Buying an expensive Swiss knife is not a guarantee that it will never dull. Any manufacturer will not give a guarantee for factory sharpening for more than a year, so the question of restoring the sharpness will sooner or later arise. Knife sharpeners are used not only to restore the blade of a conventional kitchen appliance, but they can also be used to sharpen the knife of a meat grinder or plane. The main thing is to choose the most convenient device.

Content [Hide]

- 1 How to sharpen knives: a description of the main stages and rules

- 2 Electric knife sharpeners: design and use features

- 3 Mechanical and manual knife sharpeners with adjustable sharpening angle

- 4 The main types of abrasives used for sharpening knives

- 5 Types of blades and the correct angle of sharpening of knives: what should it be

- 6 Why kitchen knives are quickly dull, the angle of sharpening, depending on the purpose

- 7 How to sharpen a knife yourself with a bar at home

- 8 How to sharpen a knife with an electric sharpener

How to sharpen knives: a description of the main stages and rules

Any knife, even the best quality, will sooner or later become dull, and this does not mean that it was used very often. Corrosion, which occurs due to humidity or temperature changes, will still do the trick. If the device is used daily, then it must be sharpened at least once a week. It all depends on the features and frequency of use. However, the properties of certain materials should not be underestimated. So, ordinary thick cardboard is able to blunt a knife by half, even after several cuts.

Helpful information! Many people worry that the tools for sharpening knives can make the device too sharp, as this can cause injury. At the same time, experts recommend taking into account the fact that the probability of injury due to a blunt knife jumping off the surface is twice as high as the possibility of a cut from a too sharp blade.

To achieve the best result, the knife sharpening process should consist of several stages, and each stage, depending on the quality of the device, may include the use of separate devices and tools. So, the regrinding process consists in changing the sharpening angle or in eliminating severe mechanical damage on the edge of the blade. This process removes a substantial layer of steel until the surface is perfectly flat. Hard and coarse abrasives are most often used for regrinding.

To restore the condition of the cutting surface of the blade, a sharpening process is carried out, in which medium- and high-grit abrasive materials are used. In some cases, knife sharpening tools can leave deep micro-scratches on the surface, which will cause too sharp spots on the blade. In order to get rid of them, another stage is carried out called "finishing" or "finishing polishing".

After this process, even minimal scratches are eliminated, and the blade acquires a mirror shine. The cutting ability in this case is slightly lower, but after finishing, the sharpness will remain for a longer period.

If the main goal is to make the knife sharper, then it is necessary to use medium to high grit abrasives.

Separately, mention can be made of the straightening step, which is used when the blade turns slightly to the side, which significantly reduces the cutting properties. At this stage, not sharpening occurs, but the alignment of the side surfaces of the edge so that they take their original position. It is important that in the process of carrying out this work, the steel from the surface of the knife is not removed.

Electric knife sharpeners: design and use features

All devices for sharpening knives can be conditionally divided into several groups:

- depending on the type of abrasive used - bars and whetstones;

- based on the features of the structure's work - manual and electric;

- according to the characteristics of use - for domestic and professional use.

To understand the name of a knife sharpener of one type or another, you should know the basic principles of their work. For example, electric knife sharpeners differ not only in the type of electric drive, but also in size.

These can be impressive-sized designs with large discs or neat compact devices designed even for use in small rooms. For example, such devices are often seen in restaurants or cafes: they are needed in order to keep kitchen utensils in constant order. However, these knife sharpeners are designed for continuous use and can repair even severely damaged blades made of strong alloys.

The very design of electric sharpening consists of several grooves through which a blunt blade is passed. Inside each recess there are discs of different materials, located perpendicular to the knife. After turning on the device, the sharpening of the blade begins, in which it goes through each groove 2-3 times. This type of sharpener allows you to choose the optimal sharpening angle of the knife and adjust it depending on the type of surface to be sharpened, which makes it universal for different knives.

Useful advice! Despite the high cost of electric knife sharpening devices, they are in great demand due to the fact that they allow you to quickly and reliably sharpen any device. Another advantage is the absolute safety of use, because here direct human contact with the blades or discs is excluded.

Household electric sharpeners are not as large as professional ones, but they are no less functional. They also provide the ability to fix the sharpening angles for various types of knives and other cutting tools, for example, for scissors, screwdrivers or chisels.

Mechanical and manual knife sharpeners with adjustable sharpening angle

Traditional mechanical grinding machines have been popular for a long time, because their use does not require an electrical connection, especially since a simple structure rarely breaks down or fails the owner.In most cases, mechanical grinders are stationary structures with a large number of advantages, among which are:

- the presence of a knife sharpening angle holder;

- the ability to select the desired abrasive stone;

- fixing the blade or grindstone in the desired position.

Mechanical devices are considered professional and allow you to carry out all the necessary sharpening stages with a knife. Many people point out that before using the device on your own, you should get some skill and experience. In some cases, you will need to go through a little training. Having gained some experience, it will turn out in a short time to learn how to quickly sharpen any knife device.

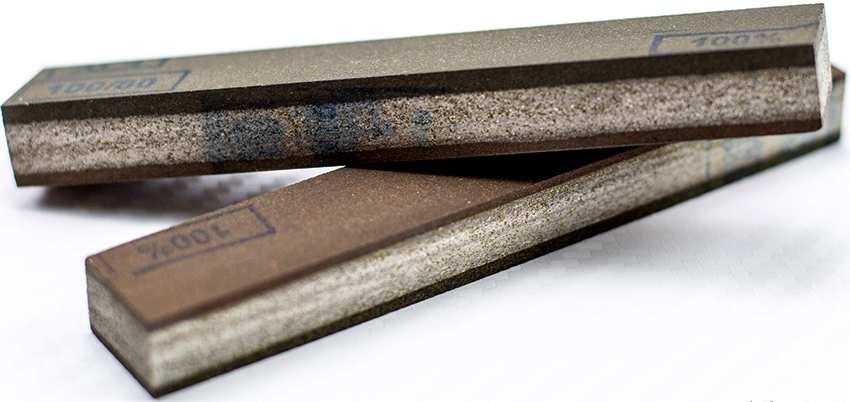

The simplest version of a manual knife sharpener is considered to be a bar or a whetstone, which is an abrasive tool used to sharpen the blades of not only kitchen but also locksmith tools. A sharpening stone is also considered an excellent tool for sharpening planer knives and other joinery equipment.

It is interesting! Sharpening a knife on a bar was used many centuries ago by ancient people. The result of work here will depend on the skill of the user. Also, the stone is considered a universal sharpener, which makes it possible to increase the sharpness of even the most blunt knife.

The main types of abrasives used for sharpening knives

In general, for the manufacture of mechanical or manual machines for sharpening knives, 4 main types of abrasive are used:

- Natural. Here, novaculite or Japanese water stone is most often used; in general, such sharpeners are of high cost. Another disadvantage is the complicated process of using this type of stones to sharpen knives.

- Diamond. The most popular type of sharpening, characterized by a variety of geometric shapes, sizes and type of grain. The main advantages are wear resistance, good sharpening result, low price.

- Ceramic. The most modern type of knife sharpening, which combines the positive qualities of natural and diamond stones.

- Artificial. The most commonly used stone options here are corundum and carbide, which are notable for their low price. But sharpening knives with a bar made of such materials does not allow finishing the cutting surface.

Polishing pastes are often used to bring the blade to a mirror finish. The main purpose of using the paste is to refine the cutting base and eliminate scratches. The composition includes an abrasive powder (diamond or ceramic), an astringent (it can be paraffin, petroleum jelly or water), as well as active additives, the main task of which is to clean and polish the surface to obtain a high-quality work result. Most often in our country, GOI paste is used for polishing, previously applied to a soft felt or fabric base, although more modern means have been developed for this.

When choosing an abrasive, one should not forget about such a concept as grain size, which is considered a determining factor in the effectiveness of a grinding device.

Interesting information! Today there is no single system that makes it possible to compare abrasives of different types, because there are several different designation systems. In the case of sharpening knives with a bar made of natural stone, the determination of grain size is generally not relevant due to the heterogeneous structure.

The universal designation for grain size is GRIT, which is calculated based on the smallest number of holes per square inch of the sieve. Here, the main concept is that the higher the GRIT value, the lower the grain size of the material.

In general, the grain itself affects the quality and purity of the sharpening. To carry out a full-fledged work on sharpening the tool, several materials of different grain size should be used. The finer the abrasive grain, the finer the processing will be and the less the metal layer will be peeled off. Coarser abrasives are needed for the initial coarse sharpening when it is necessary to restore the perfect appearance of the blade and get rid of chips or irregularities.

The table contains information about the required abrasive grain size for different sharpening stages:

| Grain, Grit | Average grain size, μm | Type of work | the effect |

| 80-600 | 180-20 | Roughing | Correcting the thickness or shape of the cutting blade |

| 600-3000 | 20-4 | Preparatory | The first stage of sharpening and removal of traces of roughness |

| 3000-6000 | 4-2 | Medium, finishing, grinding | Finishing the cutting edge |

| 6000 and more | 2-1 | Finish | Bringing to perfect blade cleanliness |

When working with a grinding stone, the peculiarities of the abrasive should also be taken into account. So, the surface of a ceramic with the same grain size gives a more delicate effect than a diamond base. The best knife sharpeners are those with several types of abrasive surfaces. The greater the difference in grain size, the more versatile the model and the more types of blade processing can be done. Of course, the availability of a variety of abrasive surfaces will also affect the final cost of the sharpener.

Musat and other common household knife sharpeners

Externally, the musat is a knife sharpener in the form of a file with a round or oval section. Convenience of working with the rod is ensured by a comfortable handle, which is securely fixed in the hand. The use of musat allows you to align the cutting blade of the knife and make it sharper, and any housewife without experience can do the job.

According to the principle of operation, the grind is similar to the sharpening rod, but if the sharpening removes part of the steel coating, then the grind only cleans the surface of the metal fringe formed during operation. The result of the work is the leveling of the surface with minimal metal abrasion along the edge of the blade.

Useful advice! If a high-quality knife is purchased and at the same time it is properly operated, then the musat is quite enough to maintain its normal sharpness. Do not forget that a small layer of metal is removed with each sharpening. This causes the blade to shorten and shrink.

In most cases, musat is made of metal. The length of the rod does not exceed 20-35 cm. Devices that are distinguished by a shiny, smooth or even mirror surface of the rod are considered the best. Another advantage of the device is the presence of a magnetized tip, which serves to attract metal chips, peeled off the knife during sharpening. Basically, musats can take the following form:

- circle or oval;

- flat with a faceted rod;

- tetrahedron.

Metal, diamond and mixed rods are distinguished according to the material of manufacture. The most effective is the musat, which has a ceramic coating, which can be used as a device for sharpening planer knives, chisels and ordinary kitchen knives.

In addition to musat, other types of sharpening are often used in everyday life, for example, folding versions of the "balisong" type, which got their name from the name of the area in the Philippines where they were first developed. The device is a folding device with a comfortable handle that unfolds like a fan at 180 °. A special type of opening, reminiscent of the flap of the wings of a butterfly, gave the sharpening a second name - a butterfly sharpener. The convenient shape allows you to use a device for sharpening chisels, scissors or other tools that need sharpness. There are the following types of sharpeners:

- rectangular;

- awl-shaped;

- rod-shaped.

Related article:

Small size, ease of use and efficient operation of the sharpener allowed the device to become widespread not only in domestic use, but also for use in hiking or travel.

The most mobile and compact are the keychain sharpeners, models of which are widely represented in retail outlets. There is a choice of different shapes, sizes and original appearance. Often, in addition to a knife sharpener, a travel nail file can be included in the kit, which further adds useful qualities to the device.

Types of blades and the correct angle of sharpening of knives: what should it be

Knives are made from different materials, but different types of steel are considered the main ones. Regardless of the material or shape of the product, in any case, over time, it will need sharpening, because working with a blunt device is dangerous for the user. The following materials are mainly used for the production of knives:

- Carbon steel. Such products are not intended for continuous use, because they quickly corrode.

- Stainless steel. In addition to the main material, chromium, nickel and molybdenum are used for manufacturing. These knives require constant sharpening.

- High carbon stainless steel. Due to the presence of vanadium and cobalt in the composition, the strength of the blade is significantly increased.

- Damascus steel. An expensive material used for elite hunting or collection knives. Such a blade only accepts hand sharpening along the edge.

- Titanium alloy. The composition also contains a carbide additive, which is why the blade remains sharp for a long period. It is better to sharpen knives using a professional sharpening machine.

- Zirconium alloy. It is made by firing and pressing high hardness mineral ceramics. No special tools are required for sharpening.

It is possible to determine that the blade has become dull not only when working with the device, but also by eye. Correct sharpening is necessary to restore the shape of the cutting edge of the blade. The main difficulty of the sharpening process is maintaining the desired angle of inclination, and special devices for the sharpening angle of the knife will help with this.

Helpful information! The smaller the angle of the blade, the easier it is to cut the required material, which is especially important when working with soft products. A knife with a small sharpening angle dulls several times faster relative to devices with a large angle.

To navigate the tilt angles, standard values are generally used. For example, an angle of 45-55 ° is sufficient for hairdressing scissors, and 75-85 ° for metal scissors. But a more delicate device, such as a surgical scalpel, requires 10-15 ° for sharpening. The sharpening angle of a hunting knife should not exceed 25-30 °.

Why kitchen knives are quickly dull, the angle of sharpening, depending on the purpose

A sharp kitchen knife is a guarantee of quick and efficient work in the kitchen, but the use of various cutting boards does not have a positive effect on the sharpness of the blade, because they round off the cutting base of the appliance. You should also know that cutting on a wooden board has less effect on the deformation of the knife blade than working on a plastic board. Other reasons kitchen knives are dull:

- Butchering an animal carcass. The bones and tendons of any animal are hard and can dull a knife even after one use. The bones of most fruits are similarly strong.

- Cutting raw fish with bones. The scales and bones of the fish are very hard in structure and quickly dull the point.

- Improper storage and care. If you store the knife not in a special holder, but together with other cutlery, the blade will quickly become unusable. It should also be borne in mind that most knives are not recommended for washing in the dishwasher.

When cutting animal carcasses, knives can become dull very quickly due to the presence of tendons and bones

When working with a kitchen knife, you need to know that even poorly peeled soft vegetables and fruits, on which sand or lumps of dirt are left, can worsen its sharpness. Therefore, all food should be thoroughly washed before slicing.

There are no special rules for sharpening kitchen knives, but nevertheless, experts recommend observing different angles of inclination for devices with different purposes, which is shown in the table:

| Knife type | Application features | Sharpening angle, degrees |

| Dining room | For chopping food on a plate, it becomes blunt mainly due to the constant contact of the cutting part with the dishes | 55-60 |

| Plain kitchen | Chopping and slicing food on the board | 25-35 |

| Professional chef | For cutting meat and fish | 20-25 |

| Povarskoy | For vegetables and fruits | 35 |

| Boning (butchering) | Separation of meat from bones and tendons | 20-30 |

| Tourist | For mixed use | 30-45 |

How to sharpen a knife yourself with a bar at home

The bar is considered an excellent tool for sharpening meat grinder knives, ordinary cookware and even carpentry tools. When using, you must adhere to the basic rules:

- observe the correct sharpening angle, based on the scope of the knife;

- maintain the position of the blade in relation to the surface of the stone throughout the entire sharpening period;

- do not allow abrupt and abrupt actions, all movements must be smooth and sliding;

- before carrying out work, moisten the bar abundantly with detergent, soapy water or oil;

- carefully inspect and rinse the knife blade.

It is necessary to ensure that the angle between the knife and the bar is the same during the sharpening process

Because the full sharpening cycle consists of several stages, it is recommended to immediately purchase a set of bars with different grain sizes. When using a block, you should adhere to the optimal sharpening angle for a particular device. To make it easier to keep the correct angle, it is necessary to use paper or wood clips. During the entire sharpening process, one hand holds the bar, and the other hand holds the knife blade itself. In some cases, it is easier to lock the block in one position and hold the knife with both hands. Sharpening is carried out alternately on each plane.

How to sharpen a knife with an electric sharpener

When using an electrically driven grinder, the work requirements remain almost the same as when working with a stone or a grindstone. The only point is that when using a device for sharpening knives, it is not the abrasive surface that is wetted on the emery, but the blade of the knife, because water will not be held on a constantly rotating circle. Other sharpening rules:

During sharpening on an electric machine it is necessary to periodically moisten the knife blade with water

- It is necessary to constantly make sure that the knife blade does not overheat too much, which can happen when the knife is pressed firmly against the abrasive surface.

- To correctly fix the sharpening angle, you need to use additional devices that are securely attached to the body of the grinder.

- To ensure the safety of using emery, do not neglect protective equipment, which includes gloves and goggles.

If a small home grinder is used, then it is necessary to maintain the optimal working interval and select the correct emery grain size, because most often the angle is fixed automatically.

There is a wide selection in retail outlets devices for sharpening knives and other instruments that need to be kept sharp. Structures of various purposes have different equipment and, accordingly, cost. When choosing a model, it is necessary to take into account the design features of the knife, as well as the material from which the device is made. Also, do not forget about the simplest sharpeners that any housewife can use on her own.