictly vertical, since any horizontal sections are capable of accumulating condensation in themselves.

This oven works as follows. Through a hole in the combustion chamber, waste oil is poured into two-thirds of its volume. There it is set on fire. When the combustion intensifies, the damper is closed. This ensures more economical oil consumption and complete burnout. When heated, the fractions that are not immediately burnt rise into a perforated pipe, where they come into contact with air, after which they ignite and burn, releasing heat in large quantities. The exhaust gases enter the upper chamber, where they are finally burned out and exhausted into the pipe.

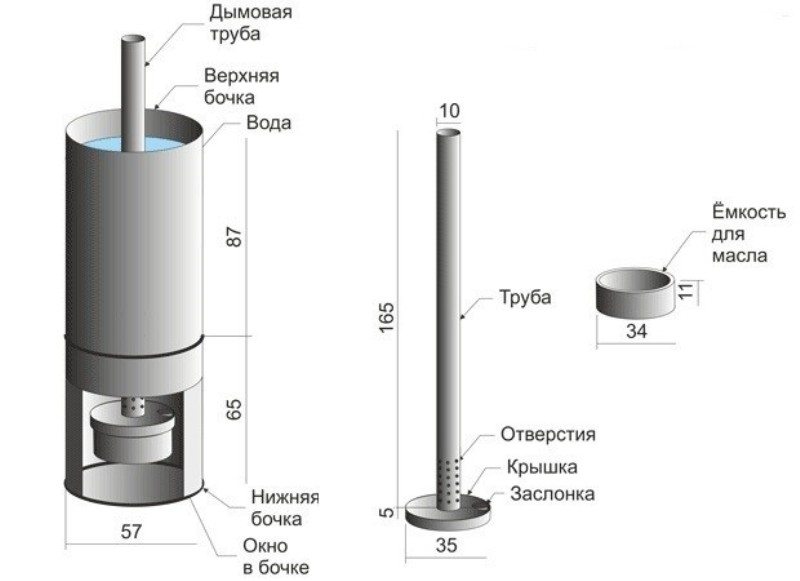

So from an ordinary gas cylinder, you can make a working furnace. A drawing with all the details and their dimensions can be seen in the photo.

Do-it-yourself furnace for working off (video)

Using capillary technologies in the manufacture of a furnace

In addition to the simplest method of manufacturing an oil oven described above, more advanced versions are also used. One of them is a working capillary furnace. It is also within the power of anyone who knows how to handle metal and tools to make it with their own hands.

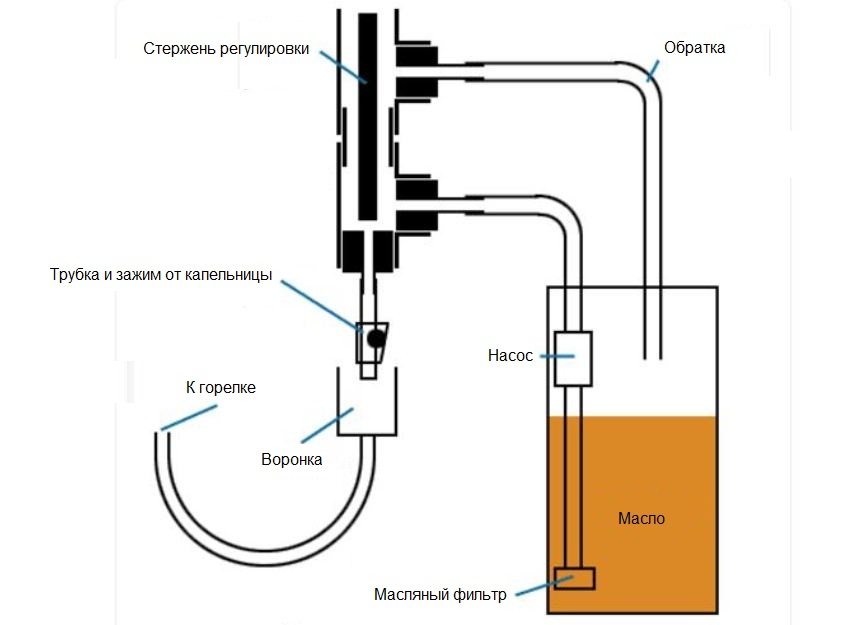

Oil in this design is not just poured into the combustion chamber, where it is in large quantities, but it is done gradually by means of a drip system. This method allows the oil to burn out with greater efficiency, and its consumption is reduced to a minimum.Separately from the furnace, an oil tank is installed in the upper part, which is connected to the combustion chamber of the furnace by a branch pipe. An adjusting valve is installed in the branch pipe, with the help of which the flow of oil into the furnace is dosed. Otherwise, the design is no different from the simplest furnace for working out. With your own hands, the drawings presented below will help you make such a unit without difficulty.

Organization of additional features of the waste oil furnace

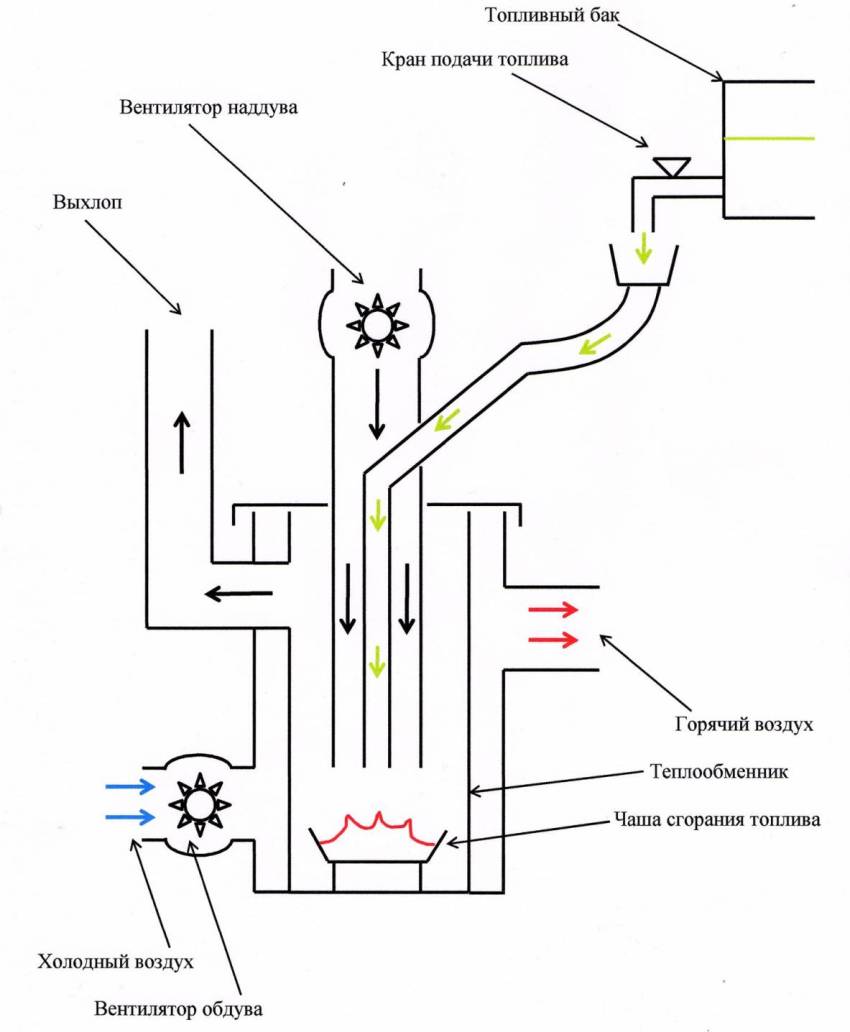

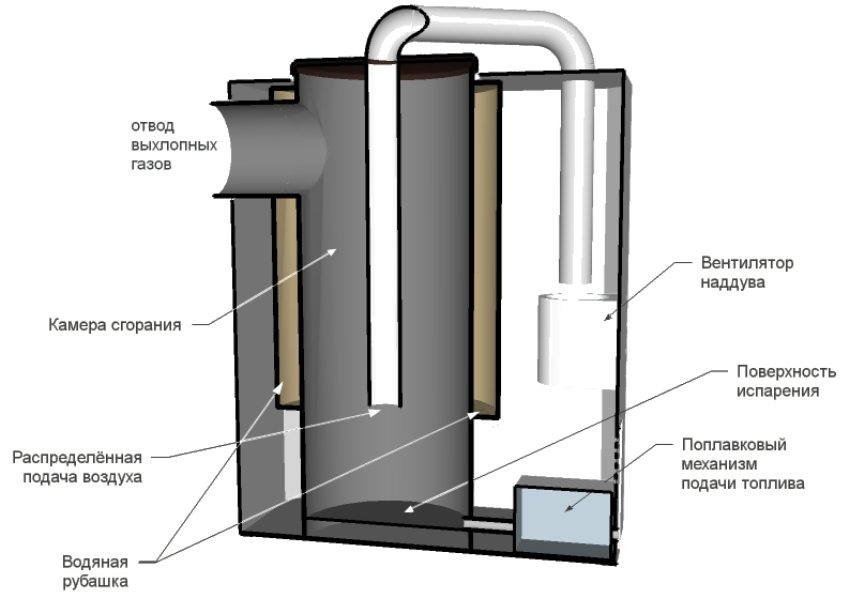

When making a homemade stove that runs on waste oil, you can use electric fans. With the help of them, it is possible not only to pump air mass into the combustion chamber, but also to remove hot air from the furnace, creating artificial circulation in the room, which will significantly speed up the process of heating it to the desired temperature. For this, a casing is mounted around the main chamber, in which an air flow is created using a fan. You can see the work of such a do-it-yourself furnace for testing live. The video of the entire combustion process is very interesting and visual.

Related article:

Do-it-yourself wood splitter: drawings, photos, instructions. How to choose a wood splitter. Types of wood splitter. Features of screw, hydraulic and rack log splitters. Self-assembly.

Another improvement is the manufacture of a water circuit for a homemade oil stove. The pipe coil is placed inside the secondary combustion chamber, where the highest temperature is observed. Or it is screwed on from the outside onto a perforated pipe. The coil is connected to the flow and return pipes of the heating system. When the liquid is heated, its natural circulation occurs in all batteries. You can make such a furnace for working out with your own hands, the video of which well reflects its effectiveness, in one day.

Helpful advice! If necessary, a centrifugal pump can also be installed in the system, which will allow more efficient use of the energy of the heated water. She will not have time to cool down much during the passage of the entire pipeline.

Advantages and Disadvantages of Oil Furnaces

Like all homemade designs, oil ovens have the main advantage - they are cheap. They can be made from old parts that have been lying around for a long time in the corner of the garage, waiting for their use. The second advantage of these devices is the fact that they actually run on cheap and unnecessary fuel, which is easy to obtain. These ovens are able to heat up a small room very quickly, as they use an open fire.

Moving on to the disadvantages, it should be said that such self-made structures do not pretend to be permanent and main sources of energy. They only help to warm the utility rooms. So, we list all the disadvantages of oil ovens:

- the inability to use inside residential premises;

- an increase in the size of the combustion chamber does not lead to an increase in the power of the device, since the efficiency decreases;

- you cannot extinguish the stove with a fire extinguisher with powder, since the mixture simply explodes from the hot parts of the stove;

- it is impossible to accurately regulate the intensity of heat transfer;

- there is a risk of explosion when mining boils.

Creating a furnace for testing with our own hands, we ask ourselves where to get fuel for it. This question can be solved in the simplest way. You just need to negotiate with the owner of one of the car services located near your home. Perhaps he will be happy to sell you this fuel that is valuable to you, but has no practical benefit for him at a low price.

Helpful advice! When operating a furnace with an open combustion chamber, fire safety rules should not be violated.

This can lead to consequences, the losses from which will probably outweigh all the benefits of such a furnace.