Increasingly, users are choosing a cordless power tool, which is compact in size and allows you to work where it is problematic to stretch the power cable. The battery for the screwdriver should be selected based on the loads to which the device is planned to be subjected, as well as depending on the conditions of use. Some batteries cannot be fully discharged and some are not suitable for cold applications.

Content [Hide]

- 1 What is the battery design for a screwdriver

- 2 Batteries: which are better, the main types, advantages and disadvantages of each

- 3 Which battery is better for a screwdriver and what indicators need to be compared

- 4 The best manufacturers: batteries for the Makita and Hitachi screwdriver

- 5 The main types of breakdowns and repair of batteries for a screwdriver

- 6 How to remake a battery for a screwdriver: video

What is the battery design for a screwdriver

The storage battery is a plastic case in which several small batteries connected by a contact strip are located. The ends of the tape extend outward and look like oblong plates. The main task of the battery is to generate constant current using the electrolysis process.

Each battery consists of the following elements:

- electrodes, represented by anodes and cathodes;

- electrolyte;

- housing.

Directly in the power tool itself there is a special hole where the battery case is placed. And reliable fastening is provided by two terminals located on the sides of the battery. For many screwdriver manufacturers, the battery can have a split case, although professionals have learned to carefully disassemble solid screwdriver batteries without harming them. In order to open the case, just use a screwdriver to unscrew the fasteners.

Mini rechargeable batteries located inside the case are cylindrical in shape. The number of batteries depends on the voltage required for the device. It can be 8, 10 or even 15 elements, which, as a rule, are placed in several rows.

It is interesting! The batteries for the screwdriver are connected with each other using a tape, which is based on nickel. Internal elements are connected in sequential order, as standard - from minus to plus. Spot welding is used to secure the tape to the batteries.

The current is generated in the battery due to the potential difference at the cathode and anode. All batteries have different properties. The main characteristics that are of interest to users are:

- material used for making the pole and electrolyte;

- voltage affecting the performance of the device;

- capacity, which determines how long you can work with the device without recharging.

The battery voltage is determined by the number of batteries built inside. One cell typically has a charge between 1.2 and 3.9 Volts. Thanks to the serial connection, the required number of volts is gained. For the operation of a household tool, an indicator of 10.8-14.4 V is sufficient, but a professional device for normal operation needs 18-36 V.

The capacity of the battery for the screwdriver determines the maximum operating time. This indicator is primarily affected by the current consumed by the device, as well as the voltage at full discharge.

Batteries: which are better, the main types, advantages and disadvantages of each

The question of what kind of batteries there are can be answered in different ways. Some products are rarely used to operate a power tool. In general, there are four types of batteries for screwdrivers. These include:

- nickel-cadmium - Ni-cd;

- lithium-ion - Li-ion;

- nickel metal hydride - Ni-mh;

- lithium polymer - Li-Pol.

Most often, for the operation of screwdrivers, nickel-cadmium and lithium-ion types of rechargeable batteries are used. Nickel-metal hydride feed elements used to be used almost everywhere, but have recently lost their relevance. The main reasons for this were the rapid heating of the device when using the charger for a screwdriver and in the process of working with fasteners.

Nickel cadmium and nickel metal hydride batteries

Nickel-cadmium and nickel-metal hydride batteries were the first alkaline batteries to power battery technology. They were developed at the end of the century before last. Nickel-cadmium devices are considered to be in demand, since, due to certain reactions inside the battery, they heat up less and guarantee a longer operation. Metal hydride devices are less hazardous than cadmium batteries.

Among the main advantages of nickel-cadmium rechargeable batteries for a screwdriver are:

- low probability of overheating during operation, which saves internal elements from melting;

durable metal body; - resistance to chemical reactions taking place inside, which excludes strong heating of the device;

- tightness of the outer coating, which prevents the internal elements from getting wet;

- the ability to function normally in frost conditions from -15 to -25 ° C, which allows you to work on the street;

- long service life subject to safety precautions (7–10 years);

- affordable cost.

In order for the nickel-cadmium batteries of the screwdrivers to maintain their quality, you should adhere to the tips regarding the features of the operation of the devices. Key recommendations:

- At each work, try to completely discharge the supply element.

- Store the device in a discharged state.

- Do not place the tool on charging if the battery is not fully seated.

The main feature of nickel-cadmium batteries is the "memory" effect, due to which it is impossible to put on charging uncharged devices, because they are able to "remember" the remaining charge level. To prevent this from happening, the battery must go through a full charge / discharge cycle.It is under such conditions of use that the devices will last the period of time promised by the manufacturer and provide the screwdriver with high performance.

It is interesting! Metal hydride batteries are safer for the environment, but they discharge faster than cadmium batteries and have a high self-discharge rate.

Lithium-ion battery for screwdriver

Lithium batteries for a screwdriver have recently begun to be used very often not only for power tools. This type of battery is found in almost every mobile technology. Lithium-ion batteries appeared only at the end of the last century, but very quickly they won the lion's share of the market. All this happened due to a large number of advantages. These include:

- high level of capacity for increased uptime;

- compactness and light weight;

- no "memory" effect, which allows you to recharge the device at any time;

- low self-discharge level;

- the number of working cycles is more than 3000;

- short time to full charge;

- no need for maintenance.

Cathodes and anodes in a lithium battery are made using a lithium salt of various acids deposited on copper and aluminum foil. The electrolyte is represented by a gel-like liquid - also based on lithium salt. A separator is used to separate the poles, and for safer operation a valve is built into the body to protect it from overpressure.

Lithium-ion batteries for screwdrivers have disadvantages such as:

- high sensitivity to voltage drops in the network;

- poor performance at low temperatures;

- loss of capacity during long-term storage of the device;

- high price;

- the likelihood of spontaneous combustion.

The undoubted disadvantage is that the service life of lithium-ion batteries usually does not exceed 3-5 years. At the same time, even those batteries that have not been used become unusable.

Lithium Polymer Batteries

Lithium-polymer feeding cells appeared after ionic ones, and in them the liquid electrolyte was replaced by a polymer one. Modern technologies have made it possible to increase the parameters of the battery capacity and reduce the size of the product by using ultra-thin batteries. The main advantages of such batteries are:

- lack of "memory" effect;

- low level of explosion hazard compared to ionic versions;

- ensuring continuous work without interruption;

- resistance to mechanical damage and vibration loads;

- quick charge for 20-30 minutes.

Like the previous version of the battery, there are also disadvantages here. The main one is that the number of operating cycles does not exceed 500. It is also inconvenient that only a special "smart" charger for the screwdriver is suitable for the battery, which controls the required voltage level in each individual internal element.

Screwdrivers with such batteries have not yet become widespread, because they are distinguished by their high cost. Mostly lithium polymer batteries are used in professional premium models.

Helpful advice! Screwdrivers equipped with lithium batteries are always easier to work with because they are lightweight. This is especially true if the instrument needs to be carried.

Which battery is better for a screwdriver and what indicators need to be compared

Before choosing a battery, you need to conduct a comparative analysis of the models and pay attention to the characteristics that affect the usability of the screwdriver. Here it is impossible to say with exact certainty which option is considered the best, because all batteries have their own advantages and disadvantages. First of all, you should understand how and where you plan to use the screwdriver.

Among the main important characteristics, the following deserve the greatest attention:

- Number of charge / discharge cycles. Lithium batteries are generally rated for 1000-3000 cycles. Cadmium batteries offer 1000 cycles, but often their service life does not end there. Using the devices, people have invented ways to reanimate a screwdriver battery at home.

- Time to charge. Sometimes one battery is not enough to work, so craftsmen prefer to purchase two batteries at once. Ni-cd and Ni-mh recharge in 2-4 hours, while the lithium battery can be fully charged in 30-90 minutes, significantly reducing standby time.

- Cost. The most budgetary ones are Ni-cd and Ni-mh. Li-Ion batteries are often twice as expensive as previous options and account for at least half the cost of the screwdriver itself.

- Tool power. Making holes in hard building materials and screwing large fasteners will require a high power tool. In this case, the charge is actively consumed, and the maximum number of revolutions will depend on the reaction of the battery. Moreover, cadmium batteries have better performance than lithium ones.

Other important battery characteristics include:

- The effect of "memory". If you put an incompletely discharged nickel-cadmium battery on charge, the remaining level will be perceived by the battery as zero. During operation, it will be discharged exactly when it reaches the mark remaining in memory.

- Self-discharge. Even when the device is not in use, the battery gradually runs out in standby mode. Nickel-cadmium and metal hydride batteries lose up to 10% of their charge in this way, lithium batteries usually do not lose more than 5% per month.

- The size. The dimensions of the battery determine the final weight of the screwdriver itself and, accordingly, the convenience of working with it. This is especially true if you plan to work for a long time or keep the tool suspended. The heaviest batteries are Ni-cd and Ni-mh. Lithium batteries are usually 40-60% lighter.

- Work in the cold. Because the cordless power tool is easy to carry, it is often used outdoors. Nickel batteries can easily withstand the effects of cold and are able to function even at -40 ° C, but lithium batteries under such conditions very quickly sit down or stop working.

- The need for a complete discharge. Cadmium batteries can be used before switching off the device and then fully charging. As for the lithium version, it is recommended to plant it up to a maximum of 15%, and it is better to charge it no more than 90%.

Helpful advice! The battery charge can be checked using a special tool - an indicator.

The best manufacturers: batteries for the Makita and Hitachi screwdriver

No matter how good the tool is, sooner or later you will have to replace the battery in the screwdriver. When this happens, you will need to choose a new battery. To make the choice easier, it is recommended to study the characteristics of known and reliable models.

Related article:

Cordless drill: the quick way to secure all connections

Technical characteristics of the cordless drill driver. The device and the principle of the tool.

Hitachi and Makita are Japanese manufacturers that are famous for their quality power tools. Firms offer a choice of different types of batteries, differing in properties and characteristics.

The most popular is the 14.4 V battery for the Makita screwdriver (model 193101-2 143). This instrument is equipped with a 2.4 Ah NiMH battery. The main advantage is fast charging for 1.5 hours. Other advantages include:

- the ability to use at a temperature of -40 ° C;

- a large number of charging cycles - 2000;

- lack of "memory" effect.

The cost of a Makita battery for a screwdriver is almost 6 thousand rubles. At the same time, users did not notice any shortcomings in the device.

The budget options include a battery for a Makita screwdriver 12 volt 193981-6. The nickel-cadmium battery is designed to operate in a temperature range of -10 ° C to + 55 ° C. The main drawback of the battery for the Makita screwdriver is the small capacity of 1.3 A / h. Therefore, users note a fast charge consumption.

One of the best batteries for Hitachi screwdrivers is the EB1233X. This is a 3.3 Ah Nickel Metal Hydride block. Thanks to this battery, the service life of the tool is much longer than that of other models. The device is designed for professional use. The benefits include:

- charging time - 1.5 hours;

- durable body;

- high-quality grip with the tool.

The cost of the battery for the Hitachi screwdriver is 5800 rubles.

Accumulators for Bosch screwdriver and budget analogue Zubr

Bosch screwdriver batteries have proven to be the most reliable and high quality. The firm mainly uses lithium-ion and nickel-cadmium technologies, which contribute to high performance and convenient operation of the device. All modern batteries are equipped with Electronic Cell Protection, which prevents the device from overheating and completely discharging. An automatic shutdown function is also provided.

All products of the company are distinguished by the presence of a shock-resistant case and low weight, which greatly simplifies the work with the power tool. The capacity of the various battery models ranges from 1.3 to 5 Ah. In terms of voltage, options are available from 12 to 36 V.

No less popular is the battery for the Bosch 12V screwdriver with a capacity of 1.5 A / h. The nickel-cadmium battery guarantees long tool life even at full power and is compatible with other manufacturers' screwdrivers. The cost of the device ranges from 2500 to 3000 rubles.

Helpful advice! Batteries from one manufacturer can be used for tools from another manufacturer. The main thing is to take into account their compatibility, which is usually indicated in the instructions.

Batteries for Zubr screwdrivers of Belarusian production have quite good user reviews and low cost of goods. Thus, the 12-volt Master battery is characterized by the same capacity as in the previous model (1.5 A / h). But in this case, lithium-ion technology is used. The cost of the device is only 1,500 rubles. At the same time, the battery has overheating protection and a shockproof housing. Fast recovery after a full discharge is considered an important advantage.

Domestic batteries for Interskol screwdrivers

The Russian manufacturer offers customers a wide range of batteries. Particularly popular are Ni-Cd, which are distinguished by their simplicity in operation and a wide range of capacities. The batteries for the Interskol screwdriver have a capacity ranging from 1.3 to 2.4 A / h. You can choose from options with different voltages - 12, 14.4 and 18 V. In general, the popularity of the tool is given by good build quality and acceptable cost for most users.

Model DA-14.4ER - lithium-ion battery with 14.4 volt voltage. The battery for the Interskol screwdriver weighs only 250 grams, and the capacity of the device is 1.5 A / h. The manufacturer emphasizes that the device can be used in the temperature range from + 4 ° С to + 40 ° С.This model is only compatible with the screwdrivers of the same company. The cost varies between 1200-1600 rubles.

A more powerful model is the DA-18ER battery with a voltage of 18 V. In the production process, sodium-cadmium technology is used, the battery capacity is 1500 A / h, which is enough to perform a significant amount of work. It takes 120 minutes for the device to reach a full charge, although some users note that on average it takes about 3 hours to charge to 100%. It should be noted the significant weight of the 18 volt battery for a screwdriver, which is 750 grams. Its cost is about 1600-1700 rubles.

The main types of breakdowns and repair of batteries for a screwdriver

Even for an inexperienced user, it will not be difficult to detect malfunctions in the tool. Among the main signs of breakdowns are:

- fast discharge during operation;

- the presence of mechanical damage to the case;

- charging very slow or too fast.

Before you start repairing batteries for a screwdriver with your own hands, you need to familiarize yourself with the main types of faults. These include:

- damage to contacts;

- natural wear and tear;

- damage due to misuse.

To check the integrity of the internal contacts, it is required to disassemble the battery and inspect the connections at the soldering points. During the opening of the case, the integrity of the remaining internal elements can also be assessed.

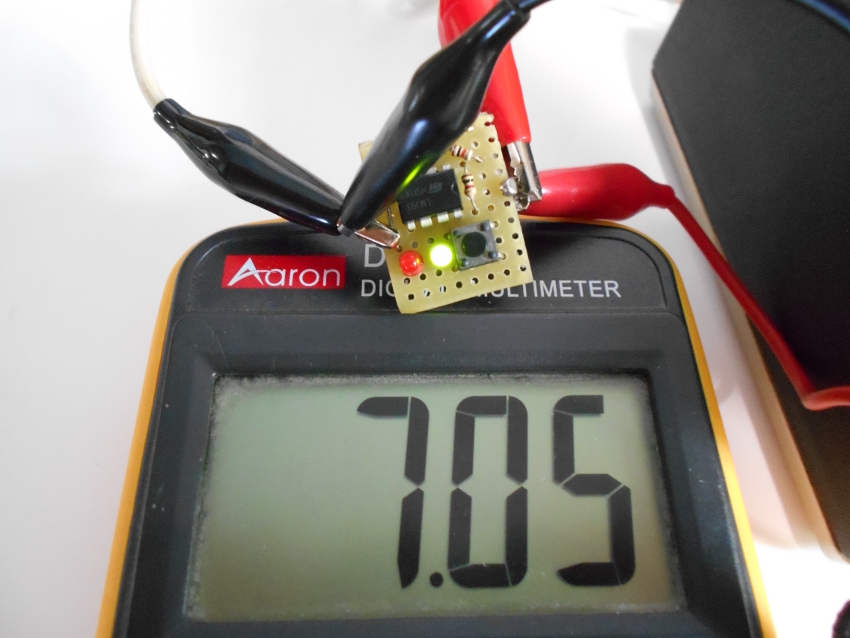

If the battery is out of order due to the end of its service life, it is worth knowing that the total voltage of a 100% charged battery will decrease. To check this indicator, you will need a multimeter, which not everyone has in stock. If the device has not been used for a long time, experts recommend 2-3 complete discharge / charge cycles without loads.

Important! It should be understood that not all batteries can be recovered. Basically, craftsmen at home repair only nickel-cadmium and metal hydride batteries.

A short list of actions in case of a battery breakdown looks like this:

- disassembly of the device;

- inspection of internal elements;

- measurement of the total voltage and each element from the chain.

If a problem occurs with one of the mini-batteries, for example, it is swollen or lacks voltage, it should be replaced, after which the device is assembled and fully charged. Disassembling the case is a task within the power of everyone. This requires a small screwdriver and, if necessary, a rubber mallet, which makes it easier to separate the parts.

As with the purchase of any power tool, when choosing a battery, you need to take into account the peculiarities of using a screwdriver. It is best if you have two batteries at hand during operation, which can be changed. It is important that the instrument is not only suitable for the instrument, but also meets the necessary requirements.