The concept of "making with your own hands" implies the manifestation of creativity, that is, the free interpretation of all kinds of practical recommendations. Having understood all the subtleties, it will not be difficult to complete the drawings of a ladder chair made of wood, assemble the structure with your own hands, and also process it. A wooden step-ladder has a lot of advantages, and it is quite easy to make it yourself, thanks to the pliability of the material.

Content [Hide]

- 1 DIY stepladder: how to choose the right material

- 2 Stepladder dimensions: the secrets of correct calculation

- 3 DIY wood stepladders: a detailed guide

- 4 Chair-ladder transformer: instructions for self-construction

- 5 Small stepladder: the nuances of design

- 6 Wooden stepladder: finishing touches of manufacturing

DIY stepladder: how to choose the right material

The degree of reliability of the entire structure, as well as its service life, directly depend on the raw materials that were chosen for its manufacture. Even under the condition of drawing up drawings of a wooden step-ladder in the process of creating with your own hands, if poor-quality material was used, the ladder can hardly boast of high strength and reliability. That is why it is so important not to make a mistake in the selection of material.

Along with factory products, homemade ladders are designed to withstand significant loads: the weight of a person, as well as a lot of tools and all kinds of devices necessary for work. In this regard, the quality of wood is of decisive importance. Of course, these requirements do not apply to wooden ladder chairs. Regardless of the modification, the most important condition is the absence of cracks, chips and rot on the material.

In addition, the wood selected for construction must be thoroughly dried. The permissible moisture content should not be more than 12%.

Important! The use of too damp wood over time will lead to deformation, and then to the destruction of the structure.

If the moisture content exceeds the specified value, the material must be dried in a well-ventilated area, without allowing direct sunlight on it.

The diameter of the bars also plays an important role. Even if the stringers are very long, the section should be 4x4, 6x6 or 3x5 cm.This will not greatly affect the weight of the structure, however, the reliability of the ladder will be fully ensured. As for the exact dimensions and types of lumber, it makes sense to talk about them only if the dimensions of the future structure are known.

Homemade stepladder: a few words about accessories

By making the structure yourself, you can improve it by adding individual elements. For example, metal knitting needles are designed to provide a more reliable fixation of the steps.

They are located under the step in special holes and are attached with nuts and bolts. The length of these elements directly depends on the size of the tread (the width of the steps) and the degree of thickness of the stringers. Moreover, their diameter should not be less than 8 mm. Otherwise, they will bend under the weight of the load. It is thanks to the spokes that the permissible pressure increases, which the steps of a wooden step-ladder can withstand in the future.

Nylon cords or iron chains are used to connect the supports and the main part on both sides, at the same time preventing them from moving around.

Protecting the floor covering from scratches and preventing slipping is the main task of the so-called "shoes". They are made of rubber, and ideally it should be hard, since soft nozzles have a short service life. In addition, the design can be complemented with bucket hooks and other tool accessories. It all depends only on the needs of the user.

Stepladder dimensions: the secrets of correct calculation

Regardless of what exactly it was decided to design, be it a full-fledged staircase or a step-stool with your own hands, dimensional drawings are the most important condition for starting work.

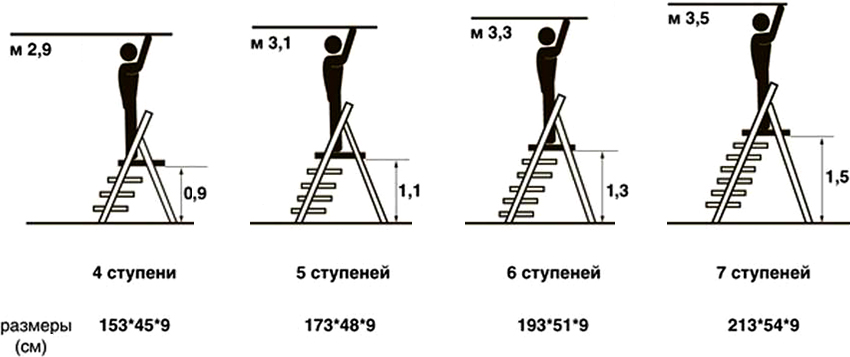

Speaking about the height of the future stairs, one should not forget what exactly it is intended for. For example, for domestic use, the linear length is considered optimal within 1.5-1.7 m.Taking into account the height of most living quarters, as well as the average height of an adult. This is quite enough to reach the ceiling, being on the upper step.

If a folding ladder is created for use in large rooms, when calculating the height of the structure, it should be taken into account whether a person can not only reach the upper racks, but also put something on them.

Note! When it comes to performing work on garden plots, a 3-step wooden stepladder is the best option. Being quite stable, such a structure will provide the ability to conveniently collect the gifts of nature from most types of fruit-bearing trees.

The size of the tread is taken based on the 45th shoe size. Since the step-ladder is intended for comfortable and safe work at height, the step width should be at least 30 cm.And if the design of the product provides for an upper platform, this indicator can be increased to 45 cm. boards can be applied with bars.

As for the number of steps, this indicator will have to be determined independently. Often the distance between the steps is created in the range of 20-30 cm. In this case, the overall height of the structure, as well as its slope, should be taken into account. As a rule, the calculation process does not get an even number of steps. The best solution in this case is to shorten the interval between the working and the penultimate site. Considering all these nuances, there will be no difficulties with the markup.

Another important criterion in the process of calculating the size of the future product is the length of the steps.Regardless of the number of steps of a wooden ladder (2, 4, 6 or 8), this indicator changes in the direction of decreasing the height of the structure. Since such a product is assembled in the form of a pyramid with a truncated top, the recommended step length is from 55 to 35 cm - for the lower and upper projection, respectively. This is enough to provide comfort during ascent and descent.

Thanks to the above recommendations, you can easily independently calculate the dimensions of the structure and understand the technology of its manufacture, regardless of the degree of complexity of the step-ladder drawing made of wood with your own hands.

DIY wood stepladders: a detailed guide

Speaking about how to make a step-ladder with your own hands from wood, it should be noted that first of all you need to create drawings of the future product. It is necessary to clearly imagine exactly how the structure will look, to determine its configuration and basic parameters. In the process of working on the drawings, you also need to think over the type of fasteners and form a list of materials that will be needed to design the stairs.

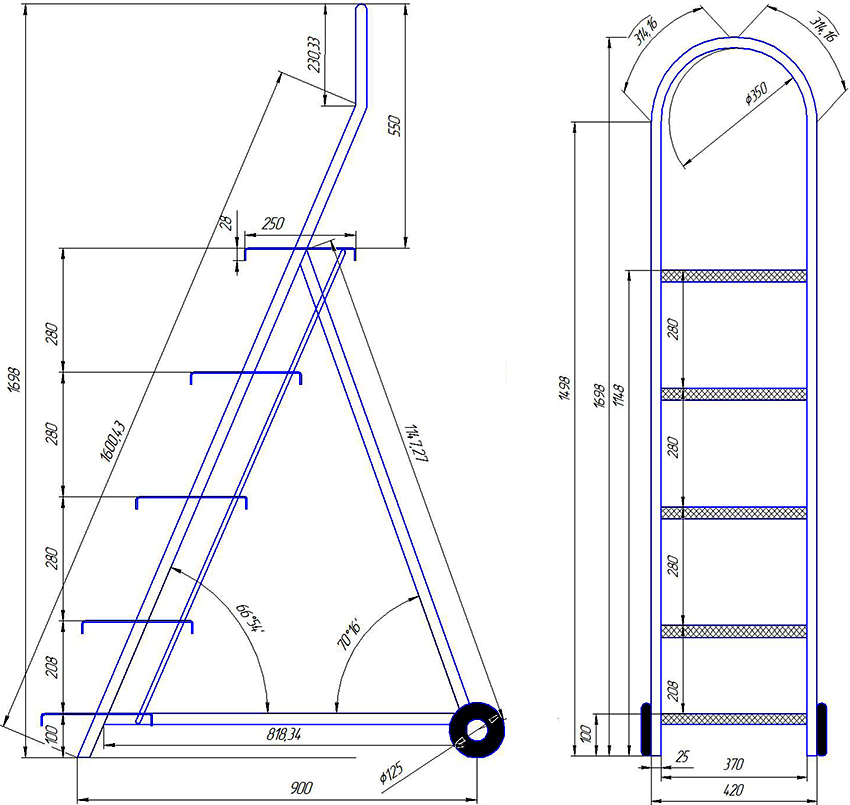

Making a metal step ladder with your own hands is a rather difficult task. This will require many special tools, as well as skills in working with metal products. That is why wooden structures are very popular.

For the bowstring of wooden stepladders for the house, beams of approximately 5x5 cm are often used, and for the steps - a board up to 4 cm wide.It is necessary to mark and cut the bowstrings-beams of the required length. They must certainly be maintained in accordance with the height of the structure. To ensure the stability of the ladder, the lower ends of the beams should be cut at approximately 30 °.

After the beams of the required dimensions have been cut, the process of making the steps can begin. The length of the lower step should be approximately 65 cm, the upper one - no more than 35 cm. You will have to make adjustments to the dimensions already in the process of constructing the ladder. After preparing the steps of the required size, it is recommended to number them on the reverse side to avoid confusion.

Important! To give stability to the product, it should be made in such a way that the bottom is wider than the top.

If the design of the product provides for an additional platform, it should be made of the same material as the steps. The second part of the ladder, which is the supporting one, is assembled according to the same principle. The only difference is that the steps are replaced with crossbars in order to increase strength, which are nailed in the transverse direction or diagonally.

Key points of the most interesting part of the manufacturing process

Creating a wooden stepladder with your own hands, bolts are used to achieve a reliable connection of all elements, special hinges are used to give mobility to parts of the product, and limiters or spacers to fix the position, which prevent the legs from sliding over the surface.

How to make a ladder yourself? The installation process should begin by connecting the crossbars and the bowstring. For this, self-tapping screws are placed at the ends, at the attachment points of the steps, by screwing in. It is required to process all joints with wood glue. The steps should be parallel to the floor while the ladder is unfolded. If the structure is equipped with a platform, it is necessary to install an additional support.

The moving elements of the ladder must be connected by means of hinges. In this case, you need to take care of the presence of a travel stop, which should be fixed to the end parts.This element is the key to the stability and reliability of the product.

If the steps of a folding step-ladder are fastened by means of glue, to increase the degree of strength of the structure, the bowstrings are pulled together with metal rods. They are placed under the steps: under the first, in the middle, and also under the step located at the top. The rods help to give strength to the stairs.

In order to protect the ladder from rotting, an antiseptic agent should be applied to the wooden parts, which forms a film with a water-repellent effect. In addition, you can cover the product with a varnish without touching the metal structural elements.

It is recommended to connect the details of the future ladder by means of self-tapping screws and a screwdriver

Following the above recommendations, you can easily create a step ladder with your own hands. Following step by step instructions is the key to success.

Chair-ladder transformer: instructions for self-construction

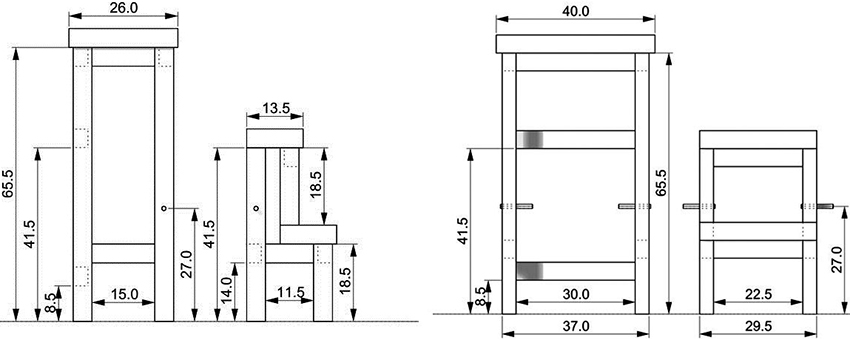

When designing a do-it-yourself transformer step-ladder chair, drawings are the first thing to arm yourself with. Not only the final appearance of the product depends on how correct the calculations are, but also its most important characteristics: convenience, strength and stability.

Since such a chair is primarily a piece of furniture, it should be a good addition to the interior. In addition, such a stool serves as a miniature staircase structure. It will help you easily get to the shelves located at a height, and will also become a very valuable assistant in the process of replacing light bulbs in a chandelier.

It is interesting! The wooden transforming chair differs from the stepladder in that to use the steps, you will need to turn the product over, more precisely, set one half of it to the opposite one.

The transformer staircase chair is not only a functional product, but also an interesting interior detail

You can design such a chair with at least minimal wood handling skills. This is due to the fact that the processing of some of its elements occurs using a milling machine or a drill with specific nozzles. In this case, it is much more important to calculate the necessary indicators so that after assembly everything converges to a millimeter.

A transformer wooden step-ladder chair planned for making with your own hands can be characterized by an arbitrary configuration. However, it is necessary to calculate the following indicators:

Related article:

Telescopic step ladder: the best solution for comfortable and safe work

Areas of application. Product advantages. Types of structures. Features of telescopic ladders. Rating of transforming products.

- the length of the support legs;

- back height;

- number of steps;

- dimensions of steps;

- seat size.

When forming a drawing of a stepladder chair, it should be borne in mind that the degree of height of the product during its operation depends on the length of the supporting legs. In addition, longer legs can be installed, which are placed at an angle to increase the stability of the structure.

As for the backrest, it should be positioned so that when the product turns into a stepladder, it is on the floor level with the base support, at right angles to the surface.

The seat is split into several parts for folding the structure. In this case, the piano hinges are the best option for connecting the halves of the seat. The number of steps depends on the final height of the product. Often there are no more than 5 of them.

In order not to worry that the legs of the chair can simply come out of the grooves, not withstanding the load, it is recommended to additionally use metal rods equipped with nuts, tightening the parts on the sides.

Diy step-ladder chair: step-by-step instructions

First of all, to complete the work, you need to stock up on certain materials. The list includes the following items:

- boards or plywood 2 cm thick;

- paints and varnishes;

- jigsaw equipped with an electric drive;

- drill;

- screwdriver;

- mallet;

- PVA glue;

- sandpaper;

- brush;

- self-tapping screws;

- loops;

- wood dowels.

First of all, using pre-prepared paper patterns from boards or plywood, you should cut out blanks in which you have to make holes for dowels or cut grooves, notches and spikes.

Important! The surface must be sanded and impregnated with compounds that are endowed with a moisture-protective function.

Then it is required to apply glue to the wood dowels, and then hammer them into the prepared holes on the seat, back and steps using a mallet. Wanting to give strength to the structure, it is better to use self-tapping screws. It is necessary to install loops in the pre-created grooves and fix them. The next step is to re-sand the stepladder surfaces, especially in the areas of secondary processing. After that, you have to apply stain and varnish or drying oil and paint.

When making a ladder stool with your own hands, it should be borne in mind that the elements of the product should not interfere with each other while driving. The two steps at the bottom, which resemble a compact chair, rotate by means of pins. During folding, they are placed inside the product. In this case, you can think of additional fasteners. The best solution would be a lock, which serves to fix the structure in its unfolded form.

The compactness of the product provides for an attentive attitude both to the manufacture of elements and directly to the assembly. The drawings include information on dimensions that must be observed. Otherwise, the process of unfolding and folding the structure may become difficult or even impossible.

Although ladders, like any other folding structure, are not a hassle during storage, they still require a certain amount of space. Chairs that can serve as ladders are so compact that they do not need additional space at all. The request "how to design a transformer step-chair with your own hands" is encountered quite often, which confirms the enormous popularity of such products.

Small stepladder: the nuances of design

For a person who is used to designing everything on his own, information about the specifics of the installation of staircase parts is completely uninteresting. For a competent home craftsman, it will not be difficult to assemble a step-ladder chair using ready-made drawings with your own hands. But some aspects really deserve special attention.

When marking the stringers, to determine the installation points of the steps, the drilling locations should also be indicated. In order to achieve strength, in some cases it is desirable to reinforce the elements with metal spokes. If for some reason this cannot be done, you can use powerful screws.

With regard to the fastening of the so-called "shoes", you should know that it also has its own specifics. First of all, the lower cuts of the stringers should be slightly rounded. This will increase the convenience of installing the ladder in any place and reduce the wear of the heel.

In addition, it is necessary to correctly determine the method of fixing the "shoes". If RTI (rubber technical products) are characterized by sufficient elasticity, self-tapping screws can be used. When screwed in tightly, their heads sink into the rubber and leave no scratches on the floor.However, since the dimensions of such a fastener are insignificant, it can quickly break the rubber goods. That is why a washer must be placed under the head.

Important! When using hard rubber goods, you should only land on glue. It will not work to press the head into such rubber, which means that the floor will be scratched not by the legs of the structure, but by the fasteners themselves.

In order for the legs of the stepladder not to disperse during a person's stay on it, a so-called limiter should be fixed at about half the height of the stringers. This device is often ignored by home craftsmen, but an installed chain or a long hook often saves you from falling from a mini-structure.

How to make a step-ladder with your own hands in such a way that it provides comfort during work? Experts recommend fixing a couple of hooks on the sidewalls of the stringers. On them, you can place a bucket of solutions or paint, a container for harvesting or a bag with the necessary tools.

The fact that a structure equipped with such devices will be much more convenient in operation is unambiguous. In addition, at least one piece of plastic pipe can be fixed at the top. The result is a functional case where you can place a hammer, screwdriver, or other accessories that come in handy for work.

Wooden stepladder: finishing touches of manufacturing

Already before the end of the work, there is very little left - just equip the upper platform and install special limiters that will not allow the stairs to travel a greater distance than it was planned. As for the construction of the site, this process will not cause difficulties. It only needs to be cut out of any material, for example, from plywood. In addition, it has to be fixed on the upper stage of the structure by a movable method. For this, standard hinges will be an excellent option.

In order for the platform to simultaneously perform the function of holding, a special latch should be installed on the opposite side, with which it will cling to the upper step of the second staircase. Choosing limiters, you can give preference to elementary straps that connect the stairs at the bottom. You just need to set the structure in working position and fasten the lower part with a plastic cable.

Regardless of what exactly it was decided to design with our own hands: a stepladder stool or a full-fledged structure made of wood - all elements of the product must certainly undergo grinding and processing with special solutions.

First of all, by means of sandpaper, it is necessary to grind all the parts that the human hands will touch. The surfaces must acquire such smoothness that during the operation of the stairs, the probability of driving a splinter is completely excluded. In addition, it is necessary to clean the surfaces in the event that they have succumbed to mold damage.

How to extend the life of finished products: protection features

To make the wooden stepladder stool resistant to external influences, the product should be impregnated with a special compound - stain. This tool acts as an antiseptic, prevents rotting, as well as the appearance of mold on the surface of the wood.

Note! The processing of structural elements with wood stain should be carried out until the moment of its assembly. This will make it possible to significantly extend the life of the product.

First of all, the wood must be treated with an antiseptic impregnation, which will become a reliable protection against decay and create a film with a water-repellent effect.The optimal solution is varnishing. In this case, it is better to try not to touch the attachment points. As for the paint, it will not always be appropriate, but only fit as an option in case of emergency. If you do everything right, the stepladder will delight you for more than one year.

Based on the above recommendations, we can conclude that it is not at all difficult to bring the product into working condition. Exactly according to the same principle, you can design a step-ladder from a profile pipe according to a drawing with your own hands. The difference between it and a wooden staircase lies only in the materials, as well as the devices necessary for the work and the method of connecting the parts of the structure.

Thus, it is not difficult to make a ladder or a step-stool with your own hands, the drawings of which are prepared in advance. The main thing is to take into account all the existing nuances of the further operation of the structure and correctly select the dimensions of all parts. Above are methods of making some of the lightest and most affordable products for design. By creatively approaching the process of their processing, you can get an original and incredibly beautiful design.