The most convenient and affordable heating method is considered to be gas equipment. Most consumers living outside the city use just such methods for heating premises. For this, it is not only necessary to correctly install the boiler, but also to organize a high-quality removal of all harmful combustion products. To do this, you need to know how the chimney for a gas boiler is arranged. The requirements for such heating elements are quite stringent, so their observance is mandatory.

External and internal chimneys metal

Content [Hide]

- 1 The main structures of chimneys and their elements

- 2 Types of arrangement: indoor and outdoor

- 3 The main elements of the chimney

- 4 Chimney for a gas boiler. Requirements for structures

- 5 Construction of a chimney for a gas boiler. Installation requirements

- 6 Removal of combustion products from wall-hung boilers

- 7 Chimney (video)

The main structures of chimneys and their elements

For the construction of a chimney system, several design options can be used. They can be made from:

- bricks;

- asbestos;

- metal;

- ceramics;

- plastic.

Brick chimney

For the construction of the chimney system, a special refractory brick is used. The temperatures inside the finished pipe are so high that conventional applications red brick not enough. It has a porous structure, into which combustion products are easily absorbed together with water vapor. This process leads to the rapid destruction of brickwork. The use of refractory materials will ensure a longer service life of the structure.

Metal construction

When using metal for organizing a chimney, you need to think about high-quality, reliable thermal insulation. Places in contact with the roof are insulated especially carefully. It is here that the heated exhaust gases can come into contact with the wooden parts of the roof, which can lead to fire and fire.

In some cases, a metal pipe is used in conjunction with a brick structure. Such a system is more reliable. The inner surface of the metal pipe protects against the deposition of waste substances on the walls. In such systems, the draft is much better, the efficiency of the boiler is maximized.

Plastic chimney system

Modern plastic designs can also serve as a chimney. They are usually used with condensing gas boilers.Plastic parts are elements of pipes made of the type of sandwich panels. They are inserted into each other, and the space between them is filled with a special material with high thermal insulation properties.

Asbestos used to be used as the cheapest material. However, low strength, unaesthetic appearance also made such arrangement options a thing of the past.

Useful advice! To choose the best option for building a chimney, you need to know the regulated rules, all the existing standards for its operation.

Types of arrangement: indoor and outdoor

The chimney system can be located inside the heated room and outside. The internal structure is usually insulated only outside the premises and where it passes through the roof. The construction of such a system is a more complex process, for which special moves must be made in the ceiling slabs and roofing elements. Maintenance of such a chimney can also be difficult.

The best option is the arrangement of the smoke exhaust system by means of an extension to the house. The device of this design is much simpler, but it requires careful insulation along its entire length. The operation and maintenance of such a chimney will not cause difficulties for its owner, and by observing the requirements for the chimneys of a gas boiler, achieve high efficiency of its operation.

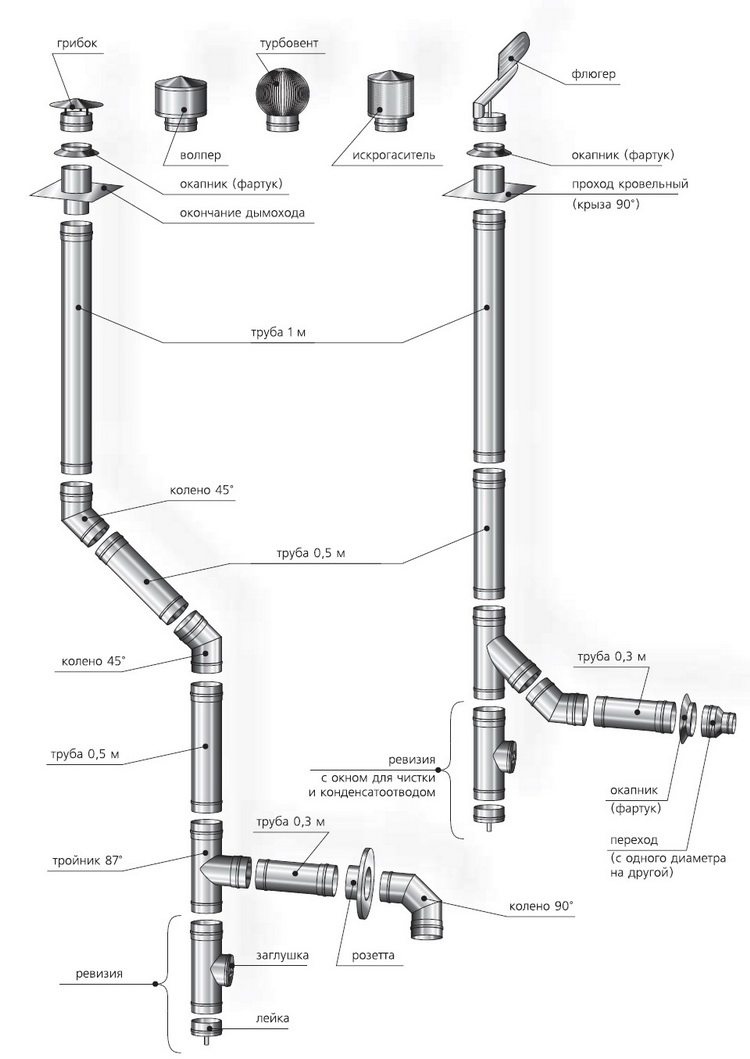

The main elements of the chimney

All existing options for arranging a chimney system, except for a brick one, imply the presence of some mandatory elements. They must be selected in accordance with the developed scheme. You will need:

- Connecting pipes, adapters.

- Pipes of different lengths.

- Inspection tee for condensate drain.

- Taper tip.

- All kinds of bends.

Chimney for a gas boiler. Requirements for structures

The correct arrangement of chimney structures must fully comply with the requirements of SNiP 2.04.05-91, all the subtleties must be taken into account so that safety is at the highest level. Safety and human health may depend on the exact implementation of existing standards and rules. As a result of compliance with all standards, the quality of work gas boiler will also be higher.

The basic requirements for the chimney of a gas boiler include the following points:

- the chimney is equipped with a moisture collector installed at the bottom of the pipe;

- the highest possible tightness is ensured for better traction;

- the verticality of the structure is controlled, the permitted slope cannot be more than 30 degrees;

- the pipe connecting the boiler to the chimney must have a vertical part;

- non-combustible insulating material must be laid along the walls and floors where the chimney system runs;

- the top of the chimney must be at least one meter higher than the roof.

Brick chimney in bedroom interior

Absolutely forbidden

- install all kinds of deflectors and other elements on the chimney head;

- build more than 3 swivel knees;

- arrange a chimney in rooms where there is no ventilation;

- use porous materials for arranging the structure;

- lay the entire chimney through the living rooms.

Useful advice! Each manufacturer of chimney structures has assembly instructions, which must be followed. Such instructions are agreed with the controlling and service organizations.

Internal organization. Work stages

- The first priority is to mark the slab and roof for future openings for the chimney.

- Openings are cut.

- Connects the branch pipe leaving the boiler with a suitable adapter.

- The revision and tee are connected, the structure is fixed with the main bracket.

- The chimney is built up to the required height, using "knees" if necessary.

- A galvanized sheet with a cut hole is put on the finished chimney, which is subsequently attached to the ceiling.

- The joints are reinforced with clamps.

- Fix the main pipe in increments of at least 2 m.

- A cone-like tip completes the entire system.

- Isolation in progress.

As you can see, there are no particularly complex requirements for the chimney of a gas boiler.

Outdoor device. Assembly order

The procedure for assembling an external chimney is practically no different from the stages of building its internal counterpart. The only difference is that the outlet will be located at the bottom of the house in the area of the foundation and pipe insulation will be required along the entire length. It is recommended to paint the outer structure with a special, high-temperature-resistant paint. It will create good protection against external influences.

Removal of combustion products from wall-hung boilers

For wall-mounted gas boiler experts recommend using double-circuit pipes. This method of arrangement is called a coaxial chimney. It consists of two pipes inserted into each other, through one of which oxygen necessary to maintain the fire enters the system, and through the other the remains of the exhaust gas are removed. Installation of a coaxial system is quite simple.