Insulation of walls of buildings and premises is a very topical issue in modern conditions. This has many benefits such as conserving heat in the home, creating a cozy atmosphere and saving on heating costs. This is especially true for northern latitudes, but it may make sense in milder climates. It is possible to mount a layer of insulation not only during the construction of a new house, but also to increase the heat-saving characteristics of an already finished building. For these purposes, you can use time-tested materials such as stone or plaster, or you can keep up with the times and mount insulation for the walls of the house outside under siding.

Content [Hide]

Types of materials and their features

There is an opinion that only brick or panel houses need insulation. However, in wooden houses, with all the advantages of the material, the standard thickness of the logs is usually not enough in order to significantly save on heating. Four main types of materials can be used as insulation for the walls of the house outside under siding:

- Styrofoam;

- mineral wool;

- ecowool;

- penoplex.

Each of these materials has its own advantages and disadvantages, as well as installation features.

Polyfoam - easy to install and cheap insulation for the walls of the house

If you use polystyrene as a heater for the walls of the house outside, you can significantly save money. This material is lightweight and tough at the same time, so it can be simply glued to the wall with construction glue. Another option for fixing foam panels is disc dowels.

Unfortunately, the lightness and ease of installation, the useful properties of the foam as insulation, come to an end. And the question of saving is sometimes very controversial, because mineral wool is getting cheaper every day. The ventilation characteristics of the material also leave much to be desired. If you use it as a heater for the walls outside, then keep in mind that you will additionally have to organize mechanical ventilation to remove excess moisture from the house.

You can often hear that foam as insulation works as excellent sound insulation. This is also not entirely true. It insulates walls from external noise no better than other insulation materials, moreover, if it is fixed too rigidly, then it will act as a sound-amplifying membrane.

Useful advice! It is not very rational to use polystyrene as a heater for living quarters, but it is perfect for insulating engineering communications or the floor. In such cases, its low thermal conductivity and minimum water absorption rates will have to be in place.

The service life of foam panels is 10-15 years, like all polymers. After this period has expired, it may simply collapse, and you will have to install a fresh layer of insulation for the walls of the house outside under the siding.

As can be seen from all of the above, polystyrene has a number of useful properties for insulating various communications, but is poorly suited for thermal insulation of residential premises.

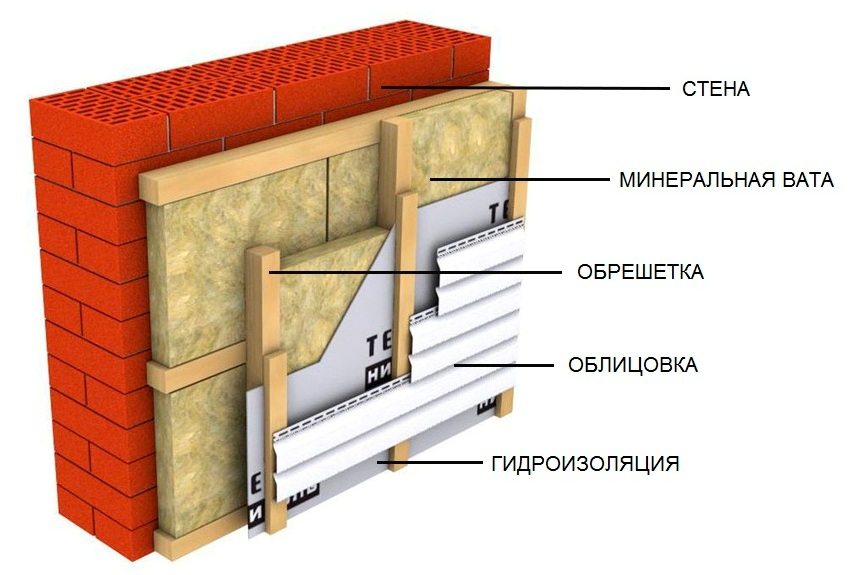

Insulation of houses outside with mineral wool for siding

Mineral wool, like ecowool, is a versatile material for insulating houses and is great for wooden, block or brick walls. Mineral wool and ecowool are materials that are very similar in their characteristics and properties, therefore, below we will consider their common features.

If you are interested in the price of insulation for the walls of the house outside, then mineral wool can cost a little more than polystyrene, but this is more than offset by its excellent performance characteristics. It works very well with plastic or metal siding cladding. If you are using a wooden crate for siding or an iron frame, then remember that you do not need rolled mineral wool, but semi-rigid slabs. The optimal size of slabs for facing is one meter by half a meter. This is due to the fact that it is more difficult to fix mineral wool or ecowool in rolls, and over time it can slide down the wall, revealing its individual sections.

Mineral wool is a material that is quite dusty. In order to avoid this, you can additionally protect the boards with a vapor barrier film. It will perform two functions: not letting small particles of cotton wool into the air and letting in water vapor well, which, in any case, will penetrate from the walls of the house.

If we consider the question, what insulation the best for the walls of a wooden house outside under siding in terms of environmental friendliness of the material, then ecowool is in the lead. It is made from cellulose, but with the use of special additives that increase its level of fire resistance and corrosion resistance.

Ecowool, however, has one significant drawback - it is produced only in a format that requires use to install it on the walls of special equipment. There are still no panels on sale that could be fixed to the wall with construction glue or dowels. But if you look at the photo of finishing houses with siding using ecowool, you can see that it fits very tightly to the walls, does not float over time and does not deform.

According to the parameters of sound and heat insulation, mineral wool and ecowool are identical. Due to their loose structure, they perfectly contain sound waves and do not release heat from the house. When insulating a brick house outside with mineral wool for siding, you get rid of the problem of noise from the street, even if you live near a motorway or in a busy place in a big city.

Useful advice! If you are comparing the price of such heaters for the walls of the house outside under the siding, such as ecowool with foam or mineral wool, then here it is also worth considering the cost of application. For ecowool, it is quite high.

If you need to familiarize yourself with the video of wall insulation outside with mineral wool for siding with your own hands, then you can easily find it on the Internet. Videos with the participation of experts will help you better understand the nuances of installing insulation.

Subtleties of house insulation outside with foam

Penoplex - This is a relatively new material, which, in terms of its performance characteristics, can give odds to all of the above materials. It differs not only in high rates of thermal insulation, but also in versatility in application. If you are interested in the question, what is the thickness of the Penoplex insulation for frost 30 degrees. is optimal, the answer will pleasantly surprise you. Due to the high efficiency of extruded polystyrene, which this special type of foam is composed of, a very thin layer of material is needed for reliable wall insulation. In addition, it has a low vapor permeability and water absorption, so you can not be afraid that the walls will "sweat".

Related article:

Wall insulation with foam. External and internal cladding technology. Wall covering. Preparatory stage of work, adhesives, installation of plates on glue and nails, reinforcement of insulation.

Another advantage of foam is a high level of corrosion resistance. It is also absolutely harmless to human health. Plus, it's very easy to mount. The disadvantages of the material include high flammability, therefore, if you plan to insulate houses outside with foam, it is better to take care of increased fire safety measures.

At the moment, there are 4 types of penoplex:

- roof - used for insulation of various types of roofs;

- comfort is a universal type that is most often used for insulating private houses;

- foundation - used in loaded structures, can be used to insulate the basement base from the outside;

- wall - can be used for external orinternal wall insulation.

There are also special super-dense types of foam that are used in industry.

When insulating with penoplex, the video helps a lot: how to insulate a house outside with penoplex with your own hands under siding.

Insulation for the walls of the house outside under siding: installation stages

Regardless of whether you need to insulate outside under the siding of a log house, brick or block, you must adhere to certain installation rules.

- Step 1. The surface to be insulated must be prepared. All old cladding should be removed from the walls, as well as shutters, drainpipes and other structures that may interfere with the installation of insulation should be dismantled. If you use a frame for siding from a profile, then the coating will be even in any case, so there is no need to align the walls;

Useful advice! If the walls of your house are old and have many cracks and defects, then installing insulation for the walls of the house outside under the siding, you simultaneously increase the thermal insulation properties of the building and improve its appearance.

- Step 2. Installing the lathing for siding with insulation is a very important stage of installation. It can be made from metal frames or wooden blocks. The first option will cost more, but it will last longer. The thickness of the lathing and the distance between its elements depends on the size of the insulation. It is recommended to additionally cover the wooden lathing with a fire retardant to increase the level of fire safety of the building. Horizontal siding should be mounted vertically and vertical siding horizontally. The accuracy of the design is adjusted using the building level;

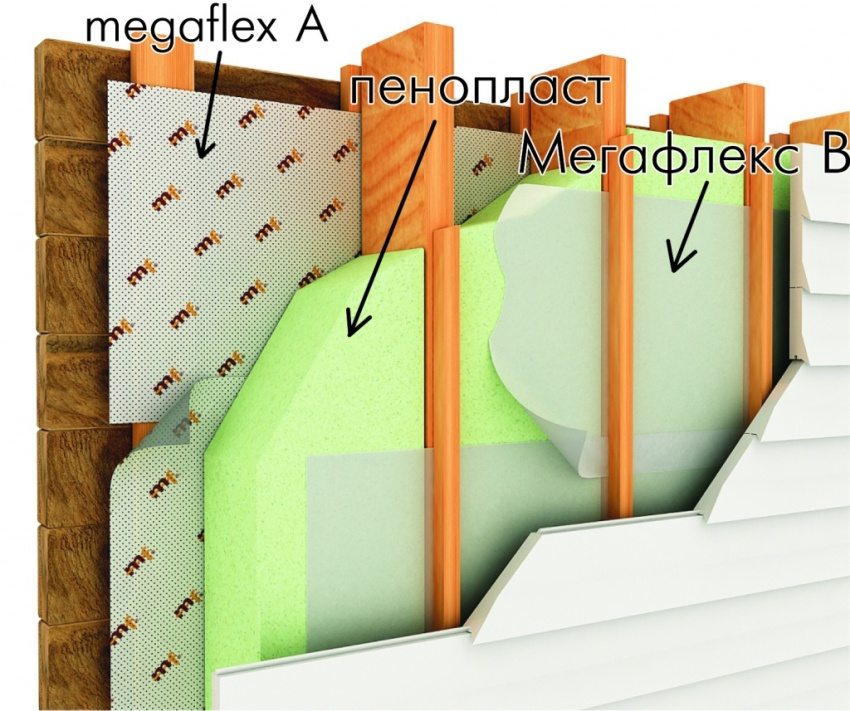

- Step 3. The next step is to insulate the wooden house from the outside under the siding with mineral wool or other material. The main thing here is to ensure the most tight fit of the material.For fastening, construction glue or dowels with a large head are used. On top of the insulation, waterproofing is mounted, which serves to remove vapors from the insulation. Usually, a special membrane is used for this, which is attached directly to the crate;

- step 4. Siding installation - this is the final stage. If you are in doubt about how to do this correctly, then a photo of decorating the house with siding outside will help you.

Step 4: choosing the right look siding for subsequent cladding of the facade of the building

Regardless of the type of material chosen, house insulation for siding will allow you to significantly save on heating and improve the appearance of the building. Buying insulation for the walls of the house outside is a very important point, so you should first familiarize yourself with the features and performance characteristics of each of the materials.