Plasterboard has been successfully used for internal construction work for many years. With the help of the material, it is easy to level walls, make arched openings, niches and ceilings. GVL sheets are gypsum fiber boards made by mixing stucco and waste paper. In appearance, the material practically does not differ from ordinary drywall, but at the same time it has a denser structure that allows it to withstand heavy loads.

Content [Hide]

- 1 What are gypsum fiber sheets, the key features of the material

- 2 Where ordinary and moisture resistant gypsum fiber boards can be used

- 3 Key materials for interior decoration: LSU, GVL and GLK, what is the difference

- 4 How to mount and how to cut moisture resistant and ordinary gypsum fiber sheets

- 5 Overview of manufacturers and prices of gypsum fiber boards for walls

What are gypsum fiber sheets, the key features of the material

GVL is one of the most popular and demanded materials for interior decoration today. The abbreviation stands for gypsum fiber sheet, and the material itself is a solid panel used for wall cladding or organizing screed on the floor.

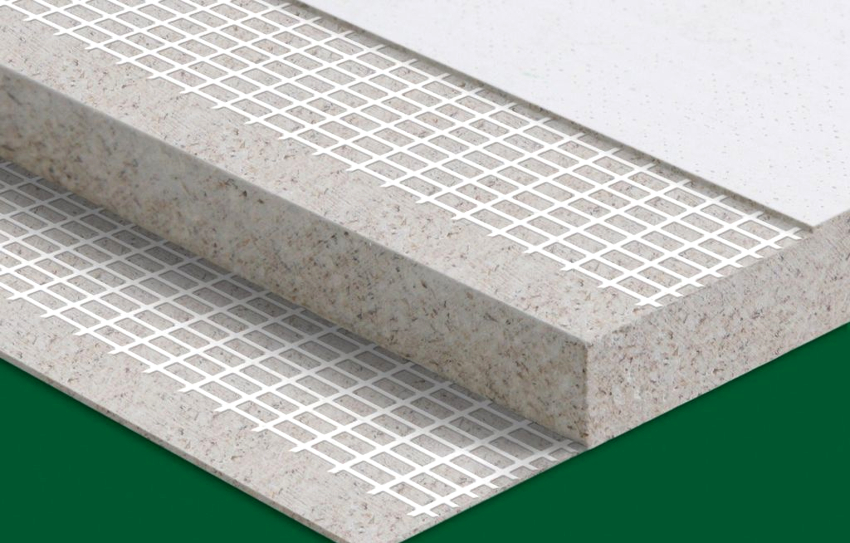

Information! Sheets are considered environmentally friendly, because GVL is a building material consisting of 80% gypsum and 20% cellulose. The main difference from a conventional drywall sheet is a homogeneous structure without a shell.

The main advantages of gypsum fiber are high strength and ductility characteristics, as well as a homogeneous structure. Thanks to this, it will be possible to hammer nails into the sheets, like into a tree. The presence of only natural ingredients in the composition allows you to maintain and maintain a special microclimate in the room, because the sheets absorb excess moisture, and then give it away.

If you think about what GVL is in construction, then first of all it is worth noting that it is a convenient material suitable for finishing various surfaces. When buying, be sure to pay attention to the presence of various marks on the packaging:

- "Ш" - means that the sheets have passed the grinding process;

- "NSh" - marked on unpolished surfaces.

Choose one of the options based on the purpose of use.For example, if you plan to perform finishing work for painting or for wallpaper, it is better to choose sanded sheets, but when the tiles are laid on gypsum fiber board, then you can take unpolished material.

Another fact that needs to be considered is the design of the joints. If you want the joints to remain invisible, it is better to choose sheets marked with the letters "FK", because in this case the plates are supplemented with a special chamfer for an inconspicuous joint. In the case of conventional sheets, reinforcement tape is used to minimize the appearance of seams.

Features of GVL boards: size options and technical parameters

Plates are especially common because GVL is such a material, the production of which is regulated by certain regulatory documents. Technical parameters and production technologies are reflected in GOST 51829-2001, therefore, when buying gypsum fiber board for walls or other surfaces, you must definitely ask the seller for a certificate confirming the quality. In the absence of such documents, it is better to refrain from purchasing goods, since you can buy low-quality and non-conforming products.

It is important to know! Before planning the purchase and use of building material, it must be borne in mind that the surface of the sheets cannot be combined with silicate dyes or other compositions based on water glass. At the same time, it is permissible to use panels together with other paints, for example, alkyd or dispersed.

In fact, GVL is a sheet finishing material with a rectangular configuration. On both sides, the panels have a smooth surface, where a water repellent or other impregnation is applied, preventing the deposition and penetration of dust into the sheets. According to GOST standards, the material is mainly produced in the following length (in cm):

- 120

- 150;

- 200;

- 250;

- 270;

- 300.

Usually, the product is presented in three standard widths - 50, 100 and 120 cm, thickness varies from 1 to 2 centimeters. The most popular in the market are Knauf GVL sheets, where the following are considered the running parameters:

- 250x120x1 cm, the plate weighs 36 kg;

- 250x120x1.25 cm, due to the increased thickness, the weight is 45 kg.

Separately, we can highlight the canvases used to decorate the screed, which are marked as "super floor". The optimal size is 120x60x1 cm, while the weight of the slab is 18 kg. In general, the nominal geometric parameters of Knauf gypsum fiber sheets (GSP-A) are:

- length - 200-400 cm;

- width - 120 cm;

- thickness - 0.65, 0.8, 0.95, 1.25, 1.4, 16 cm.

As noted, the material is made up of recycled paper and plaster, which gives all panels a white-gray color. Slabs are considered dense, but even less this indicator is half the density of red brick. Ultimate strength is measured by the following parameters:

- 53 kg / cm² - for bending;

- 100 kg / cm² - for compression.

Among other technical indicators of sheets, the following stand out:

- thermal conductivity - 0.36 W / mK, which makes the material warm to the touch;

- sound absorption - 40 dB, the indicator increases depending on the thickness of the plates;

- swelling - 1.5%, if you leave the leaf in water for a day, it will not increase by more than the specified number of percent.

What are the advantages and disadvantages of GVL sheets

First of all, among the advantages of sheets, fire resistance should be distinguished, which makes the building material incapable of self-ignition. Even in case of fire, the flame will not spread over the surface of the canvas. On the packaging of panels, the category of fire resistance is usually indicated - G-1, which means "hardly flammable sheets".

Fact! To increase the indicators of moisture resistance and resistance to deformation, a special treatment is used.During the production process, gypsum fiber is impregnated with special latex-based compounds. This not only helps to increase the water repellency properties, but also guarantees optimal adhesion to other finishing materials and to painting.

Other advantages of gypsum fiber sheets are:

- Increased thermal and waterproofing characteristics. This makes the material ideal for interior cladding of apartments or houses, as well as for the installation of interior partitions.

- Hygroscopicity. Allows the sheets to absorb moisture from the air and then release it.

- High strength. The slabs are dense, but, despite this, very flexible, which makes it possible to create complex shapes.

- The ability to withstand changes in room temperatures. Even with frequent jumps in indicators, the probability of deformation is reduced to zero.

- Environmental friendliness. The composition contains only safe materials of natural origin, so you can use the sheets in any room.

- Easy installation. For installation, both metal and wooden frames are equally effective. The connection points are easy to hide. It is also important to consider that during installation there is no large amount of waste, dust or dirt.

- The ability to interact with other materials.

An advantage can also be considered the fact that no special tools are required when installing the plates. However, before buying, you need to find out everything about the shortcomings of GVL canvases:

- Great weight. If you plan to use sheets for decorating ceilings, you most likely will not be able to cope alone, because the weight of the sheet is 18-45 kg (depending on size).

- Cost. The price for a sheet of gypsum fiber board is determined by the dimensions of the plates, on average it starts from 150-200 rubles per square.

- Relative fragility. If during the installation process the manufacturer's recommendations are not followed, there is a possibility that the panels will crack or even break.

The main types of canvases by purpose and size: what is GVLV

Generally speaking, gypsum-fiber boards differ in two ways - depending on size and purpose.

GVL canvases are used for both construction and interior finishing works. They differ in standard indicators of moisture resistance and belong to dense, safe building materials. Suitable for creating internal partitions.

GVLV - sheets that can tolerate high humidity for a long period, therefore, are considered the best option when performing repairs in the kitchen and bathrooms. Also suitable for covering surfaces in baths, saunas and swimming pools. Increased moisture resistance is achieved due to the treatment of products with water-repellent compounds.

GVL sheets "superpol". Manufactured exclusively by Knauf. Plates are not only reliable, but also highly durable. GVL Knauf sheets are suitable for performing a dry screed on the floor and are two connected plates, offset relative to each other. Thus, the installation is neat with minimal noticeable joints.

As for the size, most often during construction slabs of the standard parameter - 120x150 cm are used, which are intended to level vertical surfaces. For finishing floors, small-format slabs are suitable, characterized by a higher density and, accordingly, weight. An important feature is the presence of a seam system, which is a lock-in-lock installation. Another version of the sheets is marked "PC", which means "straight edge". In general, such products can be distinguished not only by marking, but also by their appearance.

Expert advice! To understand what type of material belongs to, it is enough to pay attention to the marking.As an example, we can consider the version GVL-A-PK-2500x1200x10 TU 5742-004-03515377-97. The second part of the numbers indicates the GOST number, which was taken into account during production, the first part indicates the type of edge, as well as the size of the blade.

Where ordinary and moisture resistant gypsum fiber boards can be used

Gypsum fiber is used to solve many tasks that are performed in residential or commercial buildings. It is considered popular to create false walls or partitions made of gypsum plasterboard, dividing a large room into different functional zones or even separate rooms. A similar performance is often observed in spacious studio kitchens or is used to divide one children's room, designed for several children.

To create a partition from GVL, first a metal or wooden frame is installed using the desired profile, and then GVL panels are attached to the finished crate. For this purpose, sheets with a thickness of 1.25 cm or more are suitable.If you want to make the structure more durable or improve the sound insulation qualities, it is recommended to lay the sheets in two layers. In this case, the lathing is made on both sides, and a layer of sound or heat insulation is laid between them.

Another popular option is wall cladding for leveling purposes or simply for a neat look. In this case, a lathing is also mounted under the sheets of gypsum fiber board for the walls. Depending on the humidity, the type of canvas is also selected - moisture resistant or normal. Additionally, the crate can be combined with insulation. In addition, with the help of cladding, it is possible to successfully hide electrical wiring, plumbing pipes or other engineering communications. You just need to try so that the sharp edges of the sheathing do not come into contact with electrical cables.

Sheets are also used in the design of suspended ceilings. In this case, the panels are attached to the ceilings on a wooden or metal sheathing. At the same time, it is important to understand that such a ceiling does not perform any load-bearing function, because the main task is to create a seamless base for the finishing surface.

Helpful advice! If you use a moisture-resistant GVL board for decorating the ceiling, it will be possible to reliably protect against leaks from the upper floors or the roof. It is best to select sheets with a thickness of 1 cm or more.

How else can you use GVL in construction

An excellent option is to carry out a ceiling made of gypsum fiber board on the attic floor, in this case, only a moisture-resistant version of the slabs is used, because there is always a possibility of a roof leak. In this case, an insulating sheathing must be laid under the crate, and the installation must be carried out directly to the rafter system.

Related article:

Pros and cons of dry floor screed and technology of its device

Materials used for dry floor screed and their specific features. Algorithm for a dry floor screed device.

Sheets are very often used to create dry screed. If we are talking about a private house or an apartment on the ground floor, it is better to start with a layer of insulation using perlite, expanded clay or vermiculite. Self-tapping screws for GVL or construction glue are suitable for fixing sheets. After finishing the screed, you can immediately start laying the finishing coating. Other popular board applications:

- decoration of walls in houses made of different materials: wood, brick, etc .;

- preparation for final wall cladding in living rooms, storage rooms and basements;

- finishing of balconies, loggias, terraces, as well as premises with high fire safety requirements, for example, elevator shafts;

- installation of floor coverings and organization of a warm floor system;

- creation of protective boxes or cabinets that hide communications.

Important! Due to the fact that antifungal agents are applied to the material, it is appropriate to use it in the construction of baths, swimming pools and other premises that are constantly exposed to high humidity.

Key materials for interior decoration: LSU, GVL and GLK, what is the difference

In appearance, GVL panels are very similar to ordinary drywall sheets and glass-magnesium finishing materials. Standard plasterboard boards are labeled as GLK. The inside of the panels is made of gypsum and the outside is made of cardboard. Like the previous material, GLA is divided into several subgroups:

- GLKO - refractory plates;

- GKLV - decoding means "moisture resistant gypsum plasterboard".

There are also combined plates containing polystyrene foam for insulation. The material is intended for external and internal work. Gypsum fiber and drywall have many similar properties: they are moisture resistant, fireproof and suitable for decorative cladding.

To understand which is better - GVL or GLK, you need to familiarize yourself with the main differences between the panels. So, drywall consists of several autonomous layers of cardboard and gypsum, while gypsum plasterboard is a solid fiber, which makes the sheets stronger and more reliable. There is another material similar in characteristics - LSU, the so-called glass-magnesium sheets, the main disadvantage of which is the content of such chemical elements as magnesium oxide and chloride.

If you choose between GVL or GLK, you need to take into account that fiber panels resist damage better, because many who have worked with drywall note the excessive fragility of the sheets. In the case of gypsum fiber cloth, you should not worry that it will easily lose its integrity with a point impact. Another important advantage of GVL is that it, unlike GLK, can be used to decorate flooring.

If drywall is used for wall decoration, it is recommended to make as few joints as possible so that the surface does not lose strength. In the case of fiberglass, there is no such problem: the number of joints does not affect the reliability of the wall.

Other material differences are shown in the table:

| Criterion | GVL | GLK |

| The ability to bend | Bends very badly | Easy to perform complex curved shapes |

| How it behaves when cutting | Can be cut in any way, because the edges remain even | Crumbles and cracks at the cut |

| Resistant to temperature extremes | Does not change its properties even when frozen | Doesn't like drops |

| Resistant to moisture | They well tolerate the effects of high humidity, especially if moisture-resistant gypsum fiber board or GLK is used for walls | |

| Installation features | Can be attached either directly to the surface or to the lathing | |

It should also be borne in mind that the cost of GVL sheets for walls is higher than the price of ordinary gypsum plasterboard panels. Many people prefer to combine slabs when decorating a room, depending on the surface.

How to mount and how to cut moisture resistant and ordinary gypsum fiber sheets

During construction work, the question will undoubtedly arise about how to cut GVL and how to do it correctly. In general, many experts argue that the technology is practically no different from sawing ordinary drywall, but only in this case it should be borne in mind that gypsum fiber bends much worse than gypsum board. Therefore, when cutting, it is necessary to make the plate sag strongly down. How to cut sheets of gypsum fiber board? The main tools include:

- a construction knife with blades no thinner than 1.2 cm, it is important that the blades are replaceable;

- drywall hacksaw for dust-free cutting;

- Bulgarian;

- a circular saw;

- jigsaw.

Gypsum fiber sheets are easily cut with a construction knife, a drywall hacksaw, a grinder and a jigsaw

Useful advice! It is better to use a jigsaw and a circular saw when you can quickly ventilate the room. And also when working with material, you need to think about personal protective equipment - a respirator and special glasses.

Before cutting GVL, you need to familiarize yourself with the basic recommendations:

- To make the seams even, you must use a level or rule.

- The finished line should be drawn several times with a knife or other tool until a deep groove is formed.

- After that, you need to sharply break the material. It is important that the breakdown is not downward but upward.

- If the edge comes out uneven, you can correct it with a roughing plane. You will need a chisel or cutter to prepare the folded edge.

Different ways to mount panels: step by step instructions

Despite the fact that the installation of plates has its own subtleties, it is quite possible to try to perform the installation yourself. Brief instructions for installing GVL (photos illustrating the process are given in the article):

Gypsum-fiber sheets can be fastened either to the lathing with screws, or directly to the walls with mounting glue

- The surface is prepared, the markings are made for installing the profile.

- The profile is glued with a special sealant tape and attached to the walls with self-tapping screws, and if the surface is unreliable, with dowels.

- Gypsum fiber is mounted on a profile using special screws for gypsum fiber board, while the head must be recessed by 1 mm.

- Self-tapping screws are installed every 25 cm, after which all joints are putty and primed.

In addition to the option with a crate, it is permissible to fix the sheets directly to the walls, in this case, mounting glue is used. The phased execution will look like this:

- The sheets are cut into the desired fragments, the main surface is prepared, which must be leveled and cleaned.

- An adhesive is applied. In this case, it is important to pay attention to the instructions, because different glue options are attached in different ways. This can be partial or complete surface coverage.

- After applying the glue, the panel is pressed against the wall, then the joints are primed and puttyed.

The flooring technology should be considered separately. First you need to dismantle the old coating, if any, and then prepare the base. You will need to close all the cracks using a mounting or cement mixture. Then the markings are made to create the backfill level. Sometimes it may be necessary to perform waterproofing. This will require polyethylene or other suitable material. For the second layer, expanded clay is most often used, which is characterized by good performance.

GVL are laid on expanded clay, and, if necessary, all communications, laid in special corrugated tubes, are mounted between the layers. If additional sound insulation is required, polystyrene foam sheets are placed between the gypsum fiber board and expanded clay.

Expert advice! The waterproofing is laid in such a way that the edges go in and stick to a part of the wall.

Overview of manufacturers and prices of gypsum fiber boards for walls

The price of GVL panels primarily depends on the type of material, type of finish and the manufacturer's reputation in the construction market. Knauf is considered to be practically a monopoly in this direction, because the product differs not only in quality, but also in a wide variety of options. In addition, there are domestic brands that produce cheaper goods, which, according to reviews, are not inferior in quality to Knauf sheets:

- Volma;

- LLC Arakchinsky gypsum;

- PSK "Golden Group";

- Sverdlovsk plant of plaster products.

Even cheaper options come to the country from China, but if it was decided to buy Chinese drywall, you must definitely pay attention to the marking, because it is not always possible to determine the type by appearance. On average, the range of prices for Knauf products looks like this:

- 2500х1200х10 mm (GVL moisture resistant) - price 520 rubles;

- 2500x1200x12.5 (normal) - 490 rubles;

- "Super floor" 1200x600x20 mm - 337 rubles;

- small-format sheet 1200x1200x20 mm - 220 rubles.

Anyone who intends to carry out repair work in the room tries to simplify the task as much as possible and speed up its implementation. GVL sheets are considered an excellent option for decorating walls, ceilings and even floors. The main thing is to choose the right material, not only in size, but also in type, based on the characteristics of the operation of the room.