A huge assortment of chipboard allows you to choose the material for various types of construction work, from furniture production to floor installation and wall cladding. The type and size of the material should be selected depending on the conditions and place of use. The main points to consider when choosing a chipboard are: sheet dimensions and thickness, price and material specifications. We will consider them in detail in this article.

Content [Hide]

What is the reason for the popularity of chipboard

Chipboard is recognized as one of the most popular and demanded building materials. The furniture industry, the construction of new facilities, the implementation of renovations, finishing and decorative measures cannot do without this reliable and inexpensive product.

Thanks to improved modern technologies, manufacturers manage to bring their final product to high technical and aesthetic indicators. The output is a smooth and high-quality sheet surface, which has high stiffness and strength. The ability to choose the required format, sheet thickness and attractive aesthetic appearance allows the material to be widely used for the manufacture of furniture, installation of partitions, floors, wall panels, ceiling cladding and wall surfaces.

Material properties

The thickness of the product affects the strength of the material and its ability to resist external loads. The thicker the chipboard, the higher its resistance to deformation, however, the flexibility index is inversely proportional. Therefore, under the influence of mechanical stress, thick sheets are more likely to break than bend, while thin sheets, on the contrary, will bend without damaging the slab.

The thickness of the slab also affects the strength of the product. If you hit a heavy, thick sheet, then only minor dents may remain on the surface, and the thin sheet will break through.

Chipboard applications

For the installation of decorative partitions and the manufacture of lightly loaded furniture elements, plates with a thickness of 8-10 mm are used.

Different sizes of chipboard sheets 16 mm and 18 mm thick can be used for floor installation, as a base for laying laminate or linoleum. If a more durable flooring is required, then a 20 mm thick slab should be used.

The standard dimensions of chipboard sheets with a thickness of 22 and 25 mm serve as a reliable basis for the manufacture of kitchen tables, thick doors, and the most loaded furniture elements.

The thickest boards with a thickness of 28-38 mm are indispensable for making durable shelves and kitchen worktops.

Useful advice! Bar counters they are made of chipboard of maximum thickness, since the final product is subjected to heavy loads.

Before purchasing chipboard sheets, it is necessary to clearly determine their quantity, taking into account the most acceptable dimensions of the plates. To perform any work using plates, it is worth first measuring all the linear dimensions of the working surface. Based on the obtained values and the areas of the plots, it is possible to select the dimensions of the sheets that will provide the minimum remainder of the material.

Often the area of the working surface can be significantly less than the dimensions of the sheet. In this case, you can resort to the help of construction workshops, where there is a lot of waste boards. Specialists will cut the chipboard according to the customer's size from the remaining material they have. In this case, the buyer will pay not only the cost of the chipboard pieces based on the total sheet price, but also the cutting services. However, the price will be lower compared to the cost of the whole slab.

For example, the price for a 16 mm chipboard sheet with a thickness and size of 2800x2070 mm is 910 rubles, respectively 157 rubles. per sq.m. And if you buy half of the sheet, taking into account the cut, then the amount to be paid will be about 650 rubles.

Chipboard: sheet dimensions and thickness, material price

Normative documents that regulate the geometric dimensions of a chipboard sheet define 18 gradations in length and 9 in width. The length of the sheets is in the range of 1830-5680 mm, the width starts from 1220 and reaches 2500 mm.

Useful advice! Chipboard sheets with dimensions (width and length) of 2440x1830, 2620x1830 and 2750x1830 mm are most often found on the market, due to their easy handling and convenient transportation.

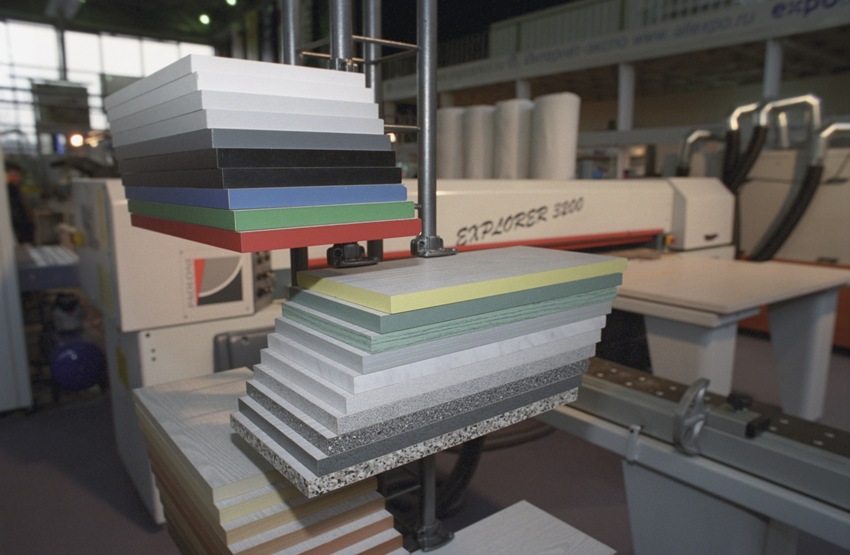

Chipboard sheets of standard sizes can be different in their thickness. This important geometric parameter is also in a wide range. The minimum chipboard thickness is 8 mm, the maximum is 38 mm. The most popular are chipboards with a thickness of 22, 18, and 16 mm. It is this indicator that should be considered when choosing a material. It determines the further use of the product and affects its level of strength during subsequent transportation. The thicker the sheet, the stronger it is, which means it can be used in loaded structures.

Dimensional table of the most common particle boards:

| Plate thickness, mm | Plate length, mm | Slab width, mm |

| 10 | 2750 | 1830 |

| 16 | 2750 | 1830 |

| 2440 | 1830 | |

| 3500 | 1750 | |

| 18 | 2750 | 1830 |

| 2440 | 1830 | |

| 2800 | 2070 | |

| 22 | 2440 | 1830 |

| 25 | 2800 | 1830 |

| 28 | 3050 | 1830 |

Chipboard dimensions and sheet price

Several factors influence the formation of the cost of any material. The first of these is the product manufacturing technology (the quality of raw materials, the presence of additional components, the application of a protective and decorative coating). The following criteria can be called the size and thickness of the sheet, on which the amount of raw materials depends. Also, an important point is the seasonality, which makes its own adjustments to the pricing policy. The next factor is the place where the product is manufactured, on which the transport component of the product price depends. In addition, prices in hardware stores in different cities may differ significantly.

Depending on the grade, brand and surface of the material, the price for a chipboard sheet can start from 650 rubles.

The price of a laminated chipboard sheet with a size and thickness of 2800x2070x16 mm will be about 1420 rubles. While polished chipboard of the same size will cost 880 rubles. This difference is justified by the costs associated with the technology of applying a certain texture to the surface of the slab.

Comparative characteristics of prices for the most popular chipboard positions are presented in the following table:

| Material name | Geometrical dimensions, mm | Thickness, mm | Price, RUB / m² |

| Chipboard | 2440x1830 | 16 | 135 |

| 22 | 160 | ||

| Chipboard white | 2800x2070 | 18 | 252 |

| 22 | 312 | ||

| Laminated chipboard colored | 2800x2070 | 16 | 259 |

| 18 | 287 | ||

| 22 | 325 | ||

| Chipboard grooved | 1830x600 | 12 | 291 |

| 2440x600 | 22 | 465 | |

| Chipboard grooved laminated | 1200x900 | 16 | 611 |

As you can see from the table, the material has a very reasonable price per sheet. You can buy chipboard at any hardware store, or place an order on a specialized Internet resource.

The leading chipboard manufacturers are:

- Plant "Kronospan", which is located in the city of Yegoryevsk. It offers quality material that is produced on continuously operating computerized state-of-the-art German equipment. The plant produces chipboard with dimensions of 2440x1830, 2620x2070 and 2800x2070 mm with sheet thicknesses of 10, 12, 16, 18 and 22 mm. You can make an individual order for sheets with a thickness of 8, 25, 28, 32, and 38 mm.

- Egger company, whose products are produced under the EUROSPAN trademark and are used for the manufacture of furniture parts and repair work. The material has a durable middle layer and thin outer layers, which makes it the most suitable for applying various decorative textures. The company produces slabs with a length of 5600 and 2800 mm and a width of 2070 mm.

Laminated chipboard: product price

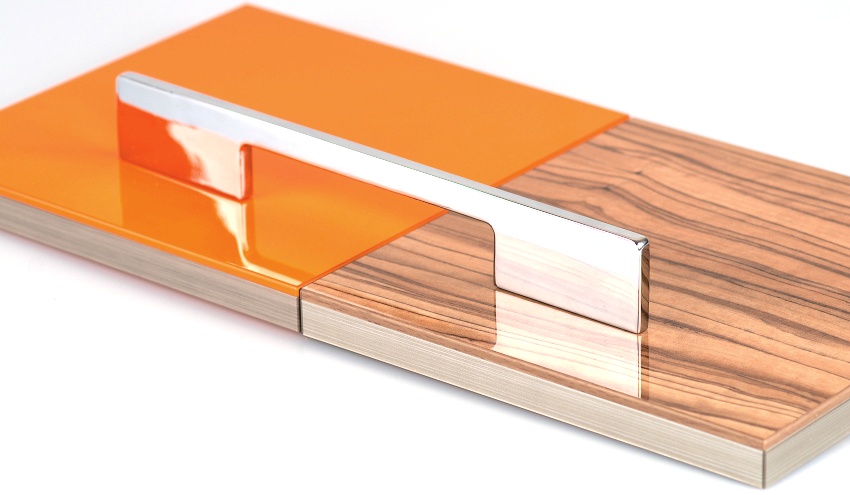

Nowadays, almost all cabinet furniture is made from laminated chipboard, dimensions which are defined by the standard. They should be taken into account when choosing a material for further cutting the necessary elements in each specific case in order to obtain a minimum amount of waste.

This material has a huge amount of texture and color variations. It is easy to process.

Important is the fact that it is not worth sawing Chipboard into separate fragments at home. Since during the sawing of the slab on a conventional machine, the laminate splits at the sawing points, which contributes to the formation of torn edges of the products. Therefore, the sawing of laminated chipboard should be carried out at furniture enterprises or construction workshops that provide such services. You can also order edging of individual elements here. All work is carried out on specialized equipment, which allows you to achieve exceptional quality of the finished product.

You can buy laminated chipboard based on the pricing policy of manufacturing companies, taking into account innovations in manufacturing technology, the capabilities of production equipment and the quality of raw materials.

The prices of laminated chipboard for a sheet of 2800x2070 mm of various thickness and type of Kronospan manufacturer are presented in the table:

| Material name | Thickness, mm | Price, rub / piece |

| Chipboard white | 16 | 1420 |

| 22 | 1800 | |

| Laminated chipboard colored | 16 | 1630 |

| 18 | 1660 | |

| 22 | 2012 | |

| Chipboard for wood | 16 | 1345 |

| 18 | 1520 | |

| 22 | 1870 |

Leading manufacturers of laminated chipboard

All well-known manufacturers produce rectangular material, where different sizes of laminated chipboard sheet vary. Such an abundance of different formats allows the furniture maker to choose the required size for a specific product, in order to ensure the minimum amount of scrap and waste.

Next, we will consider the leading manufacturers of laminated chipboard.

Kronospan brand occupies a leading position among other world companies in the production of laminated chipboard. The manufacturer produces material in two lengths and widths with different product thicknesses. The dimensions of the laminated chipboard sheet are 2800 and 2620 mm long and 1830 and 2070 mm wide. The thickness of the product starts from 8 and goes up to 28 mm. Thin sheets are used to fill MDF frame facades, for sliding doors in wardrobes, for furniture elements that are subject to minor loads.

Leading manufacturers of laminated chipboard are Kronospan, Egger, Swiss Krono Group and other brands

Egger manufactures laminated chipboard of standard size 2800x2070 mm with various thicknesses. But, unlike its competitors, the manufacturer, in addition to plates with a thickness of 10, 16, 18 and 25 mm, produces sheets with a thickness of 19 mm.

SwissPan - one of the leading manufacturers of laminated chipboard in the world. It produces the following laminated chipboard formats: 2750x1830x10, 2440x1830x16, 2750x1830x16, 2440x1830x18, 2750x1830x18, 2440x1830x22 and 2440x1830x25 mm. For the manufacture of wardrobes and wardrobes, laminated chipboard sheets with a thickness of 16 and 18 mm are used. Slabs 22 and 25 mm thick are ideal for making kitchen worktops and other furniture components that are subject to significant stress.

Plant "Nevsky Laminat" offers a unique wide range of materials for furniture making. The company constantly monitors global trends and offers its customers the most relevant and expressive textures and decors. The plant produces laminated chipboards with dimensions of 2440x1830 mm and sheet thickness of 8, 10, 16 and 22 mm.

Swiss Krono Group is one of the largest producers of wood-based panels in the world. The manufacturer offers a quality product with a wide variety of decors. The company produces laminated chipboard in two sizes: 2500x1850 and 2800x2070 mm with a possible sheet thickness of 10, 16 and 22 mm.

Related article:

Chipboard tongue-and-groove moisture resistant: a new development in the building materials market

Characteristics and main advantages of the material. Areas of use. Features and installation rules. Average cost of production.

Today the construction market is rich in a variety of wood-based products. The material has gained its popularity due to various product formats, a wide range of textures and color palette, versatility of application, and relatively low cost of the product. It occupies a leading position among materials for the manufacture of furniture. Every year manufacturers strive to improve the chipboard manufacturing technology, to increase the range of products in order to satisfy even the most demanding request of a modern person.