Correctly selected and installed toilet fittings ensure the smooth functioning of the flush system. The quality of plumbing work largely depends on the design of the tank, its technological features, as well as fittings. Therefore, this article examines the main types of toilet accessories with side, top and bottom piping. In addition, the text contains recommendations for the selection and installation of various valve components.

The efficiency of the flush tank depends not only on its technological features, but also on correctly selected fittings

Content [Hide]

Toilet fittings: its main types and general plumbing arrangement

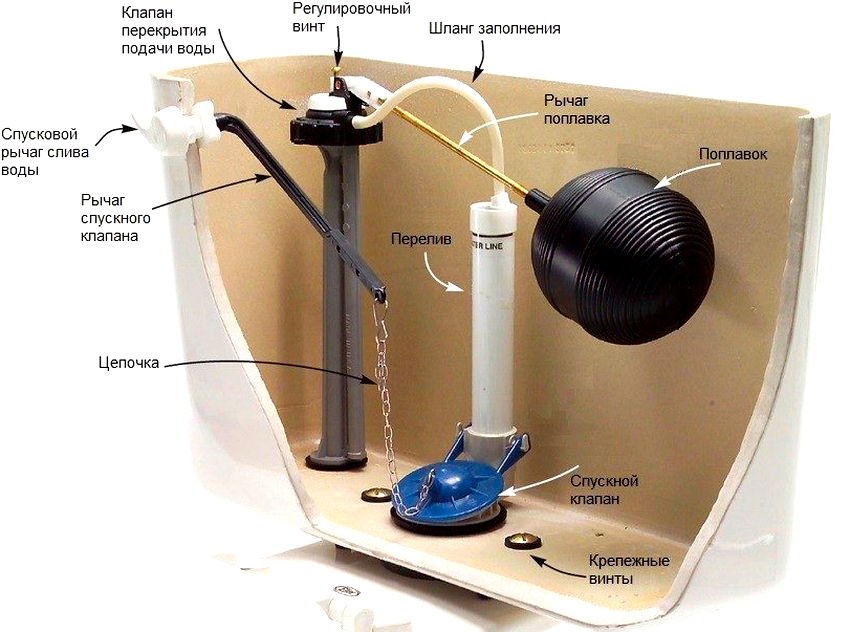

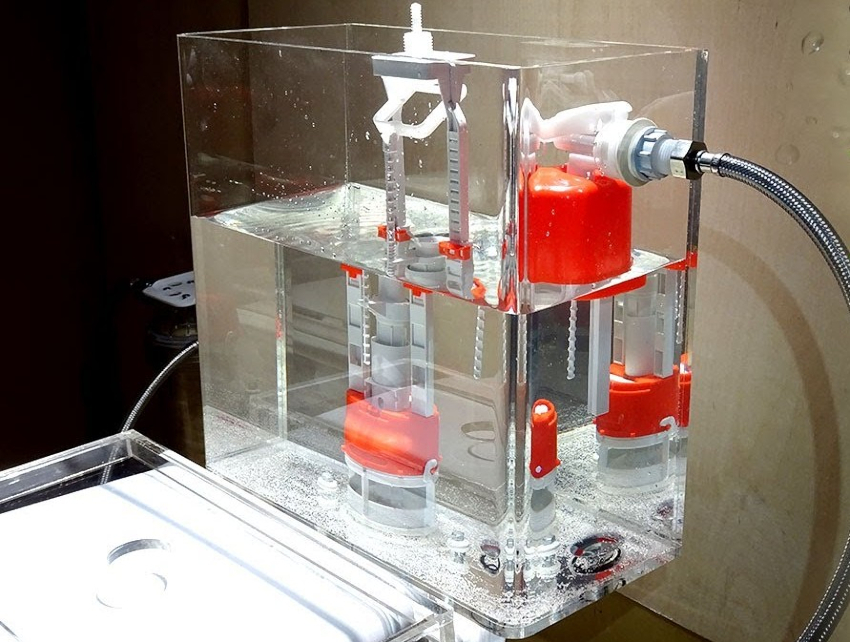

The fittings installed in the cistern are designed to fulfill several functions. Some parts help to fill the container, others are responsible for draining it, and still others prevent overflow.

The unit, which provides filling the tank with water, uses a flexible tube to supply liquid. This type of fittings is equipped with a special valve that triggers at the right time and closes access. The operation of this element depends on the position of the foam float.

The main component of a toilet flush fitting is a valve installed on the flush hole. When the user presses the trigger or release button, there is a thrust that sets him in motion.

The overfill or overfill protection is a safety device. This part is a hollow plastic tube. It is installed in a vertical position in the tank.

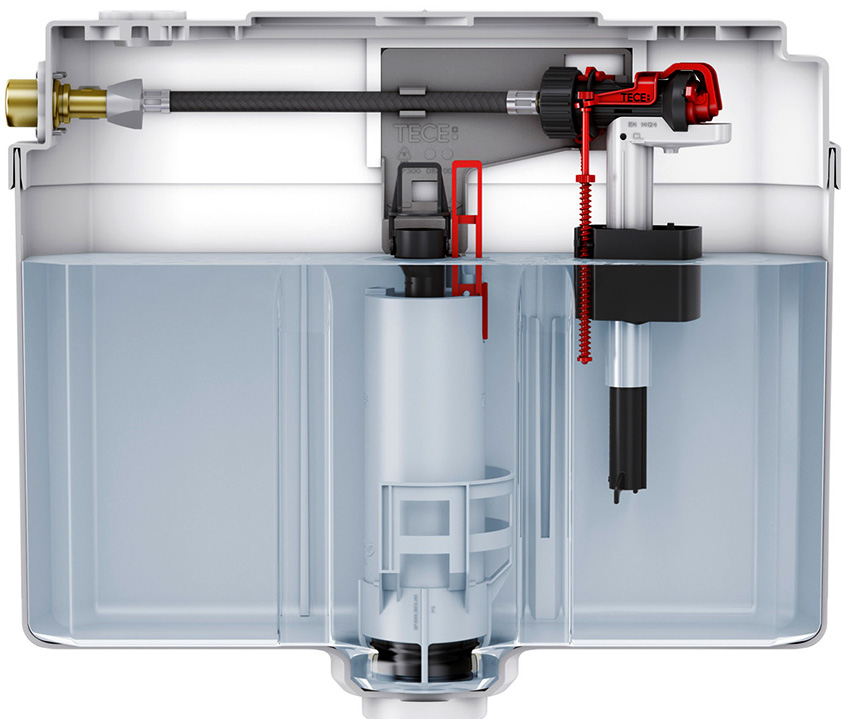

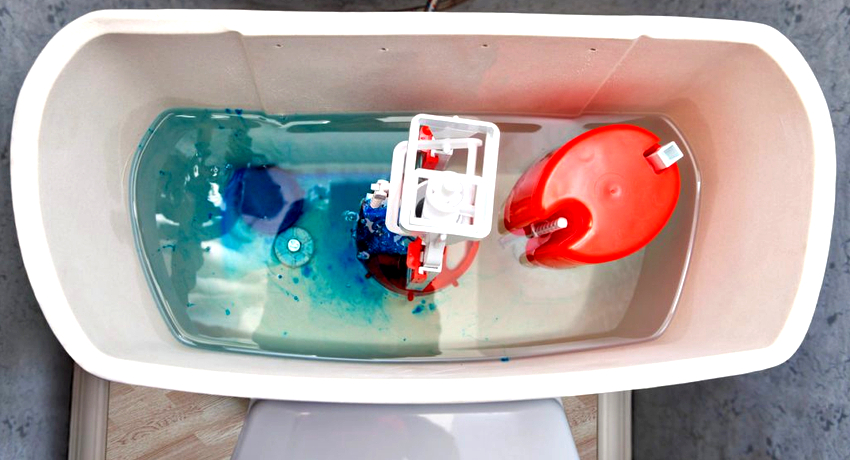

The main equipment of the toilet: the inside of the cistern

Inside any tank there are fittings that control the work of plumbing. In many models of toilets, a set of necessary nuts and fasteners is supplied with the fittings.

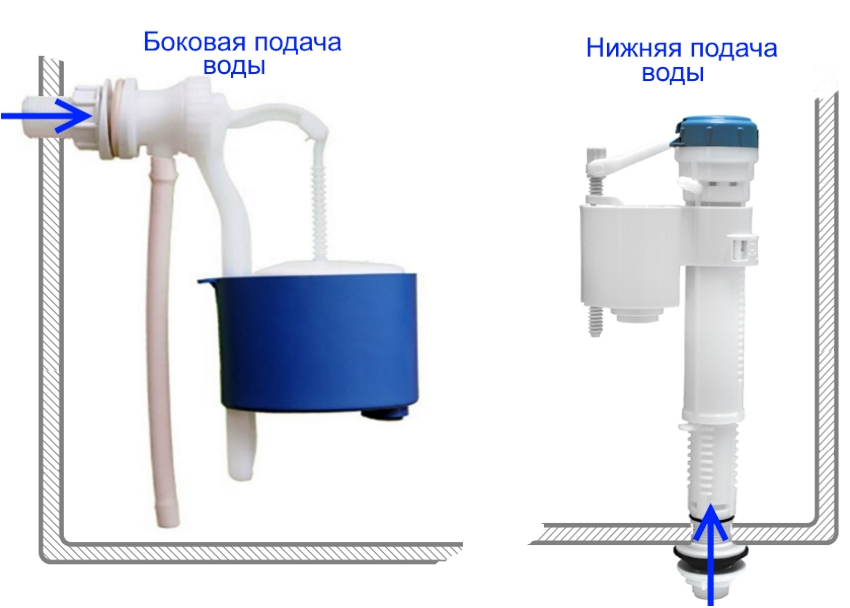

According to the method of supplying liquid, the following types of fittings (liners) are distinguished:

- bottom;

- top;

- universal.

The top line is installed on the side of the tank. In this case, a flexible tube that provides fluid supply is connected from the top.

Note! Before assembling the toilet, you need to make sure that the components and plumbing are compatible. Not all types of cisterns allow the installation of a top connection. This mainly applies to foreign-made sanitary ware. Domestic companies produce toilet bowls, which provide for the possibility of arranging the upper eyeliner.

According to the method of supplying water to the tank, such types of fittings are distinguished as lower, upper, universal

Foreign-made cisterns are mainly equipped with fittings with a lower connection. Despite the fact that the parts are made of plastic, the quality of all components is very high.

The universal eyeliner is very convenient, as it allows you to organize the supply of water both from below and from above. Having decided on the type of installation, the unused hole is simply closed with a special plug. It is supplied complete with fittings.

According to the material of manufacture, the following types of fittings are distinguished:

- plastic;

- metal (for production, an alloy of brass or bronze is used).

Most of the tanks use plastic structures. If individual parts are out of order or worn out, then buying toilet fittings is not difficult. There is a huge variety of plastic products in all plumbing stores. Even if the desired option is not on sale, you can always replace the design with a new one. The cost of plastic parts is much lower than the price of metal parts.

How to choose a toilet cistern separate from the base: types of plumbing fixtures

There are many types of toilets, which differ from each other in appearance, pressure, the way the tank is installed, the drain mechanism and other parameters. These designs can even have a different direction of discharge. There are toilets with side flush, as well as vertical and horizontal.

By the nature of the placement of the tank in relation to the base, the following types of toilets are distinguished:

- monoblocks;

- compact;

- corner;

- separate.

Unlike other varieties, separate plumbing fixtures are not rigidly bound. In such models, the user can choose the type of cistern for his toilet.

Toilet tanks are classified according to different criteria:

- installation method;

- material of manufacture;

- the option of connecting to the water supply system;

- the area where the trigger or button is located.

According to the method of placing the cistern, the toilet bowls are divided into monoblocks, compact, corner, separate

In addition, cisterns vary in cost. In stores, you can buy budget models of domestic production or exclusive products with a unique design of the elite class.

According to the material of manufacture, tanks are:

- faience;

- cast iron;

- plastic.

At the same time, flush fittings for toilet bowls are almost always made of plastic (even in expensive models). The most common are considered to be tanks made of earthenware. Plastic options are characterized by a flattened shape. This type of product is used in wall-hung toilet bowls.

Note! The flattened tanks take up much less space, which allows them to be built directly into the wall.

Plastic structures are quite reliable. They have a long service life and do not require complex care and maintenance.

Cast iron tanks are considered obsolete and extremely rare. They are too bulky and heavy, moreover, they look unpresentable.Cast iron tanks are still used in Russia, but the population is gradually switching from them to more modern options.

The cistern can be installed in several ways:

- Top mount - used in retro-style bathrooms.

- Embedding in the wall - the tank is completely hidden in the wall, which allows you to make the interior of the room more harmonious and hide the plumbing fixtures as much as possible.

- Installation on the shelf of the bowl is a traditional installation option, it is used in cases where the base and the tank are paired.

The toilet cistern is installed in several ways: by top fastening, built-in into the wall, installation on the shelf of the bowl

The main types of valves for toilets and prices

The design of valves can be combined or separate, with the first option appearing relatively recently. The split configuration assumes that the installation of the toilet flush and shut-off valve will be carried out separately. Each of these elements works offline, independently of each other.

The shut-off valve is float controlled. When the water level in the tank rises, this element blocks the fluid supply. The main component of the drain assembly is the neck, which is equipped with a mechanical or air valve. The drain is controlled by pressing the pedal, lever, button or key.

The split configuration has one major advantage. If one of the components is out of order, it is not necessary to completely replace the insides of the toilet bowl - it is enough to repair or update the damaged area. This design not only simplifies the installation and dismantling of parts, but also reduces the cost of eliminating the breakdown.

In the most recent models of toilets, as well as elite-class plumbing fixtures, combined fittings are installed in which the shut-off and drain valves are combined into one structure. These components are completely dependent on each other. If the combined fittings fail, it will not be possible to replace one of the valves. In the event of a breakdown, you will have to completely dismantle the system and carry out complex repair work.

Important! The installation of the mechanism with the upper connection is carried out after the tank is installed in its place. Arrangement of fittings with a lower type of attachment begins before placing the tank.

Purchase of fittings for the toilet: prices for products from different manufacturers:

| product name | price, rub. |

| Toilet fittings "Incoer" | |

| Side diaphragm valve, 1/2 | 300 |

| Side float valve, 1/2 | 500 |

| Luxurious side float valve, 1/2 | 800 |

| Toilet fittings "Alkaplast" | |

| Side valve | 450 |

| Bottom valve | 520 |

| Metal threaded side valve | 550 |

| Bottom valve with metal thread | 610 |

| Geberit toilet fittings | |

| Bottom valve, 3/8 (hole size 16 mm) | 1150 |

| Bottom valve 3/8 (hole size 20mm) | 1180 |

| Bottom valve 1/2 (hole size 20mm) | 1200 |

| Siamp toilet fittings | |

| Side valve 1/2 | 1600 |

| Side valve 3/8 | 1800 |

Characteristics of valves for a toilet bowl with a lower connection

Fittings with a bottom type of installation are usually mounted in foreign-made toilets. These designs do not create a lot of noise, and therefore they increase the comfort of using the plumbing fixture. Toilets with a bottom piping system look more stylish than top-piped models.

The bottom piping system consists of the following components:

- a float that regulates the process of supplying liquid to the tank;

- trigger device;

- guide (the float moves along it);

- O-rings (used to seal the structure during the installation of valves);

- intake valve.

The principle of operation of valves for a toilet with a bottom line is quite simple. This system maintains the required fluid level in the reservoir. When the container is full, the valve closes the tap and stops the water supply, and after draining, it opens it again.

Related article:

Toilet flush mechanism: the principle of operation and the basics of repairing the device

Varieties of internal tank fittings. Dismantling, installation and adjustment of the mechanism. Troubleshooting.

There are two types of filler assemblies:

- Push-button - the liquid is drained automatically when the button is pressed.

- Rod - the water is drained in the same mode, but one push of the button will not be enough. In this case, the design provides for the presence of a handle, which must first be pulled up and then returned to its original place.

The push-button version is considered more practical, therefore it is used by manufacturers more often.

Advantages of valves for toilet cistern:

- high degree of reliability;

- there is rarely a need for repairs;

- allows you to hide the inlet hose;

- works silently;

- long service life.

This option of fittings is not without its drawbacks. The installation of the system is very complicated. If a breakdown occurs, it is easier to replace the cistern fittings than to repair individual parts.

Note! For the push-button mechanism to work properly, the release button should not protrude above the surface of the structure. The optimum opening size is 40 mm. This value is applicable for round mechanisms. Some models of toilets have rectangular or oval buttons.

Characteristics of shut-off valves for a cistern with a side connection

In domestic-made plumbing fixtures, a system with an upper (side) connection is mainly installed. In this case, the supply hose is not attached to the bottom of the tank, but to the side, and it must be located above the liquid level in the filled tank.

The main components of fittings for a toilet cistern with a side connection:

- inlet valve supplying water;

- float (connected to the inlet valve using a lever);

- trigger mechanism;

- a lever designed to control the trigger.

The trigger for the side fittings can be push-button or rod.

The principle of operation of fittings for a toilet with a side connection:

- After pressing the button, a draft is formed, which opens the drain valve.

- When draining occurs, the fluid supply to the draining mechanism is shut off.

- When the water in the tank reaches the minimum limit, the release mechanism is triggered, which blocks the drain.

- Then the float hole opens.

- The vertically located valve returns to its place and closes the passage through which the descent is carried out.

- When the level of liquid in the tank drops, the float is lowered along with the water. As a result, the passage for filling the container is opened.

- When the amount of liquid in the tank reaches the maximum level, the float valve closes and the water flow stops.

Side reinforcement benefits:

- simple design that can be easily repaired and partially replaced;

- there is no need to use strong seals in the area where the inlet hose is connected to the tank;

- low price.

The disadvantages of such a system can only be attributed to the noise that appears when water enters the system.

How to install shutoff valves: photo and step-by-step guide

The installation of fittings in a plumbing fixture can be done independently without the help of specialists.The services of professionals, if you need to dismantle the fittings and install a new one instead, will cost about 800 rubles.

To work, you will need the following tools:

- pliers;

- fuma rubber;

- a set of keys (adjustable and open-end);

- screwdriver;

- water tap;

- gaskets of the appropriate size.

Helpful advice! It is advisable to install branded fittings in the toilet. Such designs are fully compatible with plumbing fixtures.

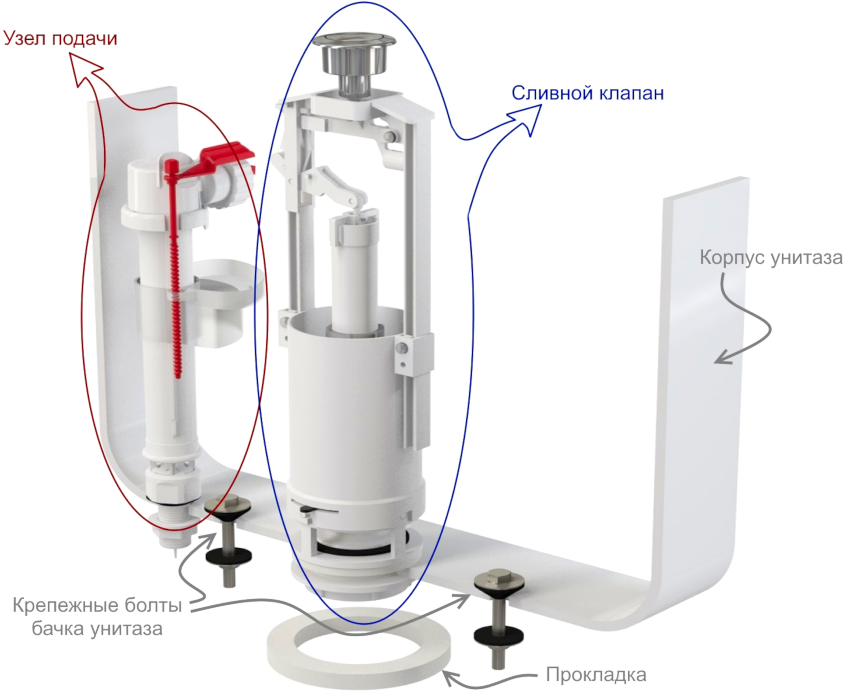

At the first stage, it is necessary to fix the base of the drain unit in the tank. This must be done so that the part fits snugly against the outlet. For this, a sealing material (rubber gasket) is placed between the bottom of the tank and the base of the drain unit. After that, the container can be installed on the toilet. Be sure to place a thick rubber ring between these components of the plumbing fixture. This is necessary so that the surfaces do not come into contact with each other. The cistern can then be bolted to the toilet.

To install the shut-off valves you will need pliers, wrench set, screwdriver and spacers

If the plumbing fixture has a lower connection, then the fittings of the toilet bowl should be installed before the tank is installed. When using a system of this type, it is imperative to make sure that the rubber gaskets are securely fastened, otherwise leakage is inevitable.

If it is planned to install side fittings, there is no need to use a sealing material, since the connection is located above the water. Such a system can be installed after the tank has been installed. To do this, insert the tube into the corresponding hole in the container and secure it with nuts on both sides.

Then the flexible hose is connected to the connection of the water supply pipe. You also need to install a faucet, which in the future will be used during repairs so that you can block the access of liquid to the toilet. Modern hoses are equipped with grommet clamps. Thanks to them, the connection is strong and reliable.

At the next stage, the position of the float is adjusted so that the maximum water level does not reach the edge of the container by 15 cm. All that remains is to organize the drainage system. To do this, insert the upper part into the hole on the cover and secure it.

The main problems with the toilet valves

The float fails more often than other parts. If there is a problem with the plumbing fixture, this item should be checked first.

The most common problems:

- during operation, the float was skewed;

- the membrane has worn out under the influence of mechanical stress;

- the shut-off valve does not close the hole well and allows liquid to pass through;

- a hole has formed in the float.

If a part is badly damaged or worn out, it should be replaced. The price of a toilet float is about 300-400 rubles. Before proceeding with the repair, you need to find out how the toilet lid is fixed. When removed, it can be easily broken, in which case the entire tank will have to be replaced.

Helpful advice! Most often, to fix the problem, it is enough to change the bend of the float or correct its fixation, therefore, first of all, it is worth inspecting its mount.

To eliminate such a problem as the skew of the float, it is enough to change the bend or correct its fixation.

If the isolation valve is the source of the problem, it must be replaced. The list of actions in this case will be as follows:

- Empty the tank (drain all liquid).

- Disconnect the water supply valve.

- Disconnect the lever.

- Remove the broken valve.

- Install a new one in its place and secure.

- Adjust the position of the float.

Features of drain fittings for the tank: installation technology and prices

The drain fitting consists of a drain lever and a drain siphon. The main function of the latter is to hermetically close the hole when the liquid has finished draining. There are several design models for siphons. The simplest products are in the form of rubber cylinders.

Average prices for cistern fittings (drain mechanisms):

| product name | price, rub. |

| Toilet fittings Alcaplast | |

| For a high-lying tank | 325 |

| For Ecology installation (height 1000 and 1200 mm) | 450 |

| For a low-lying tank | 510 |

| With stop button | 725 |

| With extended stop button | 780 |

| Double button | 980 |

| Fittings "Geberit" for toilets with installation | |

| Name of models with which the mechanism is compatible | price, rub. |

| Delta UP100, Sigma UP320, Sigma UP300 | 1350 |

| Delta UP172 | 1400 |

| "Kappa" UP 120 | 1455 |

| Sigma UP720 | 1555 |

| "Omega" 12 | 2200 |

| Delta UP182 | 2300 |

How to install and adjust a toilet flush

Before starting work, it is advisable to sort all the parts of the kit so that a gasket and a washer are attached to each bolt. The fastening is performed as follows: a washer is put on the back of the bolt, then a nut follows, which must be tightened tightly, but very carefully so as not to damage the ceramic coating.

Recommendations for toilet flushing:

- Install the drain mechanism in the tank in the place designated for it.

- In order for the part to sit tightly, you need to use a rubber gasket, which should be put on the nut.

- Fix the mechanism securely with a plastic nut.

If the sealing part has already been in operation, then the connection area must be additionally treated with a sealant (experts do not recommend reusing the seal). New rings don't need it.

Note! If minor casting defects are found in the joint zones and on the parts, it is imperative to use a sealing compound.

To set up the toilet flush by adjusting its height, you must:

- Empty the overflow pipe.

- Carefully squeeze out the element securing the glass.

- Move the stand vertically until it reaches the desired height.

- Move the glass along the guide so that its upper edge does not reach the edge of the drain tank by at least 4.5 cm.

- The placement of the overflow pipe is checked. In the correct position, this element is 7 cm lower than the top of the post and 2 cm above the surface of the water.

To adjust the drainage rate, you need to move the flap or float.

Recommendations for choosing accessories for the toilet

When replacing the tank, there are no particular difficulties with the acquisition of fittings, since the new container already has everything you need in the kit. If a partial system update is required, you will have to carefully choose the parts.

When choosing fittings for a plumbing fixture, you should take into account a number of nuances:

When buying accessories for the toilet, you need to remember that the higher the price, the better the product.

- It is desirable that the new valve is of the same design and type as the old one. In this case, you do not have to worry that the mechanism will not fit.

- It should be checked that all valve components move freely. If the parts jam even a little, you need to choose a different mechanism.

- All gaskets must be flexible and resilient. It is imperative to make sure that there are no cracks when the material is stretched. Products must have the correct shape. It is advisable to purchase an additional set of rubber gaskets, which will be a spare.

- Quality parts do not have cracks, deformations or distortions. If there is any defect, you should refuse to buy the mechanism, since in the future this will certainly affect the efficiency of its operation.

- Plastic components are usually made by molding. Their surface must be smooth, free from flaws.

- The float valve must move smoothly. Sudden jumps or jams indicate a defective product.

- It is imperative to check the strength of the assembled structure. The fixation of the elements must be reliable. If certain areas are loose or move freely, then the system will quickly fail.

When buying plastic valves, price matters. The higher it is, the better the product is. Although with the advent of a large number of manufacturers on the market, you can find inexpensive components in good performance. It also does not hurt to study information and reviews on the network or get advice from a specialist, because the result of their installation and further operation will depend on the quality of the selected parts.