Preservation of life and health is the primary task of everyone. The threat of a fire has a potential nature: short circuit, lightning, human factor ... It is necessary to create the safest conditions that will minimize the consequences of a possible disaster. Fire doors are one of the most effective methods of protection: GOST defines the requirements for such structures.

Fire doors are an effective way to protect against fire: GOST defines the necessary requirements for them

Content [Hide]

- 1 Fire doors: GOST as basic requirements for structures

- 2 Types of fire doors: design features, material of manufacture

- 3 Standard marking of fire doors according to GOST

- 4 Metal fire doors EI 60, EI 30

- 5 Aluminum fire doors: technical specifications

- 6 GOST: fireproof wooden doors are absent in the document

- 7 Custom production of fire doors

- 8 Fire door closer: functional requirements

- 9 Fire doors: prices depending on the design

Fire doors: GOST as basic requirements for structures

In accordance with modern normative acts aimed at creating and maintaining fire safety conditions, doors of a special design are installed in some buildings and structures. This applies to premises where the level of fires is quite high. These include:

- technical rooms located in basements and basements;

- evacuation exits;

- halls and elevator shafts, the doors of which open onto the staircase;

- exits to the attic from floor areas.

In cases where a residential building is connected to a non-residential one, the installation of fire doors is also necessary. Requirements for individual placement of doors are standardized by the PB regulations:

- fireproof door blocks are installed in the corridors, between workshops and warehouses, on the way to the resting places of workers;

- staircases are equipped with similar doors to enable quick evacuation of people;

- fire doors are used as interior doors in places where a large amount of paper documentation is stored;

- rooms with working electrical equipment (switchboard, computer and server rooms) are also separated by fire doors.

When executing project documentation for the construction of a building or structure, the type of doors to be installed must be indicated.

Even at the stage of implementation of design documentation for construction, the type of doors that should be installed is indicated

Types of fire doors: design features, material of manufacture

According to the information set forth in SNiP 21-01-97, fire doors are classified according to two criteria:

- by material of manufacture;

- by structural features.

As for the materials used for their production, structures are distinguished:

- metal door blocks;

- glass blind or with inserts;

- wooden fire doors.

Important! When manufacturing glass fire doors, it is not allowed to use reinforced glass and triplex.

The classification in terms of design features is the same as for conventional doors:

- swing - are divided into single-floor and double-leaf;

- sliding;

- folding.

Glass options are either made entirely of one material, or have inserts. Fireproof single-floor doors are produced, metal, wood, glass. Similar materials are used in the manufacture of double doors. With regard to double-floor structures, the swing parts can be the same or different in width.

Another indicator underlying the classification of fire doors is the degree of fire resistance. Fire resistance - the level of temporary duration of maintaining the functionality of products under the influence of fire. In total, there are 3 types of structures:

- 1st type. Fire resistance is maintained for 90 minutes;

- 2nd type. Fire resistance is maintained for 60 minutes;

- 3rd type. Fire resistance is maintained for 30 minutes.

In residential premises, doors of the 3rd type are usually installed. In institutions - type 2. For doors of the 1st type, metal is used not thinner than 1 mm. Structures are installed in industrial and other premises with an increased level of fire hazard.

Standard marking of fire doors according to GOST

Despite the fact that all the technical and functional characteristics of fire doors are regulated by GOST, manufacturers manage to use such types of markings that it is easy to get confused. Some even enter information about their company into the article, for example, the name - "Pulse DPM-01/60".

There are several persistent abbreviations that are used when marking fire doors:

- DPM - metal fire-prevention door;

- ДМП - metal fire door;

- DG - blind door;

- DOP - glazed fire door;

- DO - glazed door;

- ДТ - technical door;

- ДДП - wooden fire door;

- DV - burglar-proof door;

- DMU - reinforced metal door;

- DU - insulated or reinforced door.

The letters "P" or "L" standing next to the abbreviation indicate the direction of opening the doors - left or right. Numeric characters "01" and "02" (D1 or D2) mean the number of canvases.

Abbreviations reflecting the fire resistance of the product are also used for marking. For example, EIS60: E - loss of integrity; I - loss of heat-insulating function; S - lack of smoke and gas tight qualities. The numbers (30, 60, 90) indicate the time threshold for the door to remain functioning.

All of the above information in the section can be found in GOST 57327-2016.

GOST 30247.0-94: the main content of the standard

The content of this standard is aimed at regulating the general requirements for conducting fire tests of building structures. That is, it is fundamental for testing methods for various types of doors.During the certification processes (establishing the possibility of admitting products to operation), the technical conditions specified in this document must be created.

The essence of the method consists in determining the time from the beginning of the thermal effect on the sample until the appearance of one of the limiting states.

Bench equipment for testing building structures, including metal fire doors, GOST 30247.0-94 defines the following:

- special furnaces into which fuel is supplied and burned;

- device for setting and fixing the test specimen;

- instruments for measuring parameters, equipment for recording the process (video, photographic equipment).

GOST 30247.0-94 defines what special furnaces and devices should be for measuring the parameters of a fire door

The temperature in the oven chamber is measured at at least five points. Samples of products undergoing testing must have design dimensions, and materials of manufacture must comply with technical documentation.

Advice! If you need to get more detailed information about the research, you should refer to the original content of the document “GOST 30247.0-94 Building structures. Fire resistance test methods. General requirements".

GOST R 53307-2009: Test method for fire resistance of doors

GOST 53307 2009 contains a description of the method that should be used when testing doors, gates and hatches for fire resistance. The essence of the method is to track the time from the start of fire exposure on the door block until the appearance of one of the signs that make up the fire resistance thresholds - limit states, for example:

- loss of integrity (E), manifested in the appearance of a stable flame on the sample for 10 seconds. and more, in the appearance of a flame or smoldering of a cotton pad as a result of penetration of fire or combustible gases through the cracks, in the presence of through holes in the tested door block;

- loss of thermal insulation ability (I). A temperature of 140 ° C and higher is recorded on the surface of the prototype.

GOST 53307 2009 contains a description of the method by which the door is tested for the fire resistance threshold

Tests, according to GOST 53307 2009, of metal fire doors for smoke and gas permeability (S) are not performed.

As equipment for research, a furnace is used, smoke channels that provide the required pressure in the firing part of the furnace, as well as measuring instruments that record temperature parameters. The oven during testing has a thermal effect on one side of the sample door.

GOST 31173-2003: steel doors, product classification

This section focuses on internal steel structures. They are installed both in industrial and civil buildings and have locking devices. Metal fire doors (GOST 31173-2003 defines technical requirements for products) are classified according to several criteria:

GOST 31173-2003 regulates the installation site, design features, opening direction and finishing method for steel fire doors

1. Place of installation. It can be both entrance and interior options.

2. Design features. The door block is equipped with a closed or U-shaped box. The complete set can be supplemented with a threshold.

3. Direction of opening: inward or outward.

4. Finishing method. There are several of them:

- standard or powder paint. The first reduces the cost of the structure, the second provides a durable coating, but the price increases;

- natural or artificial upholstery: leatherette, eco-leather, tiled trim;

- glass and mirror covers;

- engraving.

5. Mechanical characteristics and features of the security system (resistance to static loads, dynamic and shock effects in accordance with GOST 31173 2003) of fire doors:

- standard doors.They are equipped with third class locks (not lower) and anti-removable pins;

- reinforced door blocks. Locks not lower than the second level with a large number of crossbars, reinforced hinges;

- protective blocks. Identical to reinforced, but the lock is first class installed.

Important! The manufacturer is obliged to provide a quality certificate for the material used for finishing.

The main requirement for steel doors is the use for the manufacture of sheets and curved profiles. Welding should be used for the connection. Other methods are allowed, but they should be superior in strength to welding methods.

Related article:

Polyurethane foam: characteristics and application

Composition, types, properties, characteristics and regulatory requirements for it. Tips, rules and techniques for safe use.

GOST R 57327-2016: classification of doors, technical conditions

This state standard regulates the technical requirements and test methods for steel single-leaf and double-leaf swing doors, both blind and with glass inserts, occupying up to 25% of the doorway area. In accordance with GOST R 57327 2016, metal fire doors, according to design features, are divided into the following types:

- deaf and with glazing elements;

- single-floor and double-floor with canvases of the same and different width;

- left and right opening;

- with the presence of a transom;

- with a closed box, porch and threshold;

- with a closed box, a threshold, but without a porch;

- with a closed box, a threshold, with and without an attached porch;

- with a closed box, a threshold, without a bunk, or with a retractable threshold;

- with a U-shaped box without a threshold;

- with a U-shaped box and an add-on threshold;

- with a U-shaped box and a retractable threshold;

- with single-circuit insulation in the vestibule;

- with two or more contours of insulation in the vestibule.

According to GOST 57327 2016, fireproof metal doors must comply with technical requirements that relate to the necessary documentation, performance, design features in relation to the conditions of use. Doors must be provided with a self-closing device; products with heat resistance levels E and I should not have a threshold.

Important! The provisions of this standard must be applied taking into account the norms of GOST 31173.

Metal fire doors EI 60, EI 30

Fireproof doors DPM 01 60 (EI 60) and DPM 01 30 (EI 30) are the most demanded designs. They are installed in the premises of various public buildings: in offices, government agencies, salons, workshops. They perfectly protect basements, garages, warehouses, etc. from fire and smoke.

Door structures characterized by the first type of fire resistance (EI 60) are classified in the middle category. Within an hour, such a door can protect the room from fire and smoke. This option is always equipped with closers, which enhances the protection necessary to ensure fire safety. Doors of this type can be either blind or contain glass inserts. The door block is installed more often on three hinged hinges, one of which may have a spring that provides self-closing.

Fire doors EI 30 can withstand high temperatures for half an hour. This is also a significant time to eliminate the fire source. Such door structures are used for interior rooms with access to a common hall or corridor. Among the doors of this type there are many models with glass inserts.Steel with galvanized and stainless steel coating is used as a material for manufacturing. In addition to their functionality in terms of fire safety, such doors represent decorative value for the interior.

Aluminum fire doors: technical specifications

The information above was mainly related to metal doors made of steel. Aluminum is not popular as a raw material. The reason for the lack of demand is most likely a bias. Aluminum is soft and light metal, but at the same time has a high level of heat resistance. Existing restrictions on the dimensions of fire doors in accordance with GOST 31173 2003 (height not more than 2.2 m, width - up to 1.2 m, maximum area - 9 m², weight limit - 250 kg) for steel structures are completely inapplicable to lightweight aluminum products.

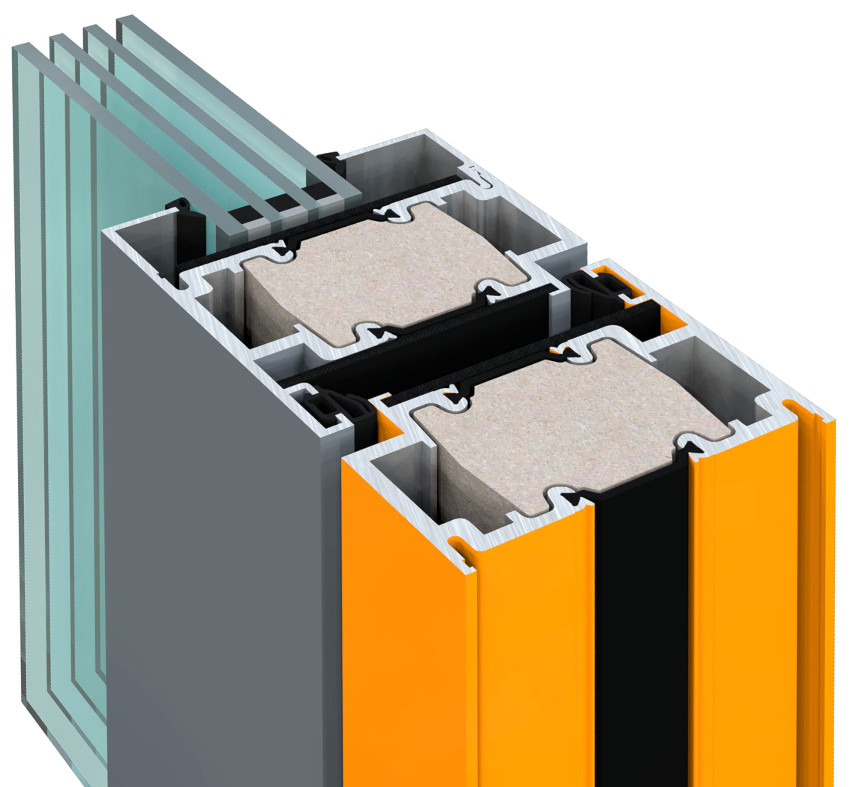

The aluminum fire door includes the following structural elements:

- frame in the form of a box made of aluminum profile;

- canvas, supplemented with thermal insulation material;

- durable glass unit;

- seals to prevent smoke penetration;

- locks of the 2nd level.

Most often, aluminum fire doors are double-leafed. This design is not only convenient in everyday use, but also provides a freer path in case of evacuation. Insulation is laid along the edge of the door leaf, which expands when the temperature rises and strengthens the tightness of the structure, preventing smoke from entering the room.

A fireproof door made of aluminum consists of a frame, a leaf, a durable glass unit and seals to prevent smoke penetration

Important! To prevent fire and smoke from entering the room until the door loses its tightness, it is necessary that the profile and other elements holding the canvas have a higher level of fire resistance.

GOST: fireproof wooden doors are absent in the document

Wood is a material subject to rapid combustion. To ignite it, 300 ° C is enough. And if a fire breaks out, the temperature rises to 900 ° C. So is it possible to make a fire door from this material? It is possible, but such door blocks should be characterized by a number of structural and technological features.

The manufacturing process of wooden doors consists of several stages:

- processing of raw materials with special compounds that increase the level of fire resistance;

- assembling a block from processed material;

- applying heat-resistant polymer compositions to the finished structure.

Both wooden single-leaf fire doors and double-leaf doors are subjected to the same impregnation and coating process. The main purpose of the treatment is to prevent the combination of the cellulose present in the wood with oxygen. This reaction is the basis of combustion. The impregnation blocks the penetration of oxygen into the wood.

The doors are equipped with a special fire-prevention handle Anti-panic

The frame and panel of wooden fire doors is much more powerful than that of conventional structures. Expanding seals are also used, metal parts (handles, awnings) have a thermal protective layer that reduces the temperature difference between wood and metal in case of fire.

Important! The concept of "wooden fire doors" is absent in GOST.

Custom production of fire doors

Can you make a fire door yourself? No. You can make a structure that can withstand high temperatures, but the category "fire-resistant" will only give it the presence of the appropriate certificate. Such a door should be ordered from companies that have a manufacturing license.

In the course of creating structures in factories, the standards GOST 31173 2016 are most often used. Metal fire doors manufactured in accordance with the requirements of this document can be installed in the outer and inner walls as entrance ones connected to alarm systems.Locking devices must be installed on the door.

The production process itself contains the following stages:

- metal is cut on high-precision devices;

- the profile is made of steel with a thickness of 1–1.5 mm;

- the connection of parts of the structure is carried out by welding;

- a primer or powder paint is applied to the surface;

- locks are installed.

Fire-fighting door leafs must open in the direction of travel.

Dimensions according to GOST fire doors are as follows:

- standard width of single-floor door blocks - 800, 900, 1000, 1100 mm;

- single-floor structures height - 1900, 2000, 2100 mm;

- width of double doors - from 1000 to 2000 m;

- height of double-floor structures - 2000, 2100 mm.

Today, manufacturers of fire doors often deviate from GOST standards and make door blocks of other dimensions.

Fire door closer: functional requirements

In the article above, it was repeatedly indicated that closers, that is, devices for self-closing, must be installed on fire doors. During operation, they perform the following functions:

- smooth running ensures accurate closing, excluding injuries to people and damage to objects and things moved through the doorway;

- extend service life by reducing hinge wear.

As for the large sizes of fire doors (the doors are difficult to open / close), in this case, closers greatly simplify the process of using such structures. Tight closure provides protection against fire and smoke.

There are two types of door closers:

- Lever. Installed above the door. Consists of two levers and a gas damper or oil hydraulic system. They work efficiently, but are very visible.

- Leverless. A hidden system based on a sliding channel.

As for the installation site, door closers can have an overhead location (this method is used for single-leaf swing doors), there are floor-based (they provide self-closing of double-leaf structures), hidden (they are mounted inside the canvas, they can be part of a canopy).

Closers and locks for fire doors must guarantee protection against flames and carbon monoxide gases, therefore their technical features and application are regulated by regulatory documents (GOST R 56177-2014). Locks on fire doors are installed on the 2nd and 3rd levels, and door closers - with a slow latch (smooth movement, turning into intensive after the door frame touches the door frame).

Useful advice! For doors undergoing constant use in organizations and institutions, it is better to install hidden closers. They do not compromise the aesthetics of the door structure.

Fire doors: prices depending on the design

It is not difficult to fulfill the requirements of GOST if it is necessary to install both internal and external fire doors. The industry produces a ton of certified options. Quite often, the choice depends on the cost. For example, the price of a fireproof metal door for painting is only 3600 rubles. The same canvas, but already painted, will cost 6-7 thousand rubles.

Useful advice! Coating is very important for a metal door. Therefore, it is worth undertaking its implementation on your own only if there is confidence that the result will be of high quality, that is, the coating will turn out to be durable and aesthetic.

The average price of a single-floor metal fire door is 12-13 thousand rubles.

Double-sided fireproof metal doors have a price range of 22–45 thousand rubles. Products containing decorative surface treatment of the canvas are distinguished by a high cost. A single-floor metal door with glazing and powder coating can be purchased for about 15–19 thousand rubles. For a structure made of the same materials, but two-sided, you will need to pay 28-30 thousand rubles.

Doors made in accordance with the provisions and requirements of regulatory documents are part of the fire safety system. Any deviation from the norms, even a minor one, can lead to tragic consequences in the event of a fire. To protect the life and health of yourself and those around you, you must not neglect the rules. GOST will help you to choose the necessary door structure.