Nowadays, along with alternative energy sources, fuels such as coal, oil or firewood are used. Many heating devices work on wood for private houses - fireplaces, ovens, boilers, etc. Until the middle of the 19th century, firewood was chopped by hand, which required a lot of time and energy. Mechanical wood splitters greatly facilitated human labor. The first models were steam-powered, very cumbersome and difficult to make at home. Today, if you need to make a wood splitter with your own hands: drawings, photos, instructions can be found on the Internet without any problems.

Content [Hide]

Features of choosing a wood splitter

If you need a wood splitter for household needs, then the first question is whether to buy a unit or assemble it yourself. The first option will cost a lot more, but the second will require some skill and tools. On the other hand, there is enough video from the network and improvised materials for making a firewood processor on your own.

Log splitter typing

In order for the drawings, photos, instructions of the wood splitter to be more understandable with your own hands, you should know what types of wood splitters exist in general. There are a large number of classifications.

One of the main parameters of the wood splitter is the location of the logs. It can be:

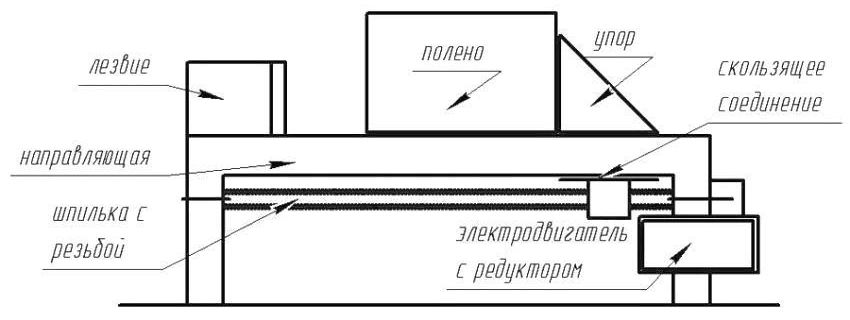

- horizontal - the logs are placed on a special bed and either move towards the cutting part, or the knife moves towards the log;

- vertical - the knife splits the workpiece from above. In this case, a fixation is needed for the log.It can be part of the structure, or the log is simply held by hands.

If you watch the video of homemade lath wood splitters, which are horizontal, it becomes clear that their efficiency is less than vertical ones, but the latter also have their own nuances of work.

The second important point by which log splitters can be classified is the type of drive:

- Diesel or gasoline fueled - the most common drive type for stand-alone wood splitter. Provides high working efficiency and is also completely autonomous.

- Mechanical wood splitters are very reliable, well suited for small amounts of work. Drawings, photos, instructions for a mechanical wood splitter with your own hands can be easily found on the Internet in large quantities.

- On an electric motor - stationary wood splitters, reliable, but not very productive.

Helpful advice! Quite often you can find home-made wood splitters mounted on the basis of tractor and other equipment. The unit, which is powered by a tractor drive from the PTO shaft, easily splits large-diameter firewood. Another interesting modification is wood splitters with an engine from a washing machine or based on a car wheel.

And the last parameter by which absolutely all wood splitters can be classified is the shape of the cleaver. There are two options here: cruciform or tapered. The cross-shaped cleaver splits the wood into four parts at once, which can be very convenient, but it takes a lot of effort. Cross-shaped cleavers can be found mainly in hydraulic wood splitters. Videos of homemade wood splitters with a cone-shaped cleaver are very often found on the network, since it is these models that are more popular.

Features of the wood splitter with a cone cleaver

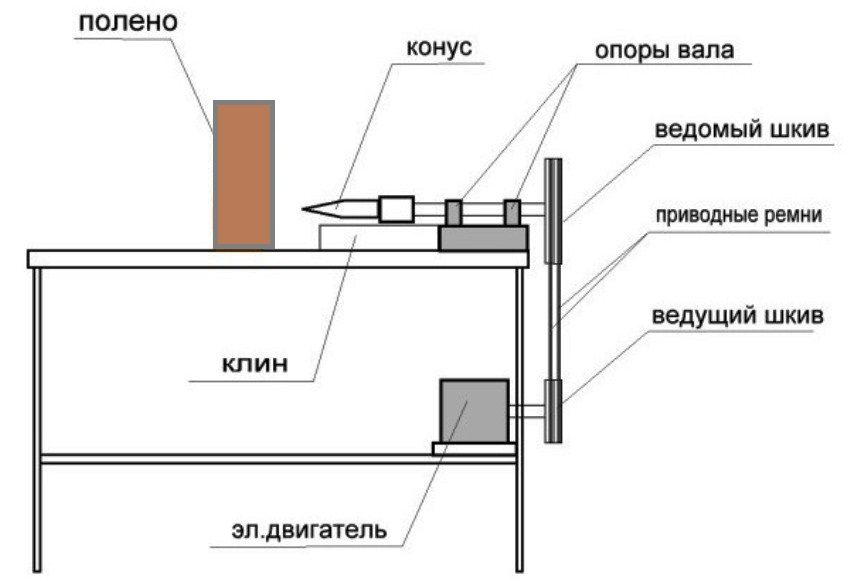

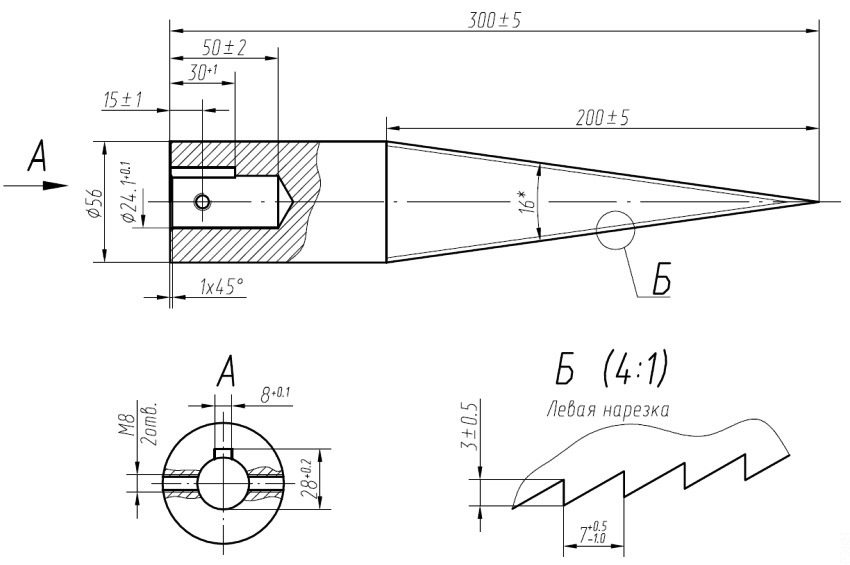

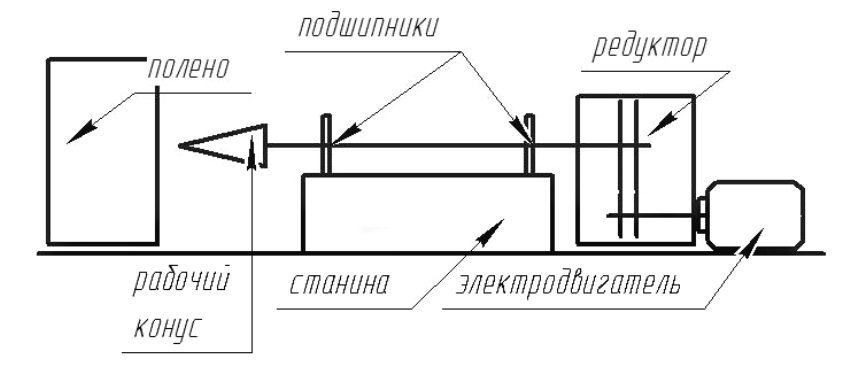

The cone cleaver, with or without threads, is often used in diesel or electric models. Its plus is that the barrel splits not only due to mechanical pressure, but also due to the rotation of the cleaver tip. It is screwed into the log, so too much force is not needed to split the workpiece. This way you save on fuel for the unit. It is very easy to find drawings of a screw wood splitter on the network, its components are not expensive, and assembly will not take you much time.

If you want to assemble a screw log splitter with your own hands - drawings, photos, instructions will be extremely simple. The main thing is to understand what main parts such an assembly consists of:

- The engine is an electric motor or an internal combustion engine. For the efficient operation of the wood splitter, the power must be below 1.5 kW, and the voltage must be from 380 V. It is also important to take into account the number of revolutions per minute, it must be at least 400.

- The bed is a table with legs on which firewood is placed. Manufactured from sheet iron, the design provides for a gearbox mount. An engine is mounted under the bed to make it more stable.

- Reducer - serves to regulate the number of engine revolutions.

When assembling a wood splitter with your own hands, drawings, photos, instructions are worth looking at, taking into account what kind of design you need. The advantage of a wood splitter with a cone-shaped cleaver is that its individual components can be bought for relatively little money, if you need to assemble a homemade wood splitter through a gearbox - a video from the Internet will help you with this. Such units are most often used to provide private houses, baths and a small boiler room with firewood. The disadvantage of this design is the need to supply firewood manually, as a result of which the productive work is not very high.

Helpful advice! If you do not need to chop wood on an industrial scale, then it is better to stop at the variant of a wood splitter with a cone-shaped cleaver, assembled from improvised parts. Otherwise, assemble the hydraulic model.

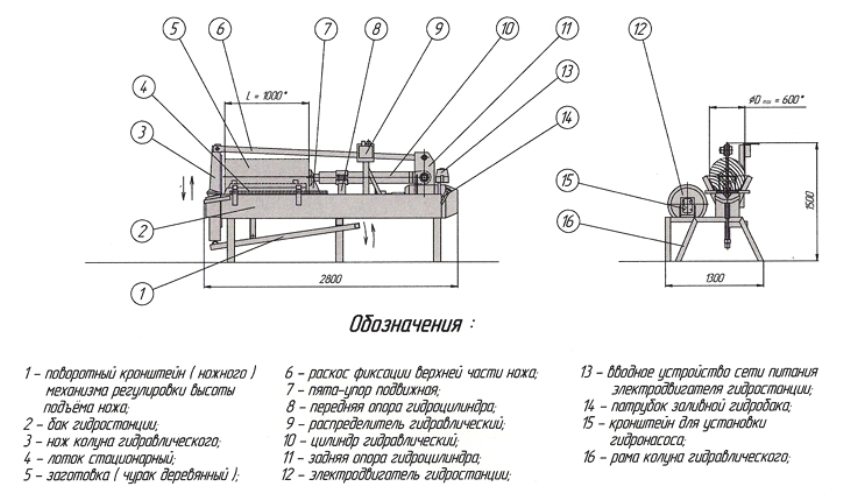

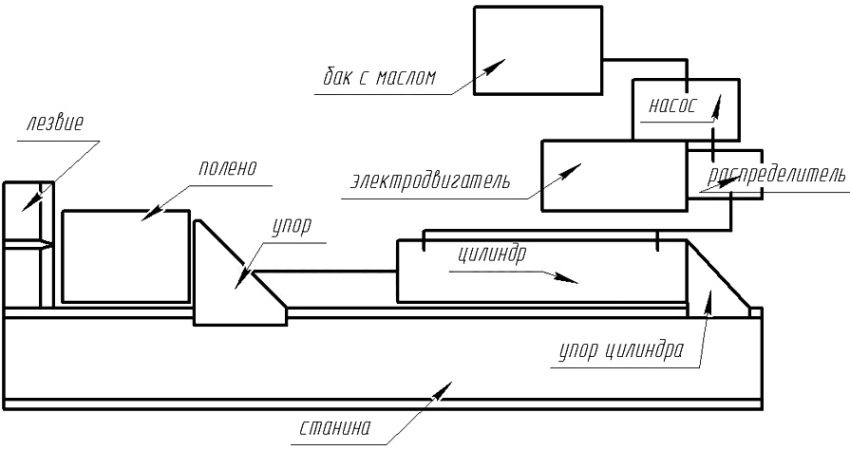

Hydraulic wood splitter

Hydraulic models of wood splitters are good because they allow you to process a large amount of firewood in a small amount of time. As the name implies, such a unit works due to a hydraulic pump and an engine. The splitter in the hydraulic model can be located in the stop structure or on the rod. The first option is more reliable, while the second is more powerful.

When assembling a hydraulic wood splitter with your own hands, it is necessary to take into account a number of important parameters:

- the location of the log - it can be vertical or horizontal;

- the maximum size of the log that the unit can handle;

- splitting force of a log - directly depends on the size of the cylinder and engine power;

- engine power - depends on what energy the engine is working on.

If you watch a video of a hydraulic wood splitter with your own hands, it becomes clear that it is more difficult to assemble it than a screw one. But the performance of this option will be several times higher. It can be used not only for home, but also for commercial purposes, for example, for chopping firewood for sale.

Drawings, photos, instructions of a hydraulic wood splitter with their own hands clearly show that, in principle, it is very similar to just a jack. This means that it is not particularly difficult to assemble it at home. The main thing in this case is to correctly calculate the size of the installation based on what size log you are going to chop.

Rack wood splitter

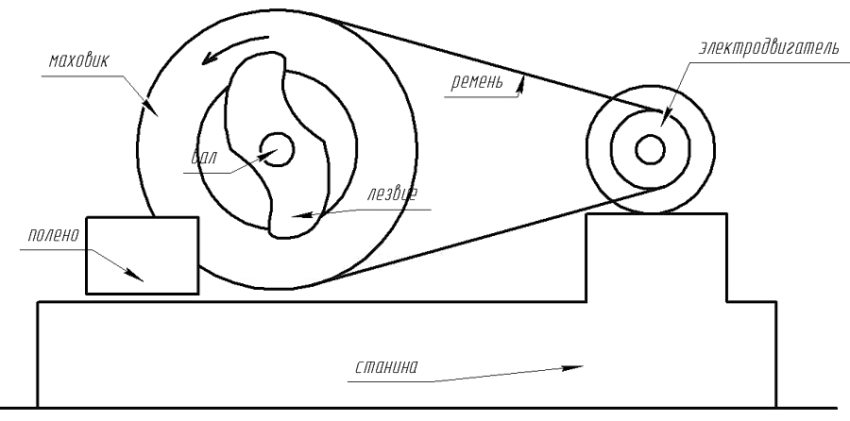

Another option for a mechanism for chopping wood is a rack and pinion. It got its name from the fact that the cleaver in such a mechanism is attached to a rack, which moves due to a gear transmission. The log is fixed here between the splitter and the protective stop located on the gearbox housing.

Related article:

Circular electric hand saw: subtleties of choice and features of work. Device, types of circular saws. Basic parameters, additional functions, selection of disks. Safety regulations.

According to the drawings, photo instructions of the do-it-yourself rack and pinion wood splitter, you can see that the split of the log occurs when you press a special handle in the structure. In this case, the gears mesh, the rack with the cleaver moves towards the log, the log splits into pieces. Its reverse movement returns the cleaver to its original position, and the split log can be removed to the place of the workpiece. For home use, a rack and pinion splitter is a very good option. It works, most often, from an electric motor, does not take up much space and does not require special maintenance.

For a rack wood splitter, the following parameters are important:

- maximum log length;

- cleaver shape - some models allow you to split the log into 6 pieces at once;

- the force with which the workpiece is split.

Rack splitters are often sold pre-assembled, but this option will cost you much more than a DIY one.

Helpful advice! Unlike rack and pinion, screw or cone wood splitters are not sold assembled. But you can separately purchase a hardened steel cone, and assemble the rest of the mechanism from scrap materials.

DIY step-by-step instructions for assembling a wood splitter

At home, you can assemble any type of wood splitter, but each of them requires a separate approach.

Assembling the screw wood splitter

In order to assemble a screw log splitter at home, you will need a splitting cone, a sufficiently powerful motor, a shaft, a reduction gear and a strong frame on which most of the parts will be attached.

First, the gearbox and the motor are attached to the frame (which must be very resistant to mechanical stress). A cone is mounted on the shaft, and the shaft itself is connected to a reduction gearbox using a motor. When assembling, it is very important to consider a number of points:

- The attachment must not be attached directly to the motor for safety reasons.

- If you do not have the skills of an electrician, then the electrical part must be installed by a qualified technician.

- The chain and belt drives must be protected by a special cover.

- The minimum rotation speed of the cleaver is 250-300 rpm.

DIY hydraulic wood splitter assembly

It is much more difficult to assemble a hydraulic wood splitter with your own hands because of the hydraulic unit.You will have to purchase a hydraulic cylinder, an oil tank, a motor for the pump and the pump itself, a fluid flow control unit from a store or on the market.

First, a frame is made of durable material.

Helpful advice! The frame is best mounted on a chassis or on wheels, so you can easily move the splitter to a new job.

Then the hydraulic part of the mechanism is mounted on the frame. There is no single instruction here, it all depends on the selected mechanisms and the required characteristics. Before taking on the manufacture of a hydraulic wood splitter, it is worth evaluating the economic benefits of this action.

An overview of the difference between factory and homemade wood splitters

As mentioned above, you can not only make a wood splitter with your own hands, but also buy it in a ready-made factory assembly. The whole difference here is mainly in the price. For example, a hydraulic wood splitter Engy Els-5030 with a splitting force of about 5 tons will cost you about 14-15 thousand rubles. And the model is more powerful, the splitting force of which is 12 tons - 85-90 thousand rubles. For that kind of money, you can easily assemble a couple of wood splitters with your own hands, then post the video on the Internet.

The main advantage of pre-assembled wood splitters is that you do not need to waste time and effort. You just buy a ready-made mechanism and use it for your pleasure. On the other hand, a homemade model can be customized to your liking. You can install any engine, any type of transmission and adjust the unit for any size of firewood. A homemade model will cost 2-3 times cheaper than the average factory one.

As for the appearance, here the self-made mechanisms are clearly inferior to the factory assembly, but when it comes to efficiency and productivity, the appearance fades into the background.

As a result, we can say that homemade models of wood splitters are much cheaper than factory ones and are great for home use. If you need to regularly chop wood on an industrial scale, then it is better to use a factory wood splitter. The choice of the type of engine, the location of the logs, the type of cleaver and other nuances depends solely on your personal needs and preferences. In addition, no one bothers you to modify the already existing model of the hand-assembled wood splitter and submit your own original model to the users' judgment.