At this time, LSU panels are a very popular material that is used in all areas of construction. It replaced the universal drywall. LSU sheets are a modern material that is a composite glass-magnesium plate. You will learn about the characteristics of LSU sheets, their features, areas of use, as well as many other things from this publication.

Content [Hide]

- 1 LSU panels: getting to know new modern building material

- 2 Advantages and disadvantages of glass-magnesium plates

- 3 Glass-magnesium sheets: technical characteristics of LSU plates

- 4 LSU sheet: characteristics and features of the use of the material

- 5 Variety of scopes of glass-magnesium sheets

- 6 How much does it cost to build a house with LSU panels

- 7 Painted LSU: features and characteristics of the material

- 8 Estimated price of LSU glass-magnesium sheets

- 9 Tips for choosing a quality glass-magnesium plate

LSU panels: getting to know new modern building material

Magnesium glass sheets, or magnelite, is a completely new sheet material that is widely used in all areas of construction, although it appeared on the market not so long ago. The construction sheet is used for both interior and exterior finishing works. Magnelite, magnesite and glass-magnesite slabs, magnesite panels, LSU - all these are the names of the same glass-magnesium material.

LSU panels are distinguished by their strength and excellent water resistance. The material is very similar in its properties to drywall, which makes it very competitive in the finishing market. Buying a constructionist will not be difficult, since many firms are engaged in its implementation.

The popularity of glass-magnesium plates is due to the excellent characteristics, ease of processing and reasonable price. Although the material can be easily cut with a jigsaw, file, plasterboard knife and other similar tools, this does not mean that magnelite is fragile. On the contrary, LSU plate is durable and flexible. In addition, virtually no dust or debris is generated during material handling.

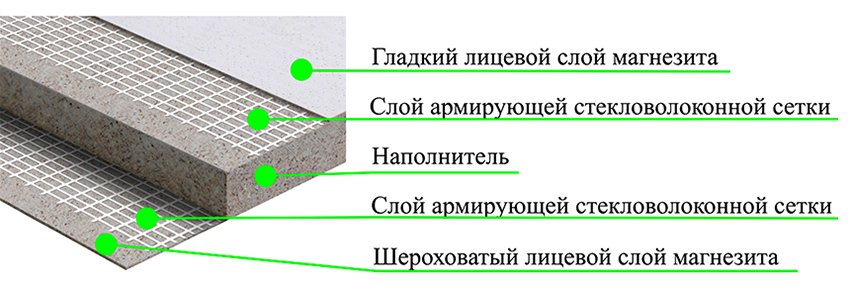

LSU panels are produced from magnesian binder and fiberglass mesh, which performs reinforcing functions. Magnesia binder is a type of concrete that results from the interaction of magnesium chloride and caustic magnesite. The classification of LSU panels is carried out depending on the sheet thickness and individual quality characteristics. There are also LSU options that are used as decor. This type of panels does not require additional finishing. Decorative sheets are available on the market in a wide range of colors.

Helpful advice! When choosing a material, you must be guided by the method of use. For external use, LSU premium is best suited. The cost of such panels is several times higher than the price of ordinary ones, but the quality characteristics of glass-magnesium sheets allow you to calmly endure the influence of natural factors.

Advantages and disadvantages of glass-magnesium plates

More recently, drywall had no alternatives on the building materials market. But with the advent of glass-magnesium sheet, which is more technological, the situation has changed. The high level of performance is due to the composition of the material, which includes natural and natural ingredients. Excellent strength values, equality of structure density are achieved through firing at a temperature of 2000 ° C.

LSU boards have special advantages over other similar materials:

- Versatility. The material is used in all types of finishes: slabs with a thickness of less than 6 mm are placed on ceilings, sheets of 6 mm are suitable for walls, a 10 mm construction sheet is laid on the floor, magnelite with a thickness of 12 mm or more is used to create facades and interior partitions.

- Strength. Magnelite plates can easily withstand any mechanical damage.

- Density. The budget material has a density of about 1 kg per m³, luxury sheets - more than 1.5 kg per m³.

- Ease of processing. Manelite is easily cut, does not crumble, does not break.

- Fire safety. Withstands temperatures over 1000 ° C, prevents the spread of fire.

- Moisture resistance. The board does not absorb water, does not swell, does not swell, does not change shape, and also does not lend itself to rotting, is not afraid of mold and mildew.

- Environmental friendliness. Does not cause allergies.

All these parameters indicate that regardless of the area of application, glass-magnesium plates are the best option. Sheets are durable, they are stronger than drywall and cheaper than tiles. Despite all the advantages, the price of glass-magnesium sheets is quite affordable, which allows you to use the material without restrictions.

As for the shortcomings, they are typical for LSU sheets in the case of using low quality material. They appear like this:

- A decrease in quality, resistance to fire and moisture occurs due to the addition of asbestos, lime and chalk to the composition of the material by some unscrupulous manufacturers. It also leads to the appearance of fine dust, which is very dangerous for allergy sufferers.

- Low-quality stoves release salts that accelerate the decay process. This can adversely affect the steel structure of the frames and formwork.

Also, the disadvantages include the price for LSU sheet. But the cost of the material is fully compensated by the excellent technical characteristics and parameters.

Glass-magnesium sheets: technical characteristics of LSU plates

Usually a magnesite slab consists of the following materials:

- expanded perlite - 5%;

- magnesium oxide - 40%;

- magnesium chloride - 35%;

- small wood chips - 15%;

- fiberglass - 1%.

Synthetic fibers are added to the composition as additional binders, and perlite significantly increases the sound insulation characteristics. The main properties of glass-magnesium sheets: strength, hardness, fire resistance and moisture resistance. The material is resistant to fungi, mold, and is able to keep its shape for a long time under the influence of a humid environment.

You can get acquainted with the parameters of glass-magnesium sheets in detail with this table.

| Technical specifications | Value |

| Slab thickness | 3 to 20 mm |

| Weight (for 8 mm sheet) | From 18 to 24 kg (weight depends on the class of material) |

| Flexural strength (wet - dry) | 17.2-22 MPa |

| Front surface hardness | 52.7 MPa |

| Water resistance | 95% |

| Frost resistance | 50 cycles or more |

| Sound insulation coefficient | 46 dBA |

| Coefficient of thermal conductivity | 0.21 W / m |

| Refractoriness (for 8 mm sheet) | Capable of holding fire for two hours |

| Fire resistance | When heated to +1200 ° C, the fire does not support |

| Density | From 980 to 1050 kg / m³ |

| Humidity | 9 to 11% |

| Wet deformation | Not more than 0.34% |

| Temperature coefficient of linear expansion | Not measured |

As for strength, the material is quite dense, with a homogeneous texture, it does not delaminate during operation. Due to the increased density characteristics, it has increased wear resistance to mechanical damage and deformation loads.

LSU sheet: characteristics and features of the use of the material

Glass magnesite sheet LSU is very easy to process. The initial edge of the slab is easily cut with an ordinary construction knife, after which the sheet must be bent in the opposite direction in the place of the cut made. Then the bend is similarly cut.

According to the criteria of flexibility, LSU board resembles drywall, plywood, OSB, DSP panels. Without humidification and heating, magnelite practically does not have this indicator.

Due to the high level of moisture resistance, glass-magnesium plates can be used for the treatment of rooms exposed to humidity: baths, saunas, shower rooms, swimming pools, as well as for any outdoor finishing work. This construction leaf does not absorb water and does not change its structure, does not swell, does not crack from dampness during the operating period. According to laboratory studies, the premium magnesite slab does not change its properties even after 100 days in water.

It should be noted the environmental friendliness of LSU sheets. For the production of the material, exclusively natural and natural substances are used that do not harm humans and the environment. Magnesite slabs do not include asbestos and other harmful components.

Glass-magnesium plates are a very popular material today. This is primarily due to the ease of installation. Magnelite is ideal for installation on both plasterboard profile systems and wooden frames. Fastening with self-tapping screws MN or TN 25-65. Pointed point screws SN and SB 25-40 can also be used for these purposes.

In the case of using premium grade A boards, you need to make light drilling under the screw head. For other types of this material, namely for classes B - G, this can be omitted, since the screw fits perfectly into the surface of the magnesite sheet. The exceptional strength of LSU slabs allows mounting even with ordinary nails and a pneumatic gun, which is absolutely unacceptable in the case of drywall application.

Due to the nature of the magnesite surface, there is no need for priming the surface before filling.

The use of magnelite can significantly save money and time, since the surface of the material does not require priming before filling, tiling or wallpapering. And the sound insulation of a room lined with magnesite sheets doubles.

Helpful advice! It is possible to cover the LSU board with vapor-permeable dyes. If you apply a moisture-proof paint, the top layer can swell and crack over time.

Variety of scopes of glass-magnesium sheets

Most often, glass-magnesium sheets are used to perform the following types of work:

- all types of exterior wall decoration, including stone cladding, ceramic tiles or stucco;

- interior wall treatment for painting, wallpapering, tiling and clapboard or paneling, puttying;

- elimination of uneven surfaces of walls, ceilings and floors;

- creation of interior partitions, regardless of the finish;

- processing the floor for laminate or parquet;

- any architectural ideas for space decoration;

- finishing of baths, saunas, bathrooms and pools;

- creation of banners, billboard advertising;

- arrangement of protective fireproof cladding near the centers of spontaneous ignition;

- soundproofing works.

Useful advice! If plaster will be laid on top of the panel, then it is better to install magnelite with the back (rough) side outward. This will ensure a tighter adhesion of the cladding to the surface of the slab.

How much does it cost to build a house with LSU panels

Glass-magnesium panels are one of the most popular materials for building a modern home. It can be used all year round, and frame-panel construction does not require special foundation construction. The energy efficiency of such buildings is much higher, and the construction costs are lower, because no special equipment is required to transport the material.

As for the price of LSU at home, the maximum average cost per square meter is approximately 25,000 rubles. As a result, you get a living space, into which you can immediately move in with your furniture. Plumbing has already been installed in the building, electricity, water supply, a boiler have been installed and work inside the house has been completed. The minimum cost per square meter starts from 6,000 rubles, but you still have to work in such a house, and you will also need to spend additional financial resources.

In terms of time, the construction process of the premises can take from two weeks to a month. This is very convenient for those who want to buy new housing in a short time. In addition, construction can be carried out at any time of the year. Using a magnesite slab allows you to quickly, efficiently and inexpensively get your dream home.

Useful advice! LSU sheets can be used for finishing the foundation. Fastening is carried out with glue or with anchors. But in this case, it is extremely important to choose the right type of material, otherwise magnelite will not only not withstand frost, but will also deform under the influence of moisture.

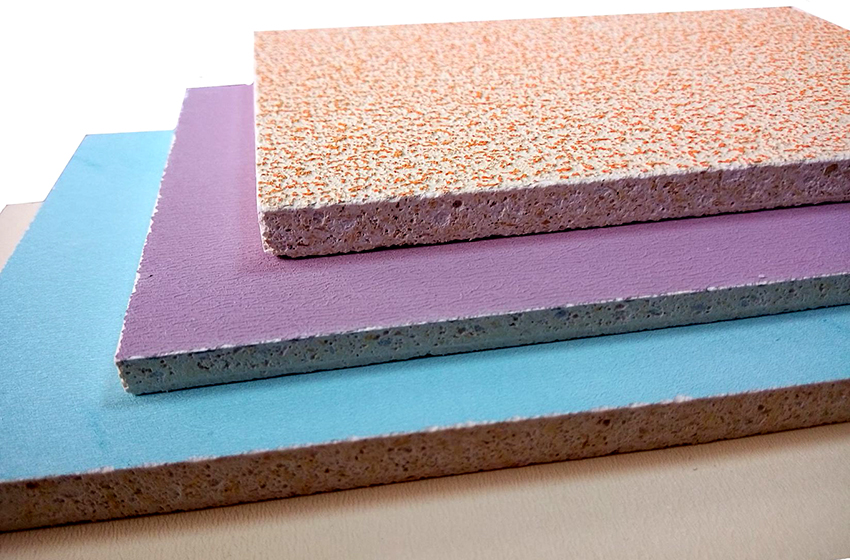

Painted LSU: features and characteristics of the material

Painted glass-magnesium panels are an optimal material with an ideal ratio of price, quality and excellent aesthetic characteristics. The basis of this product is an ordinary magnesite board covered with acrylic paints.

Related article:

Sandwich panels: sizes and prices of roofing, wall and corner panels

Varieties of sandwich panels and their characteristics. Houses made of sandwich panels. Sandwich panel garages. Editing algorithm.

Painting is carried out in an industrial way - by direct rolling of acrylic paint with steel rolls over the entire surface of the sheet. At the final stage, a protective varnish is applied to the top layer, which provides an increased level of wear resistance.

The following characteristics affect the cost of panels:

- material color;

- the number of sheets that are purchased;

- plate thickness;

- number of painted sides.

Sometimes the price of magnelite depends on the category of material. All these parameters together affect the process of production and painting of sheets, as well as the consumption of paints and varnishes. You can buy LSU, painted on one side, from 1400 to 1680 rubles. per sheet. Magnelite coated with paint on both sides will cost from 1600 to 1900 rubles. per sheet.

Estimated price of LSU glass-magnesium sheets

You can buy LSU panels for both interior and exterior decoration of the premises, they are used in the construction of a building and other works.Depending on the field of application, as well as to facilitate the choice of buyers, the material is divided into the following categories:

The cost of a glass magnesite slab depends on the thickness of the product, strength and the number of painted sides

- "Standard" (dimensions of the LSU sheet - 1220 by 2500 mm) costs from 460 to 730 rubles. for a unit. This material is most suitable for interior decoration of premises with normal temperature and humidity levels throughout the year. Self-tapping screws are used for installation.

- "Premium" (LSU plate with dimensions of 1220 by 2440 mm) can be purchased for 580-960 rubles. per sheet. This magnelite is characterized by an increased level of strength, which makes it possible to use it for cladding the walls of low-rise buildings, installing internal walls and partitions, arranging the base for a soft roof and other indoor works. For fasteners, experts recommend using stainless steel screws.

- "Super premium" (sheet parameters - 1220 by 2440 mm). You can buy such LSU sheets from 950 to 1250 rubles. for one plate. This material is a specially produced line with improved parameters of the outer surface and the possibility of subsequent painting, lamination, processing with plastic and veneer.

- "Interior" (painted magnesite slab with dimensions 1220 by 2440 mm). Buy painted LSU is possible from 1290 to 1450 rubles. a piece.

Tips for choosing a quality glass-magnesium plate

Glass-magnesium sheets (LSU) have a significant number of reviews, but not all of them are positive. But the popularity of the material does not fall, but on the contrary, the construction of many important state facilities is not complete without the use of magnelite. The main problem is that the material is missing any markings. Unscrupulous manufacturers take advantage of this, violating the technology for the production of plates.

There are negative reviews about glass-magnesium sheets due to an incorrect definition of the scope. In addition, most consumers believe that LSU panels are a complete replacement for drywall. But this is not the case, because only some types of stectomagnesium sheet can be fully used instead of gypsum boards.

Since the price of a magnesite slab is quite high so as not to waste money, it is important to know how to distinguish a quality panel from a semi-handicraft material made from cheap components:

- Material color. LSU board of excellent quality has a beige or yellowish tint. Poor quality material is usually white or light gray.

- Slab edges. Magnelite of poor quality has rough and brittle edges.

- Leaf base. Low-quality construction sheet is covered with non-woven fabric on the back. This reduces the refractoriness of the material.

Useful advice! To check the quality, you can put a piece of glass magnelite in water for a couple of hours. If the stove is of high quality, the water will not become cloudy.

Interior or exterior wall decoration is constantly in great demand. Thanks to this, modern building materials will always appear on the market. At this time, the latest finishing materials, including glass-magnesium sheets, are very popular.

Thanks to modern production technology and exclusively natural ingredients, magnesite board pushes materials such as drywall and plywood into the background. Excellent technical characteristics of glass-magnesium sheets (LSU), price are the main advantages of this material. The peculiarity of such a builder is that one side is smooth and polished, and the other is embossed.