At any construction site, one of the main mechanisms is an electric concrete mixer. This is an integral part of the successful and efficient work of both professionals and amateurs who are just starting to engage in construction on their own. It is the volume of work performed that must be taken into account when purchasing a concrete mixer. Information on how to choose the right tool is contained in this article.

Content [Hide]

- 1 Concrete mixer: a machine that makes the construction process easier

- 2 Classification of concrete mixers: photos of different types of machines

- 3 Electric concrete mixer: gravity type mechanism design

- 4 Spare parts for concrete mixer: categories and features of choice

- 5 How to properly repair a concrete mixer with your own hands

- 6 How to mix concrete in a concrete mixer

- 7 How to make a concrete mixer with your own hands: a quick guide for making

- 8 How to make a concrete mixer from a 200 liter barrel with your own hands

- 9 Electric concrete mixer: prices and popular models

Concrete mixer: a machine that makes the construction process easier

A concrete mixer, or concrete mixer, is a special machine for construction work that is designed to mix concrete and other solutions used for pouring foundations, making screeds or brickwork. The device will also be of great help in the process of gluing tiles and in other types of construction work.

Externally, a concrete mixer is an open container, in the middle of which concrete components are poured, that is, cement, sand and water. A component such as gravel may also be present. The machine prepares the solution by stirring. Then it is poured into a separate container using a special mechanism.

The device greatly facilitates, optimizes and speeds up the workflow on the construction site. Of course, you can order the solution or prepare it in a trough, stirring with a shovel, but it's much easier to fill in the ingredients and just press a button. At the same time, not everyone knows which concrete mixer to choose. As a result, on the construction of a small house, you can find bulky equipment that is idle, or small concrete mixers on huge objects.

There is a wide range of such products on the modern market. At the same time, the models are distinguished by their durability, ergonomic devices and ease of use.Having decided on the required volume, power and other parameters, you can easily choose the best option.

First of all, you should familiarize yourself with the specific variety of concrete mixers. Devices are classified according to the following criteria:

- by the principle of work;

- type of drive;

- tank capacity;

- power;

- type of food.

Concrete mixers are classified according to the principle of operation, type of drive and tank capacity

Helpful advice! The gravity concrete mixer is equipped with special emptying mechanisms, which makes it easy and quick to remove the mortar. In addition, the price of such mixers is much lower than the cost of forced-type machines, which mix the solution with the components of the fine fraction in a better quality.

Classification of concrete mixers: photos of different types of machines

Before choosing a concrete mixer, you need to get at least a general idea of the variety of devices. In the last century, a huge number of products were invented for a variety of purposes. The most popular are mobile mechanisms with a small capacity - up to 300 liters.

The main feature that underlies the classification of devices is the principle of operation. There are two types of concrete mixers in this group:

- forced type;

- gravitational type.

Compulsory devices are equipped with a fixed drum and a mechanism that works like a mixer. Thus, the ingredients are mixed in the drum. It should be noted that, despite the high-quality preparation of the solution, there are a number of disadvantages, among which the following can be distinguished:

- the complexity of removing the resulting mixture, although some manufacturers found a way out of this situation by equipping a concrete mixer with a solution unloading mechanism;

- the small size of the fractions to be mixed, therefore, gravel cannot be added to such devices, and especially large pieces of crushed stone can even disable the machine.

Considering the listed disadvantages, it would be more correct to call this type of concrete mixers mortar mixers.

The Gravity Concrete Mixer is perhaps the most popular of its kind. Consider the device of a concrete mixer. It is a drum that rotates around its own axis, resulting in a high-quality ready mix. In order to avoid the influence of the solution on centrifugal forces, the drum is equipped with special blades. According to reviews, a concrete mixer with a gravity mechanism mixes much worse, but building components of various sizes can be added to such a device.

Choosing the best concrete mixer by drive type: electric, gasoline and diesel devices

Depending on the type of drive, concrete mixers are divided:

- for electrical;

- gasoline;

- diesel.

The most popular among this group are electric concrete mixers. In addition, they are less expensive. Such devices are equipped with an electric motor, they can be connected to a 220 or 360 V. This factor must be taken into account if only a 220 V network is available. The engine on such machines usually has a power of up to 1 kW, which is especially beneficial in terms of electricity consumption.

Gasoline-driven concrete mixers are equipped with an internal combustion engine. As a rule, this is a two-stroke engine, before refueling of which engine oil must be added to the fuel. Such a device is required if you have to work on construction without access to the power grid. First the gasoline engine is started, then the mixing is carried out. It is problematic to work indoors with such a machine, as poisonous exhaust gases will be released.

Helpful advice! In terms of economy, electrically driven concrete mixers are the most profitable, since gasoline and diesel are much more expensive than electricity. In addition, the electric concrete mixer does not emit smoke, so indoor installation is allowed.

A concrete mixer with a diesel engine is more economical in terms of fuel consumption compared to a gasoline mixer. It should be noted that it is difficult to start a diesel engine in the cold, which excludes the operation of such a device in winter. In addition, equipment with a diesel engine weighs significantly more than a concrete mixer with a small electric motor.

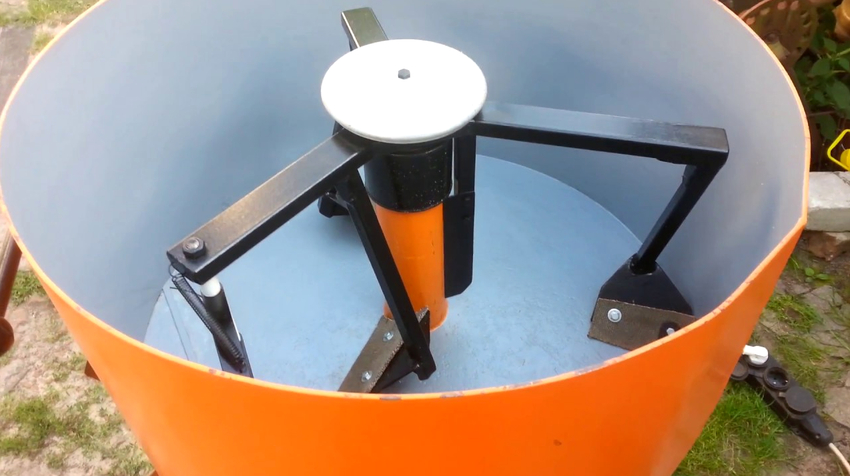

Electric concrete mixer: gravity type mechanism design

Having decided on the type of device (electric concrete mixer of the gravity type), you can proceed to the selection of a specific model of the concrete mixer. It is necessary to pay attention to some parameters.

Concrete mixer design. This should consider the usability and ability of the device to perform specific tasks. The volume of the tank plays a decisive role. The choice depends on the amount of solution. A concrete mixer with a capacity of up to 100 liters is suitable for a small construction site, for example, when you need to fill the foundation with a concrete mixer yourself or if you need to build a gazebo. For the construction of a house, you should choose mechanisms with a capacity of 100 to 150 liters, which are designed to prepare 60 or even 100 liters of solution at a time. Products with a tank of more than 150 liters are professional machines.

The type of electric drive, on which both the design itself and the type of electric motor installed on the concrete mixer depend. Distinguish between gear and girth drives.

A gearbox for a concrete mixer is located at the bottom of the product along with a motor that rotates the drum itself from below. Such devices are reliable, but they must be handled with great care, since their cost significantly exceeds the price of crown equipment.

The principle of operation of the wreath concrete mixer is that, by means of a belt drive, the motor drives the wreath, which rotates the drum itself. In such mechanisms, the belt drive is often cut off, the crown fails, and other malfunctions can also be observed. It should be noted that spare parts for such concrete mixers are inexpensive and can be replaced independently.

Concrete mixer motor: power and operating mode

On concrete mixers of the gravity type, an asynchronous electric motor with a squirrel cage rotor is usually installed, which provides the required torque. Many criteria depend on the type of transfer.

It is important to know! In a concrete mixer with a volume of 130 liters, you cannot prepare 130 liters of mortar at a time: the maximum amount is 100 liters. This is due to the fact that the filling of the tank with the solution should not exceed 85%.

Belt-driven girth concrete mixer makes starting the engine easier due to belt slippage. For a concrete mixer equipped with a toothed belt drive, the starting process is much more complicated. The hardest starting is inherent in geared concrete mixers.

When choosing engine power, these features must be taken into account. For mechanisms with a belt drive and a volume of up to 100 liters, a 500 W engine is suitable. A 700 W motor is installed in concrete mixers with a capacity of up to 150 liters. Larger devices should be equipped with an electric motor with a power of 1000 watts or more.

The food network also plays a big role in the choice of the concrete mixer.Devices that are connected to a three-phase network withstand overloads much better, they are characterized by an excellent starting torque. Therefore, almost all concrete mixers with a volume of over 250 liters are equipped with a three-phase motor.

Motor power is important, but not the main condition for the successful operation of the tool. For example, if an electric concrete mixer is equipped with a non-native engine or is made by hand, then you need to pay attention to its mode of operation.

Most of the engines are designed for continuous operation (S1). At the same time, such a load is unacceptable for a concrete mixer operating in a “torn” mode. Attention should be paid to a product that can withstand multiple starts (S4). Devices of this type are specially designed for repeated, but not prolonged, starts with phases: work - cooling.

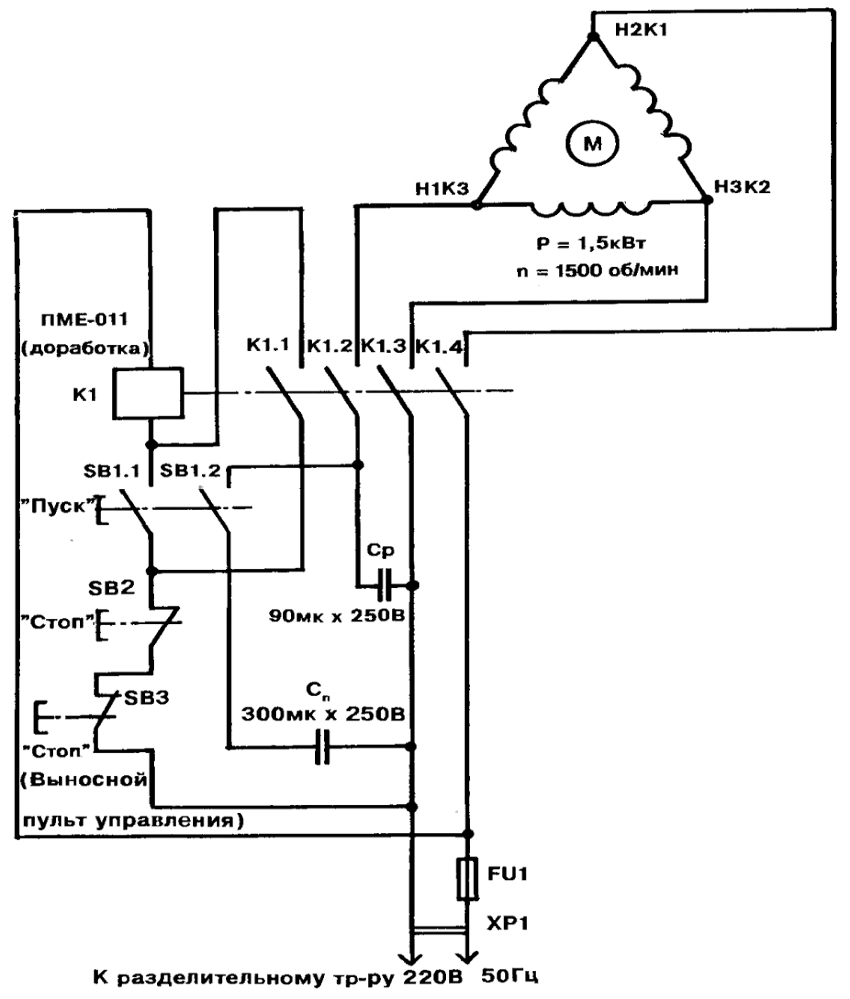

Wiring diagrams for concrete mixer motors: recommendations

After the unit is selected, questions arise about how to use the concrete mixer, how to connect it correctly, taking into account the number of drives. In this case, you must first understand the electrical circuit of the engine. Most concrete mixers are equipped with two types of motors - single-phase or three-phase. Of course, their connection schemes are different from each other. Moreover, they also have different connection options to suit local conditions and the requirements of a particular motor.

The connection of a single-phase concrete mixer motor is special in that it has only one working winding, which is laid in the stator in a certain order. After applying voltage to this winding, nothing will happen - the motor will emit a “hum”, heat up, but will not rotate. This is because the motor requires an initial moment of inertia. Thus, if you push the engine rotor well, it will start to rotate and gradually pick up the required speed.

Helpful advice! Before connecting an electric motor with 4 wires, it is necessary to understand the motor windings. There are two windings, which means there must be 4 ends. In addition, the electrical circuit of the concrete mixer assumes the presence of a capacitor of a specific capacity. It is needed so that the angle between the phases that are connected to the working and starting windings is different - preferably 90 degrees.

Each time it is quite problematic to produce such an algorithm of actions, especially if the engine is with a drive mechanism. Besides, it is not always possible to give it the necessary momentum. Therefore, it is worth considering the connection diagram of a single-phase motor with a small starting winding. When voltage is applied to it, the motor starts spinning. After it has gained rated speed, the winding must be turned off.

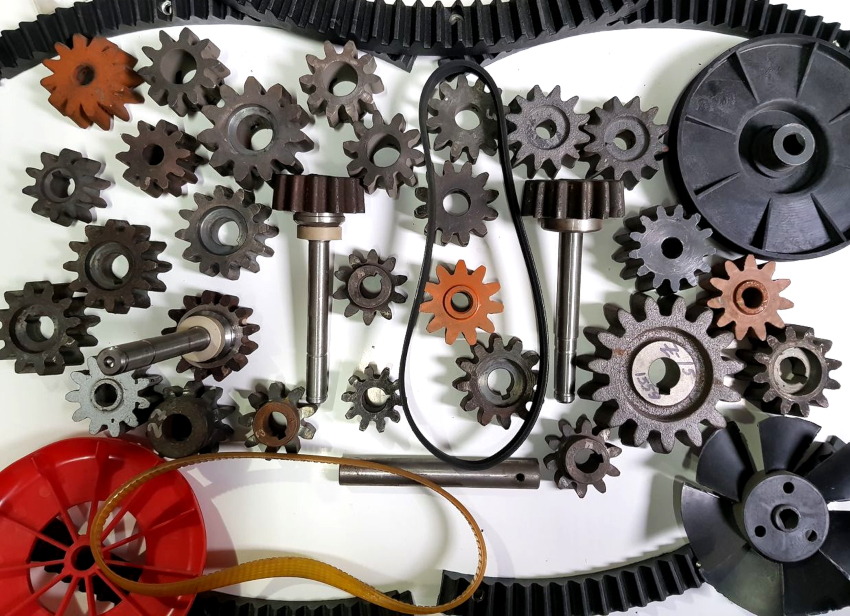

Spare parts for concrete mixer: categories and features of choice

Spare parts for concrete mixers are parts of the mechanism that play the role of consumables in it, which wear out during the use of the tool and require frequent replacement. The main spare parts are rivulent belts for a concrete mixer with a drive, as well as drive gears and start buttons for the device.

During operation, parts such as drive gears, cast iron gears, V-shaped, toothed and ridge belts wear out much faster. The listed parts must be kept in stock so that work does not stop at the most inopportune moment. The motor and gearbox for a concrete mixer deserve special attention. A little less often they fail, but gear rims, as well as the upper and lower equipment supports, called flanges, must be replaced.

Related article:

Screed floor with expanded clay: the secrets of creating a warm and durable base

Advantages, disadvantages, features and scope. Options and step-by-step instructions for the production of expanded clay screed on the floor.

Usually, the manufacturer establishes a one-month warranty on spare parts for concrete mixers from the date of purchase - provided that the rules for their installation and operation are observed. It should be noted that electrical connectors are not included in the list of spare parts for concrete mixers.

How to properly repair a concrete mixer with your own hands

Despite the degree of product quality, sooner or later a question arises regarding the repair of a concrete mixer. At the same time, a breakdown can have different prerequisites and character due to the fact that significant loads are imposed on this mechanism. The main reasons for the failure of a concrete mixer are its improper operation and storage.

To repair a concrete mixer with your own hands, you need to have minimal knowledge of this type of equipment and an idea of its structure. If in doubt, it is better to turn to professionals. When you have confidence in your own abilities, you can get to work, having prepared the necessary tools in advance. The list of fixtures includes:

- three-legged puller;

- puller for bearings;

- vice;

- a hammer;

- pliers;

- chisel;

- screwdrivers;

- keys set.

Then you need to understand the reason for the breakdown of the concrete mixer. There may be several of them:

- overloading the device;

- the drum is cleared at the wrong time;

- the rules and conditions of tool storage are not observed.

Helpful advice! It is possible to avoid or delay the repair of the concrete mixer by fulfilling certain requirements. To do this, you must always clean the bowl and mechanism after work, observe the proportions of concrete for the concrete mixer and not overload the device with an excessive amount of mortar, and store the tool in proper conditions.

Replacing consumables such as belts, drive gears and start buttons are the most common types of do-it-yourself concrete mixer repair. Bearings and rims are replaced much less frequently, as their service life is much longer.

How to mix concrete in a concrete mixer

There are various ways to prepare a solution in a concrete mixer. They depend on the design of the device and the principle of operation.

In gravitational machines, the process of combining all components of the mixture is carried out by turning the container with the solution from top to bottom or along the axis. The mixing takes place under the influence of gravity. A similar result can be obtained even in the case of using a manual concrete mixer. However, large volumes of solution cannot be achieved in this way, therefore this option is recommended exclusively for private construction.

The forced-mechanical method is similar to the gravity method: it also allows a high degree of homogeneity of the solution to be achieved. The mixing mechanism includes a bucket of horizontal or inclined type, into which the mixer is immersed. Such a container can spin itself without a mixer; instead, mixing is done by the blades, which are inside the bucket.

Methods for preparing a solution in a concrete mixer depend on the design and principle of operation of the device

The forced vibration method assumes the presence of a stationary container. For mixing, a mixer is used, which emits compression waves, which contributes to effective mixing and compaction of the mixture. It should be noted that this method is energy-intensive, since a vibration drive with a power of 1.3 kW is required to prepare 20 liters of solution.

The combined gravitational-mechanical method is a combination of all the above methods. Knowing how to properly load a concrete mixer, you can make this tool yourself.

How to make a concrete mixer with your own hands: a quick guide for making

Considering how much a concrete mixer costs, many consider it advisable to make a tool on their own. To do this, it is enough to purchase the necessary materials and acquire certain skills. Homemade concrete mixers have a different design depending on the principles of action listed above. They are manual, vibrating, and also containing an electric drive.

You can make a simple hand-held concrete mixer with your own hands. The drawings are available on the Internet. The manufacturing process consists of the following steps:

- Take the old boil or can, after checking the container for integrity.

- Slide a piece of pipe into the handle of the can and fix it to the tank with a rope or rubber band.

- Weld the vessel to the axis. If an aluminum container is used, then handles made of metal strips approximately 1 cm thick are attached to it with screws.

- A hole in the shape of the letter "U" is cut in the bed for the purpose of laying the axles and fastening the bearings.

Helpful advice! The vertical manual concrete mixer prepares the mixture much faster, but the horizontal loading device produces a better solution.

If a horizontal arrangement of the can is assumed, then on the side it is necessary to make a hatch for loading, and the container must be fixed to the axis. For support, you can take steel pipes. This design rotates slowly, so the mixing period of the solution can take about 20 minutes. At the same time, in terms of productivity, such a concrete mixer is several times superior to a machine based on the principle of operation of which is the "shovel" method. An electric motor with a power of 2.5 kW can be connected to this design, taking into account the fact that the volume of the tank is 50 liters.

How to make a concrete mixer from a 200 liter barrel with your own hands

You can also make a do-it-yourself concrete mixer from a 200-liter drum, either manually or electrically. If we are talking about a hand-held device, then the container is simply pushed onto a shaft rotating by means of the handles fixed at the ends. For greater efficiency of mixing in the middle of the barrel along and across, it is necessary to weld partitions with a height of 10 to 15 cm.

The mobility of the device allows you to install racks on a wheelbarrow or frame with wheels. The barrel must be tightly closed, as it is assumed to be horizontal. Flanges with bearings are attached on both sides, to which the shaft is welded.

To make it convenient to load the components and pour out the solution, in the process of making a concrete mixer with your own hands from a barrel, you need to make a hole where the hinges are welded and a manhole cover with an airtight layer is put on. To ensure the static nature of the product, the shaft is fixed with racks. To avoid distortions, the supports are buried in the ground, and handles are attached to the container.

A do-it-yourself concrete mixer from a 200-liter barrel can be made using a different method, but the same drawing. The main differences between the two options are the use of a motor, which is fixed through a pulley on one side of the barrel, as well as the vertical position of the device. A self-made vertical-type concrete mixer is attached to a rotary frame with a motor installed, and rollers are attached to the barrel to twist it on the shaft. To facilitate rotation, handles or a steering wheel are attached to the container.

Electric concrete mixer: prices and popular models

When it comes to value for money, you should trust trusted manufacturers.In this list, a special position is occupied by Lebedyan concrete mixers, which differ from competitors in a number of characteristics that satisfy the requirements of users. Lebedinsky plant specializes in the production of concrete mixers SBR and similar machines, which makes it possible to obtain more reliable and high-quality products.

The product line of the Lebedyan company includes both manual equipment and electric concrete mixers, which are characterized by a long service life. Professional machines with large capacity constitute a special category.

Helpful advice! If we are talking about private housing construction or low-rise construction, then you can choose Profmash concrete mixers. This company specializes in the production of small devices.

A concrete mixer is a convenient equipment that is used to prepare various types of mortars, from tile adhesive to concrete for garden paths. The modern market offers the widest range of these mechanisms, which are distinguished by their durability and ease of use. You can also make your own concrete mixer. To do this, you need to study the device design, purchase the necessary materials and tools.