A wood lathe is a device with which wood products are processed. Its structure is similar to the devices used for metal processing, however, there are functional differences. To choose a suitable mini-machine for a home workshop, you need to study their structure, main technical characteristics, as well as a model range.

For processing wooden blanks at home, desktop models of machines are suitable, which are characterized by low power

Content [Hide]

Types of woodworking machines

Today, there are three main types of turning units for processing wooden blanks, depending on their purpose:

- industrial (for large enterprises);

- semi-professional (for small businesses);

- desktop (for household use).

For the organization of small production, semi-professional machines are suitable, characterized by high productivity and not large dimensions.

Devices of the first type are characterized by high performance, therefore they are used for mass production of various products. From a functional point of view, they have no equal, since they are able to perform a large amount of work of various kinds in a minimum of time. The mass of such devices is not less than 200 kg, and the minimum power indicator is 1 kW.

Semi-professional machines used for small industries are smaller and, accordingly, lighter. Their weight ranges from 40 to 90 kg, and their functionality is much less than that of industrial devices, but it is quite enough to meet the needs of a small workshop. The power indicator of such units varies from 0.5 to 1 kW.

Desktop devices are used exclusively for domestic purposes. As a rule, such a device is installed on a workbench or any other work surface and is used to process single pieces of wood. The mass of a mini-lathe for wood does not exceed 20-40 kg, and the power indicator is always below 0.5 kW.

Note! To select a turning device, you must first of all build on its purpose, as well as the availability of individual functions.

Today you can find many varieties of turning devices for woodworking that are used at home. They differ in their functionality and a number of other characteristics. Consider the most popular devices used by home craftsmen for processing wood blanks:

- milling;

- screw;

- copy-milling;

- thicknesser;

- devices with CNC.

Wood turning and milling machines are used, as a rule, for boring grooves. Screw assemblies are used to apply threads to a workpiece and obtain parts for a cone. Machines equipped with a copier allow you to get products of unusual shapes and do the job much faster and more accurately.

Copiers use special stencils. Thicknessers allow you to plan the board. Wood lathes with CNC are automatic units operating according to a given program.

There are several types of woodworking machines on the market, differing in their functionality and characteristics

Lathe device for home workshop

Such mini-lathes differ from metal-working turning devices in that they do not require a cooling system. The power rating of the woodworking machine is also lower. This is due to the physical characteristics of the material that is processed on such equipment. Wood blanks lend themselves much better to grinding or turning, so they do not require a lot of power to work with them.

Units for home workshops take into account the possibility of speed regulation. The main structural elements of this device, which relate to the functional part, are: chuck and cutters.

The main function of the chuck for a wood lathe is to ensure reliable fixation of the workpiece, which has a certain section index. In turn, the cutter is used for manual work on a mini-machine that does not have a support. As a rule, cutting units are used for the manufacture of various household utensils (for example, cuttings for shovels), as well as for making simple blanks for painting.

The chuck is fixed to the front assembly (headstock), which includes the gearbox. This important structural element of the machine is distinguished by a cam device.

Thanks to the cam mechanism, it becomes possible to securely fix the workpiece in the chuck, and this is very important for normal operation. The chuck is massive and is responsible for accurately changing the position of the workpiece during processing. And also this device rotates the processed wood product.

The back assembly includes a taper hole. It is necessary to install the center, the function of which is to fix the wooden blank. Often this stop assembly is sold separately. It is not difficult to buy a lathe tailstock, as there are many offers on the Internet for its sale.

Mini-machines are capable of handling a basic set of technical operations. Consider what can be done on wood lathes:

- turning;

- pruning;

- grinding;

- making grooves;

- drilling holes;

- threading.

Helpful information! School models of machine tools processing wooden blanks are very popular in amateur workshops. Such units are recommended for performing the simplest tasks (trimming, turning), as well as for understanding the operation of such devices at an initial level. Over time, it becomes possible to use the knowledge gained to work on more complex equipment.

Desktop machines are distinguished by their small dimensions, but this does not affect its functionality.

Desktop lathe for wood: specifications

Bench-top wood processing machines are compact devices that are capable of performing many technical operations. The mass of most units of this type does not exceed 18 kg, which allows them to be easily installed on the work surface and change the place of work, depending on the need.

The power indicator of such equipment ranges from 350 to 500 watts. The most powerful devices are used in small-scale production. The mass of such machines can reach 90 kg.

As for the rotational speed, this parameter has a great influence on the quality of processing of wooden products. The minimum spindle speed range is 400, and the maximum reaches 3500 rpm. This indicator can be adjusted, depending on two factors, namely: the type of wood and the required processing accuracy in a particular case.

The highest quality mini woodworking machines are considered to be those produced by foreign manufacturers. The main advantage of imported devices is a higher power rating, which expands the operational capabilities of the equipment.

Features of Proma DSO-1000 Desktop Wood Lathe

This device is the most common one today and is very popular among DIYers. The company that manufactures these units is located in the Czech Republic.

Such equipment is multi-tasking and capable of performing many technological operations. The Proma DSO-1000 machine is used to process products that are not only soft, but also hard wood. The shape of the workpiece can be different:

- cylindrical;

- conical;

- shaped surface.

The woodworking unit of this model is equipped with copying equipment, and also includes a set of necessary tools that greatly simplify wood processing. The fixation of a functional part in such a machine is carried out by means of a chuck.

The power rating of Proma DSO-1000 is 400 watts. The minimum number of spindle revolutions per minute is 850, and the maximum is 2510. The frequency of rotation is adjustable, depending on the need. The length of the workpiece that such a unit is capable of turning is 1 m (35 cm above the bed).

A similar model weighs 35 kg, which affects its dimensions, which are compact and versatile. Before purchasing, it is recommended that you familiarize yourself with the photo of the Proma DSO-1000 lathe, which can be easily found on the Internet.

And also Proma DSO-1000 has an affordable cost. The price of this unit is only 6500 rubles, which, with such functionality, is one of the best indicators on the modern turning equipment market.

Woodworking machine for home workshop HolzStar DB450

This model of woodworking machine for home use is massively produced in China and has good quality characteristics. Another factor behind the popularity of the HolzStar DB450 mini-machine is its clever design.

Note! The base of the HolzStar DB450 machine (bed) is made of cast iron material to cope with unwanted vibration during operation. This increases the accuracy of processing wood blanks.

The main advantage of such a wood lathe for a home workshop is rightfully considered the spindle speed. It is regulated depending on the characteristics of the workpiece material and varies from 500 to 3150 rpm.In turn, the power indicator of the device is 370 W.

A standard device of this type is capable of processing wooden products up to 45 cm long. However, if necessary, this parameter can be increased. To do this, you will need to purchase an extension of the bed, which increases the length of processing by 1 m. With this functionality, the weight of the device is only 38 kg. The HolzStar DB450 machine costs about 12,000 rubles.

JET JWL-1220 Wood Lathe Specifications

Another model that is popular with consumers is the JET JWL-1220. JET woodworking machines are manufactured in America. Such a machine differs from the above-described devices in a higher cost, which is 18,500 rubles. (with standard equipment).

However, this cost is fully justified, since, from a functional point of view, the JET JWL-1220 machine is ahead of the previous models. The power indicator of such a unit is 750 watts, and its engine can operate in two modes and has 6 speeds. When the machine is operating in the first mode, the spindle speed varies from 400 to 3300 rpm. And when the second mode is turned on, the speed increases to 500-3900 rpm.

The base of this small lathe is made of gray cast iron. It differs from black in that it has increased resistance to mechanical damage (shock). Some functional parts of JET JWL-1220 are also made from this material, so they are more resistant to wear and tear.

It is also worth mentioning that the JET JWL-1220 is equipped with a special locking lever, which makes it easier to attach the device to the work surface. The complete set also includes rubber feet to exclude the movement of the unit during processing of wooden blanks and extension of the bed 71 cm long. The weight of JET JWL-1220 is slightly higher than that of previous models and is 45 kg.

Features of the mini lathe Corvette 71

A similar model is produced in Russia by Enkor. It is distinguished by a high level of functionality and relatively small dimensions. The machine for processing wood blanks Corvette 71 has a power of 370 watts, which is quite enough for performing simple technological operations.

Of the features of this model, it can be noted that it includes an asynchronous motor. And also it should be said that the regulation of the spindle speed is performed by changing the position of the belt on the friction wheels (pulleys).

Note! The set of the unit includes special keys that are necessary for adjusting the chuck, as well as bolts for fixing to the working surface.

The rotation speed ranges from 760 to 3200 rpm. The length of a workpiece made of wood, which can be processed on a similar unit, is 42 cm. The weight of the wood lathe Corvette is 71-38 kg.

As for vibration, it is insignificant when working on Corvette 71. This effect is achieved due to the material from which the bed is made (gray cast iron). The cost of such a device is approximately 16,000 rubles.

Home workshops are often equipped with simple training machines capable of handling most standard turning operations.

School lathe for wood STD-120

Woodworking units STD-120 are educational models that are adapted for processing small-sized wood products. The 120 series machine is most often used in schools or amateur workshops.

The main feature of such a device from its predecessors is the ability to change the spindle speed by moving the belt on the friction wheels.The pulleys in such equipment have two grooves, so the rotation speed is represented by two values: 1100 and 2150 rpm.

The block with which the unit is controlled is push-button and is located on the front unit. The basic configuration of the STD-120 machine takes into account the presence of replaceable spindles, and the workplace is equipped with special safety shutters. Such a unit operates from an electrical network with a voltage of 380 V.

Related article:

Wood cutters for a lathe: purpose and types of tools

Appointment of the tool, varieties of wood cutters. Independent production of cutting tools.

The power of the motor integrated in such a unit is 400 watts. The length of the workpiece that can be processed on STD-120 is 45 cm. The fixation of such a model of a turning device is carried out using special fasteners - anchors. STD-120 is massive and weighs 100 kg, and its cost varies from 40 to 50 thousand rubles.

Most often, these machines are used to make simple wooden products. On a wood lathe of this type, you can perform a standard set of technological operations.

Lathes and copying machines for wood

This type of wood processing machine includes a copier. A copier is a device that allows you to process a product according to a template. As a rule, a finished part acts as a template.

The very process of working a copier for a wood lathe is quite simple. To do this, you need to draw them according to the appropriate template, observing its boundaries. This technological operation has some advantages. For example, the speed of the task is increased, and when using a copier, the possibility of damage to the workpiece is excluded.

The presence of a copier on the machine allows you to perform identical technological operations an infinite number of times

Working on equipment that does not have a copier, it is not always possible to complete the workpiece "by eye". Even experienced craftsmen occasionally make certain mistakes. Therefore, the copier can rightfully be considered a very important functional element that reduces the percentage of scrap during the processing of wood blanks.

Helpful information! The use of a wood lathe with a copier is most justified in the case of manufacturing large batches of identical parts from wood.

Let's consider the work of a copying lathe on wood in more detail:

- First, it is necessary to install the copier on special locking elements that are located in the upper part of the bed.

- Next, you can get to work. During this, the roller will move along the outside of the stencil.

- The roller, attached to the cutting element, transfers the outlines of the part, moving along the edge of the stencil, onto the tree.

Using a lathe for wood with a copier allows you to perform technological operations an infinite number of times. This allows it to be used in small production environments where the speed and accuracy of manufacturing various parts (for example, cabinet furniture legs) are very important.

Copier machines are indispensable for small industries where speed and accuracy of manufacturing various parts is very important.

Types of cutters for a wood lathe

Incisors are elements that are used to remove specific volumes of wood. All of them, from a constructive point of view, are similar to each other and consist of two main elements: cutting and fixing parts (rectangular or square).

The incisal edge can be represented by one or more surfaces. This element differs in its shape and width, which are selected depending on the nature of the technological operation.The main criterion by which the incisors are classified is their location relative to the wooden blank. They can be in two positions:

- radial;

- tangential.

In the first case, the cutter is used to remove large volumes of wood. For this, it is positioned perpendicularly. In turn, the tangential position is used to remove a small amount of wood from the surface of the workpiece. This allows you to make complex patterns on it.

And also chisels for wood lathes are classified by purpose. Today there are many cutters that differ in their design and are used to perform various technological operations. Let's consider the most common ones:

Reyer... A product that is used for roughing workpieces. The peculiarity of this cutter lies in its blade, which resembles a semicircle in shape.

By choosing cutters for woodworking give preference to trusted manufacturers

Meisel... This element is required for finishing. Its use allows you to give the wooden blank the final look. Meisel is an oblique blade that is sharpened on both sides at the same angle.

Scraper... A cutter of this type is needed to level the surface of blanks, which have a cylindrical shape.

Comb... Used for carving the surface of a wooden workpiece.

Hook... Such a cutter is used to organize cavities inside the blanks.

Helpful information! There are other highly specialized incisors that are used for specific tasks, of varying degrees of complexity. Some craftsmen make these functional products themselves, changing their shape as they wish.

You can buy cutters for wood lathes at markets, flea markets, in a specialized store, or order via the Internet. Typically, these items are sold in sets.

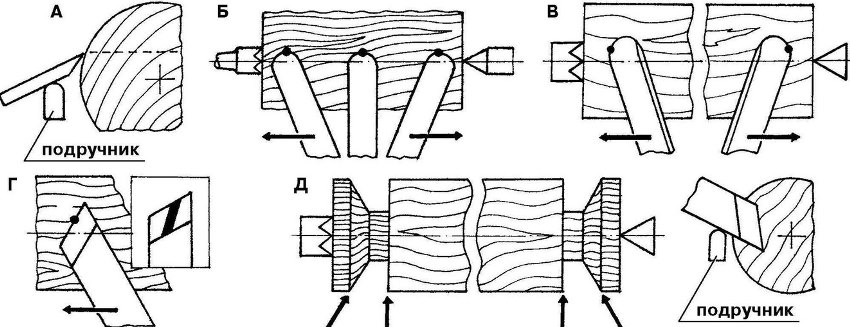

Examples of basic work with hand tools in woodworking: A - rough turning; B, C - first pass; G - cutting off shavings; D - trimming part

Which wood lathe to buy: selection criteria

There are several main criteria that are recommended to pay attention to when choosing a machine for processing wood products. The main one is the power indicator, which determines the purpose of the device. For example, tabletop models with low power are suitable for processing wood products at home. If you need a machine for frequent use, then it is best to pay attention to devices with a capacity of 500 to 1000 watts.

Another important criterion to be guided by when choosing turning equipment is the size of future wood blanks. Lathe is selected according to strictly defined characteristics. In this case, two indicators are important: the center-to-center distance and the distance from the base (bed) to the installed workpiece.

And, finally, the third parameter that determines the accuracy of processing wood blanks is the spindle speed. Today you can find machines with a speed range of 400 to 3500 rpm. In this case, the following pattern can be traced: the faster the spindle rotates, the more accurately the wooden blank is processed.

In any case, the choice of this equipment depends solely on you. A wide range of products allows you to easily select the required lathe. A video on this topic will also help you decide on the choice of a unit for home use.

Features of working on a wood lathe

When working with such a machine, you must remember some rules that are mandatory for everyone.For example, only dry wood pieces should be used for processing. The moisture content of such discs should not exceed 20%. And also it is worth remembering that the product should not have knots.

If you decide to process a wooden blank, which is large in size, then experts advise you to perform all actions at low speeds. This will allow you to do the job efficiently.

Note! In order to increase the operating life of a woodworking home unit, it is necessary to take into account that it needs periodic checks and maintenance. The basic rule is that every 500 hours of use, the moving parts must be lubricated.

The simplicity of the design of woodworking turning units is a huge advantage. This is due to the fact that if one or another part fails, it can be replaced without problems on your own.

However, before interfering with the design of the device, it is recommended to carefully study the repair instructions, which, as a rule, come with the equipment. Also, experts advise, before using such equipment, to watch training videos on a wood lathe.