The screwdriver bit facilitates and simplifies the process of mounting fasteners, as well as their removal during repairs and construction work. If the accessory is incorrectly selected, the risk of tool failure increases. This article will help you avoid such problems by understanding all the features and types of removable devices for a screwdriver, as well as the nuances of their use.

Content [Hide]

- 1 Screwdriver bit: device and general classification

- 2 Screwdriver bits: types of nozzles by type of material and shape

- 2.1 Screwdriver bit: tooling for straight slot

- 2.2 Features of Hex Bits for Power Tools

- 2.3 Characteristics of cross bits for screwdriver

- 2.4 Features and dimensions of asterisk bits

- 2.5 An overview of the parameters of long bits for screwdrivers of various shapes

- 2.6 An overview of bits for a non-standard screwdriver

- 3 How to choose bits for a screwdriver: prices and optimal sets

- 4 How to insert a bit into a screwdriver: algorithm for changing nozzles

- 5 How to upgrade a 12 volt cordless screwdriver

Screwdriver bit: device and general classification

Bits, or screwdriver heads, have a simple structure. These detachable bits consist of a rod that locks into the power tool holder. A drill is inserted into it. The rod is made in the form of a hexagon. Each bit has a specific shape that corresponds to a specific type of fastener.

All existing types of bits can be conditionally divided into three categories:

- Basic - the working body of the nozzle is made in the form of a cross. These lugs are distinguished by good adhesion to the heads of the fasteners.

- Combined - nozzles are equipped with a working body on both sides, and each of them can have its own size and shape.

- Special - attachments from this category are called highly specialized. These bits are designed to perform specific tasks, they are rarely used, and therefore are sold only by the piece.

Varieties of bits for a screwdriver by appointment

Its purpose depends on the shape of the working part of the bit. On this basis, the following types of heads are distinguished:

- for bolts and nuts;

- with anti-vandal slot;

- professional;

- for drywall;

- with "fork" type construction;

- magnetic and spring.

Helpful advice! It is advisable to buy attachments in one set. Bits are more expensive per piece.

The shape of the bits intended for loosening and tightening bolts and nuts is non-standard.The working part of these heads is not convex, like most tips, but has a hole. The size range of such bits is quite extensive. Attachments equipped with an anti-vandal slot are called "snake's eye". The shape of this tip is adapted to suit a fork wrench.

Professional screwdriver bits are distinguished by a high degree of reliability, excellent strength characteristics and a long service life. A large number of fasteners can be screwed with these heads. Professional attachments are made of high quality metal and protected by a special coating.

Professional head kits usually have a torsion bit for an impact driver. It can be distinguished from ordinary attachments by its appearance. In it, the area between the shank and the slot is very narrow. The torsion bit has a special design with a special flexible insert, which is made in the form of a spring. This component works for twisting. This design allows the torsion bit to be used for working with very hard materials, while using self-drilling fasteners. With the help of such a head, you can completely drown the self-tapping screw in the metal, and together with the cap.

A separate group of bits for self-tapping screws includes nozzles designed for drywall. They have a limiter that will not damage the material during installation. Plasterboard sheets are quite fragile, so you should avoid strong pressure while screwing in the screws.

The fork-type bit is a kind of anti-vandal slot. Outwardly, it looks like a flat version of the head, only with a slot in the middle.

Features of spring and magnetic screwdriver bits

To work in hard-to-reach places, as well as on the ceiling, bits with special capabilities are used - magnetic or with a latch. Spring-loaded tips hold well in the adapter. Like screwdriver bits, the magnetic heads provide a good grip on the grooves of the fastener (screw). The capabilities of these attachments are used to prevent the tip from sliding off the fastener head during operation.

Helpful advice! If you need to screw the screw as deep as possible, it is better to use a magnetic bit instead of a regular one.

Spring-loaded heads are classified as special. They are used in cases where it is necessary to install fasteners in hard-to-reach places or at different angles. These bits consist of a base and a slot, which are interconnected by a flexible spring. Moreover, the slot in such products is fixed manually. After that, it is inserted into the notches on the self-tapping screw. Thanks to the flexible spring, the fastener can be tightened at an angle exceeding 90 °.

Adapters, or screwdriver bit extensions, greatly simplify construction work. There are two options for these designs:

- With magnetic holders.

- With an internal retainer in the form of two curved legs.

Adapters are designed for standard attachments, they are convenient and practical.

Screwdriver bits: types of nozzles by type of material and shape

For the production of removable heads, hard and soft metals are used. The quality of these products, as well as the service life, depend on the raw materials used to make them.

The best quality tips are obtained from alloys:

- chromium and vanadium;

- silicon-fire sinter;

- chromium and molybdenum;

- vanadium and molybdenum.

Steel bits can also be found on sale, but their cost is very high. Given the short lifespan, the cost of purchasing such an expensive product cannot be justified. Even victorious solders, which are designed to extend the "life" of steel heads, do not save.A more effective protection is titanium coating, which surpasses nickel, diamond and tungsten-nickel sputtering in terms of reliability.

Important! Steel bits are not recommended for working with hard rock of mineral origin. On contact with such materials, the heads crumble.

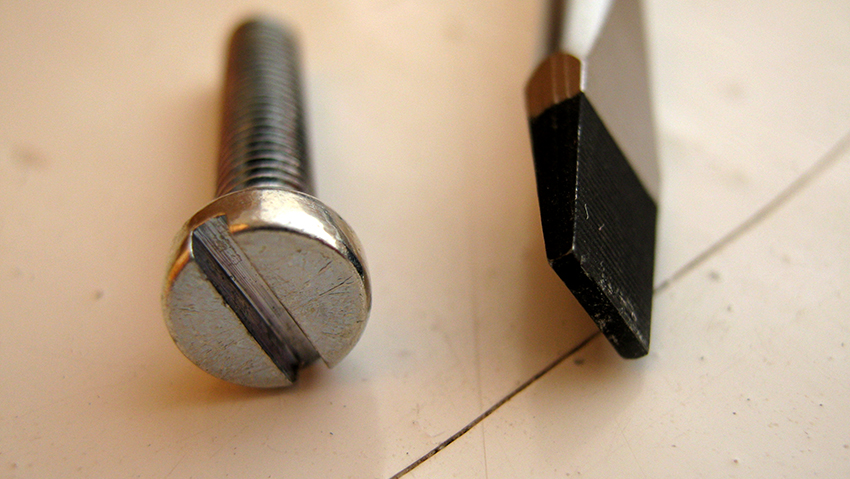

Screwdriver bit: tooling for straight slot

Slotted sockets are standard equipment in bit sets for Bosch, Metabo, Hitachi and other brands of screwdriver. They are used in almost all types of work. Slotted heads were one of the first to appear. This tool is designed for tightening screws and screws with a straight section on the head.

Slot bits can be identified by the characteristic Slot markings. Typically, these bits are marked with the letter S and a number that represents the slot width. This figure can vary from 3 to 9 mm. The marking does not show the thickness of the head, since it is standard and is 0.5-1.6 mm. To find out what material the nozzle is made of, you need to look at the shank. It is there that manufacturers indicate this information.

Titanium screwdriver bits have good strength values. Some of them are gold-plated and marked with the letters TIN. This means that the head is coated with titanium nitride. Such devices are up to 6.5 mm wide, which is more than the standard. Their thickness, on the contrary, does not reach the generally accepted indicator and is no more than 1.2 mm.

Slotted nozzles are often combined. Usually they are supplemented with a cruciform head. This approach is explained by the versatility and practicality, since it is these nozzles that are most in demand.

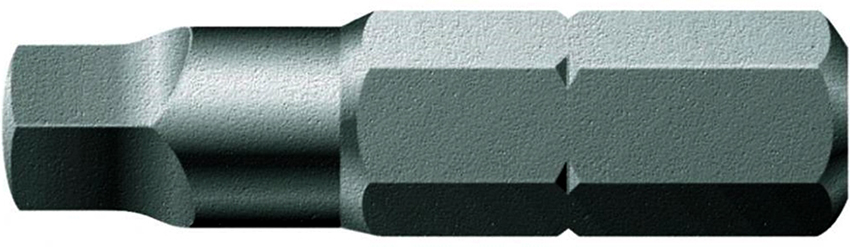

Features of Hex Bits for Power Tools

Hex bits are used to secure hex head fasteners. Such screws are used in the repair of large equipment, as well as in the assembly of heavy furniture structures. This notch shape, called an internal hex (Hex Socket), was invented in 1910. It found its first application at the Allen Manufacturing Company plant.

Hex bits are marked with the letter H. Good torque is the hallmark of these bits. This completely eliminates the possibility that the thread will break off or the head itself will be damaged during the installation of the fastener.

The bit size for a hex screwdriver is in the range of 6-13 mm. The most demanded are 8 mm heads. They are used to install self-tapping screws during roofing work. There are other characteristics of Hex attachments. One of the main ones is the distance between the sides of the hexagonal blade. Attachments with a 4 mm indicator are used for tightening furniture fasteners.

In addition, manufacturers produce a safe type of slot called Hex-Pin. A special pin is installed in its central part. Due to this, unauthorized disassembly of such connections is simply impossible.

Note! Hex head screws are slightly deformed. This nuance must be taken into account when installing such fasteners.

Characteristics of cross bits for screwdriver

Many companies make their own bits. Despite the fact that they are branded, these products have a standard shape. Philips marks the crossheads with PH. This company produces several sizes of bits for the screwdriver: PH2, PH0, PH1 and PH3. The diameter is selected taking into account the size of the head of the fastener.

The most popular are PH2 bits, they are used in construction and repair work. Heads marked PH3 are used for furniture assembly and car repairs. The length of the nozzles varies from 25 to 150 mm.To carry out installation work in hard-to-reach places, flexible extension cords are used.

Proprietary Pozidrive heads are reliable, have sufficient torsional torque and provide a strong hitch even at a slight angle. The company marks the cross-shaped bits with the letters PZ and a number indicating the head size - from 0 to 4. The PZ0 bits are designed for driving small screws and screws with a diameter of 1.5-2.5 mm. The largest size head PZ4 is used for the installation of anchor bolts.

Both companies produce titanium nitride coated bits in addition to the classic bits.

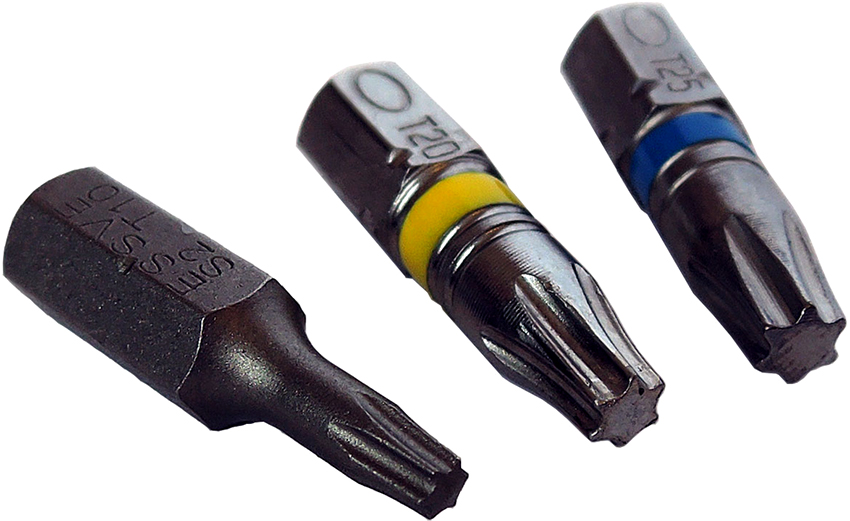

Features and dimensions of asterisk bits

The star-shaped heads are used to install fasteners used in the production of household appliances, as well as in mechanical engineering. These bits are labeled with the letters TX or T. Their full name is Torx. Next to the letter designation is a number that indicates the size of the head. This indicator corresponds to the distance between the rays of the asterisk.

In 1967, Textron introduced the first six-arm star-shaped bits to electric tool owners. Almost all of them have a highly specialized purpose.

There are several options for star tips:

- classic;

- Torx Plus;

- with TIN coverage;

- with a hole inside.

Related article:

Screwdriver bits: functional tips for power tools

Tips for power tools, their types and functionality. Removable attachments for grinding, polishing, cutting and other tasks.

Classic bits provide excellent grip to the screw or screw during installation. The user does not need to exert much effort to generate torque. The size range of these heads is quite extensive, but the most popular options are in the range from T8 to T140.

Note! Classic bit sizes from T8 to T140 are the most common. This does not mean that nozzles cannot be found that will be greater or less than the specified values.

The hex beams on the Torx Plus heads are not as sharp. They are also much shorter. This shape provides increased accuracy of movements during work that requires special accuracy. Torx Plus heads are made from very hard steel. Their sizes range from T10-T140. Titanium nitride coated tips and bored heads used in assembly plants have the same size.

An overview of the parameters of long bits for screwdrivers of various shapes

In each group of bits you can find elongated heads. This allows you to more accurately perform certain types of work. In elongated straight slotted bits, the bit is firmly fixed in the head of the fastener. Thanks to this, it becomes possible to perform high-quality small installation work. The length of these removable devices ranges from 50-100 mm.

Crossheads with an elongated design are used for installation work in hard-to-reach places. Moreover, they are no less effective when you need to unscrew the fasteners.

Cruciform bits are available in three sizes (PH3, PH1 and PH2) and can be as long as:

- 50 mm;

- 70 mm;

- 90 mm;

- 110 mm;

- 125 mm;

- 150 mm.

Pozidrive crossheads have similar parameters. Elongated hexagonal heads are used much less often in work, however, they are quite convenient and practical. These products are made of high quality steel, so they have good durability. Their length ranges from 50 to 100 mm, and their size ranges from 3 to 8 mm. As for the nozzles in the form of stars, their length is the same.Manufacturers offer these extended designs from T10 to T140.

An overview of bits for a non-standard screwdriver

Non-standard shaped tips include triangular heads marked with the letters TW. Their size is marked with numbers from 0 to 5. The design resembles a trihedral, and it is used to install fasteners with a cross recess, which is usually found in foreign-made household appliances. Specially for drywall, nozzles with a limiter are provided.

Also on sale you can find square-shaped heads, marked with the letter R. They have four edges and are intended for narrow use - the assembly of large-sized furniture structures. Square tips are available in four sizes.

Fork-shaped heads have a flat slot with a slot in the central part. These attachments are marked with the letters GR and are available in four sizes. Fork bits can be standard or extended (up to 100mm).

The TW mark is also found on products with three or four blades. These are professional attachments that are used in the aviation and space construction industries.

Helpful advice! Non-standard nozzles are found in household kits, but they are rarely used at home. If you want to choose the best bits for a screwdriver, it is recommended to give preference to sets that include the most popular types of nozzles.

How to choose bits for a screwdriver: prices and optimal sets

Bit sets are in high demand among consumers as they contain bits for all occasions. Such kits can help out in almost any situation, so it is very important to choose a really high-quality option.

How to choose bits for a screwdriver in a set? Main criteria:

- Filling - it is desirable that the set contains bits of basic shapes. They can be supplemented with highly specialized nozzles, but the cost of purchasing these sets will be justified only if such heads are really necessary and will be used frequently.

- The quality of the metal from which the attachments are made.

- Reputation and reliability of the brand - such foreign brands as Bosch, Metabo, Hitachi, Makita, Craftool, etc. are considered the highest quality. Products of domestic brands are also on sale. For example, for Zubr screwdrivers there are “Master” and “Expert” heads.

Rating table of the best sets with screwdriver bits (prices for sets):

| Category | Name | Ranking place | Number of items, pcs. | price, rub. |

| Middle price segment | Bosch 2607017164 | 1 | 43 | 1600 |

| Craftool 26154-H42 | 2 | 42 | 1250 | |

| Hitachi 754000 | 3 | 100 | 1450 | |

| Premium class | Metabo 626704000 | 1 | 71 | 1250 |

| Milwaukee Shockwave | 2 | 56 | 2100 | |

| Makita B-36170 | 3 | 47 | 1600 | |

| Compact cases | Bosch X-Pro 2607017037 | 1 | 25 | 800 |

| Metabo 630454000 | 2 | 20 | 1250 | |

| Ryobi 5132002257 | 3 | 40 | 760 | |

| Torsion bit sets | Wear Bit Impostor SET WE-057690 | 1 | 15 | 7100 |

| Matabo Impact | 2 | 7 | 2750 | |

| Bosch Impact Control / Quick release Bosch 2.608.522.327 | 3 | 7 | 900 |

The best screwdriver bit sets for popular brands

Bosch screwdrivers are in demand among consumers. Products of this brand are of high quality, reliability and performance, so it is not surprising that the bit sets of this company occupy high positions in the ratings.

Advantages of the Bosch 2607017164 kit:

- the heads are made of durable material;

- comfortable case with rubber cover;

- magnetic holder with quick-change and universal design.

Note! Many Bosch kits are manufactured in China. Despite this, product quality is still maintained at a high level.

The head set for the Hitachi 754000 screwdriver, which is considered one of the largest, since the number of nozzles in it reaches 100 pieces, falls into the same category of the best sets.Many of them are duplicated, so in the event of a breakdown, you can always use a spare bat. In terms of quality, these heads cannot be compared with Bosch nozzles, only for this reason this kit got to the third line of the rating. However, if you avoid heavy loads and use the bits with care, they will last a very long time.

If you want to buy the highest quality nozzles, you should pay attention to premium products. In this category, a set of heads for the Metabo screwdriver 626704000 was recognized as the best, which has outstanding characteristics and performance:

- convenient color marking for each type of slot;

- attractive appearance;

- the presence of bits with an elongated design;

- lightweight and compact case.

And to top it all off, you can add the relatively low cost of this kit to all the listed advantages.

How to insert a bit into a screwdriver: algorithm for changing nozzles

There are two types of chuck in screwdrivers: turnkey and quick-release. The algorithm for replacing bits on the instrument in both cases is performed in almost the same way. To change the drill on the keyless chuck, you need to do the following:

- A nozzle of the appropriate shape and size is selected, taking into account the parameters of the fastener, which will be twisted with its help.

- In the counterclockwise direction, the cartridge is unrolled.

- The selected head is installed in the central part. It should be placed between the divorced wire cutters.

- To clamp the nozzle in the chuck, it is necessary to rotate its sleeve in the clockwise direction.

Before pulling out the drill, change the direction of rotation by switching to the unwinding mode. After that, you can remove the head. In this case, the movable part of the cartridge is held with one hand, and the start button is pressed with the other hand.

Algorithm for changing a nozzle in a turnkey chuck:

- The key is inserted into the corresponding groove.

- With its help, the cartridge is unwound.

- The selected head is installed.

To fix the accessory, it is necessary to turn the key clockwise.

How to upgrade a 12 volt cordless screwdriver

Cordless screwdrivers are much more convenient and mobile than their networked counterparts. The only problem is that the Ni-Cd battery breaks down very quickly, and buying a new one will cost almost as much as a new instrument. The best solution to this problem would be to convert the unit into a lithium screwdriver by installing a Li-ion battery.

To upgrade the tool to a Li-ion screwdriver, you will need:

- Li-ion 18650 batteries (4 pcs.);

- flexible cable (2.5 mm²);

- BMS CF-4S30A-A board;

- body part from an old battery;

- soldering iron with a minimum power of 60 watts.

To charge a new battery, the native screwdriver charger is suitable, if it is universal.

If necessary cordless screwdriver can be converted to lithium

How to upgrade a screwdriver? This requires:

- Disassemble the old battery.

- Solder the old cans, leaving the terminals and temperature sensors.

- Connect all 18650 cells with a soldering iron into one battery using a flexible cable as jumpers. This must be done very quickly, since lithium batteries do not tolerate overheating.

The resulting circuit should be inserted into the body using a sealing material to fix it so that the parts are not damaged.

Such modernization measures are more than paying off, because the power of the updated screwdriver becomes more, and the charge lasts much longer than with a native battery. In addition, the battery becomes lighter after rework.

Combined with the right bit, the screwdriver will be an excellent and indispensable tool if your home needs to be renovated.You can purchase a ready-made kit or the required bits separately. The main thing is to choose a high-quality and durable tool when buying.