Drill attachments have turned this tool into a versatile helper. Thanks to these removable devices, you can not only make holes, but also cut building materials, mix mixtures evenly, and also treat the surfaces of products made of plastic, wood, metal and concrete. This article describes the main types of nozzles, their characteristics and scope.

Content [Hide]

- 1 Drill bits: purpose and classification of removable devices

- 2 The main types of polishing and grinding attachments for a drill

- 3 Overview of wood drill bits: drills and crowns

- 4 Concrete mixer and vibrator: drill bits for construction

- 5 Advantages and overview of drill bits for cutting wood and metal

- 6 Characteristics and application of angle drill bits

- 7 Other useful drill bits

Drill bits: purpose and classification of removable devices

The use of removable tools allows you to turn a conventional drill designed for hole-making into a versatile tool. The attachments significantly expand its functionality, eliminating the need to buy highly specialized equipment. Even for the most common drill, the choice of accessories presented in stores is so extensive that there is not one, but even several classifications.

On sale you can find attachments for a variety of tasks:

- tightening fasteners;

- grinding;

- mixing;

- cutting;

- milling;

- drilling holes of various sizes;

- polishing, etc.

If you use the bit and drill correctly, you can get almost the same quality of processing as with a highly specialized tool. According to their purpose, these products are divided into the following categories:

- stops;

- nozzles for cutting sheet metal;

- crowns and devices for drilling holes;

- nozzles with an angle design;

- devices for grinding and polishing various surfaces;

- cutters for metal and wood processing;

- feathering nozzles;

- devices designed for sharpening, mixing and other tasks.

The main types of polishing and grinding attachments for a drill

Polishing and grinding attachments are the largest category of drill attachments.All of them differ in the material of manufacture, in shape and purpose, although they are attached to the instrument in the same way. For this, a special cylindrical rod is provided in each nozzle. It is fixed in the tool holder.

The most common types of polishing and grinding attachments for a drill:

- end;

- disk;

- cup;

- fan-shaped;

- plate;

- drum;

- polishing in the form of soft discs.

These are just the basic types of attachments, there are other types of removable grinders. Some of them have a special design that allows processing products with complex shapes.

Note! When choosing removable tool nozzles, be sure to take into account the requirements specified in the instructions. Each type of component has a specific speed (number of revolutions) and drill power.

Expansion of functionality is the main, but not the only advantage of removable devices. The attachments allow you to perform a variety of surface finishing jobs without the need for expensive, highly specialized equipment.

The advantages of drill bits for metal and wood drills in comparison with highly specialized tools:

- High-quality processing of hard-to-reach areas.

- More convenient conditions for working with small parts.

- Profitability.

- Many attachments can be made by yourself at home.

Removable devices also have disadvantages:

- In general, a drill is not as comfortable to work with as a narrow-focus tool.

- To achieve a high-quality grinding result, you will need to practice the skills of handling the tool.

- Lower performance level.

- The tool needs constant speed adjustment.

If a drill with a nozzle will be used to perform a small amount of work, then the listed disadvantages can be considered insignificant.

Types of drill bits for grinding wood and metal: classification by material type

The scope of application of removable grinders is very wide. Using the drill bits for metal cleaning, old paint residues, traces of rust and other dirt can be removed from the surface. Such work is usually carried out at the preparatory stage before painting. Some nozzles are used for cleaning metal elements after welding.

By the type of material, polishing attachments are: grinding stones, emery cloth, attachments made of soft materials

Grinding attachments can also be used:

- for polishing metal, glass and plastic surfaces, as well as paint and varnish coatings;

- processing of edges on glass;

- grinding surfaces in hard-to-reach areas of products;

- removing burrs and other defects from the surface.

There are three types of grinding and polishing devices according to the type of material:

- Emery cloth.

- Soft material tips.

- Grinding stones.

Emery cloth is the most common abrasive material used for cleaning and sanding surfaces. Such paper can have different grain size and roughness, which allows you to choose the best option for roughing and finishing products. You can polish the surface with the emery cloth drill bits for grinding wood.

The group of accessories made of soft materials includes nozzles made of foam rubber, vinyl, felt, etc. They can be successfully used to remove corrosion and rust from the surface, as well as to remove putty from walls and clean the car body from primer.

Useful advice! The felt nozzle will allow you to polish the paintwork on your car to a shine.

Grinding stones are a special type of abrasive that is suitable not only for cleaning the surface, but also for removing various defects from it. These attachments can be used as drill bits for grinding metal, ceramics, concrete and glass.

Overview of drill bits for surface grinding

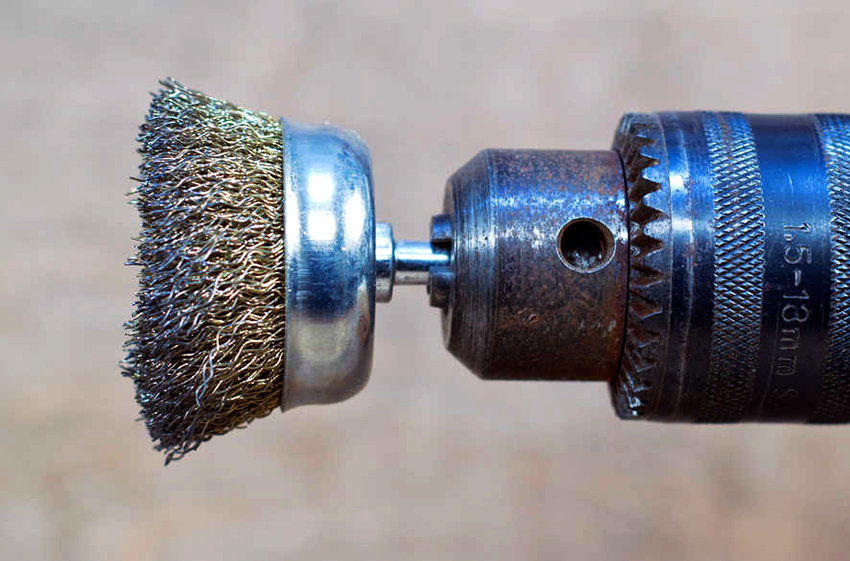

The cup nozzle is made in the form of a bowl on which the bristles are fixed. Such devices have a high degree of rigidity because their fibers are made of plastic or wire. They are commonly used as drill bits for metal drills to remove corrosion, paint residues, solid contamination and slag from the welding process.

Disc attachments have a similar design. However, in these drill attachments, the brush is directed to the sides rather than forward. They need to be used very carefully. If you do not adhere to the technology, you can damage the treated surface.

The plate nozzles are made of elastic material. The edge of the product is flexible so that the abrasive material can be brought to the surface to be treated at different angles, which allows sanding even in the most difficult-to-reach places.

A circle of sandpaper is attached to the plate nozzles in different ways, for this they can be used:

- adhesive composition;

- Velcro (Velcro fastening);

- Double-sided tape;

- clamp.

The fan-shaped attachments for the drill look like a lady's fan. A small disc is located in the center of the nozzle. Sandpaper is attached to it. Moreover, it is made not in the form of a continuous web, but in the form of petals with an abrasive coating. The fan-shaped nozzle design is very flexible. During use, it can change its shape, adjusting to the relief of the surface to be treated. With the fan nozzle you can process:

- cavities;

- internal surfaces;

- hard-to-reach places;

- surfaces with complex relief.

Drum-type nozzles resemble the design of fan-shaped devices, only their petals are located perpendicular to the plane of rotation of the inner disk. They are designed for sanding hard materials. With the help of drum nozzles, the glass edge is cleaned after cutting.

End fixtures work on the same principle as a grinding wheel. At the end of the rod, they have an abrasive material fixed, which can have different shapes:

- bowls;

- disk;

- cylinder;

- cone, etc.

The end caps are small, which allows not only balancing the fixture, but also using it to reach hard-to-reach areas.

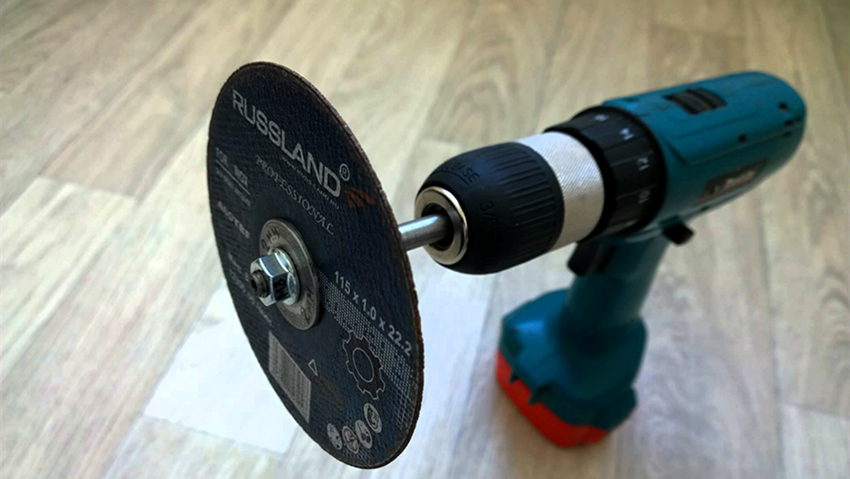

Useful advice!For disc nozzles, you can use cutting and abrasive discs from grinders. Using an adapter with a centering drill, they can be securely attached to the shaft.

Features of drill bits for surface polishing

The attachments for surface polishing are very similar to grinding attachments. The difference between these devices is only in the abrasive. Soft materials are used in the polishing attachments, resulting in a finer surface finish.

The polishing tools are in the form of a disc made of soft material. A soft filler is fixed on them, for example, felt, foam rubber or felt. By the degree of softness, polishing attachments for a drill are:

- tough;

- medium hardness;

- soft;

- super soft.

In addition, polishing tips vary in size and shape.Such a large assortment allows the buyer to choose the best tip option that is ideal for processing a particular surface.

The choice of tip depends on the type of work to be done with it. For example, cone-type bits are designed for polishing holes. For the same purposes, thin cylindrical devices can be used. Petal nozzles are better than others to cope with the treatment of hard-to-reach places on embossed products. The cup attachments come in handy when you need to polish the finish.

Overview of wood drill bits: drills and crowns

Drilling holes is the main function of the drill, for which there is a huge selection of removable devices, presented in a single form or in the form of whole sets. The most common types of attachments used for this purpose:

- Forstner drills;

- crowns;

- feather drills.

Related article:

Metal crown: types, sizes, methods of application

Technical design and method of application. Types of cutting edge. Drilling bits Bosch, Enkor, Zubr, Fit. Correct use of the tool.

The Forstner drill has wide cutting surfaces located on the sides. A point is provided to center this tip. This type of nozzle is used to form medium and small holes in wood. This prevents the tip from going through the material. The presence of the tip allows to achieve high accuracy when creating holes for mounting hinges.

Pen drills are designed to make wide holes, the diameter of which can be up to 6 cm. These attachments make it possible to install accessories in panel materials from wood and even in solid wood. These drills are equipped with wide side blades and a centering point. With this flat design, the recess is accurate and the hole depth is limited.

Crowns are nozzles with a complex design designed for material sampling. The cutting surface of these tips has a characteristic profile, it is wide and has a high safety factor. Crowns work on the principle of an incisor, and in some cases, multiple incisors. They are used to create holes with a diameter of up to 10 cm. A drill is installed in the center of the tip. It sets the first hole, which centers and guides the bit. Crowns can be used not only on wood (fiberboard, chipboard, solid wood), but also on metal and concrete.

Note! When choosing a nozzle of any type, it is imperative to take into account the size of the chuck of the electric drill on which it will be installed.

Depending on the configuration, the drills can be used as drill bits for concrete, wood and metal. Tips with a high margin of safety are called victorious. This group of accessories includes attachments designed for impact and vibration equipment.

Concrete mixer and vibrator: drill bits for construction

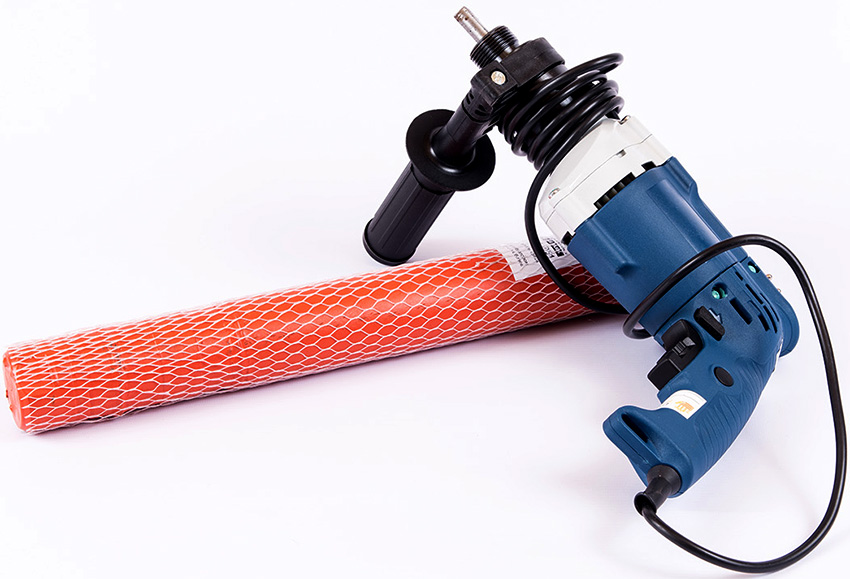

The construction of monolithic walls and foundations has its own characteristics. A high-quality result can be achieved only if there are no voids when placing concrete. For this, special mechanisms are used, called vibrators or seals. There are many varieties of these devices, which differ in the principle of operation (method of vibration transmission) and the type of drive.

Vibrating attachments for a drill or hammer drill are classified as portable or hand-held devices that connect to a power tool.The construction of concrete seals includes the following components:

- vibrator;

- connecting drive;

- motor (in this case, the motor of the electric drill).

The tip creates high-frequency mechanical waves and transfers them into the concrete mix. The design of a vibrator or vibration beater can be varied, but their purpose is the same. The tip is connected to the motor of the electric drill using a drive, which can be metal or flexible, short or long. The outer diameter of flexible products reaches 1.5-3.5 cm, their length varies within 0.5-15 m.

Benefits of using a vibrator:

- excess air and moisture are removed from the concrete mixture;

- the quality and strength of concrete increases due to the elimination of voids;

- forms are filled evenly;

- the mixture is homogeneous and fluid;

- the hardening period is reduced;

- the service life of the finished building is significantly increased.

In construction, drill attachment mixers are also used, designed for mixing solutions with different degrees of density, for example, concrete, paint composition or wallpaper glue.

Note! The configuration of the removable device is selected taking into account the consistency of the solution, otherwise the mixture will turn out to be heterogeneous.

Advantages and overview of drill bits for cutting wood and metal

Devices for cutting metal or wood are used in cases where it is not possible to perform this procedure in another way. In addition, they will be useful if heating the sheet material during cutting is undesirable.

Advantages of attachments over the grinder:

- High cut quality.

- The ability to make holes in the material of any shape.

- There is no need to purchase consumables (discs for a grinder).

- Simple system of use.

- Some attachments can cut certain thicknesses of plastic sheets.

- If a cordless drill is used for work, the tool becomes mobile. It is independent of the mains supply and can be operated in the field.

- Low weight.

Overview of drill bits for cutting sheet metal

Three types of attachments are used for cutting metal sheets: "Cricket", "Scissors" and "Beaver". Each of them has its own characteristics, structure and is designed for cutting material of a certain thickness.

In the process of using the scissors attachment on the drill, the rotation of the chuck on the tool is converted into reciprocating movements. As a result, a special matrix knocks out a strip in the metal and separates the material. The thickness of this line is 3.1 mm. With this method of cutting sheets, the cut is of high quality and even. The Scissors attachment allows you to completely eliminate or minimize edge finishing on metal.

The Beaver attachment works in a similar way, only with its help you can make both straight and curved cuts, the minimum radius of which is 12 mm.

The "Cricket" drill bit can be considered a versatile device, since it can be used to cut not only metal, but also plastic sheets. In some cases, it can be used for cutting profile products. The device is equipped with two cutting heads for a perfectly straight cut.

Table showing limitations on material thickness processing:

| Material type | Recommended thickness, mm |

| "Nibblers" | |

| Stainless steel | up to 0.8 |

| Brass and copper | up to 1.5 |

| Aluminum | up to 2 |

| "Cricket" | |

| Stainless steel | up to 1.2 |

| Steel | up to 1.5 |

| Aluminum | up to 2 |

| Plastic | up to 2 |

| "Beaver" | |

| Stainless steel | up to 1.3 |

| Steel | up to 1.8 |

| Aluminum | up to 2 |

Note! To efficiently cut metal using the Scissors attachment, the power of the drill must be at least 2700 rpm. The recommended indicator for the Cricket nozzle is 1500-3000 rpm (depending on the material), and for the Beaver nozzle - at least 1500 rpm.

The main types of drill bits for cutting wood

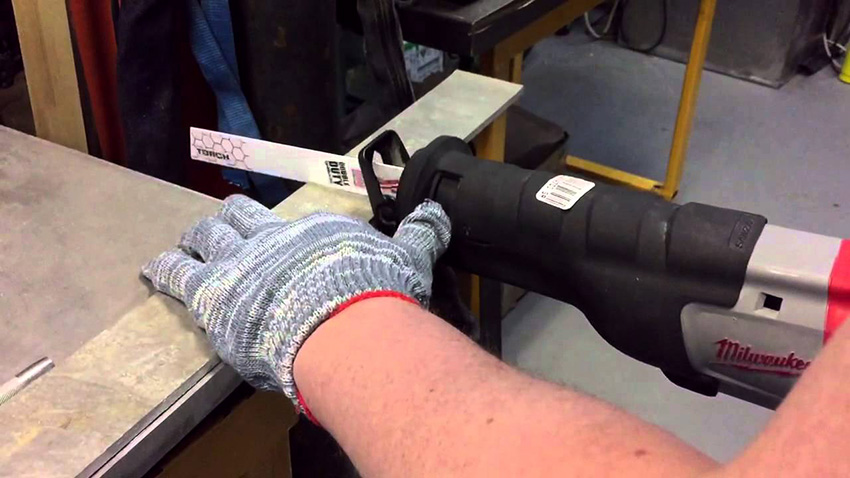

The nozzle designed for cutting wood has a rather complex structure. This mechanism is similar in principle to a jigsaw. With this device, you can cut wood, the thickness of which does not exceed 2 cm, as well as cut plywood sheets and chipboards.

In addition, the saw attachment for the drill can be used not only for wood, but also for cutting plastic and thin sheets of steel. For this reason, this device will be a very useful addition to the set of tools in the home workshop. It is worth noting that the cost of such a nozzle is very high, this is due to the complex structure of its mechanism.

You can find whole sets on sale, which include:

- the nozzle itself (mechanism);

- three saber saws of different configuration;

- Allen key for chuck.

Reciprocating saws are made of durable plastic. The removable devices in the kit differ in the length and shape of the prongs. The scope of application depends on the configuration of these products. There are such types of files:

- for cutting wood;

- for fast wood cutting;

- for cutting metal (the file is short and seated with fine teeth).

Removable plastic files are lightweight, and therefore very convenient to use. In the lock, the attachments are fixed with a special screw.

Characteristics and application of angle drill bits

The category of angle drill bits includes several types of removable devices for performing various operations. Some tips are designed to create holes where a conventional drill tool will not reach. There are nozzles with adjustable and fixed angle. In the second case, the device is rotated 90 ° and fixed in this position.

Corner fittings can also be used as restraints. In fact, this bit simultaneously performs two functions: it limits the depth of the hole formed and provides the required position of the drill, as a result of which the angle is accurate.

In addition, on sale you can find a screwdriver attachment for a drill. It has a more complex structure than the usual version. Such devices allow you to tighten fasteners (screws) at different angles.

Important! The adapter for tightening the fasteners can only be used with those tool models in which it is possible to reduce the speed of rotation.

Contra-angle bits are usually sold as kits, which include different tip diameters. Thanks to this, it is possible to install screws and screws of different sizes. In rare cases, there are removable devices that allow you to turn an electric drill into an angle grinder.

Other useful drill bits

There are many other narrowly targeted attachments that cannot be classified into general categories due to their specificity, but many of them can be useful both in construction and in everyday life. For example, drill sharpeners will keep this type of component in good shape.

Using the pump attachment on the drill, you can pump solutions and liquids from one place to another. These tools are used in combination with a very powerful drill. This type of attachments will come in handy in a private or country house in the event that an emergency arises.

Owners of suburban housing may benefit from feather-cutting drill bits. They are used for plucking wild or poultry. This does not damage the skin and meat.

All kinds of cutters will be a great addition to your home workshop. With their help, craftsmen can decorate products made of wood with relief patterns, as well as create grooves and holes, and get rid of some defects.

The list of detachable attachments for electric drills on the market does not end there. There are dozens of other adaptations to increase the functionality of this tool and add new features to it. Some of them can be made by yourself. In any case, it is imperative to adhere to safety precautions and check the reliability of the attachments.