Front door seals prevent noise and cold air from entering the room from the street side. This article will help you understand the existing varieties of products that differ in configuration, material of manufacture, size, purpose and installation technology. Here you can find tips on how to choose the right type of seal and correctly install it on the door.

Content [Hide]

- 1 Seals for entrance doors: features and benefits of application

- 2 Types of sealing strips for doors by configuration type

- 3 How to choose a seal for different types of doors

- 4 Classification of seals by texture: liquid foam rubber, flexible and pile tapes

- 5 Types of seals for iron entrance doors: classification by installation site

- 6 Sizes and shape of door seals: D-profile, P, V, E and others

- 7 Door seal mounting technology: how to glue and fix different types of products

Seals for entrance doors: features and benefits of application

A seal for an entrance metal door is a flexible product in the form of a tape or a small tube. It is installed in the gap between the door leaf and the frame along the entire perimeter. Thanks to its easy and easy fixation, the material has a wide range of applications. It applies to pasting window frames, interior doors, compartment-type wardrobes, vents. With a high-quality seal, the front door takes on a finished look. This product eliminates many design flaws.

The material is universal, since it is capable of simultaneously performing several functions at once:

- protects the interior from drafts;

- prevents the penetration of dust and odors from the outside;

- ensures the tightness of the structure;

- it is used as a door insulation;

- provides sound insulation;

- absorbs the door leaf, reducing the noise level when closing.

Note! The insulation is able to compensate for minor defects in the door leaf, for example, small errors in size, bending of sheet metal, providing a more comfortable and tight closing.

Thermal insulating benefits of door strip

The main purpose of the door seal is to eliminate gaps and crevices, preventing wind and cold air from entering the room. This is an indispensable attribute of structures in a private house, facing directly to the street.

If the door is made of wood, then it will sensitively react to dampness and moisture during the rainy season. In the hot season, the material is prone to drying out. In such conditions, the door frame is strongly deformed, the tightness of the canvas is lost. You can replace the design with a new one, but such an event will cost a penny. There is a budget option for solving this problem - the use of a seal, which, if necessary, can be easily and quickly replaced. It will keep the room warm and extend the service life of the door structure.

As a heater for doors, the gasket acts on both sides: it limits the ingress of cold air from the outside, retains heat from the inside. If there is no seal in the design, then the efficiency of the heating devices is reduced by 40%. That is how much heat goes out. Taking into account heating prices, without installing insulation, the owner loses a large amount of money, especially during the winter months.

Soundproofing Advantages of Door Sealing Rubber

The soundproofing properties of the products will come in handy if there is a construction site, a railway or high-speed road, a playground next to the house. In such an environment, occupants will suffer from noise due to insufficient sound insulation. The shock-absorbing properties of door sealing rubber reduce the force of impact if the door has been abruptly closed by a draft. Usually such a servant is heard not only by the residents of the house, but also by the neighbors.

In this case, the seal performs two functions at once:

- Softens shock, absorbs unpleasant sounds.

- Extends the service life of the door structure, because strong pops contribute to rapid wear of hinges and other parts.

The shock-absorbing properties of products for metal doors are especially beneficial. These designs make a lot of noise during operation. The question of choosing a high-quality sealant with good soundproofing properties is relevant for urban residents. Large metropolitan areas are active both during the day and at night. In order not to suffer from city noise around the clock, it is advisable to choose products that provide enhanced sound insulation.

Note! Quality products can withstand temperatures ranging from -65 to 95 ° C. Having made the right choice, you can not be afraid that the material will crack if it is severe frost or, conversely, heat outside.

Types of sealing strips for doors by configuration type

The existing types of products are classified according to different criteria. They differ among themselves in material of manufacture, shape, color, size and purpose.

Several varieties are distinguished by configuration:

- Ribbon - soft products in the form of cords about 9 mm wide. The section of the tape is rectangular.

- Tubular - are widely used as a seal for iron doors, although the ability to seal the structure is much lower than that of tape.

- Grooved - made in the form of soft rubber profiles, they are hollow inside. There is a brush on one side of the products, which facilitates the installation of the seal into the groove.

- Mortise - designed for wood door structures. Installation is carried out in a recess previously cut in the box.

- Spring-loaded - products are installed not on the door, but directly on the box. The area of their installation must have a perfectly flat surface, otherwise the seal will not be able to fully perform its function.

- Folding - designed exclusively for doors with a folding leaf. These include interior designs such as a book or an accordion.

A rubber profile with a complex configuration is considered a universal option. It is installed on both entrance and interior structures. Available in several types of rubber with varying degrees of density. The standard width is from 8 to 10 mm.

How to choose a seal for different types of doors

When buying a seal, you must first take into account the type of door, and where it will be used. This is important, since the choice of a product with certain properties and characteristics depends on the operating conditions.

The seals can be installed on different types of doors:

- Input - mainly a tubular version of rubber is used. If you have a good budget, it is possible to install a magnetic door seal.

- Glass - aluminum and silicone products.

- Plastic - rubber types of products with a special configuration and slot type of installation.

- Interior - foam rubber products on an adhesive base and brush seals for compartment doors.

Important! It often happens that only one seal is suitable for a specific model of plastic doors. In such cases, it will not work to pick up an analogue. Therefore, when choosing doors, it is imperative to clarify whether it is possible to replace the seal on the front door with products from another manufacturer. Otherwise, in the event of repairs, the entire structure will have to be updated.

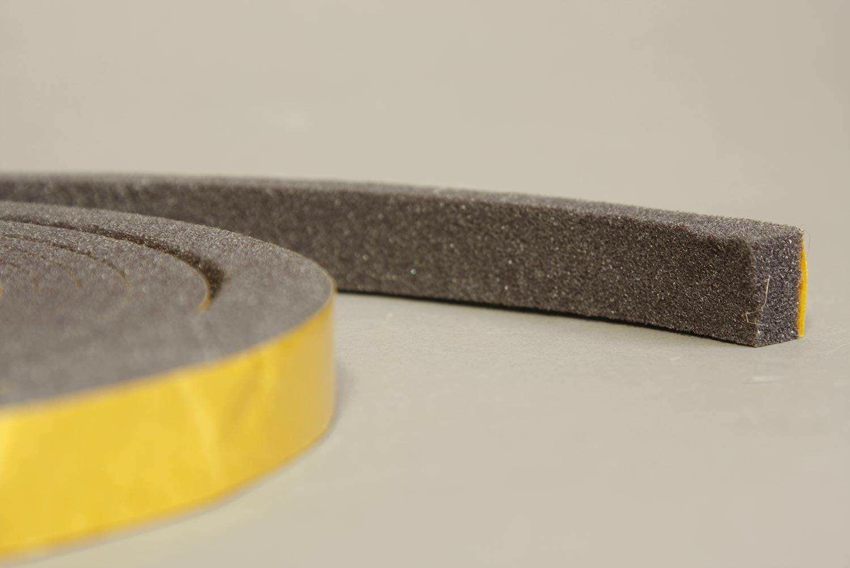

Features of tape self-adhesive door seals

The simplest and most affordable product option. It is produced in the form of a self-adhesive film of various thicknesses, on top of which foam rubber is fixed. The fixing of the adhesive base depends on the type of door where the tape will be installed. For wood structures, wallpaper nails are used. If you need to install products on a metal door, the best solution is glue with an increased margin of safety, which is designed specifically for this type of material.

Foam tapes have several disadvantages. First, they do not have good thermal insulation properties. Foam rubber has a porous structure. This feature of the material is clearly visible on belts with a large width. Air passes freely through the holes in the foam, so products can let cold streams into the room. Due to their poor thermal insulation characteristics, foam rubber tapes are not recommended for use as a seal for metal doors. They are more suitable for interior structures inside residential premises.

Secondly, foam tapes are short-lived. The material is not resistant to wear, therefore products quickly lose their properties and become unsuitable for further use. In this case, the tape is replaced.

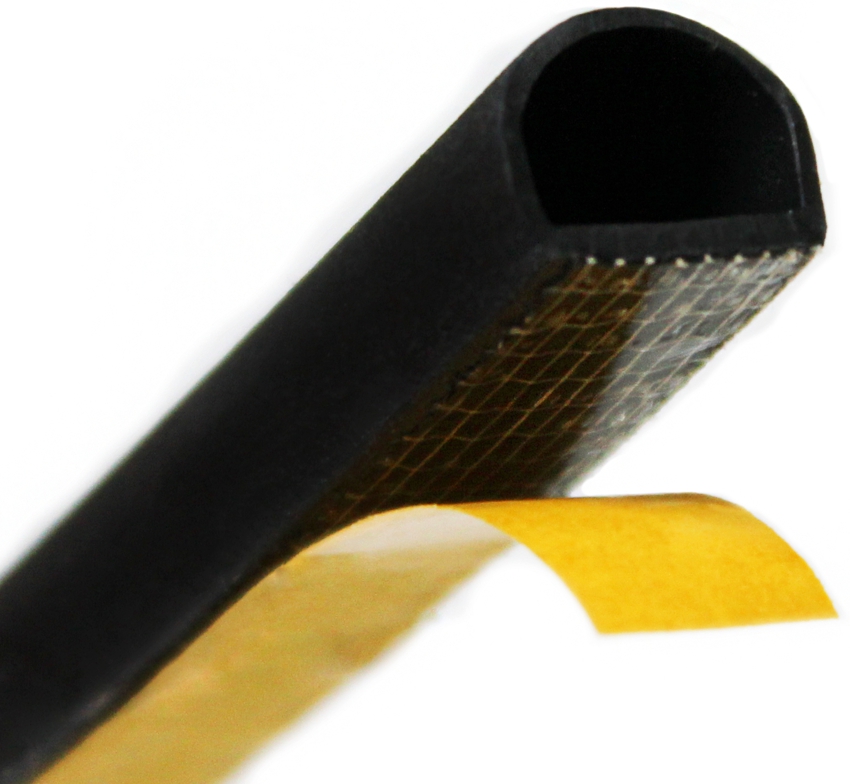

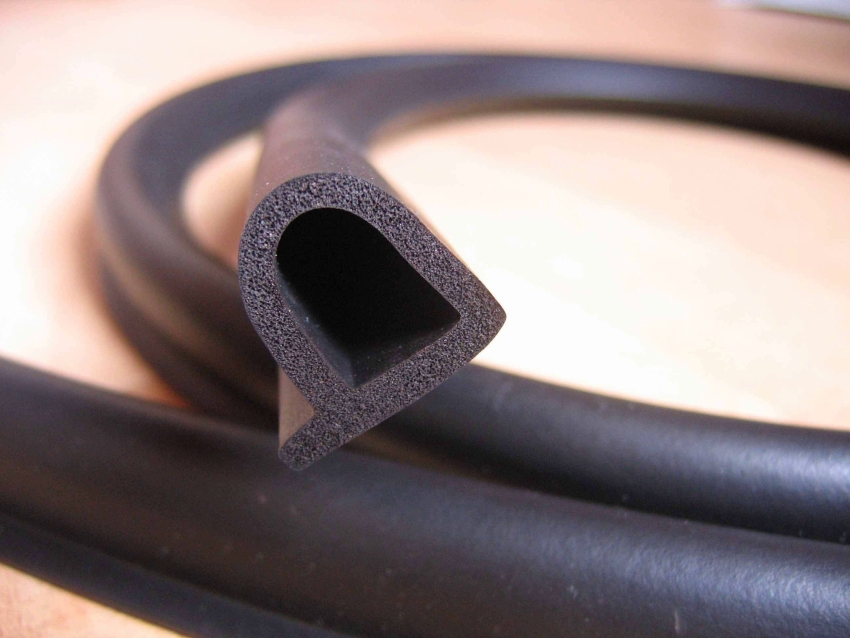

Feature of Tubular Rubber Door Seals

Outwardly, rubber products resemble a thick bundle of dense material. There is a rather large cavity inside it. Due to the special structure of the tubes, as well as the high strength of the rubber, the door leaf fits as tightly as possible, without forming gaps and gaps between itself and the frame. For the manufacture of tubular seals, manufacturers use porous rubber. This type of material retains heat well inside the room, has increased sound insulating properties.

Self-adhesive rubber seals are often on sale. This greatly simplifies the process of assembling products.The rubber itself is quite durable, the service life of the adhesive base is much shorter. By the time it expires, the bonding compound dries up and the material simply falls off. Despite this, the rubber seal is able to last for several years. After that, the product can be easily replaced with another one.

Useful advice! It is advisable to select a sealing gum on the door with an average stiffness. If you install a product that is too soft, then it will wear out very quickly. A very hard material will obstruct the door from closing properly.

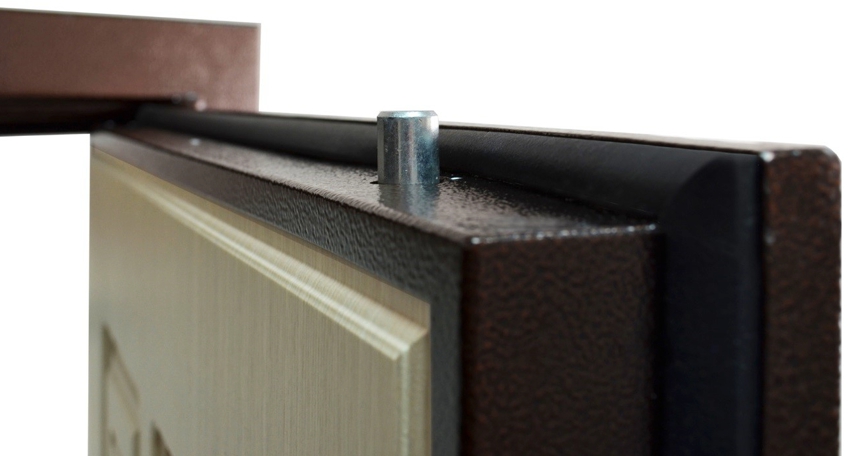

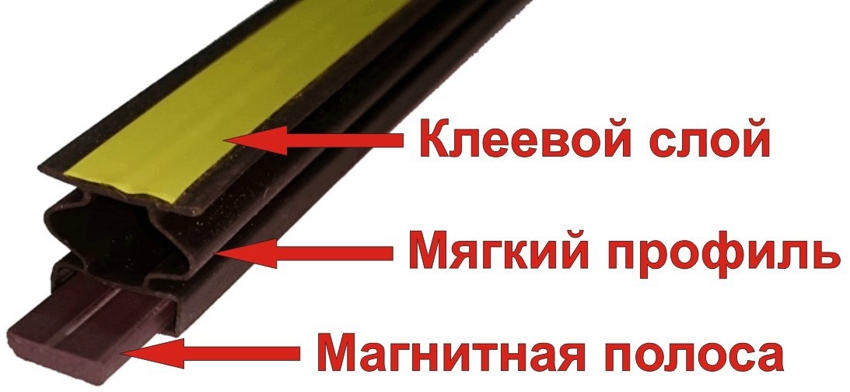

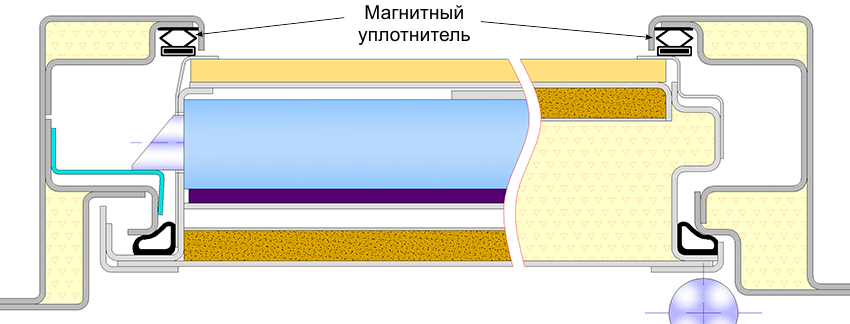

Magnetic seals for metal doors

Magnetic products are a kind of frame. It completely follows the contour of the door. The frame is carefully tailored down to the millimeter. This type of seal is considered to be of the highest quality and most effective, since it has a high strength indicator. For this reason, experts recommend using a magnetic seal for metal doors. The product consists of two parts. One of them is made of a soft TPE material (thermoplastic elastomer), the second has the form of a magnetic insert, which attracts the metal sheet and smoothly closes without unnecessary noise.

The cost of a self-adhesive magnetic door seal is quite high. During the installation process, you will need to strictly adhere to the technology. But this type of product is able to effectively serve for a long time, due to its increased resistance to wear. In addition, it provides a good level of shock absorption. When closed, the door makes no noise and is perfectly sealed. Slots and gaps are completely absent.

The disadvantages of the material are related to its magnetic properties. If the force of attraction is incorrectly calculated, the door will fix too weakly or, conversely, additional physical efforts will be required to open it. If you overdo it, the child will not be able to use the door without the help of adults.

Aluminum and silicone glass interior door seals

Glass sealing products are produced exclusively for doors made of this material. They exactly match the dimensions of the structures for which they are intended. The profile shape of these seals is individual, the section depends on the characteristics of the door leaf. Manufacturers usually use silicone to create these products. The material is quite soft and has good flexibility. Copes with the function of keeping warm. No adhesive is required to fix the silicone seal. To fix the product, it is enough to moisten it with water and immediately press it on the desired area of the door.

Note! Silicone, which is used for the manufacture of door seals, has special properties. The wetted material adheres firmly if you keep it pressed against the glass for a while. Such good adhesion to the surface cannot be provided by conventional pads with an adhesive base.

Aluminum profiles are less popular. To install them, you must additionally use a sealing rubber band for the doors, which complicates the installation process and increases its cost.

Silicone seals are widely used to seal doors leading to high humidity areas such as a kitchen or bathroom. They are ideal for showers with sliding or hinged glass doors. On sale there are combined versions of products - magnetic with silicone inserts.

Brush seals for interior doors

The brush seal is called Schlegel. The product has a tape at the base, with a pile attached to it.Various materials are used to make the bristles:

- nylon;

- felt;

- natural bristle;

- silicone;

- metal wire;

- polyethylene.

The width and density of the bristles, as well as the color, can be different. Their height varies in a wide range - from 3 to 15 mm. The materials used for the production of bristles are resistant to ultraviolet light and are chemically neutral. The tape itself is plastic, metal, sometimes made of polymers. There are products with or without an adhesive base.

In addition to general functions, Schlegels prevent insects from entering the room, and can also be used as seals for sliding doors installed in the closet. They are also used in swing structures when it is required to eliminate the gap that forms in the lower part between the sash and the floor. In this case, the seal replaces the threshold.

Related article:

Replacing the door lock: causes of breakdowns and detailed instructions for their elimination

Common causes of broken locks. Types of locks. Replacement of cylinder, lever and crossbar devices. Replacement of the larva. Professional advice.

For each type of door structure, there is its own kind of Schlegels:

- Canvases made of metal and wood - self-adhesive seals.

- Glass doors - products with a U-shaped profile.

- Windows and some types of doors are grooved seals.

Useful advice! For sliding doors in interior doors and wardrobes, experts recommend taking shlegels with short and dense bristles. It is advisable to choose the colors taking into account the interior so that the buffer tape is not too conspicuous.

Classification of seals by texture: liquid foam rubber, flexible and pile tapes

By texture, flexible, liquid and pile types of products are distinguished. Each type of seal is used for a specific purpose. Flexible belts are in the form of profiles with a smooth surface. Silicone and rubber are used for their production. Magnetic strips for door structures also fall into this category.

Liquid options are used to insulate the canvas. The material is under pressure inside the cylinder. This version of the seals resembles the liquid equivalent of foam rubber. Pile products were one of the first to appear on the market. Felt is mainly used for their production. Pile seals are available in the form of ribbons and braids. On sale there are artificial analogues of this material, made of synthetics.

Features of using a liquid seal for doors

Liquid seals are designed to insulate metal entrance doors. A non-standard form of release requires careful handling of the material, as well as compliance with certain rules when applying it. Liquid foam rubber is inside a metal container. The composition is applied to the required area of the structure by spraying. The insulation on the door freezes in a matter of seconds. Therefore, you need to act not only carefully, but also quickly. After hardening, the material significantly increases the thermal insulation qualities of the door structure.

A distinctive feature of the liquid sealant is its dislike for areas with high humidity levels. It is not recommended to use the material where dampness is constantly observed. Spraying the foam correctly requires some knowledge and good dexterity. It is advisable to practice before this or entrust this work to professionals, otherwise you can spoil the appearance of the door structure.

Note! Heaters in liquid form do not contain harmful substances. This material does not pose any danger to the environment and human health, therefore there are no special restrictions on its use.

Characteristics of nap seals for doors

Felt products belong to pile seals. Also on the market you can find synthetic analogs of this material. Since the felt is made from natural animal hair, it provides excellent sound and thermal insulation. Analogues of artificial origin are much inferior to him in these indicators. There are several types of felt. Taking into account this nuance, products are marked in a certain way. All varieties are suitable for sealing the door structure. In order to carry out the installation of the product with high quality, you need to properly cut the material, taking into account the size of the canvas.

The advantages of natural felt:

- resistance to wear;

- long service life;

- ability to withstand operation in severe weather conditions;

- ecological cleanliness and safety;

- large margin of safety, the material retains its structure;

- high density, perfect sound absorption;

- fire safety.

In the category of artificial analogs, among buyers, pile tapes of small thickness are in special demand, which are fixed to the surface with an adhesive base. These products prevent dust from entering the home. Artificial materials are rarely used as a seal on entrance doors. They are more suitable for sliding wardrobes.

Types of seals for iron entrance doors: classification by installation site

Existing products can be classified by location. Taking into account the installation zone, seals are:

- threshold;

- contour;

- fire-fighting.

Threshold varieties are not only magnetic. Most often, these seals are equipped with an automatic control system. Thanks to this, the profile can be "adjusted" to the size of the gap that forms between the floor and the door leaf. Moreover, both in the open and closed position. These seals are used in cases where a threshold is not provided in the door structure to prevent the formation of drafts.

Contour products are the simplest and most common. During installation, they are fixed along the entire perimeter of the door frame or sash. This eliminates all existing gaps and crevices. Contour options are ideal for front doors. In such cases, it is advisable to use products with a triple profile.

Important! Three-circuit seals are installed on fire doors. Such products significantly increase the thickness of the door leaf and its weight. For this reason, it is advisable to reinforce the box, install accessories of special strength.

In rooms with a high level of fire hazard, it is advisable to use a special type of contour seal - thermally expanding. Exposure to heat or smoke triggers a chemical reaction. The material foams or expands, preventing air from entering the room. Due to the lack of oxygen, the fire is reduced. These products are called fire protection products.

Sizes and shape of door seals: D-profile, P, V, E and others

The size of the seal depends on its type. The optimal parameters are selected taking into account the size of the gap. When buying a product, the size of the door structure is of no small importance. Taking into account its dimensions along the perimeter, the footage required for compaction of the web is calculated. For entrance doors, it is advisable to take wide products with a sufficient level of density. Flexible rectangular profiles are sold in rolls. The footage of the material depends on the manufacturer. Such products are designed to eliminate small gaps that do not cause serious problems during door operation.

In some cases, it may be necessary to install rubber profiles with a complex shape. Such products are suitable for installation on conventional and even armored doors with a heavy canvas. There is a D-shaped seal, as well as products in which the section resembles other letters - E, C, O, P, etc. Each configuration is used to eliminate gaps of a certain size.

The C-, E- and K-shaped profiles are able to cope with the bridging of small gaps, the width of which is no more than 3 mm. The P- and V-section gaskets are suitable for masking gaps up to 5 mm. D-shaped seals, as well as in the form of the letter O, are used much less often. They are designed for doors with large design errors. These products can eliminate a gap that reaches 7 mm.

If the material is soft, it is better to buy it with a margin. Such seals fail very quickly. It is advisable to have a small supply of material on hand in order to quickly carry out a replacement if necessary. Rigid types of seals are made for the dimensions of the door structure. It is problematic to independently measure and calculate the required amount of material without making a mistake. It is better to seek help from specialists.

Note! To seal the door, at least 5-6 m of tape is required.

Door seal mounting technology: how to glue and fix different types of products

In most cases, a new metal door already has a sealing material. In the absence of one or the need to replace, you can perform the procedure for installing it yourself, adhering to certain rules.

How to glue the seal on an iron door correctly:

- in high-quality door structures, special grooves are usually provided for gluing the seal, which greatly simplifies the process;

- preliminary surface preparation is required. Remove dirt and dust. If the seal is replaced, the remnants of the buffer tape are removed with emery;

- the surface must be degreased. This is done with alcohol, acetone or solvent;

- the best sealing will be provided by multi-layer gluing. To do this, the door is pasted over with a seal several times. For the structure leading to the entrance, 2 layers will be enough. If the door goes directly to the street, triple pasting will be required (inner side of the canvas - box - outer side of the canvas);

- when using a self-adhesive seal, you need to check the expiration date of the glue on it, otherwise the product will be unsuitable for installation. It is advisable to take options where the adhesive part is mixed with fine fiberglass particles;

- if the paint on the door has been updated, then you must wait at least 20 days before gluing the seal;

- rubber products are attached with silicone glue. To do this, the composition is applied in a dense layer over the tape, after which it must be well pressed to the surface.

Useful advice! When choosing products, be sure to pay attention to all markings, check the expiration date, type of material, carefully study the manufacturer's information. Only in this case the compaction result will be of high quality, and the profile itself will last long enough.

How to seal doors in different ways: recommendations

Each type of seal has its own installation nuances. The groove profiles are equipped with a special fastening in the form of a brush. To install such a seal, additional materials are not required.

The main difficulties of this process are the fitting of dimensional parameters. Most people fail at this task. Rubber is not only flexible, but it also stretches well. After which it easily returns to its original state.For this reason, when cutting the material or pressing it into a groove, care must be taken not to accidentally stretch the rubber. Experts advise, on the contrary, to slightly "press" it.

Trimming of the material is carried out only after the groove seal is in place. Do not rush with this, otherwise you can cut off more than necessary. As a result, the structure will be leaky and the work will have to be redone.

Installation of self-adhesive tape does not cause any particular difficulties. To work with the material, you only need a painting knife. This tool is required to trim the seal to correct its length. On a previously cleaned and degreased surface, the tape is glued from left to right, and on the sides - from top to bottom. In other words, the top corner is the starting point.

The protective layer on the adhesive side must be removed carefully and gradually. Be sure to ensure that the material does not stretch. A free piece of adhesive tape (about 10 cm) must be fixed, only then a little more of the protective layer is removed and the next section is glued.

A high-quality sealant will keep the room warm, protect it from dust and noise. This is possible provided that the material is selected and installed correctly. The technology itself is usually straightforward, so anyone can handle the installation of the tape. All that is required is to adhere to the manufacturer's recommendations, avoid rushing, and coordinate carefully.