Blacksmithing is a hard physical labor that requires special equipment combined with the specialized knowledge and experience of the master. However, to make some artistic elements, you just need to bend the blanks at the desired angle. Metal deformation can be performed mechanically without heating, for this, cold forging machines are used. What features such units have - will be discussed in this article.

Machine for cold forgingallowing you to create wavy elements

Content [Hide]

- 1 Cold forging machines: advantages of their application

- 2 Varieties and purpose of forging machines

- 3 DIY cold forging: machines, drawings, video

- 3.1 Cold forging machine design, preparatory work

- 3.2 How to assemble a torsion bar for cold forging with your own hands

- 3.3 How to make a cold forging machine gnutik

- 3.4 Do-it-yourself snail machine for cold forging: design options

- 3.5 Drawings of the cold forging machine snail do it yourself

- 3.6 Making a snail: how to make a machine with your own hands

- 3.7 How to improve with your own hands a snail cold forging machine

- 4 Homemade machines for cold forging metal with your own hands: video instruction

Cold forging machines: advantages of their application

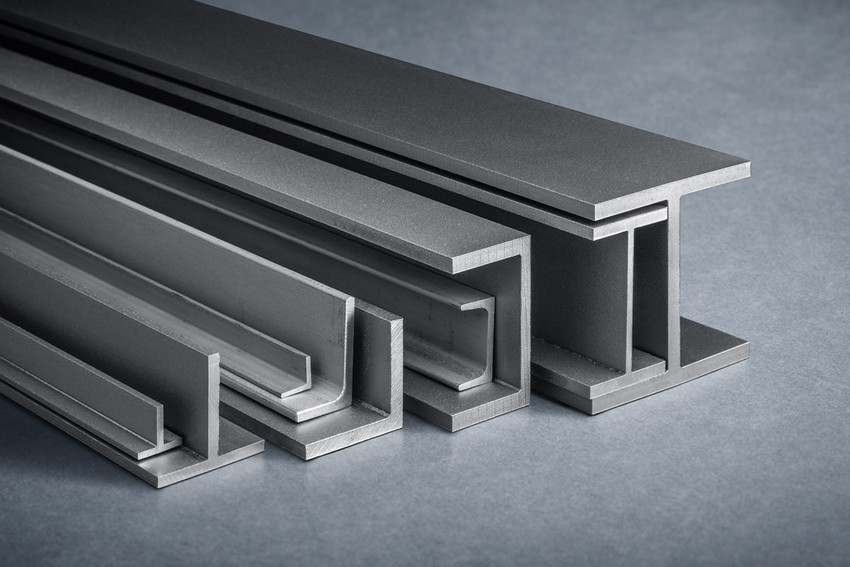

The cold forging method uses such a property of the metal as plasticity, that is, under mechanical stress, it is possible to change the original shape of the workpiece within specified limits. Therefore, soft metals are suitable for this process, for example: low-carbon steel, copper, aluminum, etc. For use as blanks, the following can be used:

- rods of any section: round or square;

- metal strips of various cuts;

- pipes;

- rolling profile.

The products that the blacksmith produces during the hot forging of metal are one-of-a-kind and unique. If you need to create a set of identical elements, which are then assembled into a finished structure, then uniqueness will only interfere. It is for this purpose that the cold forging method is used: it guarantees the formation of a large number of identical elements.

Hot metal is handled by professionals who have experience in using this technology and are able to masterfully handle a complex instrument. With cold forging, the highest skill is not needed - everything is much simpler. Manual forging machines allow you to obtain a sufficient number of products for a project without significant physical effort.

In addition, the time spent on preparing the elements is significantly reduced when working on special machines, not to mention the comparison of this method with hot forging technology: a few minutes for the manufacture of one element is an undeniable advantage.

Varieties and purpose of forging machines

The machine for any purpose is used to facilitate manual labor. Various equipment can be used for cold forging, which minimizes the physical efforts of the master and allows you to perform the following basic operations:

- bending the profile at the desired angle or radius;

- making spirals or curls;

- longitudinal twisting of workpieces.

The variety of parts obtained allows you to build them in combinations and intricate designs, create a neat artistic canvas for fences and gazebos, symmetrical decor for park benches, as well as other items for various purposes.

Note! Decor machines help to create elements of the same shape and size in a short period of time, reduce the cost of each of them and shorten the duration of the manufacturing process.

Cold forging machines can be specialized (perform only one operation) and universal. There are these types of special machines:

- benches (bending machines) - allow you to bend the workpiece at an angle or a given radius (wave);

- snails - twist blanks in spirals and curls;

- torsion bars - help to twist longitudinally a workpiece or several such parts at the same time;

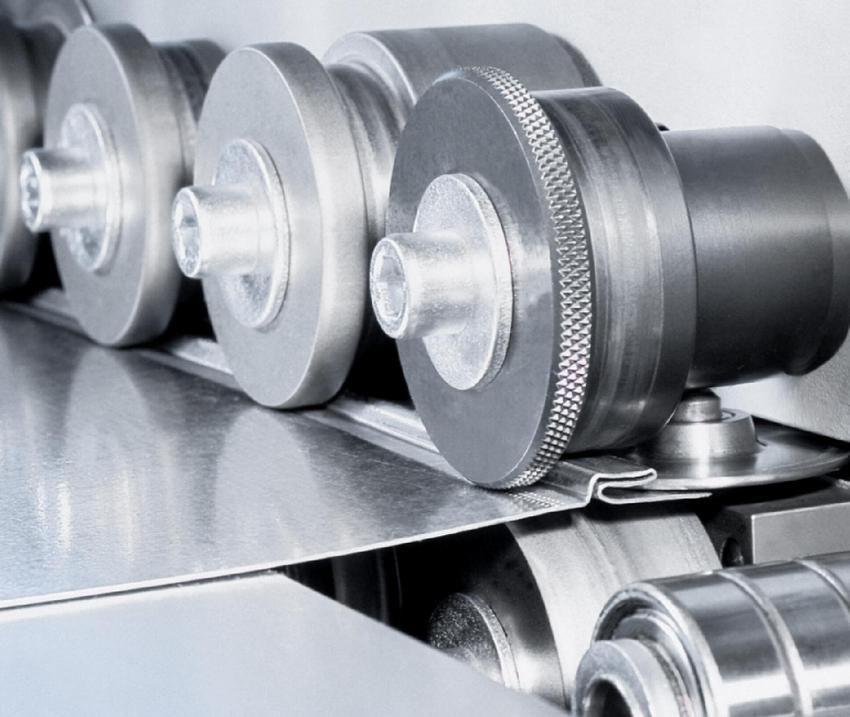

- punching machines - with their help they make decorative clamps, shaped tips, a wave with a fine pitch.

Universal machines include components of special equipment in various combinations.

Cold forging attachments are driven mechanically (hand-held machines) or electrically. The electrically driven equipment is fast and easy to process workpieces. The cold forging machine, which can be quite expensive, is highly productive. When there is no need for productivity and speed, then a manual machine will be enough to get the job done, especially if blacksmithing is a hobby.

Is it possible to do it yourself a cold forging machine

You can buy a manual cold forging machine from a specialist tool store or order online. The question is the price and the buyer's ability to pay. An alternative option is to assemble it yourself. The principle of operation will not differ in any way from the goods purchased in the retail network, and the functions performed are absolutely identical to the factory ones. Additional advantages - cost savings, confidence that the structure will not fail after the first use.

Important! Not all equipment can be made by yourself, some parts require industrial production or customization.

To begin with, it is worth familiarizing yourself with the design features of each type of machine in order to assess the possibility of its self-assembly.

The torsion bar must twist the metal rods, therefore its design assumes the presence of two elements that hold the workpiece. One of them serves as a clamp, and the other contains a rotating spindle, which, in fact, will twist the rod to the desired helical wave frequency. The device is quite simple to build yourself, and some craftsmen generally manage with a vice and an uncomplicated manual collar.

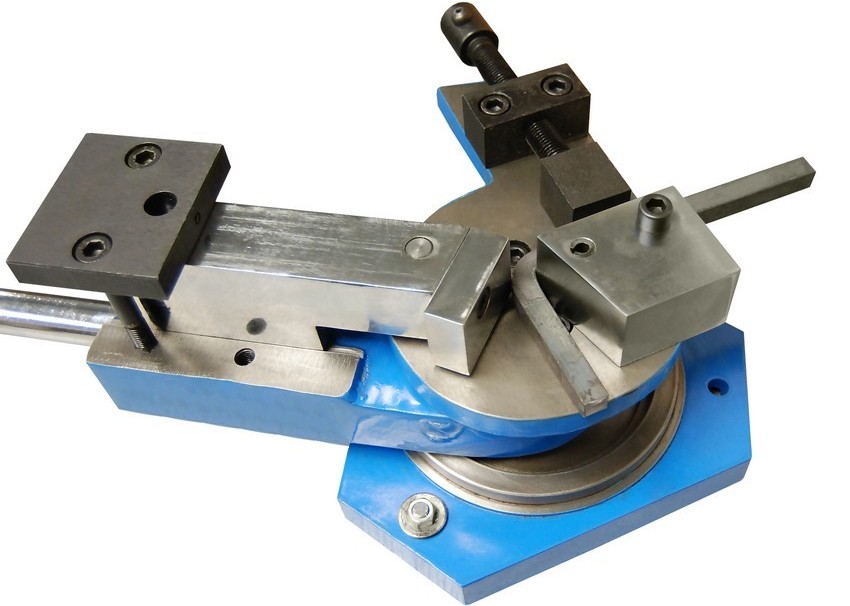

The design of the bending machine is also simple, but it contains several mandatory elements, the assembly of which is impossible without a specialized tool. The base is a massive metal plate with a groove in the middle, into which a movable stop is inserted, moved by a worm gear. The other two cylindrical stops are stationary and are attached to the base on both sides symmetrically relative to the groove. It is the installation of stops that can cause difficulty, since holes for fasteners are drilled only on a specialized machine, such a workpiece made of high-strength steel will not succumb to the impact of a drill.

The snail metal forging machine can be of two types: with a collar or lever type. The first option allows you to vary the shape of the bend during operation, but it has a number of vulnerabilities in the design and is very demanding on the strength of the materials of manufacture. The second type is more stable, but less productive. Masters consider the snail to be the simplest machine, the self-assembly of which will not cause difficulties.

DIY cold forging: machines, drawings, video

It is quite simple to make convenient and functional equipment for cold forging, guided by the basic principles of its operation and purpose. Any drawings, videos and photos of structures always leave room for the author's creativity and the perfection of the finished product. Below we will focus on the main points that are important for the assembly of machine tools.

Cold forging machine design, preparatory work

The first and main condition for assembling a cold forging machine with your own hands is drawings. Several such graphic documents will be required:

- drawing of the foundation of the future machine for installing equipment;

- assembly diagram or several diagrams for each performed device;

- drawings of replacement parts, if they are provided in the design.

Important! At the design stage, it is worth considering how moving parts and nodes will move in an already finished product. This is especially necessary in the manufacture of replaceable working tools, for example, a snail or a bunch.

To assemble a homemade cold forging machine, you will need the following tools and materials:

- medium-carbon heavy plate steel (grade not lower than 35);

- thick-walled pipe with a square or rectangular cross-section;

- a metal cutting machine (preferably portable) or a grinder;

- manual fastening tool;

- welding;

- milling cutter;

- bending device;

- tool for measurements and marking.

Useful advice! For products made by cold forging to be of fairly good quality, it is necessary that the parts of the homemade machine are also of high quality. For this, all welded joints, cut ends and finishing surfaces are carefully ground.

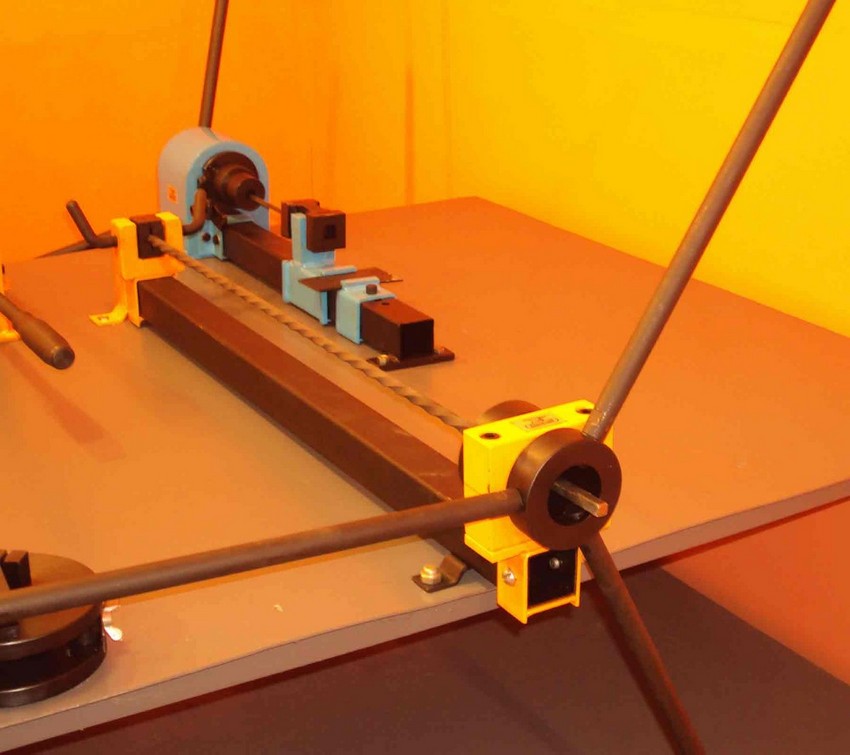

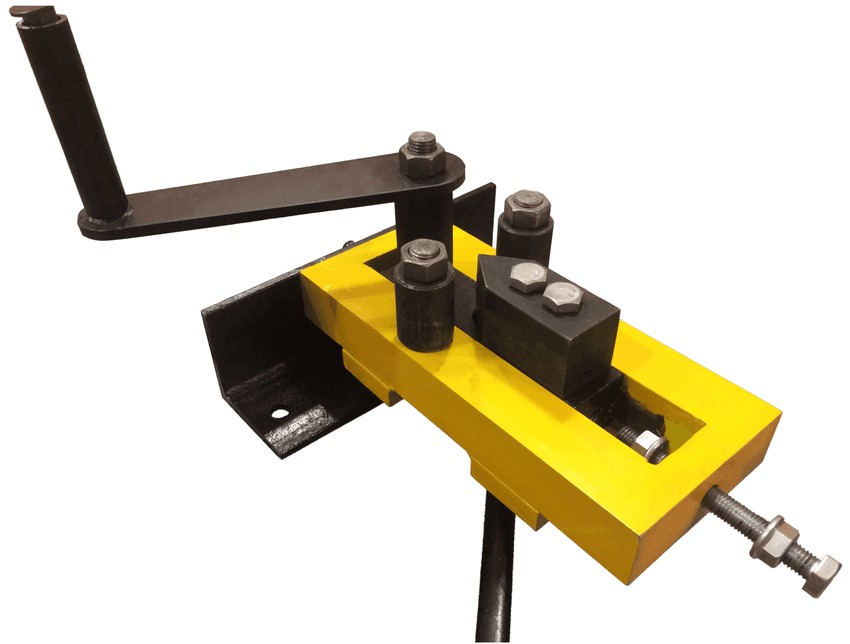

How to assemble a torsion bar for cold forging with your own hands

Some craftsmen do simple twisting without a machine, clamping one end of the workpiece with a vice, and rotating the other with a regular collar. With this method, the workpiece can not only twist, but also bend, especially in the area of the fixed end. To prevent this from happening, a guide structure is constructed in the form of a narrow groove, for example, from a pipe with an upper longitudinal cut (U-shaped section). It is worth considering:

- the length of the groove - it should be shorter than the workpiece, which will decrease when twisted;

- the width of the gutter - it is necessary that it be 1.5 times wider than the workpiece, since it will expand during deformation.

You can get the desired result without a machine - this will require physical strength and a lot of time to work. For whom this option is not suitable, it is more advisable to take up a universal equipment project.

It is permissible to assemble a torsion bar forging machine with your own hands in two versions: simple and universal. A simple model will be an improved method of working with a vice, and on a universal model, it is possible to additionally perform elements such as a lantern or a basket.

Related article:

DIY cold forging as a separate art form

Selection of tools and materials for forging. Tips for Beginning Metal Artists. Description of the forging process, features and warnings.

The main working force required to deform the material will be taken over by the support, so the base of the future machine must be strong. For this purpose, an I-beam or a pair of channels welded together is suitable. Stability to the base will be added by legs from a similar profile, welded to the overall structure. Then you can start making other units - the tailstock and the spindle.

In each of the nodes of a self-made cold-forging machine with your own hands, cartridges designed to accommodate workpieces in them must have strong screw clamps (in order to securely fix). Due to the reduction in the length of the workpiece during twisting, the tailstock is always sliding. It is allowed to build a headstock from a vice, fixing them on the base with bolts of at least M16 standard size. On the same axis with the clamping unit, a sleeve is installed for the movable part of the machine, in which holes for the clamping bolts are pre-drilled.

The movable part of the spindle is rotated by a handle, which consists of 4 levers, which are long enough to absorb the force applied for rotation. Rubber grommets can be added to protect hands from slipping.

The main difference in assembling a universal homemade cold forging machine is the design of the moving part. It should provide a screw feed in the manufacture of lanterns and baskets and be fixed with the usual twisting of metal. Therefore, the movable part is supplied with a set of two spindles - smooth and screw. In this design, the slide head requires a locking screw for fixing.

Useful advice! If it is necessary to make a workpiece that is not twisted along its entire length, but only in certain areas, limiters are added to the machine structure. They are made as a tailstock - with screw terminals and sliding.

Work on a torsion lathe is physically tedious; it is difficult to obtain high-quality products in large quantities. Therefore, the introduction of an electric drive into the design would be a reasonable solution.

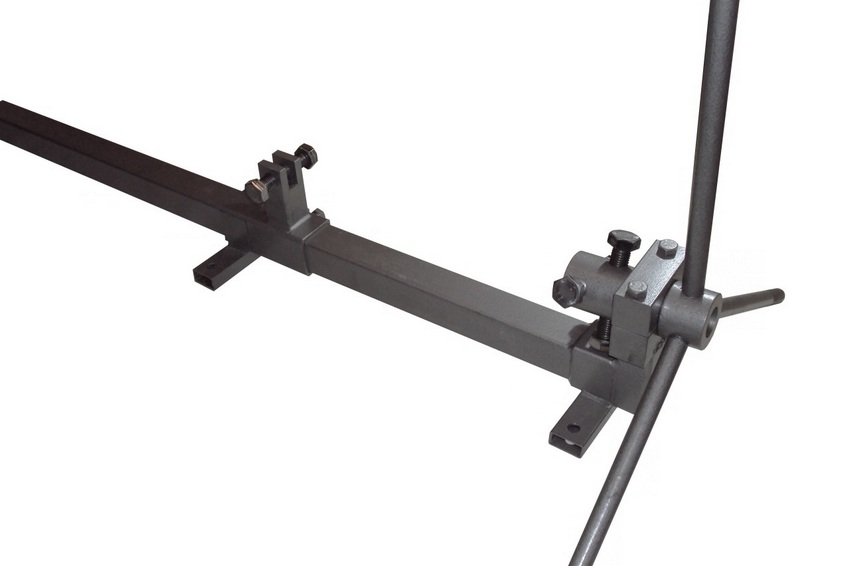

How to make a cold forging machine gnutik

The gnutik machine is monumental, massive, simple in design and assembly, but difficult in finding and fitting parts. Its purpose is to bend the workpiece at different angles, so the force on all nodes will be equally large, which means that the requirements for assembly parts are high.

A thick steel frame is selected for the base of the machine. It is worth considering that the machine will be mounted on a table. Usually fasteners are bolted, for example, like a vise. A guide is made in the center of the frame, which will be movable. It is driven by an eccentric mechanism, which, in turn, is fixed to the base frame. Additionally, three stops are installed, creating a kind of "fork" - these are the working elements of the structure. Depending on the profile of the fold, they are changed: round rollers - to make a wave, a "hammer" - to form corners.

Working elements are made only of structural steel. Their strength is the reliability of all equipment. The processing and fitting of such products requires exclusively professional equipment. Therefore, if there are difficulties in ordering, buying or manufacturing the main units, then it will be advisable to buy a machine for cold forging gnuts in a store. Its cost is low, but it can be additionally useful for bending pipes.

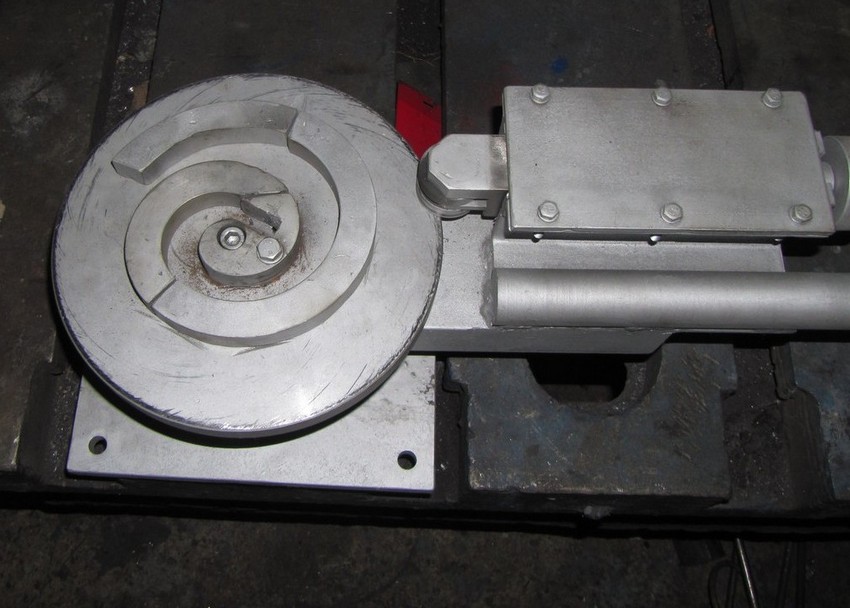

Do-it-yourself snail machine for cold forging: design options

The assembly algorithm for a homemade cold forging machine with your own hands is quite simple and straightforward. Only when creating a snail are three options for a design idea possible, and even then very approximate. Each craftsman sees the execution of a curl or spiral, as well as the sequence of bending the workpiece in his own way.

Like any creative process, making a cold forging snail with your own hands begins with the basics - designing the key nodes of the machine. In this case, these are the frame, table top and main shaft with a rotation lever.

The frame or table for the snail must be made of metal. The tree is completely unsuitable for this structure: long-term and heavy loads will destroy it in several applications. A corner, thick-walled pipes or a channel will be appropriate as the material used. For the countertop, you also need metal - a sheet with a thickness of at least 4 mm: the thicker, the more reliable. The shaft and arm is the main assembly that will cause the metal workpiece to bend to a predetermined pattern. The lever is connected on one side with a roller that bends the workpiece, and on the other with the main shaft.

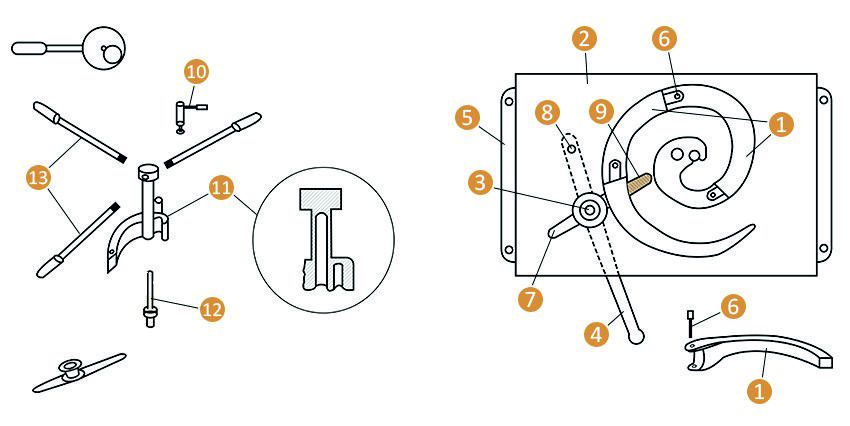

According to the type of execution, the snail machines are of three options:

- monolithic with a fixed bending pattern;

- with removable bend designs that allow you to make a different kind of curl;

- With collapsible curl designs and revolving table top for complex, high precision curl profiles.

Drawings of the cold forging machine snail do it yourself

Many craftsmen, who undertake the manufacture of machine tools for the first time, neglect the design stage, build templates "by eye", and are engaged in the development and modernization of units directly in the assembly process. A drawing of a snail for cold forging with your own hands should be done at the preparation stage. It will help to avoid some subtle nuances during assembly, and will also significantly shorten the manufacturing process.

It is not necessary to follow the drawings made by another master. The availability of materials of manufacture or assembly conditions may vary, and it is likely that the vision of the finished structure may also be different.

One of the design options: 1 - snail share; 2 - the basis of the machine; 3 - pressure roller; 4 - lever to control the pressure roller; 5 - fastening the base; 6 - pin for fixing the plowshares; 7 - groove for the pressure roller; 8 - axis of the control lever; 9 - spring for pressing the roller; 10 - clamp for the workpiece; 11 - snail leading share; 12 - main axis; 13 - levers

Scheme of a snail machine for processing products by cold forging

A drawing is especially important for constructing do-it-yourself curl patterns. A video of cold forging equipment will help you correctly calculate and build a proportional spiral. This stage is necessary in order for the curl, made on a homemade machine, to have an aesthetic appearance.

Useful advice! Templates for a snail are built according to the rules of mathematical spirals, taking into account the number of turns, their density, the width of the opening for the equipment on the machine and the initial radius of the entrance to the curl.

Making a snail: how to make a machine with your own hands

A monolithic lathe is the simplest design of a volute. The spiral pattern is applied directly to the worktop. Then, following the figure, several pieces of thick metal are cut. They are welded to the table top, observing the markings applied earlier. Work on a snail of this type is progressing slowly, but the machine allows bending both workpieces of symmetric diameter and metal strips that are laid flat without vertical deformations.

A monolithic machine can have an alternative design, when the base is not fixed, but pivotable. For a given rotation and to facilitate physical labor, a worm gear is used.

How to improve with your own hands a snail cold forging machine

A homemade snail doesn't have to contain only simple elements. You can immediately assemble an improved model. For example, what if the curls are needed in different shapes, and with different spiral patterns? It would be impractical to assemble a separate machine for each sample. Therefore, instead of a tightly welded single template, a number of removable options with different patterns are created on the tabletop. Adjustments are made to the design that allow you to change the template, fix it stably, while maintaining the overall reliability of the machine.

The most professional of the snail models is a machine where the tabletop rotates, and the curl pattern is made of several collapsible segments. It should be noted that all sections are made with high precision. It is difficult to implement this in a home workshop, so the production of a unit is ordered in workshops or at a factory. The curvature of the template is changed with the help of adjusting screws, and a number of holes are made on the surface of the tabletop, which will fix the segments of the template in a given position. In a similar way, you can bend any kind of curl.

It is quite simple to make a machine for cold forging with your own hands, a drawing of which will help to complete this task, if you understand the principle of its action and design features. At the same time, it is important to calculate everything carefully and take measurements. It is possible that someone will be able to come up with their own new options or improve existing models.

Homemade machines for cold forging metal with your own hands: video instruction