Wood has rightfully earned the title of the main building material. As a rule, wood is used as a base for various structures, but the aesthetic component of this unique material with a unique texture should not be underestimated. Wooden stair railings are not only the best design solution, but also provide safety and convenience when moving between floors.

Content [Hide]

- 1 Wooden railing for stairs: design features

- 2 Wooden handrails for stairs: material advantages

- 3 Wooden railing: a brief "educational program" on design

- 4 Wooden handrails for railings: manufacturing instructions

- 5 Wooden railing for the terrace: a few words about painting

- 6 Railing for stairs made of wood: installation options

Wooden railing for stairs: design features

Any staircase that contains more than three steps must be equipped with handrails. If you want to make your home cozy, choosing a wooden railing will be the best solution. In this case, the design should be selected based on the features of the decoration of the room. To build a handrail for stairs made of wood with your own hands, you should first familiarize yourself with the technology and basic nuances of designing such a product.

Note! In accordance with the norms, the height of the railings for wooden flights of stairs should be at least 90 cm.In addition, for small family members, additional railings can be installed at a height of about 60 cm.

Often in the minds of people, railings are associated with handrails. In reality, they are only part of the whole structure, which serves as a fence for wooden stairs.

Thanks to the handrails, the process of climbing and descending the stairs becomes absolutely safe and comfortable. The so-called balusters are a load-bearing part to which all structural elements are often attached. These posts can be attached to the bowstring or to the steps. In addition, the enclosing structure includes infill to be installed between the posts. It serves several important functions:

- is a fence, thanks to which the probability of falling between the posts is excluded;

- is a decorative element that adorns the entire structure.

The distance between the posts should be no more than 20 cm. Otherwise, children can easily crawl between them, which will cause an accident.Moreover, the height of the fence should be comfortable for adults.

Making wooden railings is a fairly simple task. Perhaps the most important step here is determining their design.

Fences often have the following configurations:

- racks installed at a small distance from each other, to which the handrail is mounted;

- racks located at a significant distance, to which the infill is attached - frames with a lattice or horizontally located strips.

The first type of fence is characterized by attractiveness and simplicity in terms of manufacture. Chiseled balusters look especially impressive. In order to decorate the product, you can alternate racks of various shapes, for example, square with round turned. In this case, the balusters, which are located first and last, are larger. This is due to the fact that it is they who take on the greatest load.

Due to the fact that chiseled racks and other ready-made structural parts can be purchased at specialized retail outlets, the process of designing wooden railings for stairs with your own hands will become the most comfortable and efficient task.

Wooden handrails for stairs: material advantages

Wood is a traditional material used to create such structures. It is characterized not only by its stylish look, but also by its durability, due to which it is ideal for equipping houses made of various materials. If the exterior finish of the building is made of wood, then the wooden railing on the porch is the best solution.

It is interesting! When using the woodcarving technique, you can add sophistication and originality to the interior.

This building material, donated by nature itself, is endowed with the following advantages:

Wooden handrails for stairs are characterized by aesthetics, ease of installation, environmental friendliness and safety

- Aesthetics. It lends itself well to the processing process, so it is an excellent base for creating various designs.

- Ease of installation. If you want to install wooden railings in the house yourself, you can do it without special skills and relevant experience. For such work, the simplest tools are used that are available in every home.

- Environmentally friendly. Natural material does not have a negative effect on the body, therefore it rightfully deserves the title of the safest building component.

- Security. If small family members live in the house, you should give preference to wooden railing for the stairs. In case of hitting them, the little fidget will remain unharmed. In addition, tactile contact with the railing will not cause discomfort, since even under the influence of critical temperatures, it does not become too cold or hot.

To protect products from the harmful effects of a humid environment and other negative factors, they should be treated with special solutions. In addition, you should not forget that you need to take care of ensuring the safety of the skin of the hands when touching the railing.

To protect wooden railings from negative factors, they should be painted or treated with special solutions.

On the Internet, there are many photos of wooden railings made in a variety of styles and variations. Among them, you can find the best option that will be an elegant addition to the interior.

Wooden railing: a brief "educational program" on design

The manufacture of each element of the staircase requires the use of a single tree species. Thanks to this, the probability of deformation of the product is fully excluded.

Note! Before proceeding with the installation of wooden railings, a number of calculations should be performed and an estimate for materials should be formed. In this case, the number of balusters is calculated based on the length of the product and the width of the step.

The process of manufacturing a fence for stair structures is a step-by-step process and consists of the following steps:

A sketch of the future railings with an indication of the dimensions of the elements is as necessary as the materials themselves

- Before starting work, it is necessary to sketch a sketch of the future product indicating the dimensions of the elements.

- After that, the balusters are turned in accordance with the created sketches.

- The next step is to drill the dowel holes on the underside of the supports.

- On the other edge of the balusters, a cut should be made at an angle equal to the angle of inclination of the staircase. Due to this, the handrail will be located in a parallel direction with respect to the stairs.

- Then, wooden handrails need to be carved from the bars of the required length.

- The next step is to sand all the elements. This can be done with special equipment or on your own using sandpaper.

- Before installing the railings and balusters on a wooden structure, you need to apply the markings.

- Then, holes should be drilled in the steps for the dowels.

- After that, the dowels should be coated with a layer of glue and installed in the steps, after which it is necessary to string balusters on them.

- The next step is to connect all the supports using a rail, which is fixed by means of self-tapping screws.

- Next, a handrail must be attached to the rail. In this case, the screws are screwed in from the bottom, from the side of the steps.

- The finishing touch is the coating of the product with varnish.

This completes the process of creating the enclosing product. It is the same regardless of what kind of structure the railing is created for - for a concrete staircase or for a wooden march.

It is important! The moisture content of wood used for the manufacture of fences should not exceed 7-8%. In the case of a greater value, the elements during the use of the design can simply lead.

Thus, with at least minimal experience in working with wood, it will not be at all difficult to design such a product. At the same time, the price of wooden handrails, created by ourselves, will be significantly less than the cost of an already finished fence.

A few words about the design and installation of balusters

The manufacturing process of these parts takes place in accordance with the prepared sketches. If a lathe is not available, the supports can be ordered from any of the carpentry shops. In the case of purchasing special equipment, the total price of a railing made of wood, of course, will turn out higher, but the tool can be used in the future to create other wooden masterpieces.

Making balusters begins with the execution of drawings. moreover, all the details must be numbered in order to avoid mistakes in the future. After that, the boards are adjusted in accordance with the dimensions of the future balusters. Then they are turned on the machine, as a result of which they acquire the required configuration. You can give the details the shape of a circle by pre-forming them in the form of octagons.

In the process of creating a handrail made of wood with your own hands, you may encounter difficulties during fastening. The reason lies in elementary inexperience. In this regard, initially it is necessary to create blanks in an amount slightly exceeding the required one.

In order for the racks to have an aesthetic appearance, they are given the proper shape by means of incisors (according to the drawings).At the same time, it is best to fasten the balusters on spikes, for which you need to drill a small depression in advance.

At the final stage, all wooden products are carefully polished. Speaking about the price of wooden railings, it is worth noting that it is fully justified by the reliability and durability of this material.

Wooden stair rails: how to make a connection

After preparing all the necessary elements: balusters, handrails and pedestals, you have to collect all the details. Installation should be characterized by strength, and also provide not only safety, but also the aesthetic appearance of the structure.

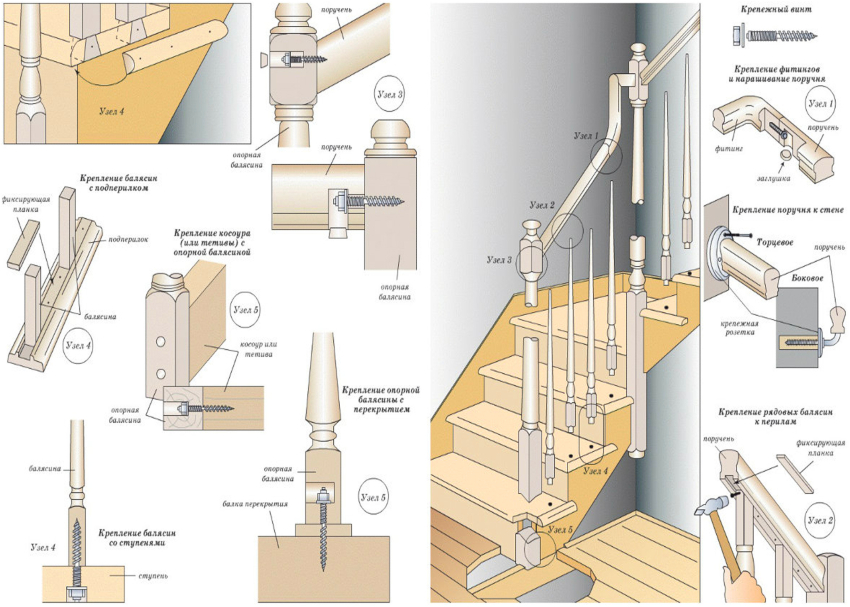

For the purpose of the reliability of the fasteners, the nodes of the wooden march are used. Thanks to them, the connection of balusters and steps is guaranteed, and with proper handling, they can prevent creaking.

Related article:

Wrought iron stair railings: the beauty of metal patterns

Advantages and disadvantages. Varieties. Choice of style and design of wrought iron railings. Wrought iron porch railings. Prices for different products. Care rules.

In addition, the knots are used when it is necessary to connect the carved part of the handrails with the curved elements “joint to joint”. The installation process is actually incredibly simple.

After fixing the structure, it is necessary to putty, so that absolutely all defects and irregularities can be eliminated. After that, the fence should be sanded with fine emery material.

The finishing touch is the application of a coating that performs a decorative function. They can be paint or varnish. The choice of coverage depends on the characteristics of the interior of the room.

Wooden handrails for railings: manufacturing instructions

Railings are designed with wooden handrails, which can be expensive. That is why a rational solution is to independently manufacture this element of the staircase.

When performing this process, the following requirements must be observed:

- The handrails are made of wooden beams, the section of which is identical to the section of the balusters. In this case, it is very important that the surface of the structure has a rounded shape.

- If the dimensions of the staircase itself are small, in order to design the handrails, you can use one board approximately 1.5 m in size.

- The future product should be processed using a lathe, after which it will be necessary to grind it.

- In order to simplify the fastening of the balusters directly to the handrail, appropriate grooves must be made in it.

Handrails are made of wooden beams, the section of which should be the same as the section of balusters

There is another option for constructing handrails using glue. It will be an excellent solution when it comes to spiral staircases. The essence of this method is reduced to gluing boards one on top of the other. In this case, they must be pre-sanded. For this purpose, you can use a grinder.

In this case, plywood will act as the basis of the future wooden fence, which must be attached to the railing. Paper is laid on masking tape.

Subsequently, the base is dismantled, and the paper is used in order to prevent the base material from sticking to the plywood sheet. In this case, the dimensions of the railing and the base must be equal. The finishing layer is placed on the base, which should be fixed with clamps. For a tighter installation with a miter saw, the boards must be trimmed along the entire length of the product.

By analogy, the second finishing layer is laid, the boards are also trimmed. In this case, the seams of the additional layer should overlap the seams of the initial one by about 5 cm.Then it is necessary to fasten the formed layers together with the help of glue, which is quite suitable for PVA. In this case, the consumption of glue should be minimal, otherwise it will be noticeable at the joints.

Note! For the convenience of distributing the adhesive layer over the surface, it is better to use a brush, which must be stored in a container filled with water.

To ensure a tight connection of the clamps with each other, preference should be given to wooden bars, which must be fastened to self-tapping screws. The handrail assembly process continues in a similar manner. In this case, the height level of both the railings themselves and the handrail is determined depending on the number of layers.

In the process of gluing the railing for a wooden staircase with your own hands, you will need to be patient, since this is a rather laborious and lengthy procedure. All layers will take at least 12 hours to dry.

After complete drying, all layers are subject to processing, grinding, and the excess edges - to a cut. Already finished products should be processed using a milling machine equipped with a semicircular nozzle. The base must be carefully removed, and then unscrew the screws. At the final stage, the handrails will only need to be attached to the railing using the resulting holes. In this case, the installation of handrails on a wooden staircase should be carried out strictly in the center.

Wooden railing for the terrace: a few words about painting

The price of wooden railings for stairs is quite justified, because a tree with proper care can serve for a very long time and not succumb to destruction under the influence of moisture. Since wood is a rather vulnerable material, special compounds should be applied to it for maximum protection.

The paint is also used as a decorative coating, due to which it is possible to change the appearance of the porch almost beyond recognition. In addition, the paint stimulates the natural structure of the material. These formulations also help prevent mold growth.

To paint a wooden balcony railings, you have to acquire:

- chisel;

- sandpaper;

- rollers with coarse pile;

- brushes;

- brush, which is needed to remove dust.

In addition, for painting, you will need a wood filler, which is necessary to seal small cracks on the surface, as well as a primer used to increase adhesion and form a protective layer. The main consumable is paint, the selection of which must be taken with the utmost care.

Special compounds are used to paint wooden products that are under the influence of atmospheric conditions. They are divided into the following types:

- oil paints;

- alkyd;

- water emulsion;

- reactive;

- polyurethane.

The composition of oil paints contains special oils, in particular, linseed and hemp. They are characterized by the ability to perfectly absorb into the wood surface.

It is interesting! Previously, for the purpose of painting wooden surfaces, just such compositions were used, since they serve as an excellent protection for the material. However, over time, their prevalence has decreased, as they tend to give off a pungent odor, and they take a long time to dry.

Water-based solutions, when applied, almost do not exude odor and perfectly protect wood from the influence of ultraviolet radiation. However, they are practically not inclined to resist physical influence.That is why it makes sense to use this type of paint for railings, for a porch made of wood only if the structure plays the role of a decorative element.

Alkyd substances require much less time to dry than other formulations. It is thanks to this that they have gained great popularity. This type of paint is characterized by resistance to mechanical stress and provides reliable protection against moisture ingress.

As for reactive compounds, they are made from pigment resins and a hardener. Before applying them to a wooden surface, these elements should be mixed. The result of the reaction between them is the formation of a protective film characterized by a high degree of hardness.

The most important characteristic of the composition, which is intended for painting wooden porch railings, is its resistance to external factors. Therefore, the choice should be made based on the following parameters:

- average temperature in summer and winter seasons;

- the degree of influence of snow, wind and rain;

- the level of impact of a mechanical nature.

In order for the paint to hold for a long time, it is necessary to use all kinds of varnishes and other wood preservatives. If you follow the above recommendations, the price of a wooden handrail for railings will be justified not only by its highest reliability, but also by its beauty.

Railing for stairs made of wood: installation options

It is worth noting that the method of making fences directly depends on the features of the interior, as well as on the type of wooden stairs for which they are designed.

For example, a distinctive feature of spiral staircases is their compactness. As for the installation, it also does not cause difficulties and involves the installation of two types of balusters: large ones are mounted in the corners, and those that are smaller are mounted on the steps.

At the tops of small racks, it is necessary to mark the angle of inclination of the ladder structure and cut it off. A hole needs to be drilled at the bottom. Moreover, its height directly depends on the size of the dowels. During the installation of these elements, a little glue can be added to increase strength. After that, the installation of balusters and main parts is performed.

The method of making the railing directly depends on the features of the interior and the type of staircase itself

For screw designs, you will need to create a curved bowstring.

Interesting! You can do this yourself. To do this, the wood blank should be soaked in boiling water to give it softness.

Then the workpiece must be fixed in the desired position and dried. After that, all parts of the ladder should be connected.

It should be noted that fences can be forged. Such railings for a wooden staircase in a private house are a sign of the excellent taste of its inhabitants. The key point when creating a tandem of wood and metal is to ensure the correct and reliable connection. However, speaking about the material for a staircase made of wood, it is worth noting that additional elements made of natural material have no equal.

If we are talking about creating a combined structure, in this case, assembly adhesive and a groove system are used. In addition, you can use elements for fasteners, including self-tapping screws. Having decided on a combination of forged balusters with wood, you should organize the treatment of the connection with an anti-corrosion compound.

The process of creating a handrail for a staircase made of wood in a private house is quite lengthy and painstaking, and caring for them requires some effort, which is fully justified by creating a stylish and luxurious look for the house.

In buildings with several floors, stair railing are a necessary attribute ensuring the safety of staying on the stairs, balcony or terrace. In addition, wooden railings will add sophistication to the interior and become an elegant decorative element.