No industrial and residential construction site is complete without the use of concrete. The quality of this artificially obtained material directly depends on the mixing sequence and the ratio of the components used. The table "Proportions of concrete per 1m3" will guide you in the most correct distribution of the constituent parts of the solution for use in certain structures.

Content [Hide]

Concrete specifications

The cement and water that make up the concrete form a mass when mixed, which, hardening, turns into a cement stone. In this form, this material is easily deformed, many microcracks are formed in it, which leads to significant shrinkage.

The addition of fillers (crushed stone, sand, gravel, etc.) to the composition of the cement mixture contributes to the formation of a kind of reinforcement, which takes on internal stress. Due to this, the strength indicators are improved, the mobility of the mixture and the deformation from shrinkage are weakened.

Taking into account the degree of concrete strength, the material is divided into classes (designated "B") and grades (designated "M"). The higher the numerical values of concrete grades (for example, M200, M300 or M400), the more durable the material is considered. It depends on the class and brand in which types of structures it will be used.

If the construction of your facility is supported by a project, then concrete grades necessary for the construction of a foundation or other structures are already predetermined in it.

Concrete strength table:

| Concrete grade | M75 | M100 | M150 | M200 | M250 | M300 | M350 | M400 |

| Load (standard), kgf / cm2 | 65 | 98 | 131 | 196 | 262 | 294 | 327 | 393 |

Compliance of the brand with the use of concrete

Concrete mixtures with different brands are used for different types of structures.

The table shows the scope of possible use of concrete, depending on the brand:

| Brand M100-M150 |

Brand M200-M250 |

Brand M300 |

Brand M350 |

Brand M400 |

| Base (substrate) for a screed, foundation, tile or concrete track. | Foundations one-story buildings, screed, blind area, platforms, stairs. | Strip foundations, monolithic walls, screed, blind area, platforms, stairs. |

Casting of reinforced concrete structures (beams, support columns, girders, lintels, floor slabs, pools). |

Hydraulic structures (dams, bridges), fortifications (bunkers, storage facilities). |

Consumption and proportions of the main concrete ingredients depend on many factors. As for the sand, you should take into account its moisture content, size, impurity content.For crushed stone and gravel, indicators of moisture, pollution, voids, non-standard inclusions (debris) are important.

For cement, its brand is taken into account. The type of work for which the concrete solution is being prepared is also taken into account: concrete screed, pouring the foundation, erecting walls, etc.

The main component of the concrete solution is cement. The consumption ratio of this material expresses the concrete grade. The grade of concrete is higher, the more cement it contains.

Traditionally, concreting is carried out during a period when the air temperature is positive. This contributes to the high-quality hardening of the solution.

Useful advice! It is not recommended to carry out concrete work at negative temperatures, due to the possible probability of obtaining material of poor quality in terms of strength.

When working with concrete in the cold season, there is a possibility that the water in the solution will freeze and become a source of destruction inside the material. Thus, the strength will decrease.

The setting of concrete takes place in a period of 12 hours, within two weeks, concrete accumulates 80% of its strength. Operation of the finished structure becomes possible in a month.

The main components of the concrete mix

When purchasing compound ingredients for preparing a solution, make sure (as far as possible) in their quality:

- water: fresh water is used;

- sand: should not contain clay, you can visually check it by color. If sand yellow saturated color - means the content of clay in it is high. White or gray sand is used for the solution;

- cement: the bags with cement should not have hardened parts to the touch and the material should be manufactured no earlier than four months from the date of purchase;

Useful advice! When purchasing cement, pay attention to the marking. Only from trusted manufacturers, the marking on the bag corresponds to the quality of the cement it contains.

- crushed stone: clean material is used, without dust and other inclusions. Otherwise, the adhesion to the mortar will be insufficient, which will negatively affect the strength of the concrete. Crushed granite rock is ideal;

- in addition to crushed stone, gravel (usually used for grade 450), limestone (suitable for grades 100 and 300), granite (characterized by strength, frost resistance and low water absorption) are used as a coarse filler for the concrete mixture.

Consumption of materials. Table "Proportions of concrete per 1m3"

Consumption of components for cooking 1m3 concrete directly depends on the purpose of the structures and the brand of cement involved in the manufacture. For this, the values of the proportions of the composition 1m3 concrete.

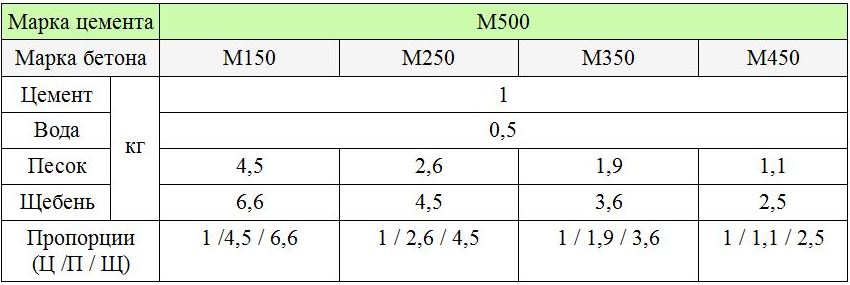

Below are two tables of concrete proportions per 1m3.

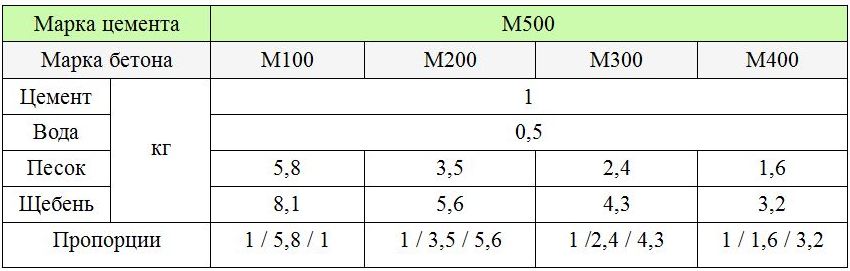

Table 1 - proportions of concrete for grades M100, M200, M400 and M400:

Thus, if it is necessary to produce concrete M200, the proportions will be

1 m³ mortar - 1 / 3.5 / 2.6 (kg), for concrete M300, the proportions will be - 1 / 2.4 / 4.3 (kg), the proportions of concrete M400 - 1 / 1.6 / 3.2 (kg).

For example, you can calculate the quantitative composition of the components taken into account in the table of proportions for the preparation of M400 concrete using M500 cement. Take 20 buckets of cement. The proportion of sand will be (20 x 1.6) = 32 buckets. Crushed stone, respectively - (20 x 3.2) = 64 buckets. And water - (20 x 0.5) = 10 buckets. Knowing the density of all components, you can easily translate the required number of buckets into those units of measurement by which the materials are sold.So, a bucket with a capacity of 10 liters filled with cement will weigh 12 kg (10 x 1200), where 1200 kg / m³ is the density of the cement when poured, a bucket of sand - 14 kg (10 x 1400), where 1400 kg / m³ is the density of sand , the same volume of gravel will weigh 15 kg, given its density.

The proportions of the composition of concrete for the foundation

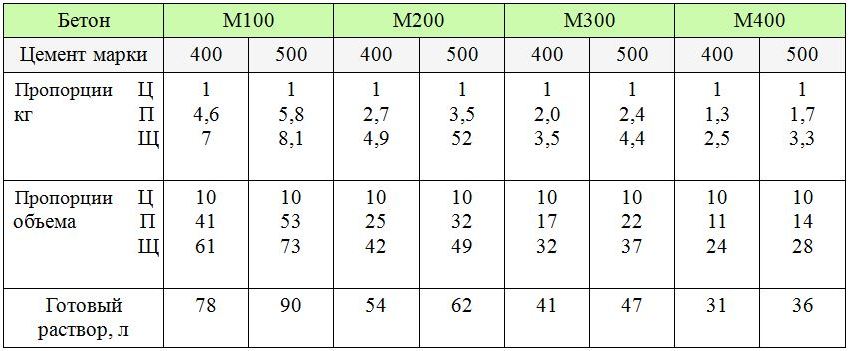

If concrete work is carried out in small volumes, for example, in private construction or one-time small works, it is advisable to adhere to the proportions of concrete in buckets. Such quantitative measures are used if it is not possible to place special equipment on the construction site, and also when the solution is poured in small portions.

When producing concrete for a foundation structure, it is necessary to adhere to the following proportions of concrete to foundation, given below.

Table of proportions of concrete on the foundation in buckets, for grades M100, M200, M300 and M400:

Solution preparation procedure

In the conditions of individual construction, a concrete solution for the foundation is prepared by measuring out parts of the components with buckets. It should be borne in mind that the cement bucket and shovel must be extremely dry. To obtain more accurate proportions, the composition of sand and gravel in the bucket is slightly compacted and leveled along the edge of the bucket. Measured crushed stone with sand is mixed well in a convenient wide container, forming grooves where prepared cement is poured. All ingredients (the amount of which is selected from the table of proportions) is fairly mixed until a mass uniform in color is obtained.

Related article:

How much does a cube of concrete weigh? Main characteristics and composition. Determination of weight. Varieties of concrete, depending on the material. Types of concrete (light and heavy). What affects the weight of concrete?

The resulting mass is formed under a cone, a depression is made in the middle, where water is poured. Gradually pour the mixture from the edges into the middle until the water is completely absorbed. As soon as the first portion of water is saturated, the procedure with water is repeated until the desired consistency of concrete mortar is formed.

Useful advice! It is not recommended to break the water-cement ratio, trying to obtain a more liquid solution. Excess water will leave voids, which will reduce the strength of the concrete.

Adhering to the table of proportions for preparing concrete, you can get a composition from a homogeneous, plastic mixture. This will serve as a guarantee of the strength and durability of concrete in operation.

Compliance with technical standards in the preparation of concrete mixtures contributes to the preservation of the main indicators required in construction.