Many modern materials are offered for the manufacture of stairs. Nonetheless, wooden stairs in the interior of the house are the standard of impeccable style. It is the wooden structures that create the feeling of home comfort. The key points in the arrangement of the stairs are accurate calculation, high-quality manufacturing and correct installation. A staircase to the second floor with your own hands made of wood with a turn of 90 degrees can be installed due to strict adherence to the recommendations for the design and calculation of the structure. It will save useful space and provide free and comfortable movement on it.

Exact calculation a wooden staircase greatly simplifies its installation, guarantees convenience and a long service life

Content [Hide]

- 1 Types of stairs to the second floor. Photo of design of different models

- 2 Types of rotary flight stairs

- 3 Do-it-yourself stairs to the second floor made of wood with a turn of 90 degrees: we design ourselves

- 3.1 DIY materials and tools for making wooden stairs to the second floor

- 3.2 Features of calculations of a 90-degree rotary staircase

- 3.3 Calculation of a wooden staircase to the second floor with your own hands: drawings, diagrams, tables

- 3.4 Independent production and installation of the supporting stringer beam

- 3.5 Making steps and assembling stairs

- 3.6 Do-it-yourself installation of balusters and railings for a staircase made of wood, photos of carved products

Types of stairs to the second floor. Photo of design of different models

Before equipping your house with a staircase, it is necessary to determine exactly what type of staircase will be and from what material. The choice of the type of staircase system depends on its location in the room, the layout of the house and the individual preferences of the owner. The materials for their manufacture, given the rapid growth of technologies, can be a variety of samples: plexiglass and ceramics, natural stone and marble, metal and wood.

The main types of stairs are classified according to the type of the supporting element:

- marching stairs - on kosoura or bowstrings;

- spiral staircases - with a support in the form of a bearing rack;

- ladders on bolts - bezosourny systems. The steps of such a staircase are attached to the wall, and are connected to each other using bolts;

- combined - when one system includes several types of structures.

The main difference between the stringer design is that the steps are fixed on top of the supporting element. While bowstring systems have recesses where steps are inserted. Marching systems, in turn, can consist of several flights, interconnected by a platform or winders.

The choice of one or another marching system depends on the location of the stairs in the room and the availability of the necessary space for its installation. In the case when space is limited, rotary systems of flight stairs are used. To connect different levels in private cottages, stairs made of wood are most often used. Such structures are quite lightweight, fit well into various interiors and can be made independently.

Numerous photos of wooden stairs to the second floor with their own hands confirm the popularity of the use of this material for staircase structures.

The ladders on the bolts do not have a frame in their design. Each step of such a staircase with the help of special fasteners rests on the wall on one side, and on the other, is connected in series with bolts. The structures of the stairs on the bolts have an openwork light appearance and are highly durable. Such stairs can be installed along the wall, which will be the supporting element, or anywhere else in the room - then a metal profile will act as a supporting structure.

The variety of modern staircase systems in the interior is evidenced by do-it-yourself photos of stairs in the house to the second floor.

Types of rotary flight stairs

Marching staircase systems can be straight and rotary. Straight flights in private houses are used when the dimensions of the rooms are spacious enough to install a long straight span. Most often, wooden rotary systems are used to connect the first and second floors. So, there are wooden stairs to the second floor with a turn of 90 and 180 degrees. They are called L-shaped and U-shaped, respectively.

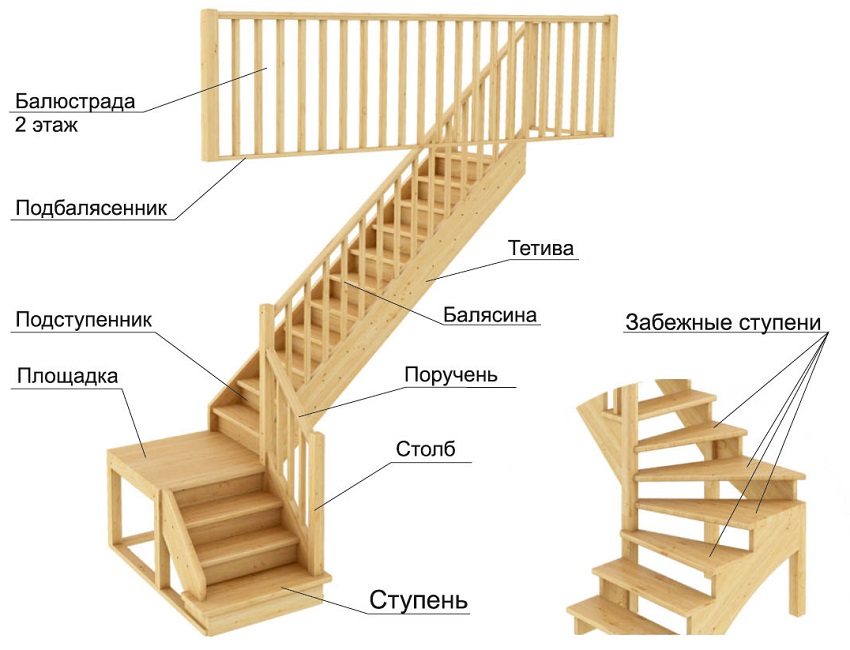

Marches of L-shaped stairs can be interconnected by platforms, two winder (turning) steps, three turning steps. The more the number of turning steps, the less convenient it will be to move along them. The structures of the stairs, installed in the corner and having a fence, include in their design an angular (support) post, on which run-in steps, balusters and a bowstring are attached. The corner post is installed on the base or can be suspended.

U-shaped staircase systems are constructively solved through a turntable or run-in steps. When arranging a U-shaped staircase, an important point is that the staircase railing in the upper projection should not intersect, therefore it is important to correctly calculate the stairs to the second floor. In both U-shaped and L-shaped rotary staircases, the use of winder steps allows you to maximally save room space.

The space left under pivoting stairs is often used to advantage for storage rooms or cupboards. Some photos of stairs to the second floor in a private house with their own hands clearly demonstrate this.

Calculate the stairs to the second floor possible, taking into account the arrangement of the recreation area under it

Do-it-yourself stairs to the second floor made of wood with a turn of 90 degrees: we design ourselves

Many manufacturers today offer ready-made sets of elements for staircase systems. To order such stairs to the second floor you will need to make clear measurements of the height of the span, determine the estimated width and length of the stairs and transfer the data to the selling company. However, this method will deprive you of the pleasure of making a staircase structure yourself, endowing it with individuality and originality.

DIY materials and tools for making wooden stairs to the second floor

The use of wood in construction, including for the manufacture of staircase structures, is due to its high strength characteristics, environmental friendliness, ease of processing and a relatively affordable price.

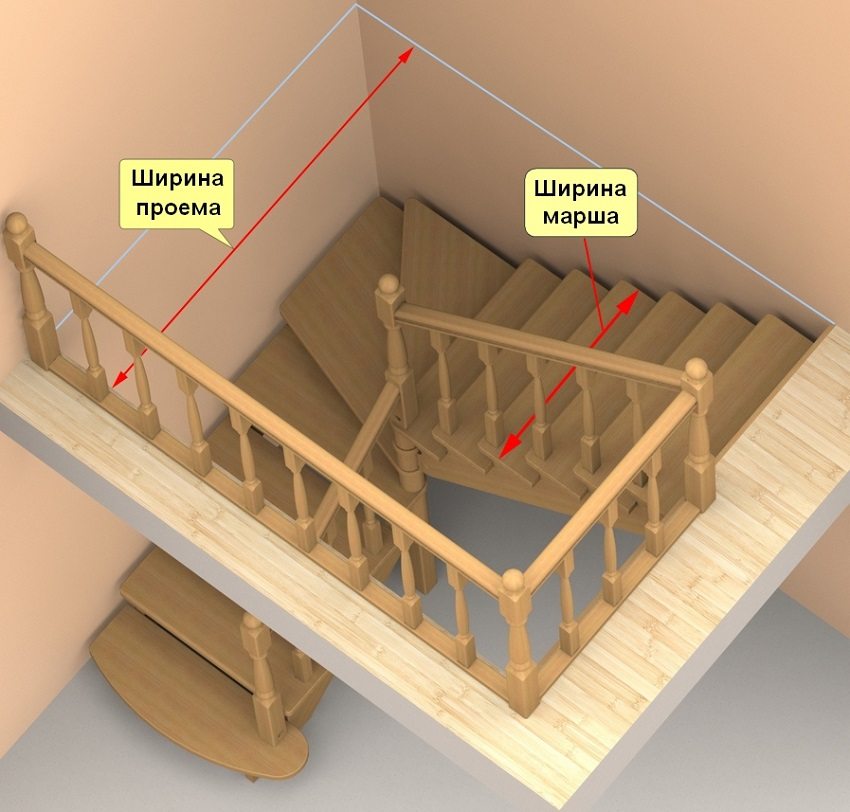

The width of the stairs is selected based on the convenience of movement and the availability of free space

The staircase to the second floor with your own hands made of wood with a turn of 90 degrees can be made of the following hardwoods:

- beech - used for rooms where high humidity is not observed;

- maple - its wood is very stable, has sufficient bending strength. However, it should be borne in mind that maple is prone to cracking;

- oak is an excellent building material. It has strength, hardness, rather heavy material;

- larch is a decay-resistant, hard and durable wood. In terms of hardness, this breed is second only to oak.

Sometimes pine is used for stairs, but you should check the wood for knots. Under the influence of the temperature regime, the deformation of the staircase is possible, as a result of which the knots can fall out, and entail the weakening of the structure.

When starting to manufacture a staircase, the wood must be thoroughly dried and treated with special compounds to make it resistant to moisture, mold and mildew.

To make a staircase made of wood to the second floor, you will need:

- bearing bar 100x100 mm (the section may be large, depending on the height of the flight of stairs);

- edged board with a thickness of 40-50 mm;

- handrails, railings, balusters;

- wood glue for sealing all joining lines and gaps.

A staircase to the second floor with your own hands made of wood with a turn of 90 degrees can be made and mounted using the following tools:

- a hacksaw for wood, a set of drills, a chisel, a file;

- screwdriver, hammer drill, drill, jigsaw;

Helpful advice! When working with a power tool, follow the safety rules: use protective equipment (goggles, gloves), do not hold the cord of a working tool, watch the position of the wire to avoid damage to it, do not use the tool near open flames.

- ax, hammer;

- square, ruler, level;

- gas wrench, side cutters (side cutters);

- hardware: self-tapping screws, screws, anchors, corners.

Features of calculations of a 90-degree rotary staircase

For the correct calculation and design of a marching rotary staircase, you should familiarize yourself with some of the features of such structures.

The main elements in them are:

- bearing beams - these can be stringer or bowstring beams;

- steps - in rotary staircases these are straight steps and rotary (run-in) steps, with the help of which the rotation of the structure is realized;

- stair railings - includes balusters, railings and handrails.

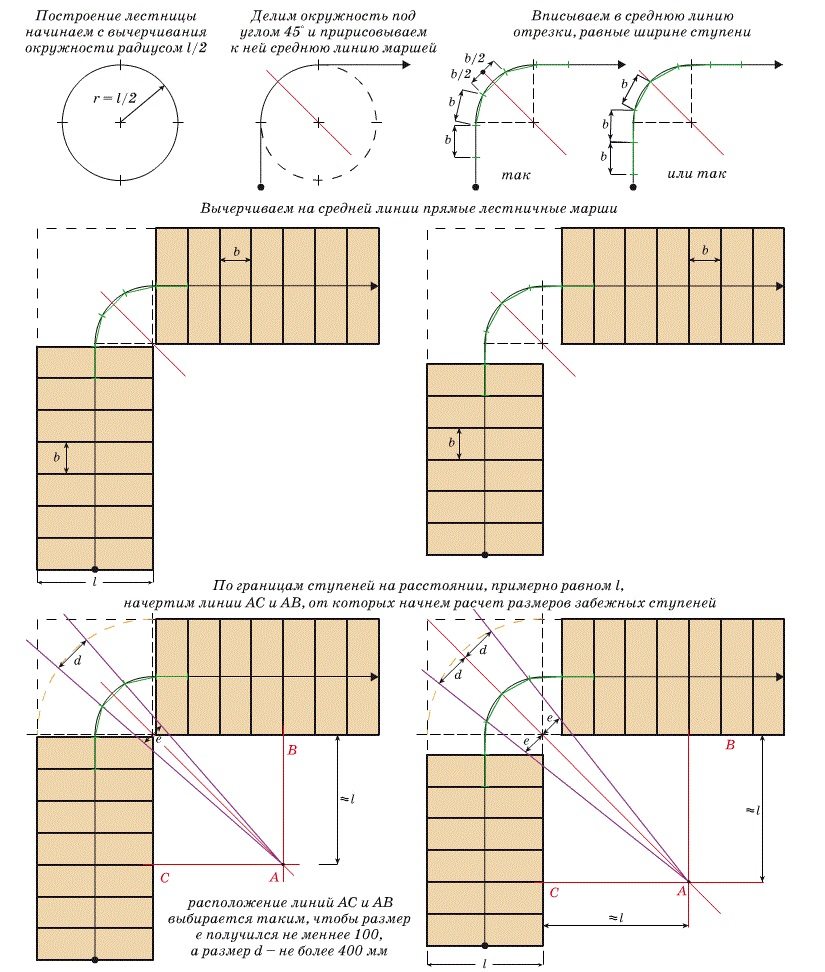

The calculation of rotary stairs is carried out using:

- geometric formulas;

- graphic methods - here you need to determine the middle line of the span (march). In a curved structure, this line runs parallel to the inner edge of the structure at a distance corresponding to the middle of the step width. The radius of curvature of the turning step depends on the radius of the circle between the two spans.

- you can use an online calculator to calculate, where you enter basic data: the length and width of the opening, the height of the steps, the thickness of the stringer and the ledge of the steps.

The choice and calculation of the staircase marching structure is determined by the width of the opening and the height of the room

Calculation of a staircase made of wood to the second floor with your own hands: drawings, diagrams, tables

When calculating a staircase made of wood to the second floor with your own hands with a turn of 90 degrees, you should decide in what way the turn will be ensured: by means of an intermarch platform or turning (winder) steps. Considering that stairs with a platform are installed in fairly spacious houses, we will give as an example a rotary staircase with winding steps.

The dimensions of the stairs are selected individually, but it is worth adhering to certain recommended parameters:

| Stair element name | Recommended sizes |

| Minimum width of the turning step on the narrow side | not less than 10 cm |

| Difference in width of the narrowest and widest step | no more than 10 mm |

| Span (march) width for private houses | not less than 90 cm |

| Width of the turning step at the center line | not less than 20 cm |

| Stair tread height | 10 cm |

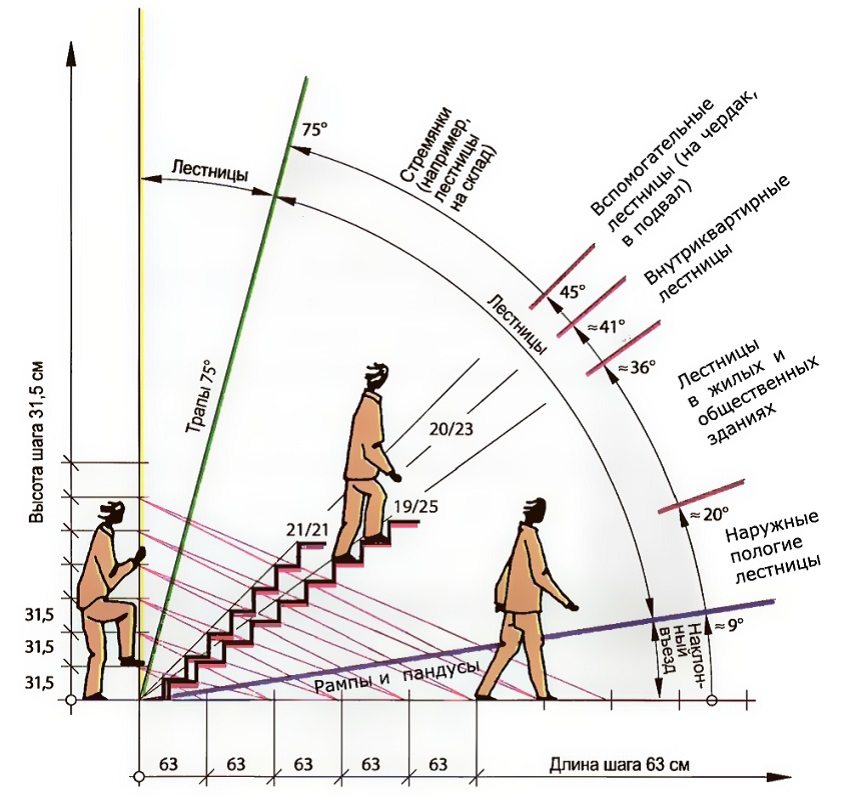

| Steep stairs for a comfortable climb | 45º and less |

When designing and calculating a staircase yourself, you must take into account the following points:

Height and width of steps. They should be such that stairs to the second floor any person could move, including a child or an elderly person. Considering that the average step of a person is 60 cm, you can calculate the height and width of the steps of the stairs using the formula:

2b + c = 60 (cm), where

b, c - steps dimensions (height and width).

Based on the formula, we get the width of the tread, equal to the average length of a person's foot. Then, when walking, the entire foot is supported on the surface of the step. If the width of the steps is greatly increased, then when walking up the stairs, a step will be lost and it will become inconvenient to move along it. If the steps are very narrow, it will be difficult and unsafe to go down such a ladder.

The angle of inclination of the structure. Many people make the stairs steeper to save space. This is not always justified, as the descent and ascent of such a ladder will be difficult.

Helpful advice! If it is not possible to install a staircase in your room with a slope of more than 20 degrees, it is recommended by design specialists to replace the staircase with a ramp (ramp). Stairs that are too steep should be replaced with fold-out stair systems.

The most convenient model of a ladder is considered to be a design with an inclination of 25 to 35 degrees.

Swivel steps. When determining the dimensions of the winders, it should be taken into account that their width on the narrow side should not be less than 100 mm and the overhang of the turning step over the previous one should not be more than 50 mm.

You can order a graphical calculation method from professionals, given the complexity in the design and calculation of stairs to the second floor in a private house (photos, prices are presented in the price lists of design companies).

Independent production and installation of the supporting stringer beam

A stringer is made from a wooden beam with a length equal to the size of the flight of stairs (march). The thickness of such a support should not be less than 50 mm. Before you start sawing the stringer beam, you need to make a template. A piece of triangular plywood with dimensions corresponding to the height and width of the steps can act as a template. According to this sample, a marking is applied to the beam and a toothed structure is cut out.

Our design assumes two supporting elements. Subsequently, the steps of the stairs will be attached to the teeth of the stringer beams.

Next, they begin to fix the stringer beams. It is recommended to start with fastening the upper parts of the stringer so that possible errors can be easily eliminated below. Usually, one of the stringers is attached to the ceiling beam and support bar with a section of 100 mm. The beam itself is fastened with anchor bolts or concreted into the floor if the repair work on the floor is not yet completed.

Helpful advice! In order for the kosour to be firmly fixed, a small depression is cut out in the support bar. The size of the recess should be 1 mm less than the cross-section of the stringer, with a depth of about 2 cm, so that the stringer beam fits closely into this groove.

Then they arrange supports for the kosour, which will be located directly near the wall. For this, props made of 50x50 mm timber are used. With its help, they make a base for turning steps. To do this, cut out the end of the support bar for the inserts of the rotary steps. The work is controlled by the level.

For a more detailed acquaintance with the method of performing the work, we offer the video "Do-it-yourself wooden stairs to the second floor":

Making steps and assembling stairs

The steps for the stairs are cut according to the template. All steps, except for turning ones, must be of the same size. Winders are also cut out according to the prepared sample according to the drawing. All prepared steps are covered with protective agents and varnished in several steps.

Related article:

|

The next stage of work will be the manufacture of a bowstring for the lower flight of the stairs. It is made from a board, but already without serrated cuts. The steps in the bowstring support will fit into the grooves cut in advance from the inside of the bowstring.

The bowstring that is attached to the wall is made in the same way. The upper part of the outer bowstring support should completely hide the end of the turning step, while the lower part is sawed off perpendicular to the floor.

Installation of steps is performed by fixing on self-tapping screws from the outside, and the inside is treated with wood glue. In the steps, grooves are cut out so that they clearly enter when laying on the kosour.

When attaching the turning steps, it is necessary to ensure that the connection to the support is sufficiently rigid. If the connection is weak, you can try to fix the step or cut another.

Fastening the risers starts at the bottom of the stairs. The risers are cut 5 mm less than the height of the steps. This is done so that in the event of swelling, the risers do not deform the entire structure. Sometimes the gap between the steps is not covered with risers to give the staircase a lighter appearance.

How is a wooden staircase to the second floor made with your own hands? The video at the end of the article will help you understand in detail the installation stages.

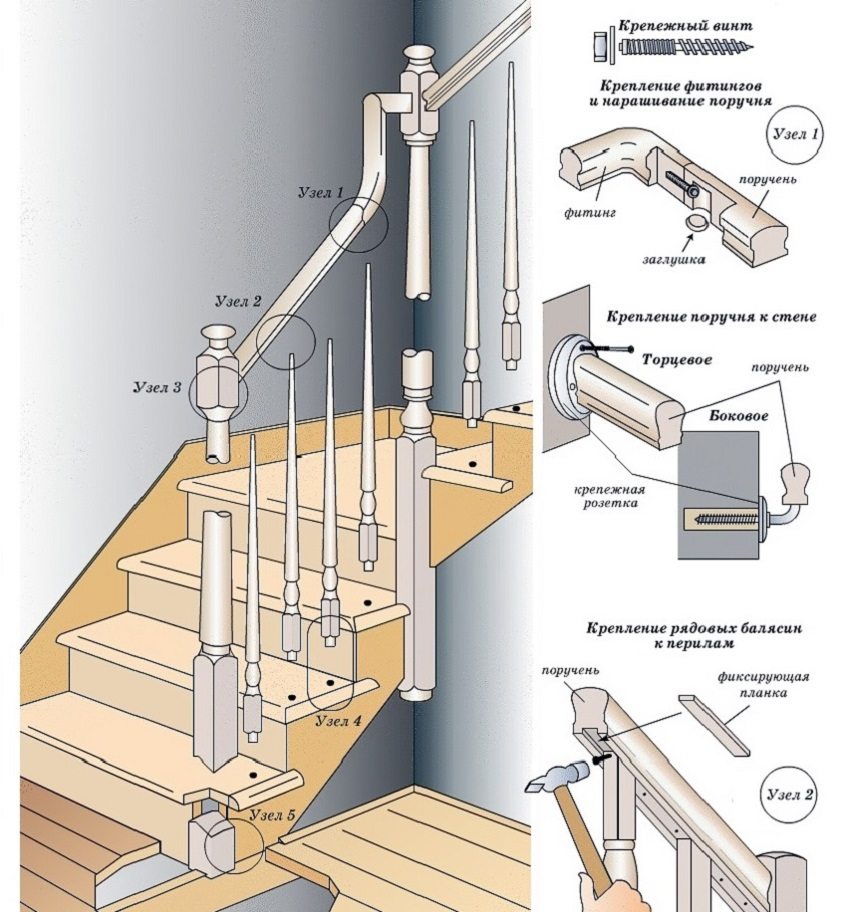

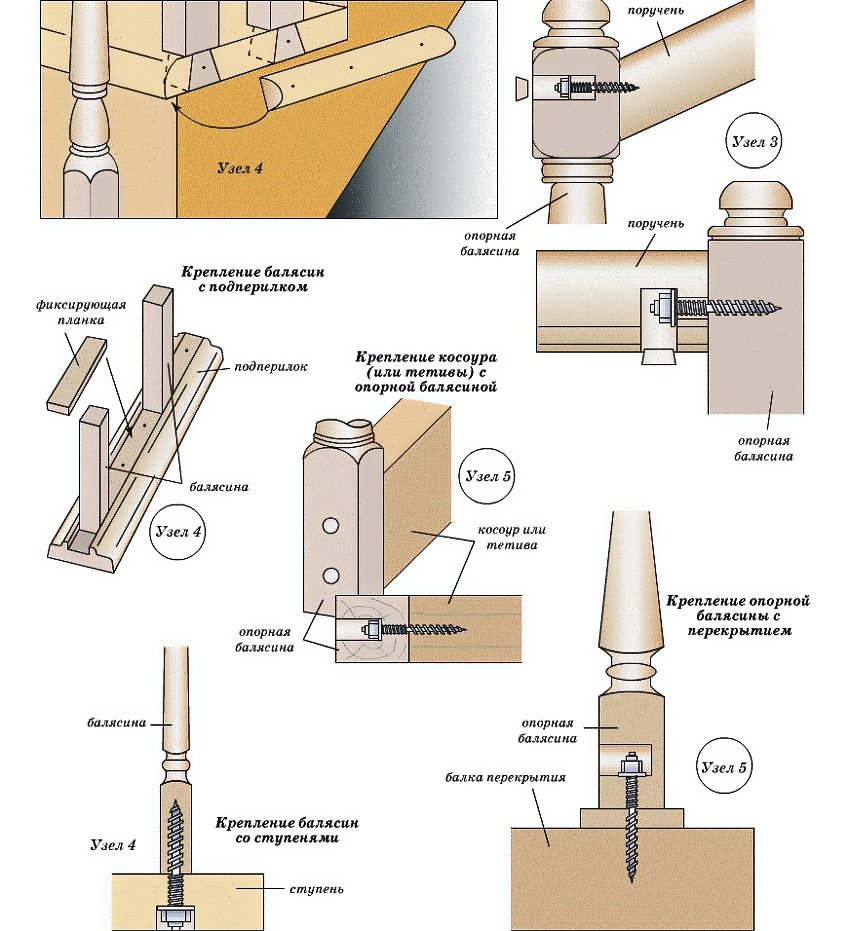

Do-it-yourself installation of balusters and railings for a staircase made of wood, photo of carved products

Self-production of balusters is a painstaking and delicate work. If you are sure that all the elements will turn out to be the same and aesthetic, you can do it yourself. If in doubt, it is better to purchase finished products. Their choice is quite large: from simple to sophisticated decorative elements. You can come up with your own drawing and order balusters and railings from the manufacturer - experienced craftsmen will make elements of any complexity. The available photos of the railings for the stairs made of wood confirm the huge selection of such elements.

Helpful advice! For safe movement up the stairs, especially for children, it is recommended to carry out a baluster fence at least at each step.

Balusters are attached to the steps by means of dowels (wooden rods). To do this, in each step along the edge, the corresponding holes are drilled. The hole should have a smaller diameter than the dowel, which will ensure the rigidity of the fastening. Before inserting the rod, wood glue is poured into the hole.

In places of turns of flights of stairs, as well as at the beginning and at the end of the flight, more durable balusters, called pedestals, are installed. They will subsequently act as a place for fixing the handrails.

In the balusters, they arrange the same holes for a wooden spike and they are also treated with glue. Then insert the dowel into the baluster and fix it on the steps.

How to make a handrail for stairs made of wood? Photo, video tutorials will help you learn how to fix the elements of the staircase.

To mount the railing neatly and evenly, a painted fishing line is stretched between the uppermost baluster and the support bar. It will leave marks on all balusters. If it turns out that there are extra centimeters of balusters, they are cut parallel to the stringer beam.

To fasten the handrail, select a groove in it along the entire length, into which the rail will subsequently enter. We grind the rail with a width equal to the width of the groove in the handrail. We nail the rail to the balusters, thus fixing them. The handrail is put on the rail and fixed on the support balusters (pedestals) at the top and bottom of the span with the help of pins.

Making and installing wooden stairs is a rather complicated task. If you do not have specific experience with wood and carpentry tools, it is worth ordering ready-made sets of prefabricated stairs. They are manufactured in compliance with all technical standards for individual and standard sizes.

Wood is a typical staircase material and has always been prized. Constructions made of natural wood are environmentally friendly, durable and can be the main decor of a country cottage. The only condition is high-quality processing and careful care of the wooden elements of the stairs. If these conditions are met, the staircase will serve you for many years, keeping its original appearance.