PVC windows have long ceased to be a luxury and have become an indispensable attribute of a modern home. In addition to the fact that they have a lot of useful performance characteristics, since they serve for a very long time and look attractive. Before installing metal-plastic structures, it is very important to know the parameters of the window opening and the standard sizes of plastic windows.

Content [Hide]

- 1 Window opening elements

- 2 Types of plastic windows and their correct measurements

- 3 Standard PVC window sizes and options

- 4 What window parameters need to know

- 5 How to choose the right plastic window

- 6 Installation of standard size windows

- 7 Typical malfunctions of plastic windows and how to fix them

- 8 Why you need to consider the standard sizes of plastic windows

Window opening elements

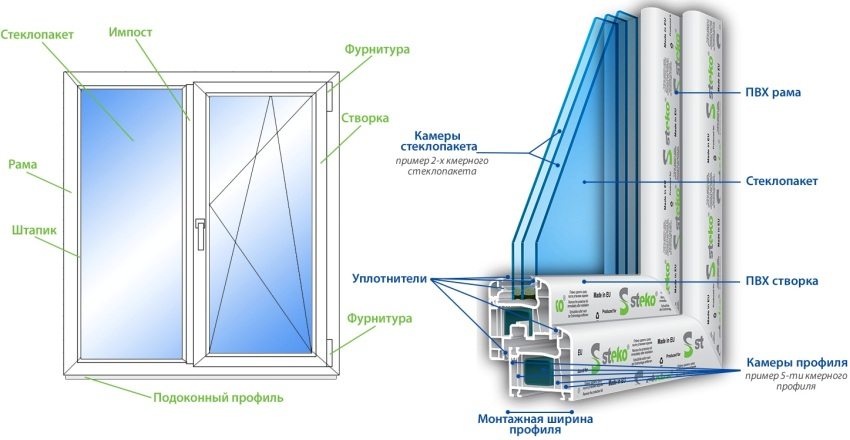

Before purchasing and installing windows, you should understand what is included in the window structure. With any house architecture, it consists of the following elements:

- the window is the main element of the opening, it can have a different size and shape, be opening or deaf, and differ in other characteristics. The standard size of the window opening for plastic windows depends on the type of building;

- ebb - a part of the opening, which is mounted on the outside of the window frame and serves to drain rainwater. The correct installation option for the ebb is when its edge comes under the bottom of the window frame. Thus, you completely eliminate the ingress of water into the layer of insulating material, which is located under the ebb;

- window sill - an analogue of the ebb from the inside of the window frame. Unlike its external counterpart, it performs a purely decorative function. The width of the window sill directly depends on the thickness of the wall of your house. The sill and window can be made of different materials;

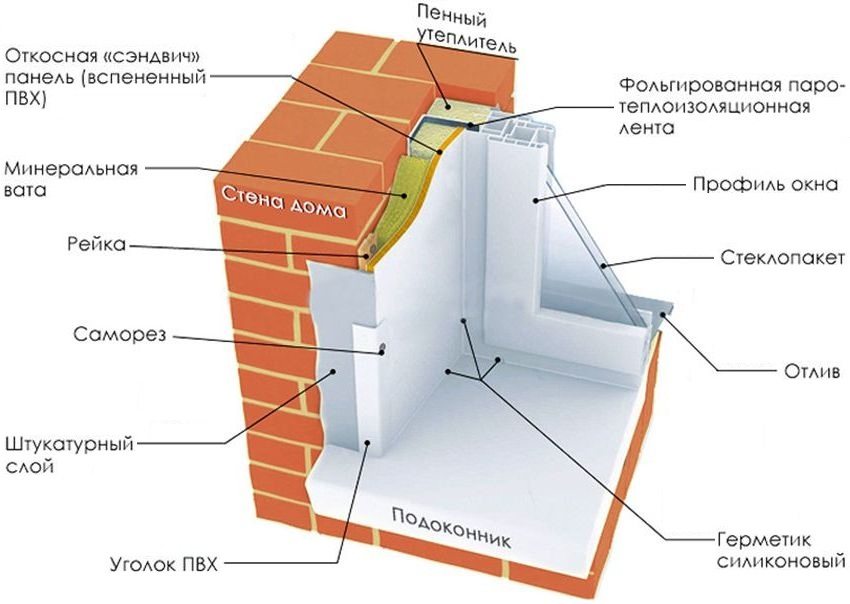

- slopes - lateral and upper part of the window opening. When installing new PVC windows, the slopes are finished with sandwich panels, which insulate the room well from noise and cold, and also perform a decorative function.

Types of plastic windows and their correct measurements

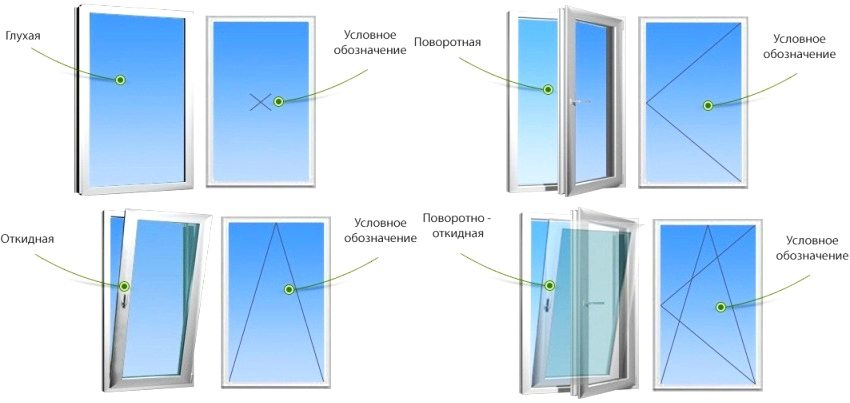

According to GOST, the dimensions of the windows depend on the design features. That is, there are standard parameters for each of the main types of windows. The following types are distinguished:

- blind window;

- swing-out single-leaf;

- bivalve;

- tricuspid;

- balcony window;

- window with transom.

The most popular option in modern homes is a double or triple wing window. The standard parameters of a double-leaf structure are 130x140 cm.If the size of a window in a Khrushchev or another type of house does not match the parameters of the selected PVC window, then it can be increased or decreased. Of course, it is best to select such window dimensions that will fit as much as possible into your window opening.

The size of the window in a brick Khrushchev implies an opening with a quarter or a quarter. In order to accurately calculate the appropriate parameters of the window structure, you must first measure the gap between the side walls. Then the width of the window is calculated by subtracting from the total width of the gap located in the assembly seam. For polyurethane foam, it is necessary to leave gaps of 20-30 mm on each side.

After that, the height of the opening is measured. The gaps and the estimated thickness of the sill are subtracted from the obtained value, which is usually 40 mm. Remember that the size of the window sill for a plastic window may differ from this figure in a smaller or larger direction, so the calculations should be done after purchasing a double-glazed window.

A plastic window with a quarter must be installed after the calculations are made for the outer and inner sides of the wall.

Helpful advice! The length of the ebb should be equal to the width of the opening on the outside of the window.

Standard PVC window sizes and options

Despite the existing standards, the sizes of plastic windows can be absolutely any. Depending on the customer's requirements, modern manufacturers can produce metal-plastic structures with various parameters. There are a number of popular sizes:

- single-leaf window - 1150x1900 or 850x1150 mm;

- bivalve - 1150x1900, 1300x2200 or 1500x1900 mm;

- three-leaf - 2400x2100 mm.

The maximum window size in panel Khrushchev is 1450 mm in height and 1500 mm in width, and the minimum is 1300x1350. For brick houses or modern new buildings, these parameters may differ.

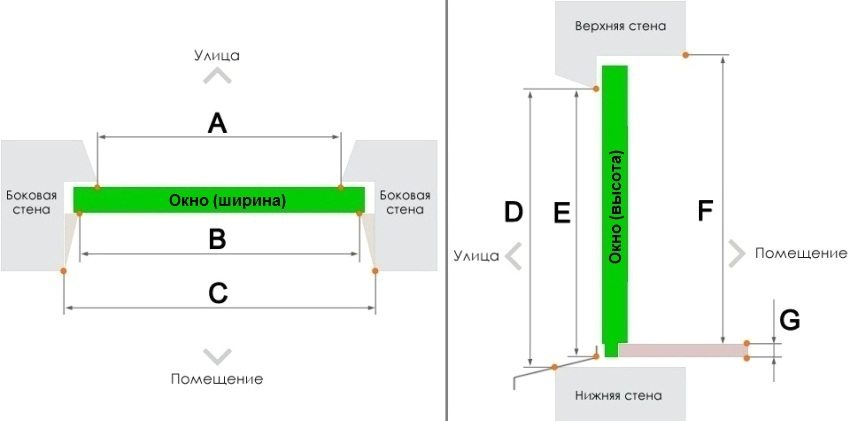

Correct measurements of the window opening: A - the width of the outer slope, B - the width of the inner slope, C - the width of the inner window opening, D - the height of the outer window opening, E - the height of the outer window opening, excluding the installation profile, F - the height from the window sill to the upper inner slope, G - the height of the window sill

The standard for window sizes is regulated by GOST 30674-99, as well as SNiP, which indicates the ratio of window parameters and the total area of the room in which it is installed. The dimensions of the window opening are regulated in accordance with GOST 24699-81. If we are talking about the size of a window in a panel house of a new sample, then there may be two options:

- double-leaf window - 1300x1400 mm;

- three-leaf - 2060x1400 mm.

For brick stalinkas, the parameters of window openings can be 100-150 mm larger, therefore it is very important to know the exact dimensions of the PVC window (width and height) before buying. A standard window opening, in the case of inaccurate calculations, can be increased using building materials. The more precisely the dimensions of the window correspond to the opening, the less time and effort will be spent on its installation, and the room will be better insulated from external noise and protected from heat loss in the cold season.

Standard window sizes for various types of apartment buildings:

| Residential building type | Standard size of the window structure, mm | ||

| Double sash window | Three-leaf window | Balcony block (window / door) | |

| Khrushchev | 1280x1340, 1450x1500 |

2040x1500 | 1350x1340 / 680x2070 |

| Stalinka | 1080x1080, 1250x1800, 1500x1900 |

1500x2700 | |

| Panel houses | 1150x1420, 1410х1450, 1450х1410 |

1700x1420, 2030х1410, 2050x1410 |

400х1410 / 680х2140, 500х1410 / 680х2140, 1200х1410 / 680х2140, 1700х1410 / 680х2140 |

When calculating the size of the roof window, you need to proceed from the standard parameters, but it is also important to take into account the angle of inclination of the roof. The height of the window directly depends on this parameter, and the distance between the rafters should be 4-6 cm wider than the window box.

Related article:

Do-it-yourself slopes on installed plastic windows: video and installation instructions. Comparative characteristics of various options for finishing window blocks, installation of drywall.

What window parameters need to know

If you use the services of third-party specialists to install new windows, then the design parameters will also affect the cost of work. To determine the cost of installation, you need to know the following data:

- window height and width;

- sash type - blind or swing;

- number of flaps;

- type of glass unit - number of chambers;

- type of opening mechanism - swivel or swing-out;

- the presence or absence of additional coverings or mosquito nets;

- type of fittings and their manufacturer;

- length and width of the low tide;

- window sill dimensions and the material from which it is made.

All these data affect not only the price of installing a double-glazed window, but also the complexity and duration of the work.

How to choose the right plastic window

Regardless of the size of a standard window in a brick or panel house, there are a number of important points that you should pay attention to before making a purchase. Let's consider them below.

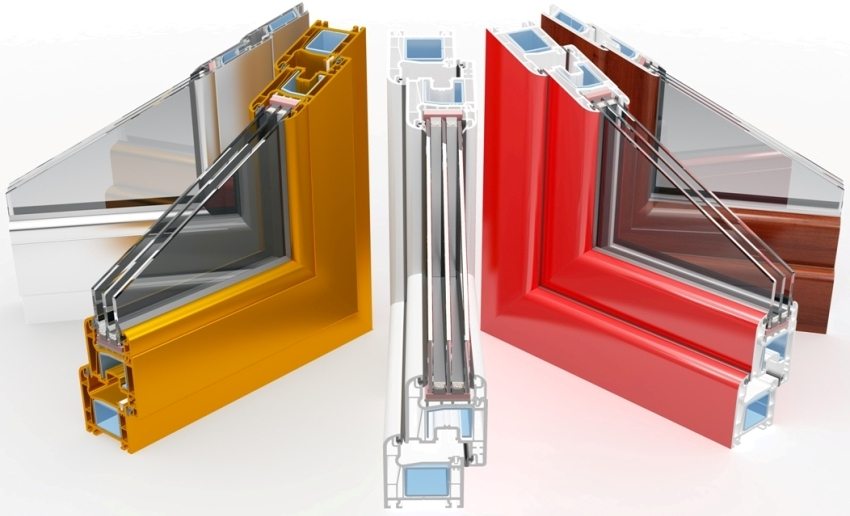

Profile type - the main parameter of modern PVC windows. Now there are several dozen manufacturers on the market, each of which offers its own version of the profile. A quality product is one that comes with a 40-year warranty. During this time, the profile will not crack and will not lose its attractive appearance.

The type of product also affects its thickness, it should be 68-84 mm, this is the best option for effectively retaining heat in the room. There are profiles of class A (thickness of outer and inner walls is 2.8 and 2.5 mm, respectively), class B (2.5 and 2.0 mm) and class C (all other options). The latter class is not suitable for residential installations. A useful addition to the profile, which not all companies install, is a drain bar that prevents water from entering the window during ventilation.

Helpful advice! Some window manufacturers make their products from the so-called object profile. Its peculiarity lies in the fact that it is intended for installation in non-residential premises, and it is categorically not recommended to install it in living rooms due to its low characteristics of rigidity and thermal conductivity and in a possible unpleasant odor.

Reinforcement - PVC windows are also called metal-plastic due to the fact that there is a metal part inside the profile, which ensures the rigidity and strength of the structure. Not all manufacturers care about the presence of reinforcement, but it is quite simple to check this moment - you need to take a magnet and attach it to the frame.

Build quality - a parameter that directly affects the durability of products, heat and sound insulation, and many other parameters. It is quite difficult to determine these properties by eye, it is necessary to check the compliance of the characteristics and dimensions of the profile with a plastic window, to control its quality in accordance with established standards.

Hardware quality - the price of a standard size plastic window largely depends on this parameter, because the better the fittings, the longer your purchase will last and the more comfortable it will be to use. For example, it is very important to have an erroneous action blocker, which does not allow the structure to be switched to ventilation mode when the sash is open and vice versa.

Also important is the presence of mating strips, which are responsible for the density of the frame porch and the absence of drafts, the quality of handles and hinges. A good option is metal fittings in a plastic case, they will last longer than conventional plastic models.

Slopes - an important point for the performance of the window. Of course, you can make slopes for a plastic window with your own hands, but for this you also need to know a number of nuances.For example, slopes made of insulated sandwich panels do not have joints, are protected from the formation of fungus, and provide an adequate level of insulation from noise and heat loss. Various videos of installing slopes plastic windows demonstrate with their own hands that the joints on the slopes are best sealed with liquid plastic.

Number of air chambers - a parameter that affects protection against loud sounds and cold. The minimum number of cameras in a plastic window is 3, and the maximum is 8, but the latter option is used very rarely, models with 3-4 air chambers are more popular.

Quantity and quality of double-glazed windows... Double-glazed windows are glass blocks, hermetically connected to each other. The number of glasses in a block affects its strength and insulating properties. Also in modern windows, double-glazed windows with various additional properties are often found. It can be a special coating that reflects infrared rays, fireproof or triplex laminated glass. The latter option is particularly durable, and if such glass breaks, then sharp fragments are not formed from this.

Seal quality - affects the tightness of the window closing. The cheapest and most wearing option sealant - this is rubber, a more reliable material is silicone or rubber. They are resistant to temperature changes and do not deform from prolonged use.

Installation of standard size windows

If you have the skills necessary for self-assembly and want to save money, then a metal-plastic window can be installed with your own hands. To do this, you need to make all the measurements described above, after which you can go shopping. A very important point here is to take into account the window fastening system. This can be fastening with the help of support reinforcement, which is mounted on the frame at the stage of manufacturing the structure, or fastening through the frame in the window mounting plane.

The first option is easier for self-installation, since it practically eliminates the risk of damage to glass units and a violation of the tightness of the window during installation. The disadvantage of this option is the large weight of the window and the inability to install it yourself. In the second case, double-glazed windows are removed from the doors, and the frame is mounted separately, which allows you to do all the work alone.

Preparatory work

Before proceeding with the installation, it is necessary to clear the place in front of the window opening. It is recommended to cover the floor and furniture with a thick cloth or construction film. Then you need to prepare the window. If we are talking about a three-leaf window of a standard size or other heavy structure, then you must first dismantle the double-glazed windows or swing leaves from the frame.

Helpful advice! If you are installing a blind window, then you do not need to do this, since the weight of the one-piece structure is not too large for self-installation.

In order to dismantle a double-glazed window, you need to use a chisel to pull the glazing bead out of the groove, which secures the package. In order not to confuse the glazing beads when installing back, they must be marked. Then plugs are removed from the canopies of each of the swing leaves and the clamping bolts are unscrewed.

As a result, you should be left with one frame, in which holes for anchoring should be made from the inside. You need to use a metal drill for this, since there is a metal insert inside the plastic frame. Usually, anchor bolts with a diameter of 8-10 mm are used to secure the window.

There are models in which the fastening is carried out using special lugs. In this case, it is not necessary to disassemble the window, it is enough just to screw the fasteners to the frame.

To improve the thermal insulation qualities of the structure, it is recommended to fill the inner space of the support profile with mounting foam. This is best done a day before installation so that the foam hardens and hardens.

Dismantling an old window

If the new window is not installed from scratch, then you must first dismantle the old one. For ease of dismantling, the frame and window frame can be sawed in several places, after which each of the parts is pryed off with a crowbar or nail puller and removed from the opening.

After dismantling the frame, the layer of insulation and sealant is removed. Together with them, part of the slopes is removed. If you want to install new slopes later, then the old ones must be completely removed. The window sill is dismantled together with the cement substrate located under it.

After that, you need to collect and take out all the construction waste, align the ends of the window opening and clean it of dirt and dust, and the surface must be primed.

According to GOST, the size of a window opening in a wooden house may differ from common standards, therefore, you will have to use foam and lay a layer of waterproofing so that the PVC structure fits snugly against the walls. In special cases, it may be necessary to reinforce the window opening by inserting a wooden window frame.

Installation of a metal-plastic window

Installation of PVC profile windows takes place in several stages.

On the lower end of the window opening, you need to lay a substrate made of wood or plastic. The tops of the substrates must be in the same horizontal plane. They need to be installed under the edges of the frame and in the center.

The entire window structure or just a frame is installed on top of the substrates, depending on the installation option you choose. The supports placed on the frame should not be removed, since the anchorage itself cannot support the full weight of the structure.

The opening is sealed at the sides with pegs that are driven in between the wall and the window. This should be done closer to the edges, otherwise the frame in the middle may bend. After the pegs are driven in, the horizontal plane of the window must be checked using a building level.

Helpful advice! To measure the accuracy of the installation of a structure horizontally or vertically, it is best to use a water level, since the bubble level can give a significant error.

After completing the above work, proceed directly to the fastening of the window. If the fastening takes place through the frame, then using a punch through the previously prepared holes, it is necessary to drill holes in the wall, then the anchors are inserted into them, but they are not completely twisted. Installation should start from the bottom of the frame, after which you need to check the verticality with a level, after which you can tighten the fasteners completely. But do not clamp the anchor too tightly, otherwise the frame may deform.

If your window model has special fastening plates, then they have ears for fastening anchors. The arm must be bent so that the eyelet fits snugly against the wall. As in the case of fastening through the frame, you must first fix the lower part, and then the upper one.

A separate stage in the installation of the structure is the installation of the drainage system. It is inserted into a special groove that runs along the outer edge of the window, and then additionally foamed. Some models provide for the option of fastening to the window frame with screws.

Build and check the window

After the frame is bolted to the opening, you can start assembling the structure. This must be done in the reverse order from how the window was disassembled. That is, first, double-glazed windows are inserted into the frame, which are fixed with glazing beads, first with the upper and lower ones, and then with the side ones. You can click the fasteners all the way with a rubber hammer, so you will definitely not damage the glass and frame. After that, the swing leaves are inserted, their normal movement and tightness of closing are checked.

Particular attention is paid to checking plastic windows of non-standard sizes and shapes.

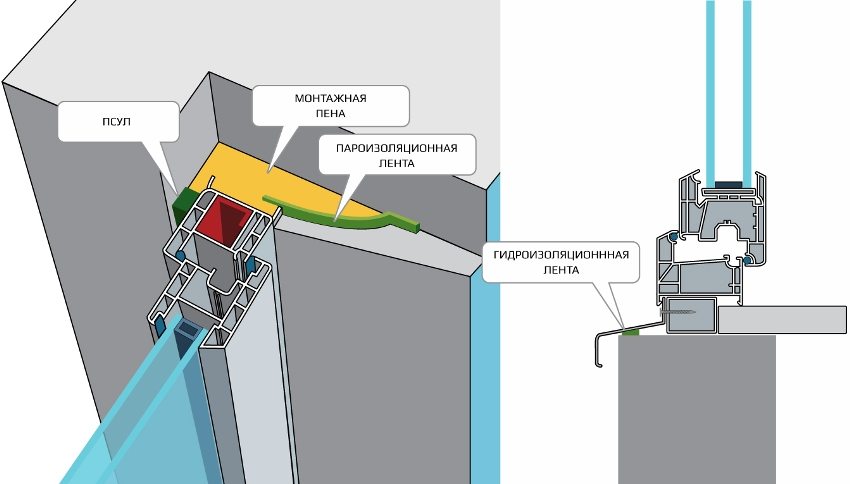

Sealing assembly seams

Even when installing a structure ideally suited to its dimensions in a standard-sized window opening, it is imperative to perform additional sealing of the assembly seams. For this, regular polyurethane foam is used, which can provide a sufficient level of thermal insulation. A special hydro-barrier should be created on top of the polyurethane foam, since the foam can eventually lose its insulating properties from contact with the external environment.

It is quite simple to arrange such a barrier - for this, a special vapor barrier adhesive tape is glued to the inside of the window, designed for such purposes. And from the outside, you need to glue a vapor-proof moisture-resistant membrane, which will not only protect the foam layer from moisture, but also ensure its removal from the insulation.

A special foil waterproofing strip is glued along the lower inner edge of the window.

Window sill installation

The sill must be trimmed along the edges so that it fits into the window opening and fits under the window frame. Its edges should go to the wall by 50-100 mm, and the angle of inclination should be slightly directed towards the interior of the room. The space under the windowsill is flooded polyurethane foam or filled with cement mortar. The structure is fastened with self-tapping screws, which are screwed in from the inside of the frame.

Helpful advice! After the complete installation of the window, you must wait another day until the polyurethane foam completely hardens. And only after that you can start opening the sashes and checking the work of the fittings.

After installation windowsill additional vapor barrier can be made using a special tape

Installation of PVC slopes

Plastic slopes are very popular due to their high performance and ease of installation. The advantage here also lies in the fact that the PVC panels from which the slopes are made correspond to the material of the reinforced-plastic windows, therefore, when the temperature changes, the window and the profile expand equally, which does not create additional stress.

With the standard size of the window opening, the slope can be installed in just a few hours, if the following sequence of actions is followed:

- Strips of the required length and width must be cut from the PVC panel.

- The slope is pre-cleaned, then the panels are attached to it using liquid nails.

- The panel is fixed in the desired position using a special rail, which is equipped with a snap-on corner. Alternatively, you can use a cheaper option - wooden slats, fastened with a construction stapler.

- The butt between the wall and the slope is covered from above with special plastic corners. They extend the life of the wallpaper near the window.

Installation diagram slope using sandwich panel

Remember that any PVC panel will not work for mounting the slope. The material must be resistant to prolonged exposure to direct sunlight, temperature changes, high humidity and mechanical damage. Usually sandwich panels, which include expanded polystyrene and PVC, can boast of similar properties. They do not allow heat to pass through, fungus and mold do not form on them, they do not turn yellow from exposure to the sun and do not crack in the heat.

Typical malfunctions of plastic windows and how to fix them

No matter how high the quality of the window structure, sooner or later minor problems arise. You can get rid of them with the help of qualified specialists or on your own. If you are interested in self-repair, then you should be aware of common problems that may arise during operation.

Repair and replacement of the handle - the simplest option, which requires no special skills or tools. It is enough just to buy new hardware and dismantle the old one. To do this, unscrew the screws that are under the plate at the base of the handle. After that, a new one is installed in place of the dismantled part.

The ventilation position regulator plate and the regulator itself are just as easy to replace. It is best to purchase fittings from the same manufacturer as the window itself.

The handle is stuck open... To fix this type of malfunction, you must first find out the brand of the hardware. In AUBI handles, you need to find a thin steel plate with a spring under the handle and press it against the seal with the window sash closed. If you have a pen from another manufacturer, then instead of a plate, you will find a metal tongue with which you need to do the same.

Handle sticks... This problem can be easily remedied with the popular WD-40 grease. It processes all the moving parts and joints of the mechanism. Of course, it is best to disassemble the handle for this, so that you have access to all the details.

Draft from under the seal eliminated by adjusting the eccentrics. For each individual brand of accessories, this process may have its own characteristics.

Draft from the hinge side... This problem occurs either as a result of improper window installation or as a result of a factory defect. It is quite difficult to eliminate it, but it is possible. To do this, you need to remove the glazing bead using a chisel, then move the window sash from the glass unit by 4-5 mm and install homemade plastic plates that can be made from a regular ruler into the gap formed. The thickness of such a plate should be the same as the thickness of the glass unit, and its edges should in no case rest against the glass from the inside.

Replacing the glass unit completely... This type of repair is quite complicated, and its implementation requires certain skills and a set of specialized tools, so if you are not confident in your abilities, then it is better to seek professional help. For self-replacement, you must first disconnect all the glazing beads, and then remove the glass unit from the frame.

The new package is installed on adjusting plates, by decreasing or increasing the number of which the correct sash geometry can be achieved. After that, the glass unit is assembled in the reverse order of the analysis.

Helpful advice! When troubleshooting PVC windows, you can and should use video instructions from the Internet. As a rule, they show in detail and clearly all processes, from replacing the handle and glass unit to eliminating drafts and adjusting the tightness of the glass.

Why you need to consider the standard sizes of plastic windows

The size and price of a plastic window are interrelated things, so designs of a typical size will cost you less than non-standard ones. Based on this, you need to carefully measure before contacting the seller. Also, knowing the size of the window opening, you can determine which window model is suitable for your home.

Choosing PVC profile windows for your house or apartment, you get a number of significant advantages.For example, you reliably isolate your home from street noise, save on heating due to the high energy-saving characteristics of plastic windows, and get an attractive-looking interior element. In addition, metal-plastic windows differ from wooden ones in a long service life, therefore, having installed such a structure once, you can not think about replacing windows for several decades.

For a quality installation, it is very important to know the standard dimensions of a window in a panel house, brick or other type. For different building options, the sizes of window openings can vary significantly and, if you are not sure of the exact numbers, it is better to make measurements yourself or use the services of experienced specialists. So you can choose or order exactly the window model that you need.