New technologies in human life can only be considered valid when they have more efficient energy-saving and environmentally friendly qualities than the previous ones. Plastic rings for a well have practically proven their right to exist. They are replacing heavy reinforced concrete structures, the installation of which is laborious and very costly. Products simplified the process of arranging wells, and made operation reliable and affordable.

Content [Hide]

- 1 The variety of types of wells and their area of application

- 2 Requirements for the placement of a plastic well for water supply

- 3 Purchase of materials and methods of laying plastic rings

- 4 Sizes and prices of plastic rings for sewage

- 5 Features of carrying out repair and preventive work

- 6 DIY plastic well

- 7 Rules and tips for the operation of plastic wells

The variety of types of wells and their area of application

Polymer rings for wells have firmly and reliably entered various spheres of human life. Wells assembled from them provide production and consumer needs. Based on the characteristics of the intended purpose, wells can be divided into the following types:

- classical. It is a source of drinking water. Traditionally, water is supplied by a pump or pumping station;

- sewer well. Installed in the absence of sewerage. Kinets are installed at the bottom, through them waste water goes into the soil;

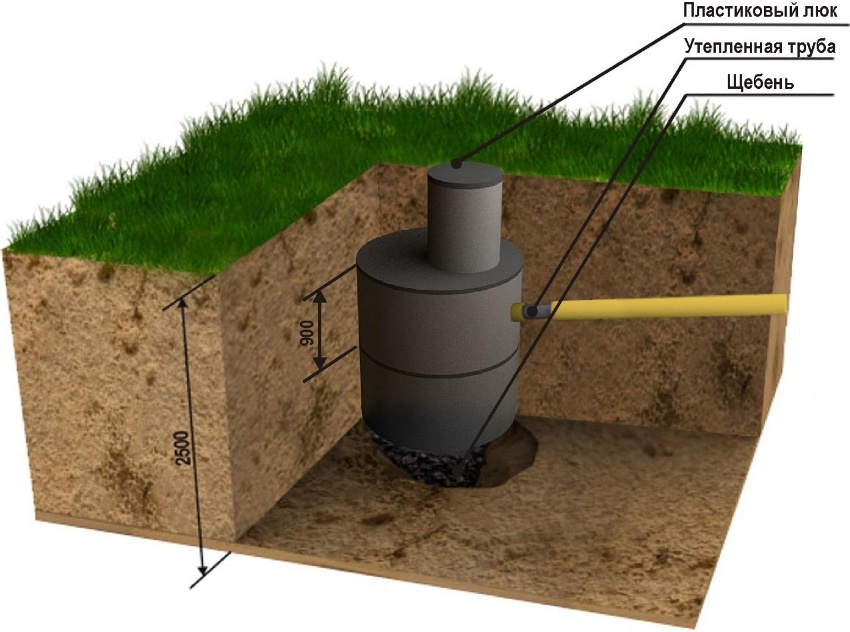

- drainage (absorption). This is a kind of sewer well, only without throws. A layer of gravel or sand is poured onto the bottom;

- cumulative. Serves to collect water, usually rainwater, which can be used for irrigation or other needs;

- telecommunication. Designed for placement of couplings and stowage of a stock of fiber-optic and power cables. Installed both in the pedestrian and in the transport area;

- lookout. Designed for control and repair of sewer systems. Ladders, handrails and other devices are mounted in it, allowing you to lower to perform repair and maintenance work;

- septic tank. A special treatment plant where waste water is processed in a sump. The underground filtration system decomposes without oxygen.

Useful advice! To quickly and correctly select the desired version of the plastic well, it is better to use the ready-made configuration.

Large plastic pipes diameter as an alternative to concrete structures

The appearance of plastic rings for wells constituted serious competition for the seemingly proven and maximally improved technology for laying concrete structures. Comparing functions, labor costs and the final price of a plastic well, we come to the conclusion, that the advantages of the latter are obvious.

The weight of a polyethylene ring with an inner diameter of 900 mm, a height of 2 m and a wall thickness of 25 mm is 46 kg. A reinforced concrete ring with an inner radius of 1000 mm, a wall thickness of 80 mm and a height of 890 mm weighs 600 kg. This weight, naturally, will cause difficulties during transportation and installation.

Threaded, groove and silicone gasket connections create virtually maximum tightness for the plastic collecting pipe. Seams between concrete rings are sealed with cement mortar, which degrades over time.

Plastic rings are easy to cut. They can be made to individual sizes. Concrete ones are produced only in standard dimensions, they cannot be changed.

The presence of pores and indentations in the concrete rings creates an environment for bacteria to grow. The inner side of the plastic rings is absolutely smooth, the presence of bacteria on the walls is excluded.

The plastic pipe for the well is lightweight, which greatly facilitates the construction of a water source

There is no negative attitude towards the installation of plastic wells on the part of environmentalists. Such structures have good functionality and have characteristics that meet modern health and safety requirements.

The main features of plastic wells:

- do not corrode;

- resistant to vibration and other mechanical stress;

- frost-resistant, tolerate temperature extremes;

- have a rigid structure;

- do not require additional processing;

- are sealed at the points of entry of pipes;

- quickly mounted;

- safe for the environment.

Important information! The price of plastic sewer rings is much higher than concrete ones. But, taking into account the costs of transportation and installation of the latter, the total cost of the wells turns out to be practically equivalent.

Production material: features of the polymers used

Rings for a well (sewer, switching, drinking water and septic tank) are usually called in one word - "plastic". Since wells made of this material are used for various industrial purposes, in everyday life, to create drainage systems, since they function in different soil and under different mechanical and thermal influences, they are made from different polymers.

For the manufacture of plastic well rings use:

- polyvinyl chloride;

- polyethylene;

- polypropylene;

- polymer-sand mixture.

Despite the overall high performance, the materials still differ in a number of features. Fire resistant PVC wells. This material is resistant to various chemical influences. Polyethylene products withstand temperature extremes best of all, freezing and thawing water does not deform the rings.

Polypropylene is used for installation in places where there is a constant mechanical or vibration effect on the structure. The material is plastic and the most wear-resistant. The polymer-sand well is characterized by almost absolute tightness.

Full tightness, which polyvinyl chloride rings have, excludes seepage of waste products into the ground

Useful advice! When choosing rings for a plastic well, be sure to pay attention to the material of manufacture and compare its quality with the conditions of use and the purpose of the well.

For a drinking well, in the absence of problem soil, you can buy plastic rings. They are inexpensive and quite suitable for their functional features. If the soil is unfavorable, it is worth buying a polymer-sand well.

For a switching well that is exposed to constant mechanical stress (for example, a car drives in, leaves, or is parked), it is better to purchase PVC rings. Their price is the highest, but only this material can withstand constant loads without consequences.

For a septic tank, you can buy inexpensive rings made of polyethylene. The accumulation of gases does not deform and does not negatively affect the state of this polymer. The cost of purchasing a more durable material is unnecessary.

The constantly growing demand is provided by the choice of proposals. Today, you can buy plastic rings for a well at any store that sells plumbing equipment and plastic products. It is not difficult to choose a pipe from the desired material.

Plastic rings for the well: dimensions and connection methods

The sizes of well rings are different. The main indicators are diameter, height and thickness. The diameter of the rings varies from 400 to 1500 mm. It should be borne in mind that it should be 10 - 15 cm smaller than the diameter of the prepared shaft.

Height is the second indicator by which to choose rings. It is necessary to calculate this value based on the depth of the future well. Typical ring heights are 500, 1000, 1500 mm.

The average wall thickness is 55 mm (some types of polyethylene rings are 6, 8, 22 mm). The outer diameter of the rings ranges from 455 to 1555 mm. It is the dimensions that make the carrying capacity and installation of plastic products available.

The diameter and wall thickness of the pipe required for the well depends on the size of the well hole and the type of soil in which it is located.

For the arrangement of a drinking well, it is recommended to choose rings with a diameter of 680, 800 and 900 mm. For sewerage, switching wells and drainage systems - 800, 900, 1500 mm.

Useful advice! The deeper the shaft of the future well, the thicker the rings should be.

Collecting rings into a single structure is not difficult. This process does not take much time and does not require significant preparation and a large number of participants. The rings are connected in three main ways:

- twisting along the thread;

- falling into the groove and snapping;

- welding.

With a correctly technologically executed installation, all types of connections provide a high degree of tightness. The first two methods are recommended to be performed using silicone seals. Welding requires additional equipment.

The rings for the well, the dimensions of which do not exceed half a meter in height, can be mounted without assistance due to their low weight

One-piece plastic rings are also used to create wells. They are actively used for the restoration of old concrete wells that cannot be dismantled.

Such products are also used for septic tanks. The advantages of non-separable rings are:

- thickness from 6 mm (you can order the required one);

- the height can reach 5 m (this greatly simplifies installation);

- the diameter starts from 95 mm (allows you to equip the well).

Useful advice! When buying plastic rings for a well, it is imperative to inspect their outer and inner surfaces. Inhomogeneous color of individual areas may indicate a violation of density or the presence of deformations.

The length of one-piece plastic rings can be up to 5 meters, which greatly simplifies their installation

Requirements for the placement of a plastic well for water supply

Arrangement of a plastic well, like any other project, should begin with planning. If the well is potable, it is imperative to know at what depth the water layer is located and where it is most close to the surface. This will save the physical and material costs of the device and make it more convenient to use the well in the future.

Related article:

Diy well: step-by-step construction instructions

Varieties of rings. Pump selection. Well construction: site selection, installation instructions.

Only hydrogeodesy of the site can give such information. There are enough organizations licensed to carry out such works. The order is carried out within three days (taking into account the drawing up of an act-report).

In addition to information about the nearest depth of the water layer, such work will also provide information on the quality of the soil. Depending on the results, it will be possible to choose the location of the mine preparation and the method of installation.

Useful advice! When choosing the location of the well, it is necessary to avoid closely growing trees. The roots can damage the walls of the device.

The dimensions of large-diameter plastic pipes for a well with drinking water are selected taking into account that they must be at least 50 cm higher than the surface of the site. This will prevent rain and melt water from entering the well. For devices of other types, this condition is not necessary, since their design includes a closing hatch.

Accommodation requirements plastic well for sewerage

When determining a place for a sewer well, you need to know if other communications are nearby, so as not to damage them during the preparation of the mine. It is necessary to remove the well from growing trees at least two meters. The elements of the sewerage system should be laid at a distance of 1.5 m from the water supply pipes.

The sewer well should be located no further than 10 meters from the outlet of waste streams and at least 3 meters away from the building. It is better to buy plastic rings for a sewer well with a diameter of at least 900 mm. This size will make it available for repair and revision work.

Regardless of the purpose, private or public, the installation of sewer wells must be carried out according to certain rules and requirements

Purchase of materials and methods of laying plastic rings

Only after studying the technical conditions and preparing the design component, you can start purchasing materials. You need to purchase accessories based on the required depth of the well, taking into account the possible or desired diameter. When sizing, be sure to take into account the subsequent operation.

Useful advice! If there is uncertainty about the correctness of the preparatory stage, it is better to contact the organization that installs plastic wells to draw up a plan and estimate. Even minor errors can lead to the impossibility of normal operation of the device in the future.

Plastic rings for a septic tank do not have to be expensive. It will be quite enough polyethylene (they are the cheapest) of average thickness (20-30 mm). It is better to buy a plastic drainage well from a more resistant material - polypropylene, since it will most likely be located in a place where external loads are inevitable.

Depending on the composition and mobility of the soil layers, the rings can be laid open or closed.

The open method is used if the soil is not loose and mobile.A mine of the required depth is dug, having a size 10-15 cm larger than the diameter of the rings. If the well is drinking, a filter made of sand, pebbles or geotextiles is laid on the bottom. A corresponding tray is installed in a sewer device or a well for another purpose:

- solid;

- with profiling in the form of grooves;

- distribution;

- checkpoint.

A pipe is assembled from separate plastic rings and lowered into the well shaft. The pipe is leveled, and the space between the plastic and the ground is filled with small pebbles, sand or their mixture. The neck is mounted, a hatch is installed.

Useful advice! No need to fill the space with cement mortar. This will significantly complicate the repair or reconstruction of the well in the future.

Plastic does not emit harmful substances into the water, therefore, concrete and metal pipes of old wells are replaced with polymer ones

The closed method of installing a well is advisable where the soil is loose. The mine is dug to the depth of one ring, which is subsequently installed. Then the soil is selected so that the ring lowers under its own weight. To use this method, it is important that the method of connecting the rings is simple - thread or groove. After laying the entire pipe, the required bottom is poured from sand, pebbles or cement mortar. Next, the space between the soil and the walls of the mine is filled, a hatch is mounted.

Types of standard manholes for plastic wells

An important condition for the long and normal functioning of the well is the correct selection of the hatch. The standardization is based on the load that a plastic well structure can supposedly withstand. There are different load-bearing hatches:

- Up to 1.5 tons. They are used in areas where there is no constant mechanical pressure. These can be footpaths, lawns, lawns.

- Up to 12.5 tons. Installed on sidewalks, in places of transport parking.

- Up to 25 tons. Designed for installation on city roads.

- Up to 40 tons. Withstand the load of constant traffic flow, including trucks. Placed on highways.

Plastic manholes for wells are made of resistant polypropylene that does not fade in the sun, does not corrode and withstands a wide range of temperatures

Depending on the set of components of the well, hatches are installed:

- directly to the mine;

- on the neck;

- on the unloading ring.

Only hatches that can withstand a load of up to 1.5 tons can be installed directly on the mine. For other types, any installation method is applicable. When installing the well, it should be borne in mind that the thickness of the plastic rings for the sewage system must correspond to the weight that the cover can withstand.

Sizes and prices of plastic rings for sewage

The prices of plastic rings for a well most often depend on the size and quality of the polymer used. The manufacturer and place of manufacture also have a certain influence on the cost. The most affordable are polyethylene rings. Polyvinyl chloride structures will be more expensive.

The best seller is polypropylene rings. They have a reasonable price and high technical performance. They are used for arranging almost all types of wells.

Below are the price tables for sewer rings made of two types of polymers.

Well rings price made of polyethylene with a wall thickness of 8 mm:

| Diameter, mm | Height, mm | Price, rub. |

| 950 | 1500 | 21000 |

| 2000 | 25300 | |

| 2500 | 29400 | |

| 3000 | 38600 | |

| 1450 | 1500 | 34300 |

| 2000 | 40400 | |

| 2500 | 46200 | |

| 3000 | 52300 | |

| 1900 | 1500 | 47670 |

| 2500 | 63750 | |

| 2000 | 64300 | |

| 3000 | 71500 |

Well rings price made of polypropylene with a wall thickness of 8 mm:

| Diameter, mm | Height, mm | Price, rub. |

| 950 | 1500 | 25117 |

| 2000 | 30000 | |

| 3000 | 33000 | |

| 2500 | 35000 | |

| 1450 | 1500 | 40750 |

| 2000 | 47600 | |

| 2500 | 54300 | |

| 3000 | 61200 | |

| 1900 | 2000 | 55500 |

| 1500 | 55700 | |

| 2500 | 74200 | |

| 3000 | 82700 |

Useful advice! The price of rings for a well is the bulk of the cost, but when planning material investments, it is worth considering in advance the cost of hatches, necks, tees, cones and other specific elements of plastic wells. As a result, their amount may turn out to be considerable.

It is important to consider the costs not only for well rings, but also for hatches and other consumables.

One of the most popular products is considered to be the products of the domestic company "Ecosystem". The manufacturer sells plastic rings according to the following principle: outer diameter - 950 mm, inner - 900 mm, height - 1500 mm, price - 9 thousand rubles; outer diameter - 600 mm, inner - 650 mm, height - 1500 mm, price - 8 thousand rubles.

Rodlex is another leading company in the production of plastic water supply, drainage and communications systems. She sells plastic rings at the following price: height 500 mm - 4320 rubles; height 1000 mm - 8640 rubles; height 1500 mm - 12900 rubles; height 3000 mm - 25,900 rubles. You need to pay 3-4 thousand extra for the tray.

Produces prefabricated polyethylene wells and the capital plant FDplast. It offers designs that consist of a chute, a shaft, a mouth, a telescopic tube and a compact hatch. The plant's products are competitive. Average prices, guaranteed shelf life of products - 50 years, tolerable temperature - from -60 to 70 degrees. Tightness is achieved using adapters and O-rings.

The average price of large-diameter plastic pipes of domestic manufacturers is 9 thousand rubles (standard one and a half meter model). Structures with a tray cost 3-4 thousand more. An ordinary mine with a bottom will cost 12-13 thousand. Covers and other system elements are purchased separately and are not included in the standard package. Their cost depends on the shape and material. The average price for round and square lids is 2-3 thousand rubles.

The Wavin company is popular among foreign manufacturers. It produces inspection and storm types of prefabricated plastic systems. All Wavin products are characterized by high performance and good resistance to mechanical damage. Prices for the products of this company differ from domestic ones by 3-7%. Some items are more expensive, but there are a considerable number of items that have a lower cost. Detailed information can be found on the company's website.

Features of carrying out repair and preventive work

Drinking concrete wells (even with constant cleaning) need major repairs or replacement after 25-30 years. With the advent of plastic rings, repairs have become less of a problem. It will be about a new plastic drinking water well in place of the old concrete one.

Signs indicating the need to replace a concrete well can be considered:

- the appearance of an unpleasant odor of dampness or rottenness in the water;

- the presence of an admixture of clay (the water became cloudy);

- critical drop in water level;

- significant destruction of concrete rings.

It is necessary to choose rings for repair, adhering to the requirement that they will be 10-15 cm less than concrete ones. The remaining concrete shaft is a certain obstacle to the action of moving soils. Considering that concrete rings will continue to collapse and, possibly, aggravate the action of the soil, the material of plastic rings for renewing the well must be chosen strong, wear-resistant.

The assembled pipe is lowered into the concrete, the gap is filled with a mixture of sand and pebbles. In the presence of intense groundwater and leaks in the old structure, it is advisable to additionally seal the joints of the rings with silicone.

It is important! Bottom cleaning and replacement of the filter layer must be done before lowering the plastic pipe into the shaft. Otherwise, it will be possible to replace the bottom only partially, which will certainly affect the quality of water purification.

A sufficient number of wells have survived, where the mine is made with the help of brickwork. It is most often rectangular or square in shape. Such designs are commonly used for telecommunications networks, so they are shallow.

If the size of the well allows, it can be restored with plastic rings, following a certain sequence of work:

- remove the hatch;

- disassemble the top layer of masonry;

- clean the well of collapsed debris;

- mount and lower the pipe assembled from the rings (taking into account the switching channels);

- fill up voids between brick walls and a pipe;

- install a new hatch in an appropriate manner.

It is possible to repair wells using a one-piece structure. Its main advantage is that it is completely sealed. In this way, it is advisable to repair shallow wells - up to 500 cm. The lower edge should be installed on a flat surface. When deciding whether to repair or install a well using a one-piece structure, it is imperative to take into account the thickness of the pipe and compare it with the load.

DIY plastic well

In the presence of appropriate conditions (water is relatively close to the surface, unproblematic soil), the well can be made independently. If you need a shallow mine (up to 1 m), you can dig it by hand. If the water is deeper, a wide auger should be used. At a considerable depth, you will need attachments for it. The optimal diameter of the rings used is 40 cm. The pipe must be assembled, visually make sure that the joints are tight.

Then it is necessary to make many holes in the lower part at a distance of 50 cm from the lower edge using a 10 mm drill. The perforated area must be wrapped with a net made of synthetic materials that are not susceptible to water. It will act as a filter. The gap between the plastic and the ground should be covered with sand.

Useful advice! To avoid unnecessary costs or the need to additionally purchase rings, it is better to purchase them after preparing the mine.

Rules and tips for the operation of plastic wells

Plastic wells do not require constant complex monitoring of the condition during operation. The inner surface of the rings is smooth, therefore, precipitation can appear on the walls only after a long time. Cleaning does not cause problems: a brush, a broom, a jet of water under pressure will remove plaque. If the seams are correctly connected and sealed during assembly, then no cracks will appear until the end of the service life (up to 50 years).

If you need to add rings (for example, in case of subsidence of the soil), you need to remove the first one in order to free access to the threads. To prevent this action from causing damage to structural parts, they should be easily removed (not cemented).

It is better to close the part of the plastic well that is above the surface. Direct sunlight can deform the rings, especially if they are thinner. You can imitate a log house if it is a drinking well. Brickwork will give an aesthetic look. The original canopy will protect from the effects of the sun and will become a design element of the site on which it is located.

Wells made of plastic rings have become a significant step forward in the field of rational and reasonable improvement of living and working conditions. Today there is no worthy alternative to them. Dimensions of structures, availability of installation in any area, high manufacturability,long service life make them the only reliable way to ensure the normal functioning of water supply, sewerage and other communications.