With the advent of plastic windows, the problem of protecting a house from burglars came to the fore. The most reliable way to deal with unexpected guests is to install wrought iron bars on the windows. This is especially true for ground floor residents. The use of ordinary lattices turns the house into a medieval fortress, but the modern design of the products also allows for a decorative function.

Content [Hide]

- 1 Metal bars on windows: scope of use

- 2 Types of grilles on the windows

- 3 Differences between forged models

- 4 Lattice material and manufacturing features

- 5 Forged lattices on windows: product design

- 6 Competent operation is the key to long-term use of the grill

- 7 Features of the installation of structures

- 8 Forged structures: how to determine the quality of the lattice

- 9 Forged lattices on windows: the price of products

- 10 Installation of forged gratings: cost

Metal bars on windows: scope of use

Iron bars on the windows are the best method of insuring against unpleasant situations. They are ideal for both private houses and apartments, as well as for the protection of office and banking institutions, shops, utility rooms, garages and warehouses. In some cases, forged grilles are installed on doors, for example, in government premises. Forged gratings are often installed on balconies and loggias.

Types of lattices on the windows

At this time, craftsmen are making a huge number of gratings. All products can be classified according to the following characteristics:

- by manufacturing method: welded and forged gratings;

- by type of opening: sliding, swing and deaf;

- at the place of attachment: external, built-in and internal;

- by type of attachment: stationary and removable;

- by purpose: decorative, security and decorative security.

The peculiarity of security and decorative security products is that the distance between metal parts is narrower than that of decorative analogs. Most often, consumers prefer decorative and security grilles, since they look beautiful and reliably protect the room. Such models are ideal for courtyards and utility buildings. Among the above-described products, blind forged structures are least often installed, since they contradict fire safety rules. Also, internal grilles are rarely used on windows.

Let's consider some types of forged products in more detail.

Characteristics of welded and forged gratings

Welded gratings are a cheap and reliable option.This view is made by welding and forging according to a previously created drawing. It strictly specifies the dimensions of the parts and the design of the elements for the window grill. The design of the product is created using cold or hot welding. The excellent quality of the external seams of the structure is achieved through the use of semi-automatic welding. Welded lattices for windows are made from shaped pipes, fittings, corners, circles and strips.

The assembly of such gratings is carried out by electric welding. Manufacturers always have ready-made models of this type available, which simplifies the process of choosing a lattice for a window. Welded models have an advantage - this is a price, their disadvantage - reliability is lower than forged ones. Also, such lattices must be painted.

Forged models are a guarantee of a unique style and reliable protection of the building. Until welding machines were invented, hand forging was very popular. A master blacksmith is able to transform a heap of metal into delicate lace, delicate flowers and a vine. Forged items have become works of art. The downside of metal bars for windows is the price, it is quite high, but such products are extremely durable.

Stationary or removable model: what to choose

Stationary grilles are a confidence in safety, since the metal structure is inserted directly into the window opening tightly. The main advantage of this mount is that it is almost impossible to remove the grille quickly and without special tools. However, this is also very dangerous.

Useful advice!Place at least one removable or hinged grill in your home, with an internal or mortise lock. This will allow in the event of a fire or other force majeure situation to leave the building through the window, which can save lives. In addition, the presence of such a grill complies with fire safety standards.

Detachable models are characterized by a simple and secure attachment. Bolts are used to mount these grilles. If necessary, they can be unscrewed and the metal structure removed. But this also takes time and in the event of an emergency it creates a life-threatening situation. Therefore, it is necessary to choose a reliable but easily accessible place for the key from the lock.

Deaf, hinged and sliding lattices on windows

Sliding window grilles are rarely used in residential premises, because they are installed on the inside of the window and open only 80% of the opening. They are ideal for offices, shops and warehouses. Most often, steel is used for their production. The inner sliding lattice for the window consists of rods, which are connected by a movable piece in the shape of the letter "X". This design allows the grid elements to move. When opened, such a model is almost invisible. Another advantage is that they do not make it difficult to take care of the window. The product is fastened to the wall.

Hinged grilles provide effective protection and comfortable use. These window products consist of several shutters and are closed with locks at the junction of the edges. Hinged grilles on windows are convenient to use, reliably protect the building and, if necessary, are easy to open, which means that such a product does not pose a threat to life in case of an emergency. Despite the popularity of hinged window grates, the price remains affordable for customers.

Deaf gratings are installed less often, however, this is allowed in private houses if there is at least one hinged one.

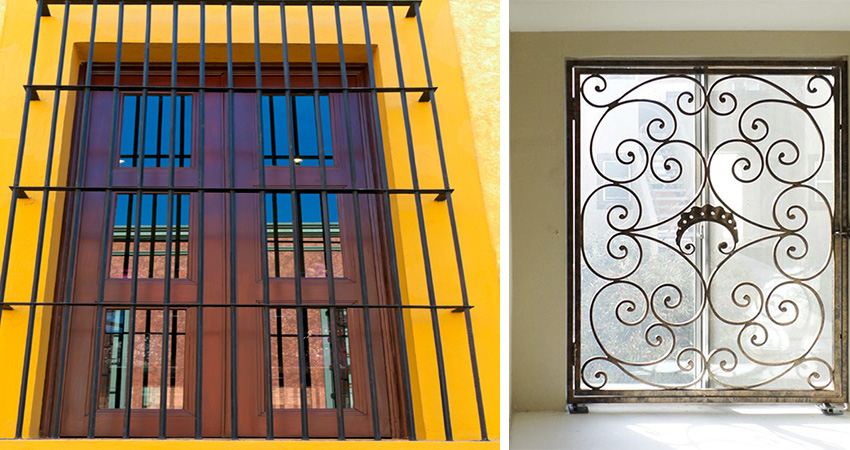

Decorative, decorative security and security grilles for windows

The design of the decorative model is determined by the customer. Craftsmen also provide ready-made sketches and photos of forged gratings for selection. In its function, it is more of a home decoration than a method of protection.Openwork lattices are striking in their elegance and lightness.

Decorative and security grilles - this is the optimal solution, since such models simultaneously protect and decorate the house. The construction of this product is reinforced. The distance between the individual elements is narrower than in decorative grilles. The base of the metal structure is simple rods, and on top they are decorated with decorative elements.

Security grilles are strict and reliable protection of the building. There is no simpler design than this species. However, such models have the most reliable design. These grilles protect the windows of factories, warehouses and garages, as well as secure facilities. The presence of steel parts and locks increases the reliability of the product. And the color of the lattice in the color of the building makes them less noticeable.

Differences between forged models

Forged lattices came to us from the Middle Ages, when castles were guarded by powerful iron gates. At this time, the forged lattice looks much more beautiful and is an excellent decoration for the facade of any building.

Decorative parts of forged models are made by cold or hot forging. The choice of method depends on the complexity of the sketch of forged gratings on the windows and the presence of delicate details. Small elements are attached to the frame by welding. The strength of the entire lattice depends on the adherence of the structure to the frame. Reliability also depends on the number of attachment points.

The main advantages of forged window grilles:

- durability and reliability;

- resistance to damage;

- independence from weather conditions;

- sophistication and aesthetics;

- versatility.

At first glance, such qualities as reliability and sophistication should not be harmoniously combined in openwork window structures, however, even the most unusual and delicate design is distinguished by its power and durability. The price of welded grids on windows is lower than forged structures. This is the only drawback of forged models.

Lattice material and manufacturing features

Most often, for the manufacture of forged gratings, special carbon steel is used, with an impact-resistant function. The production uses rolled products of round and square profiles, as well as strips and rods with a section of 10 and 12 mm. By using metals of different thicknesses, elegant and expressive designs can be created. This ensures the strength and durability of the entire product. Copper and brass are very rarely used. These metals are perfectly forged and have excellent decorative characteristics, but the price for such window structures is much higher.

Forging involves flattening and then pulling and bending. This is what guarantees the creation of original patterns. Individual elements are connected using electric welding or special rings and plates.

Related article:

Transparent grilles on windows and their functional advantages

Transparent grilles on windows: types of structures for houses and dachas, their advantages and characteristics. Prices for the purchase and installation of products.

Forged lattices on windows: product design

Regardless of the production method, the design pattern can be varied. Decorative grilles made of metal are characterized by smooth, pointed and curved lines. The combination of twisted rods of various thicknesses with stripes and round details creates a unique model. In the drawing of window structures, geometric details, ornaments with animals and plants, and fantasy details are also often used. These elements give the building a romantic and sophisticated look.

- classical;

- Gothic;

- Greek;

- modern;

- country.

The design of the product can be complex, with many branches, or simple. The shape of the product depends on the window opening: round, square, rectangular.Convex lattices look original. You can also add a flower compartment to the design.

In any workshop for the manufacture of these structures, customers will be offered a choice of ready-made models, or they will recommend viewing photos of forged gratings on the windows. You can also create an individual design for your future design yourself.

Competent operation is the key to long-term use of the grill

In order for the grille to retain its presentable appearance for a long time and organically fit into the design of the building, it must be coated with special solutions or anti-corrosion paints, specially suitable for open air. The most commonly used varnish is black. Thanks to this paint, forged products look graceful and elegant, and the structure will be a great addition to any building design.

Useful advice! Lattices painted in gold, silver or bronze look rich. It looks beautiful, impressive and luxurious. You can paint the entire structure or individual elements.

Dust and dirt are less visible on painted metal products, so they are more practical to use. Antique window grilles look original. Balcony structures are complemented by decorative glass, plastic, wooden details.

If heavily soiled, the grille can be cleaned. To do this, use gentle detergents and a water jet from a hose. Such actions will remove dust, preserve the top layer of paint and prevent rusting of the metal.

Features of the installation of structures

The grille must completely cover the window. There are two mounting options: inside the opening or overlay. A more reliable way is directly into the opening, since it will be almost impossible to pull out the metal structure. The overlay method is less reliable and therefore rarely used.

Most often, two technologies are used to attach forged gratings to windows:

- Fixation by welding to special metal rods. To do this, holes are drilled in the brick or concrete wall of the building from the end, in which iron pins of square or round cross-section are fixed. They are installed to a depth of 12 cm, and protrude outward by 5 cm. A frame is welded to them, to which an openwork window protection is attached. This method is considered the most reliable and used most often.

- Bolt-on. Installation is carried out over the window opening on the wall. In this case, hardware or anchor bolts are inserted into the drilled holes. The forged grille is bolted through special holes. For such an attachment, the material of the walls does not matter. Anchor bolts are used only for bricks, and technical screws for wood.

You can also fix the grille through the method. This option is best suited for timber houses. In this case, the hole is drilled through the entire wall. The structure is fastened to the lining using bolts, which are tightened with nuts from the inside of the building.

Useful advice! When installing the grille in rainy weather, it is necessary to exclude the ingress of moisture. You can install a visor or canopy above the window.

Regardless of the selected installation method, the product is inserted into the frame. The doors can be sliding or swinging. They are locked with special locks, the key from which should always be at hand. Deaf grilles are practically not used, although they were previously popular. It often happened that they were the cause of the death of people who could not get out of a burning house.

Forged structures: how to determine the quality of the lattice

The grille design does not affect the protective performance of the product. Each customer chooses a model based on their taste. But it is important to pay attention to the following characteristics when buying a grill to protect a house from intruders:

- Fastening elements. Most craftsmen attach the forged product to a 5 mm thick metal frame, with which the grille is fixed to the wall. When placing an order for the manufacture of a lattice for a window, ask the master to use a T-profile. An experienced thief will not be difficult to cut an ordinary 5 mm strip, but you will have to tinker with the profile.

- Product parameters. Regardless of the sketches of the lattice for the window, the distance between the bars should not be too large. If anyone can easily shove hands with tools between them, then this design does not perform any protective functions, but is only a forged decoration.

A wrought-iron window grill, made according to all the rules, is installed only from the side of the room with an open window. Quick installation from the street means that just as easily anyone can remove the structure and get into the house. Of course, a forged grille does not provide a 100% guarantee of protection, however, a reliable design will significantly complicate breaking.

Forged lattices on windows: the price of products

The cost of products is formed depending on many factors, namely:

- mode of production. Manual production is always more expensive;

- amount of metal. The more steel is needed, the higher the price;

- design. You will have to pay more for a significant number of small details in the ornament;

- the size. Small structures are cheaper.

On average, window bars of conventional design cost 2-3 thousand rubles. per m2. The cost of exclusive lattices with a complex ornament is discussed with the master personally before production. The price of manufacturing hand-made window grilles with a special design starts at 7 thousand rubles.

Useful advice! Order grilles only from trusted craftsmen with a reliable reputation. Because the protection of your home depends on the work they do.

Installation of forged gratings: cost

The installation price of a forged structure depends on the dimensions of the window or door opening. The cost of installing a conventional product is 20-30% of the market price of the grille itself. The installation of decorative grilles on windows is carried out by companies that specialize in their manufacture. The reputation of such firms must be impeccable, since the safety of your home depends on their work.

Professionally made and well-mounted forged gratings will favorably emphasize the individuality of the building and become a reliable protector against burglars. If you wish, you can make a grate on the windows with your own hands, but this will require you to purchase all the necessary materials and work hard.