A barrel stove is a simple and economical way to arrange heating in any non-residential building, for example, in a garage. For the manufacture of such a stove-stove, metal containers are used, the volume of which is 200 liters. To make a reliable and efficient heater from a barrel, you need to understand the principle of the stove and clearly follow the instructions.

Before starting the self-assembly of the stove from the barrel, you need to understand how it functions

Content [Hide]

- 1 Advantages and disadvantages of a homemade barrel stove

- 2 The principle of operation of a potbelly stove from a barrel: what you need to know

- 3 Varieties of stoves, depending on the location: vertical model

- 4 Barrel stove: features of the horizontal model

- 5 How to make a stove with your own hands: the preparatory stage

- 6 Rules for installing a homemade potbelly stove

Advantages and disadvantages of a homemade barrel stove

Currently, there are many options for self-manufacturing stoves for household needs. To assemble the stove, old gas cylinders are used, as well as sheet metal. In the first case, it is rather difficult to get the required capacity. As for sheet iron, it is not cheap. However, there is a more affordable source material, from which it is easiest to make a heating unit - a metal barrel for 200 liters.

Why is this volume recommended? The explanation is quite simple. When assembling a potbelly stove with your own hands, you need to make sure that it contains a large amount of fuel. This will maximize the time interval between loading new batches of firewood. In addition, the dimensions of such a container make it easy to allocate space for an ash pan.

Most often, these self-made structures are used to heat basements, garages, as well as workshops that do not provide autonomous heating.

Note! Before using the drum, inspect it for rust. Tanks with traces of corrosion on the surface must never be used. These vulnerabilities will simply burn out under the influence of high temperatures, which can cause an emergency.

In order to answer the question of how to make a potbelly stove, you must carefully study the instructions. There are other advantages to using a metal barrel to design a heater. For example, the natural dimensions of the tank do not impede the free burning of the fire.And also such a stove does not require the selection of special fuel.

Self-made structures are used to heat basements, garages, in which autonomous heating is not provided

As with any other device, some disadvantages are characteristic of a homemade potbelly stove. During operation, the container body heats up to a very high temperature, since the metal sheet is thin. Thus, during the operation of such a stove, it is strictly forbidden to touch it. You can make a stove from a 200 liter barrel with your own hands quite quickly (in just a few hours).

Such stoves have low efficiency, which is explained by the peculiarities of their design. During operation, part of the heat energy simply evaporates into the chimney. Experts do not recommend using coal as fuel for such barrels. It's all about its high combustion temperature, which thin walls can not withstand.

The principle of operation of a potbelly stove from a barrel: what you need to know

Before starting the self-assembly of such a device, you need to understand how it functions. Understanding the principle of operation makes it possible to simplify the process of making such an improvised oven.

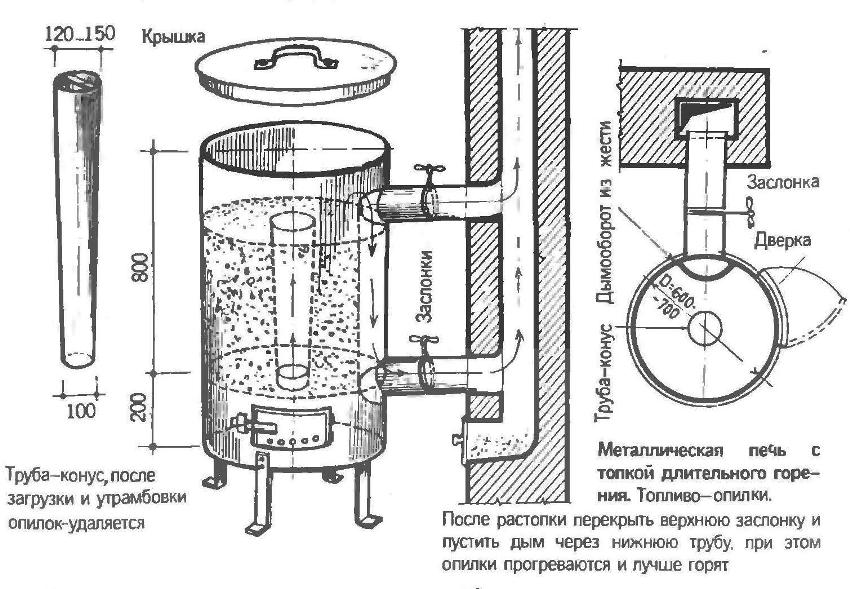

Sawdust or firewood is used as fuel for a homemade stove from a metal tank. Compressed sawdust is distinguished by the fact that it takes a long time to be processed inside a home-made oven. Among other things, the cost of such fuel is minimal, so it has become widespread.

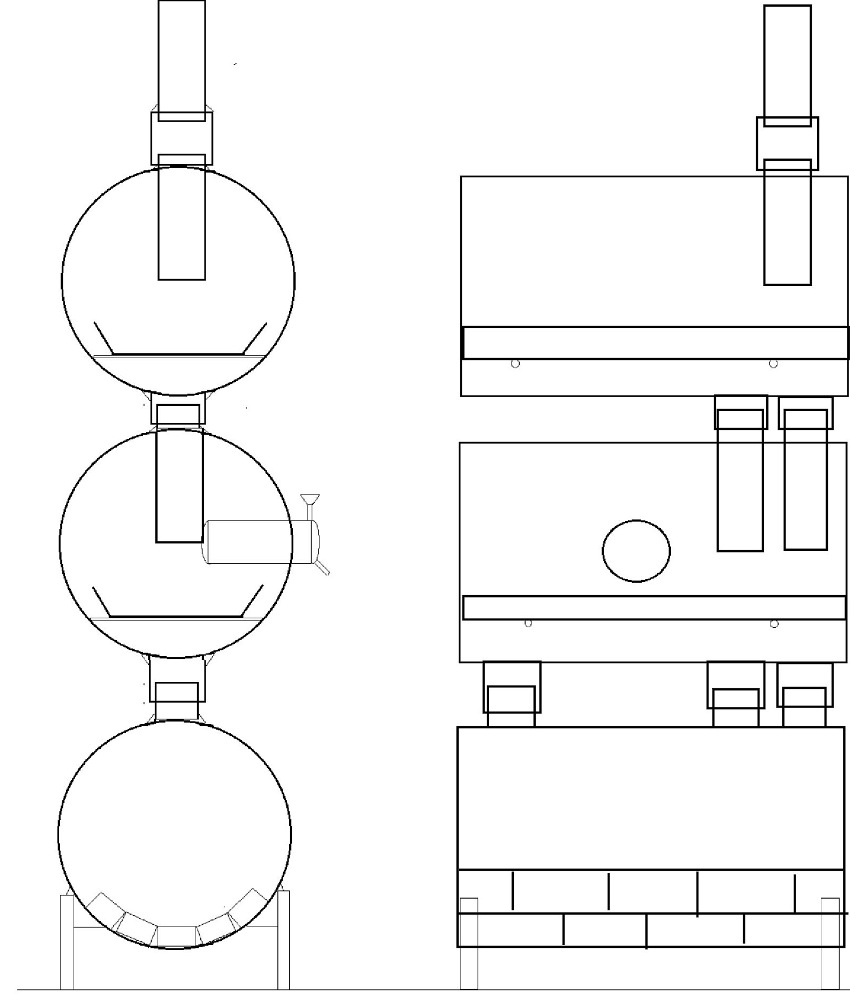

Before starting the self-assembly of the stove from the barrel, you need to draw up a design diagram

The diameter of a 200 liter barrel is 600 mm. If you wish, you can make a fairly functional design, which, moreover, will have an attractive appearance. The dimensions of a tank with a volume of 200 liters allow you to place a hexagon inside it, the sides of which will be equal to 314 mm. In this case, according to the manufacturing technology, the devices resemble traditional furnace units.

It should be noted that the finished device has a not very high efficiency - only 15%. To increase efficiency, one more component is often added to a homemade design - a screen. The reflective shield, of course, contributes to an increase in efficiency, but this solution also has a negative side. The use of a heat-reflecting shield will shorten the life of the homemade stove.

Helpful information! The main reason that the furnace has a rather low efficiency is the height of the tank. The drums, which have a capacity of 200 liters, are 85 cm long. The second problem is too thin a sheet of metal, the thickness of which rarely exceeds 2 mm.

It should be noted that if the grates in the unit are raised due to the high location of the blower, then the efficiency of the device decreases. This is due to the fact that heat in such a structure is dissipated into the air through its lower part. To solve this problem, it is necessary to hide the lower part of the stove from the barrel in the brickwork. With your own hands, not only instructions, but also educational photo and video materials will help to complete such an assembly.

The service life of stoves made from metal barrels is on average 3-4 years under normal use. Many tricks are used to increase the efficiency. However, it should be said that with all the desire to get more than 20% of the return from a homemade unit will not work.

How to make a stove: tips for choosing a quality barrel

The technical characteristics of the future heater and its efficiency depend on the choice of the barrel. In order to assemble a stove-stove yourself, you need to prepare a metal tank, the recommended volume of which is 200 liters.Of course, the stove can be made from a smaller container, but in this case the efficiency of the heater decreases, which is already quite low.

To assemble a potbelly stove with your own hands, you can use any metal barrels made of steel material. Steel has good resistance to high temperatures, so its use for assembling a heating unit is more than justified. For the same purpose, you can use the barrels that were used for storage:

- oils;

- paints;

- fuel;

- bitumen;

- liquid glass;

- sand.

All containers produced and used for storing various compositions are divided into types according to several criteria. First of all, they can be with or without a closed top. And also such tanks differ from each other in the thickness of the bottom and the open cylindrical structural element (shell). Regardless of the type, for the production of a metal furnace with your own hands, it is necessary to pre-clean the tank.

The operational life of such a stove in any case depends on the thickness of the barrel walls. Based on this, it is not recommended to use tanks for assembling the heating unit, which have a wall thickness of less than 2 mm. The shelf life of the device is also influenced by the frequency of its use.

Note! The most appropriate is the use of barrels for the manufacture of which stainless steel is used. This material has the highest technical characteristics, including resistance to high temperatures.

Before proceeding with the assembly of the unit, it is necessary to complete a drawing of a long-burning furnace. The more detailed it is, the less likely it is to make mistakes during the design of the heater.

Varieties of stoves, depending on the location: vertical model

Depending on the plane in which the metal tank will be located, there are two types of home-made stoves: vertical and horizontal. Each of these types of heating devices has its own advantages and disadvantages.

The oven from a vertical barrel is installed not on the floor, but on the legs. To make the door, you will need to cut out the side of the tank and provide it with hinges. It is important to remember that the hinges must be fixed to the barrel and the door not from the inside, but from the outside.

An obligatory element of this design is a perforated metal plate, which is called a grate. To fix such a lattice, you can use the usual corners. In order to perform the blowing, you will need to prepare a metal pipe with a slide gate. The thickness of the metal walls must be sufficient, otherwise the structure will quickly burn out.

The damper for a long-burning wood-burning stove, located in a vertical plane, is fixed with special bolts. When igniting fuel inside the tank, open the blower to the limit.

A circular hole must be made at the top of the canister. It will be needed in order to connect a chimney structure to a homemade stove. Docking of a pipe to a metal surface is carried out using welding equipment.

The function of the grate is to protect the bottom of the canister from burning out, as well as to retain heat energy. Thus, this element is necessary when installing a home-made long-burning furnace.

Before starting the assembly, it is recommended to draw up an individual drawing of the device.It should be as detailed as possible, contain a drawing of the future unit and its individual components, and also indicate their dimensions.

Design features are determined depending on the purpose of the device and the place where it will be located. If you wish, you can download a ready-made drawing of a potbelly stove on the Internet. However, in this case, it is necessary not to be mistaken with its volume.

The vertical version of a homemade heating device is easy to assemble. You can find an application for such a unit both in a private house and in the country. The firewood used for kindling a heating device of this type is selected depending on the dimensions of the firebox.

Barrel stove: features of the horizontal model

From a barrel, which has a volume of 200 liters, it is also possible to make a heating device located in a horizontal plane. In this case, it is also necessary to prepare the supporting structure. Its height is calculated taking into account individual operational characteristics. When choosing this indicator, first of all, you need to focus on the dimensions of the room in which the homemade heater will be installed.

In the drawing of the furnace, you need to take into account the features of its location. The assembly of such a structure takes place in an almost identical way as in the case of a vertical heating device. Let's consider in more detail the process of self-manufacturing of a potbelly stove from a metal canister.

From a barrel with a volume of 200 liters, you can make a heating device located in a horizontal plane

Note! The ash pan dimensions should not exceed 1/3 of the canister height. The size of a 200 l barrel (more precisely, the height) is usually 85 cm.

An opening must be made in the bottom of the tank, which will be used for ash removal. At the same time, you need to understand that its parameters should not be too large. Next, you need to make an ash pan. As a material for this element, an ordinary metal sheet of appropriate thickness is used. Then it should be docked with the bottom of the heater. For this, it is customary to use welding equipment.

Related article:

Waste oil oven: DIY options for making a device

Principle of operation. Device types. Factory assembled models. Making a furnace for working off with your own hands, design options.

When arranging the ash pan, it is necessary to provide for a viewing window through which this compartment will be cleaned. Next, the installation of the chimney structure is carried out. In this case, there are two common options for the location of the pipe - on the back wall or at the top.

A potbelly stove of long burning, located in a horizontal plane, can be used not only for heating garages, basements and outbuildings, but also for cooking. For this, it is equipped with a special hob. Such a device is mobile, so it can be taken out into nature.

How to make a stove with your own hands: the preparatory stage

Before you start assembling a potbelly stove from a barrel, you should purchase the necessary tools and materials. And it is also very important to prepare the tank itself, since not every tank is suitable for designing a solid fuel heater. During the manufacturing process you will need:

- two barrels (200 l);

- door;

- grate bars;

- sheet metal;

- metal corners;

- rods;

- metal pipe;

- brick (refractory);

- Bulgarian;

- drill;

- welding equipment.

Installation is carried out in accordance with the stove diagram, made in advance.It should be said right away that the barrel for the manufacture of a stove must be prepared before starting work. For this, paint and varnish material is removed from the surface of the container. If you ignore this stage, then during operation the stove will emit caustic smoke that is harmful to health for some time.

You can make a potbelly stove from a barrel of a more complex design with your own hands thanks to the scheme

For those who care about the appearance of the future device, experts recommend grinding the container after removing the paint. An ordinary metal grinder is suitable for this purpose.

In addition to removing paint, you will need to cut two rectangular windows in the body of the canister. In doing this work, you should be careful, since the removed segments will be used as doors in the future. After cutting out the windows, it is necessary to process the edges of the holes with a grinder. This will smooth them out, which will ensure a convenient and safe use of the wood-burning stove. It will not be difficult to complete all the actions with your own hands. Any beginner can handle this job.

Note! The door used for the firebox must be larger than the ash pan door.

The last thing to do during the preparation phase is to remove the top of the container. This must be done in order to install the grate.

Stove from a barrel of 200 liters: dimensions and installation of the grate

Reinforced metal rods are used to assemble the grate. The diameter of a standard canister, which has this volume, is typically 571.5 mm. When assembling the grate, this indicator must be taken into account. In any case, it should be smaller.

The grate is installed between the firebox and ash pan doors. Metal corners are used to fix it. Video materials on this topic allow you to give a more accurate answer to the question of how to make a stove with your own hands using a barrel.

When making an ash pan, it is necessary to take into account how much fuel will be processed per day. Such homemade heaters generate quite a lot of ash, so the recommended collection compartment depth is 10-13 cm.

The doors for the ash pan and combustion tank must be enlarged using welding equipment and strips cut from metal sheets. The width of the strips should be approximately 2 cm. It is recommended to mark this stage of work in advance in the drawing of the stove. You will need to design handles with your own hands. The simplest option involves welding individual pieces of reinforcement to the doors. Then you need to install the hinges.

The next step is the assembly of the support elements. In order to make the legs, you need to prepare segments of dense reinforcement. And also for this purpose, you can use metal corners, the thickness of which must be at least 3 mm. When choosing the optimal stand height, you must be guided by individual preferences. The standard distance from the floor to the heater is 10 cm.

How to make a stove from a barrel: chimney preparation and final assembly

The place in which the homemade stove will be installed must be prepared in advance. It is recommended to sheathe the floor and walls with metal sheets. This will protect the surfaces from the negative effects of high temperatures. The design of the furnace, made from a barrel, without fail requires a chimney. The best option is a removable device (pipe in pipe).

A removable chimney is fairly easy to do on your own. To do this, a pipe with a smaller diameter must be welded to the tank. The length of such a segment should be no more than 15 cm.Then a second pipe is simply put on, which has a larger cross section. Profile forums help to answer the question of how to make a potbelly stove with your own hands. Before designing a heater, it is recommended to read the advice of the masters.

Helpful information! Collapsible factory versions of chimneys are often used. It is not recommended to construct a one-piece pipe, since in case of clogging it will be much more difficult to clean it of soot and burning.

After the chimney is welded, you can proceed to the final stage - the assembly of the heater. The stove from a barrel of 200 liters must be placed in a place prepared for its operation. Further, a grate is placed in it, made of reinforced rods. Then it is necessary to weld a lid with a narrow tube to the top of the barrel and put on a wider tube on the branch. This completes the assembly of a homemade potbelly stove from a metal tank.

After the stove is ready, you need to test it. Such a device can be used not only for heating the room, but also for cooking. Some owners use a 200 liter barrel stove to burn garbage.

The correct operation of such a heater is the key to its long service life. In order for a potbelly stove from a canister to serve at least 5 years, it is required to carry out regular preventive cleaning of the unit.

Rules for installing a homemade potbelly stove

Before installing the stove, you need to familiarize yourself with some rules. This will ensure maximum safety when working with the unit. First of all, it is worth remembering that the potbelly stove should be located only on the surface that is resistant to fires.

The fire-resistant surface can be organized on your own. To do this, you need to prepare a brick or ceramic tiles. A platform is laid out from any suitable facing material. It is also recommended to protect the walls from the high temperatures generated by the wood-burning stove.

Another way to protect your work surfaces from heat is to use a special fireproof drywall. It is important to remember that there should not be any flammable materials in the immediate vicinity of the stove.

If desired, you can make a potbelly stove with a water circuit. This heating option is more complex from a constructive point of view. It requires the organization of a heat exchanger, as well as piping.

It is recommended to protect the floor from the high temperature produced by a wood-burning stove using tiles

Note! In a room that will be heated by such equipment, it is necessary to organize competent ventilation communication. It is most advisable to use a structure that belongs to the forced type, since natural ventilation in this case may not be enough.

For the manufacture of a potbelly stove, it is worth using only high-quality, reliable materials. Before starting work, it is recommended to study the video on this topic. Photos of stoves also help to understand the intricacies of the assembly. The unit, which was made competently, is able to serve for more than one year.

Thus, in order to make a stove from a metal barrel, you do not need to have any special knowledge. Strict adherence to the instructions, as well as an understanding of the principles of operation of this device - this is all you need to know in order to make a reliable unit.