From this article you can find out what a cutting element such as a wood router for a hand router is. The text provides a detailed classification of products: the main varieties and features of parts, their technical characteristics and practical use. The article contains useful recommendations to help you decide on the choice of cutters for hand tools.

Milling cutters for a hand milling cutter are presented on the modern market in a wide variety, which makes it possible to choose the right tool for performing specific technological operations

Content [Hide]

What is a cutterwhat is the purpose of this cutting element

The handheld router is a convenient and efficient tool designed for processing sawn timber, including shaped, as well as flat surfaces. In addition, this device is suitable for the formation of various technological recesses, for example, grooves, ridges, grooves for the installation of hinges. To do this, it is enough to buy cutters of the corresponding configuration. Each such element has individual design features and is used to perform certain functions.

Today it is not a problem to purchase both the manual router itself and the working attachments that turn such a device into multifunctional equipment.

Appointment of a manual cutter for wood:

- Edge processing - it is supposed to use a cutter for splicing wood for a hand router, when it is required to connect various workpieces together by connecting a tenon / groove.

- Inset of hinges and other accessories.

- Decoration - in this case, cutters are used to form three-dimensional shapes on the surface of flat products, as well as to make wooden blanks with a complex configuration.

Professionals know dozens of ways to use router bits on a hand router. However, in order to correctly determine the choice of cutting parts for the tool, it is advisable to study the official classification of existing products.Having figured out what cutters are and the features of their use, it will be much easier to make a choice.

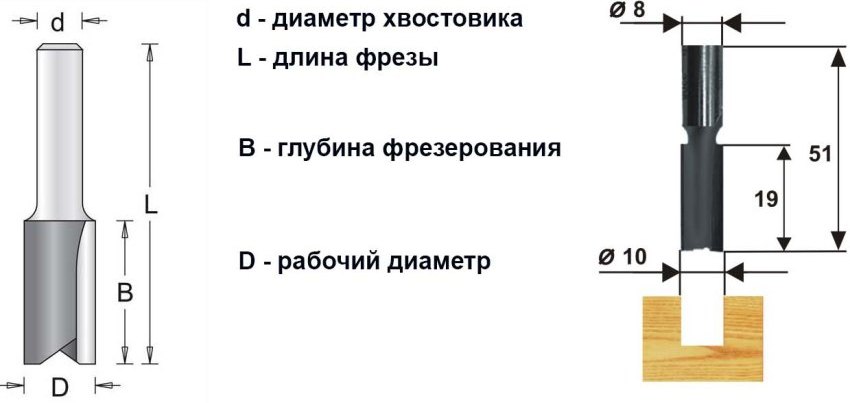

First of all, you need to pay attention to the unit of measurement of the shank diameter. For this, millimeters or inches can be used. The unit of measurement depends on the type of collet included in the cutter package. These components are for clamping the shank. If the size is calculated in millimeters, then the most common options will be products with a diameter of 6, 12 and 8 mm. If, however, inches are taken as the unit of measurement, in this case it will be possible to buy cutters for a hand router in only two sizes - ½ and ¼.

Before choosing a cutter, you must first decide on the method of its attachment, or rather, in what units the shank diameter is measured - inches or millimeters

Note! You cannot combine a millimeter shank and an inch collet and vice versa. This can damage the tool.

Types of milling cutters for a manual router for wood: types constructions

There are dozens of product options on the market with various purposes and costs. If we consider the design features of cutting elements, the following types of wood cutters for a hand router can be distinguished:

- Prefabricated - have the form of a blank with welded cutting edges. These cutters are very easy to manufacture, which is why most of the products on the market are of this design.

- With replaceable edges - the products are equipped with replaceable cutting edges with double-sided sharpening. When the knife is blunt on one side, the cutter can be turned over and used further.

- Monolithic - cutters, at the base of which the cutting edges are turned. They rarely break, but after a few sharpenings, the part will have to be changed.

With a hand router, you can create all kinds of profiles, notches or grooves using a wide range of accessories

Types of cutters for wood: product classification by blade type

Cutters can have vertical, spiral or inclined blade arrangements. Products with straight edges will be cut from the workpiece pieces of wood, which increases the likelihood that chips will appear during the cutting process. As a result, the quality of the milling is significantly reduced. This doesn't happen with slanted blades.

Consumers can buy wood cutters with two types of blades:

- High speed (HM) - used on surfaces made of soft wood.

- Carbide-tipped (HSS) - used for the treatment of hard surfaces.

Products with carbide blades have a higher temperature coefficient and have improved performance, which affects their cost.

Classification of cutters: an overview of the main product varieties

Cutters are rotary parts that are dotted with teeth. These elements are available in various configurations. Milling cutters can be used for processing metal and plastic surfaces, but most often they are used for working with wood.

There are the following types of products:

- end;

- end;

- cylindrical or slotted straight lines;

- shaped elements, which are both grooved and edge;

- disk, etc.

Useful advice! Periodically lubricating the thrust bearing can increase the life of the part.

Formation of edges, grooves and grooves of various depths and shapes - each operation has its own types of wood cutters for a hand router

Features of Wood Hand Tool End Mills

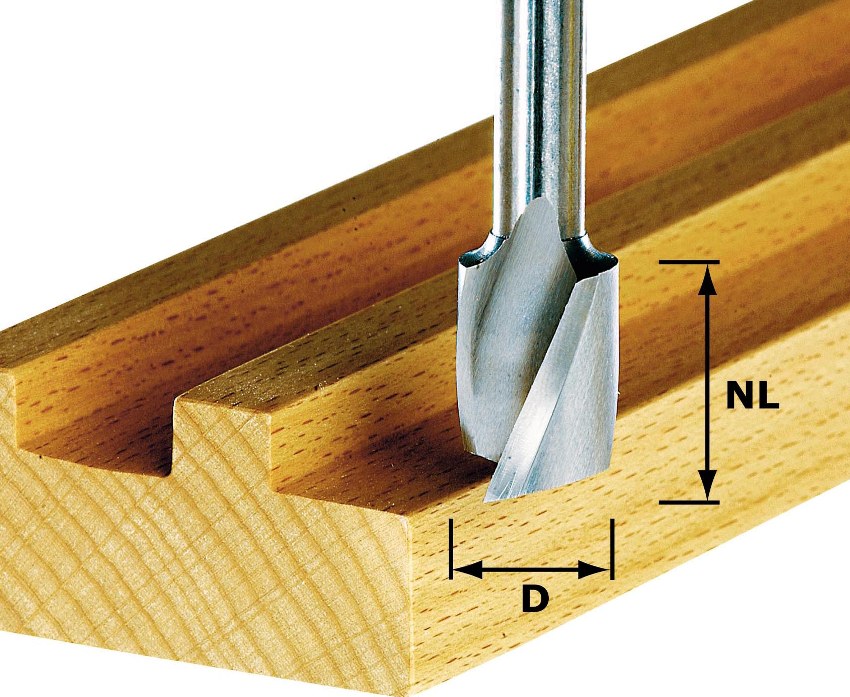

Wood Router End Mills have cutting edges on the end face of the work piece. However, they work not only due to the application of axial load.These cutters also use side edges, due to which it becomes possible to move the rotary element in the plane of the support platform on the router. As a result, it is possible to obtain different cuts and grooves in the wood. Such parts can have a different number of cutting edges, which affects the finish.

In most cases, end mills are of a monolithic design, but sometimes you can also find composite end mills, for example, crown, used as milling cutters for drills in wood. This option is used in cases where there is no hand router at hand.

This product category includes the following types of cutters:

- end;

- spiral;

- burrs;

- profile;

- conical;

- spherical.

Wood face mills are used to form grooves of various configurations and sizes. They are not only suitable for making wood products, but also for making tenon / groove joints. Therefore, end mills are often classified as grooved products.

Profile cutters represent an extensive group of accessories for the following tasks:

- end part processing;

- the formation of grooves with a complex configuration;

- surface decoration with ornaments.

Wood cutters have another name - cutters. They are designed to make holes with a specific configuration. Such cutters are used at an intermediate stage of processing. In addition, with their help, you can make the final configuration of some parts.

Classification of wood bevelling cutters for hand router

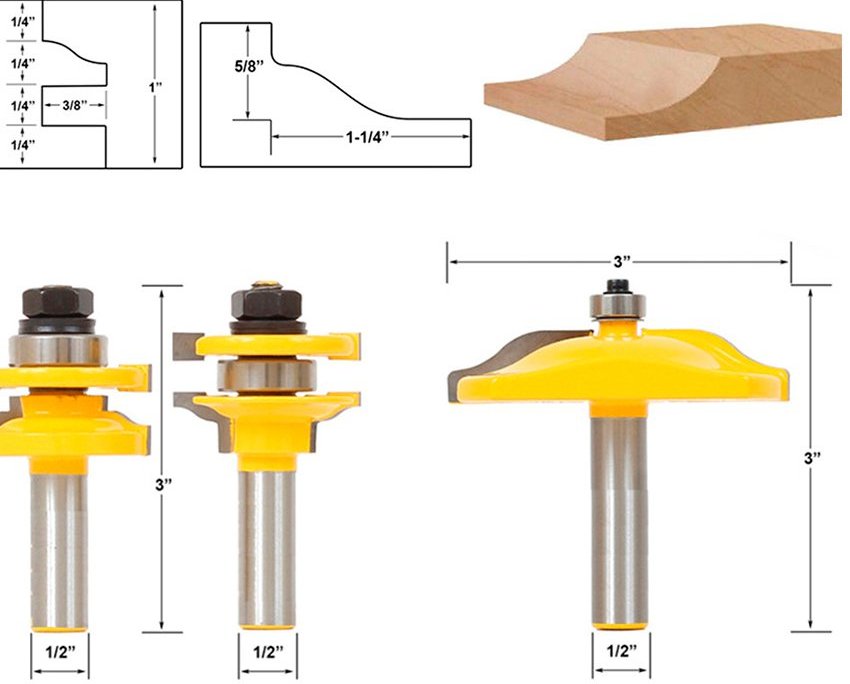

Edge cutters are the most common group, since hand tools are most often used specifically for making edges on products made of wood. Even in large sets, edge mills represent the bulk of the parts. This option is more preferable for DIYers. It is easier to buy a set of wood cutters for a hand router than to select these elements one at a time.

This group includes:

- profile - to give an intricate shape to the edges of the product;

- molding or shaped - to round off the edge, while obtaining a convex shape on ¼ of the circle;

- conical - designed for chamfering at an angle, the most common option is 45 °;

- disk cutters for wood - for the formation of grooves in the edge part of the product;

- folded - designed for sampling a quarter in the edge part of the product;

- fillet - used to make grooves in the edge on a ¼ circle;

- figrean - intended for the manufacture of panel edges.

In most cases, bevelling cutters are equipped with a thrust bearing. This element limits the movement of the tool, preventing it from sinking into the wood. In this case, the cutting part of the part can be located above or below the bearing. By setting the tool support platform to a certain position, you can adjust the depth of the cutter overhang.

Useful advice! If the cutter makes large cuts, it is advisable to carry out the processing of the product in several stages, each time deepening it into the material until the support bearing works.

In some cases, there is no bearing in the cutter design. To work with such a part, you will need a template and a copying sleeve or a parallel stop. The size of the molding cutters depends on the cutting height. If the profile has several roundings, then the manufacturer indicates the dimensions of the largest diameter that can be obtained using such a part. Moreover, the distance between the cutting parts can be adjusted at your discretion.

Horizontal figurine cutters with a large working diameter are designed for decorative processing of panel edges

Figurine cutters of the horizontal type have a large diameter and weight. These elements require a lot of cutting force, for this reason they are made exclusively with a 12 mm shank. These cutters are designed for the stationary router design.

Related article:

Manual wood router: features of the tool and its scope

TOaccessories, instruction manual. Recommendations for the choice of designs and an overview of the best models.

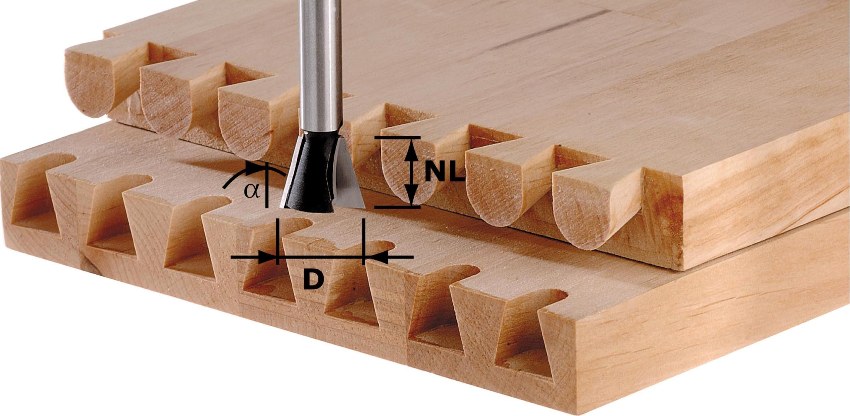

Classification of groove cutters on wood for a hand router

The main purpose of the groove cutter for wood is to make grooves in the wood - grooves.

There are several types of such cutters:

- fillet - these parts are intended for the manufacture of semicircular grooves;

- tapered - elements are used to thread flat surfaces;

- spiral cutters for wood for a hand router - in many ways they are similar to end elements. However, they have a more pronounced cutting edge located on the outside. In fact, the design of a spiral cutter for wood resembles a drill;

- T-shaped cutters for the formation of grooves of the corresponding shape;

- elements of the "dovetail" type;

- shaped;

- groove straight cutters for wood - cylindrical parts that form a groove with a rectangular section;

- combined - cutters are used to connect large wooden panels.

The combined elements include dowel / groove cutters. Most often, such elements have a monolithic design, however, there are also options equipped with carbide cutting edges. They are used for splicing workpieces.

Copy cutters or straight cutters are the smallest group of accessories for a hand router. Between themselves, these parts differ in the number of cutting edges, sizes, as well as the nature of the placement of thrust surfaces and bearings, which can be located both above and below. There are also options with two-sided placement in relation to the cutting part. During operation, the bearing moves in a pattern, which makes it possible to obtain a part of the required configuration from the workpiece.

The head of fillet cutters has a rounded shape. The resulting cutaway groove looks like the letter "U". The walls of the recess can be rounded immediately at the surface itself, or they can be located at right angles for some time. It depends on the depth of cut.

Note! Although the “fillet” is considered a semicircular notch, this category also includes cutters that form a V-shaped groove. If in the process of work it is necessary to make grooves with different angles of inclination of the walls, it is advisable to have an appropriate set of wood cutters for a hand-held router, where there are cutting elements of different configurations.

Wood router bit for hand router: choosing the optimal set for the job

Buying the right woodworking tool is not a guarantee of excellent results. In order for the processing of the material to be accurate and of high quality, it is advisable to purchase good equipment. For these purposes, sets of wood cutters for a hand router are intended, which include a set of cutting parts suitable for performing certain jobs.

When choosing cutters for a wood router, you need to pay attention to their shape, the type of hole being made and, accordingly, the scope of application depends on it

What is better to buy wood cutters for a hand router

When choosing equipment for a hand router, you need to pay attention to the main criteria:

- Workmanship.

- Thermal strength level.

- The type of connection between the cutting part and the shank.

- Solder material.

Before purchasing a set of wood cutters, you should pay attention to the quality of the soldering. It must be made so that during long-term operation the tool does not lose its longitudinal stability. This is especially true when the work uses products made of hard wood, for example, pear, hornbeam, oak, etc.

Solders of the following grades are considered to be of high quality: PSr 37.5 and PS r40. They are characterized by a high content of copper and silver. If a different brand of material is used to solder the plates and the shank, it is most likely that it contains nickel, which does not provide the required level of strength of the joints. It is not allowed to use elements in sets of cutters for a hand-held milling cutter, in which the working cutting part is welded to the shank. This kind of rig is not the best option.

Monolithic cutters also need to be checked for the hardness of the material of manufacture. This operation can be done at home. To do this, it is enough to walk over the working part of the cutter with a tared file. If no visible marks remain on the surface, then the element is made of quality material. The optimum hardness is 58-62 HRC.

Note! The quality of work also depends on the availability of additional devices. Therefore, it is advisable to purchase a set of templates and stops.

An overview of the Encore router bit catalog for a hand router

Very often, manufacturers offer craftsmen to purchase a ready-made kit designed to perform the same type of work. For example, some Encor wood cutters for a hand router are combined into sets that allow you to get a certain result. These kits are used to make identical joints or wood products. Moreover, in the second case, the cutters allow you to complete a full processing cycle.

In the catalog of Enkor cutters there are sets with different numbers of elements. For example, a set of two combined 12mm shank frame cutters can be used to create frame products. These elements are not only designed to form the inner edge. They can be used as corner jointing cutters for hand router.

Enkor cutters are made of high quality materials and are characterized by precisely calculated cutting edge geometry

With this set, you can create not only frame products, for example, thin window frames, but also splicing wooden boards into large boards.

Of course, each of the cutters of this set can act as an independent element, with which you can perform other operations for processing wood products.

Consumers can buy a set of Enkor wood cutters for making lining. Using these elements, you can form the edge of wood products, which can later be used for interior decoration. In addition, the manufacturer offers sets of decorative cutters, which can include from 4 to 12 elements with different configurations. The average price of the sets is in the range from 1370 to 8300 rubles.

An overview of the catalog of cutters for wood for the CMT hand router

The products of the Italian manufacturer CMT are in high demand among consumers. On sale are individual cutting elements and whole sets designed to perform various jobs.

SMT (Italy) - a premium brand known all over the world as a manufacturer of high quality woodworking cutting tools

The catalog contains the following types of CMT cutters for wood for a hand router:

- groove and end;

- overtaking;

- for furniture strapping and splicing;

- disk;

- T-shaped and "Dovetail";

- paneled;

- edging molding;

- profile;

- jointing and chamfering.

The kits offered by the manufacturer are designed for specific types of work or for the formation of specific joints. The buyer can purchase a ready-made kit designed for the manufacture of doors, furniture facades, wall paneling, strapping and various bindings. The cost of the sets varies from 5610-63000 rubles.

Cylindrical cutter of the CMT brand for wood, for cutting thorns (the most famous modification is "dovetail")

Buying hand-held wood cutters: the price of popular types of products

Wood cutters are suitable not only for the manufacture of solid wood products. These elements can be used to process lumber such as plywood, chipboard, veneer, fiberboard, etc.

Average prices for Encor cutters:

| Type of cutters | A type | price, rub. |

| Slot | Fillet V-shaped | from 185 |

| Direct | from 189 | |

| Shaped | from 190 | |

| Structural T-shaped | from 202 | |

| Structural | from 206 | |

| Fillet | from 212 | |

| Edging | Direct | from 220 |

| Kalevochnye | from 287 | |

| Conical | from 352 | |

| Folded | from 405 | |

| Semi-rod | from 519 | |

| Fillet | from 550 | |

| Curly | from 615 | |

| Cultivating adjustable | from 1500 | |

| Multi-profile | from 1570 | |

| Combined | Universal | from 1130 |

| Framework | from 2160 |

The existing range of accessories for the hand router has several classification options. These products differ in design, structure of the teeth, as well as the material of manufacture. By choosing a cutter with the required characteristics, you can create an edge, grooves, ledges, grooves and other elements of the desired size and configuration in a wooden blank. In addition, cutting parts are used to install various functional and structural elements. For example, hinges, locks, latches.