This article discusses in detail such a type of equipment as a wind generator for a private house: design features, its purpose and scope, internal structure and classification. In the text you can find useful information that will help you decide on the choice of a high-quality wind turbine, average prices for popular types of equipment, as well as a detailed description of the manufacturing technology.

Content [Hide]

Wind turbine for a private house: purpose and design features

Private house wind farms are widely used as alternative sources of electrical energy to achieve savings. Often, such devices are installed in summer cottages.

Most often they are used in areas remote from the main power grids. However, this is far from the only reason in favor of buying a wind turbine for a private house. Most land owners use these designs to achieve autonomy and savings.

Not every site is suitable for the installation of such devices, since not all conditions meet the requirements of this equipment. This primarily concerns the wind speed. For a wind farm to function normally, the average wind speed must be at least 4-4.5 m / s. Only in this case the installation of the structure will be economically justified.

You can use the wind map to find out the average annual wind speed. It reflects approximate data by region. More accurate indicators can be obtained using a special device - an anemometer, as well as a device for reading its signals.

Note! The measuring device must be installed very high, otherwise trees and buildings will distort the result.

For the efficient operation of the wind turbine, the area of its installation must be wind turbine

The principle of operation and structure of a wind generator

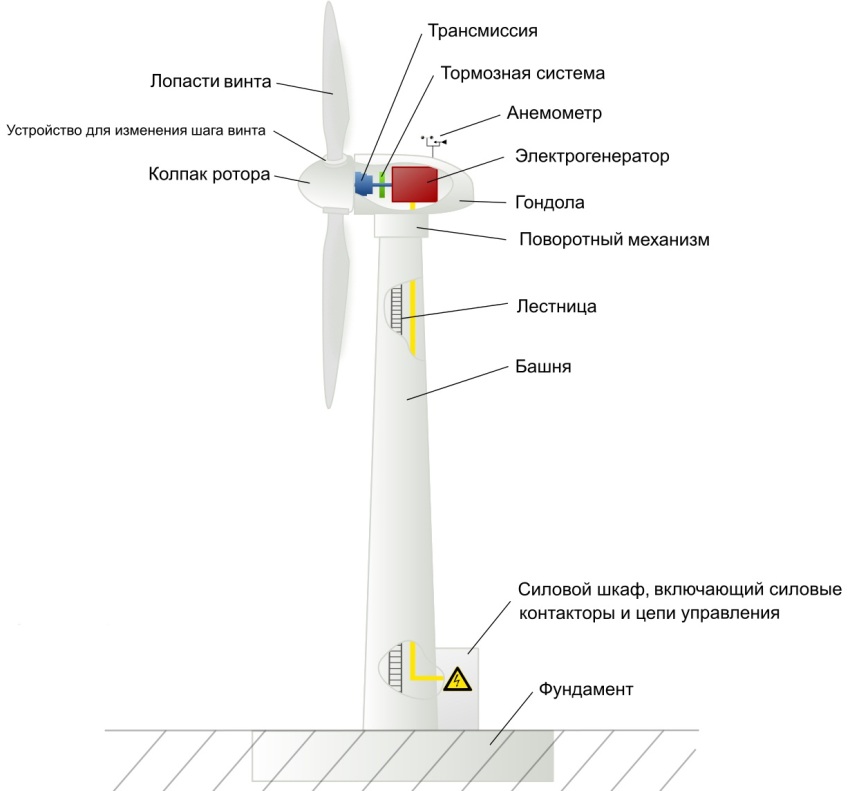

A wind generator is a special type of equipment that converts kinetic wind energy into mechanical energy. It drives the rotor blades mounted on the generator. As a result, an alternating current is created in its windings. The generated electrical energy is stored in storage batteries, from where it is fed to household appliances.

The described scheme of work is simplified. Of course, the construction of a wind generator is much more complicated. There is also a controller in the energy chain. Its function is to convert three-phase AC to DC. Then it goes to charge the batteries.

Most household appliances are not capable of being powered by DC power. Therefore, an inverter is installed in the chain behind the battery. It converts direct current into alternating current, the voltage of which is 220V. All these operations take away part of the initial energy - about 15-20%.

The building can be replenished not only from a wind farm, but also from solar panels, as well as from a gasoline or diesel generator. If these elements are present in the chain, then the circuit is supplemented by another component - a circuit breaker. When the main power supply is turned off, it starts the backup ones.

A wind farm consists of the following components:

- a rotor with blades (depending on the features of the model, there can be several blades for a wind generator, as a rule, there are 2 or 3 of them, although there are also multi-blade options);

- a gearbox or gearbox that controls the speed between the generator and the rotor;

- a protective casing that protects structural parts from the negative influence of external factors;

- "Tail", which ensures the rotation of the structure following the direction of the wind;

- a storage battery that stores a certain amount of energy;

- inverter installation that converts one type of current into another.

What kind of wind farm can you buy: equipment classification

There are several classifications according to which wind power plants are divided into groups:

- In the direction of the rotational motion of the blades - horizontal and vertical windmills.

- By the number of blades - two-, three- and multi-blade devices.

- By the type of material used to manufacture the blades - sail and rigid blade designs.

- By control method - windmills with fixed or adjustable blade pitch.

Useful advice! In most cases, experts recommend that owners of suburban housing buy a wind turbine with a fixed blade pitch, since adjustable devices are too difficult to operate.

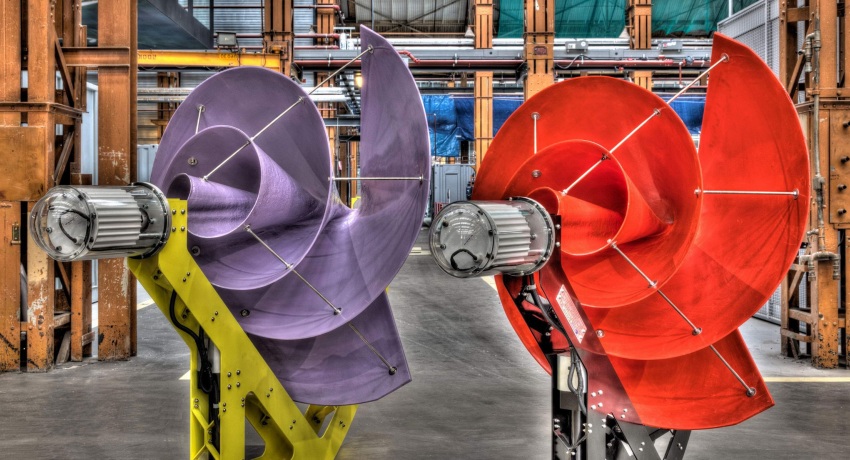

A wind farm with a horizontal axis is positioned perpendicular to the air flow. The design has a similar structure and functions on the same principle as a conventional weather vane. Wind turbines with a rotary generator have high efficiency, while they are affordable. The operation of these devices is based on the resistance of the air flow.

Vertical axis wind turbines, or orthogonal wind turbines, have a compact design, but their price is much higher. Due to its special structure, this type of equipment is completely independent of the wind direction. The blades are in the form of turbines, which significantly reduces the load on the axial part. It will be advisable to buy a vertical wind generator if the wind on the site is constantly changing its direction.

Advantages and Disadvantages of Home Wind Power Plants

Like any other type of equipment, wind farms have both advantages and disadvantages. To decide on the purchase of this device, it is advisable to weigh its strengths and weaknesses.

Why is it profitable to buy a wind generator (220V) for a private house:

- No additional costs as no fuel is required to operate the device.

- There is no need for constant monitoring. The structure generates electricity on its own every time the wind blows.

- A relatively quiet and completely environmentally friendly method of generating electricity.

- The device can be used in almost any climatic conditions.

- Wear of parts is minimal.

Installing a wind generator for a home is accompanied by the following disadvantages:

- equipment purchase costs pay off in 5-6 years;

- a relatively small indicator of efficiency, which is reflected in power;

- high price of wind turbines;

- to compensate for the inactivity of the device on windless days, additional equipment is required: a generator and a storage battery (the cost of these elements is very high);

- in some modes, wind turbines for the house emit infrasounds (the same happens if the installation of the equipment is made with errors);

- regular preventive maintenance is required;

- a hurricane can seriously damage the equipment.

Depending on the power of the device and the wind map of the area, a windmill can provide electricity to both a small country house and a large country cottage

Useful advice! It is imperative to calculate the profitability before buying a wind generator for your home, the price of the equipment may be too high, and the cost of purchasing it will not pay off. To do this, you need to calculate the average power indicator of the house (the power of all electrical appliances is taken into account), assess the area where the equipment will be installed, and find out what is the number of windy days per year.

Feasibility of buying: prices of wind turbines for a private house

The cost of wind turbines for private houses is quite high. The cost of purchasing equipment will pay off only if the area has suitable conditions.

The installation of a wind farm is justified in the following cases:

- the terrain meets the equipment requirements;

- the region in which the site is located is characterized by strong winds;

- there is no possibility to use other alternative sources of electrical energy.

In other cases, the cost of buying a wind generator for a home will not pay off. If the number of windy days per year is small, these devices can be supplemented with solar panels or generators powered by diesel or gasoline.

How to increase the profitability of a wind turbine for a private house

Seaside areas as well as open areas in mountainous areas are ideal for installing wind equipment. In these regions, the wind speed is over 60-70 m / s. Residents of these areas can completely abandon central power supply systems and move to wind farms. On flat areas, the wind flows are more uniform, but their strength is not enough to fully provide the house with electricity.

It is highly undesirable to install equipment near forests and plantings. Trees will trap some of the energy, which will reduce the profitability of wind turbines. The air flow increases with distance from the ground. This means that the higher the mast of the wind farm, the more impulse the device can capture. On the other hand, an excessively high structure needs additional reinforcement. Strong gusts of wind will make it easier to knock it down than windmills with a mast that reaches 5-7 m.

Experts recommend installing equipment at a height of 10-15 m from the ground. There are two ways to fix such a structure:

- By concreting the base.

- Using metal braces.

The most effective for generating electricity is considered to be a combination of a wind turbine and solar panels.

To concrete the base of the windmill, you will need to dig four deep wells with a small diameter. The mast extensions are immersed in them, after which they are poured with cement mortar. This process is quite laborious and costly, but it is highly reliable. Even with strong gusts of wind, the mast will remain stationary. The only risk is blade breakage.

Fixing the mast with guy ropes involves the use of a metal cable. It is stretched until the wind turbine is located strictly perpendicular to the ground. After that, the cable ties are securely fixed in the ground.

Important! Wind turbines with high masts need to be grounded.

Which is better to buy a wind generator for home: manufacturers and cost

The choice of a wind farm must be approached thoroughly. The main criteria are the power of the equipment, the type of axis (horizontal or vertical), and the manufacturer. Before buying, you must carefully study the technical characteristics and compare products from different manufacturers.

Prices for Russian-made wind turbines:

| Manufacturer | Price, thousand rubles |

| Wind power company | 30-300 |

| Rkraft | 65-908 |

| Wind power | 78-130 |

| Sapsan-Energy | 149-319 |

| GRC-Vertical | 204-600 |

Many of these organizations manufacture custom-made equipment and assist with design and calculations.

The prices of foreign-made home wind turbines are much higher. The minimum cost of installations is 120 thousand rubles. The products of foreign companies are distinguished by a high level of quality due to the use of high-tech equipment in the production. However, the repair of such installations will be expensive and the purchase of spare parts can be difficult.

Benefits of factory-made wind turbines:

- the ability to purchase a device in a complete set and even order its professional installation;

- an extensive selection of manufacturers and modifications with various characteristics;

- quality assurance;

- the ability to call a qualified specialist to carry out repair work.

Given the high cost of factory equipment, many owners of suburban areas prefer do-it-yourself structures. It takes about 3000-5000 rubles to make a homemade wind generator. Most of this amount is spent on purchasing a quality battery that can hold a charge for a long time.

Related article:

DIY solar panels: an affordable power source

What is the device, how it works. Varieties of solar panels. The feasibility of using for a summer residence and at home.

The advantages of DIY wind farms:

- significant savings in money;

- when creating a homemade windmill, the designer will know all the features of its structure;

- the ability to make the main parts and blades for a wind turbine with your own hands from scrap materials.

Homemade structures, unlike factory wind farms, fail much more often.

Note! It is better to call a specialist for installation of a factory design. Otherwise, any mistake made during the installation process will void the warranty.

How to make a windmill with your own hands: technology and recommendations

Using a homemade device on the site can cause resentment from neighbors.Therefore, before you make a wind generator with your own hands, you need to take care of observing several rules.

All individual buildings are subject to height restrictions. Installation of a windmill with a mast height of more than 15 m is prohibited if the following objects are nearby:

- tunnels;

- bridges;

- airports.

The wind turbine should not create airborne interference. To prevent their occurrence, it is recommended to use special protection. In addition, the level of noise emitted by the blades should be monitored and kept within normal limits.

Materials required for making a vertical wind generator with your own hands

A vertical axis wind farm can be used to provide electricity to various household buildings or a small garden house. Its power is enough to illuminate the local area in the dark.

To create a wind generator with your own hands from a car generator, you will need the following materials:

- rechargeable battery for 12V (acidic or helium);

- capacious cylindrical container made of aluminum or stainless steel (pan, bucket);

- automobile generator (12V);

- voltmeter;

- semi-hermetic push-button switch (12V);

- automotive battery charging relay or charge indicator lamp;

- converters (12-220V and 700-1500W);

- wires with a cross-sectional area of 2.5 and 4 mm;

- clamp for fixing the generator to the mast (2 pcs.).

To do the job, you will need tools and devices such as:

- grinder (you can use metal scissors);

- marker or construction pencil;

- nippers and tape measure;

- drill with a set of drills;

- screwdriver and a set of keys.

Manufacturing technology of a wind generator from a car generator

As a basis, a cylindrical container will be used, for example, a bucket, an old boil or a saucepan. Using a pencil and a tape measure, you need to mark it up so that you get a division into 4 equal parts. According to the marks, cuts are made using a grinder so that vertical blade-plates are obtained. In this case, it is very important not to cut the metal to the end.

Note! If the container is made of painted sheet or galvanized steel, you cannot use a grinder for cutting, otherwise the metal will overheat. In this case, it is advisable to use scissors.

Holes for bolts should be made in the pulley, as well as in the bottom of the container. At this stage of creating a wind generator for a private house with your own hands, you need to be extremely careful and careful about symmetry. Any inaccuracies in hole placement will result in unbalanced structure during rotation.

The blades should be bent, while they should not stick out too much. When performing this work, it is necessary to take into account the direction of the rotational motion of the generator. Most often, the windmill is oriented clockwise. The rotational speed and the area of contact of the air flows with the structure will depend on the chosen angle of bending of the blades.

Next, a container with blades is fixed on the pulley. The generator is installed on a mast, after which it is fixed with clamps. All that remains is to connect all the wires and assemble the circuit. All cables are fixed to the windmill mast. To connect the storage battery, use wires with a cross-section of 4 mm. For this, a piece of 100 cm in length will be enough. Connecting household and lighting devices to the network is carried out using wires with a cross-sectional area of 2.5 mm. The inverter or converter requires 4mm wire.

How to make a wind turbine from a washing machine

To create a wind generator from a washing machine with your own hands, you will need a list of certain parts. Some of them can be removed from old household appliances, and the rest will have to be bought.

The wind turbine design will consist of the following elements:

- reducer for adjusting the rotational speed;

- rotor with blades;

- protective casing;

- storage battery;

- tail section;

- inverter;

- masts for fixing the generator.

The generator of the design is made from an electric motor from a washing machine. Its power must be at least 1.5 kW.

In addition, you will need:

- sandpaper and glue;

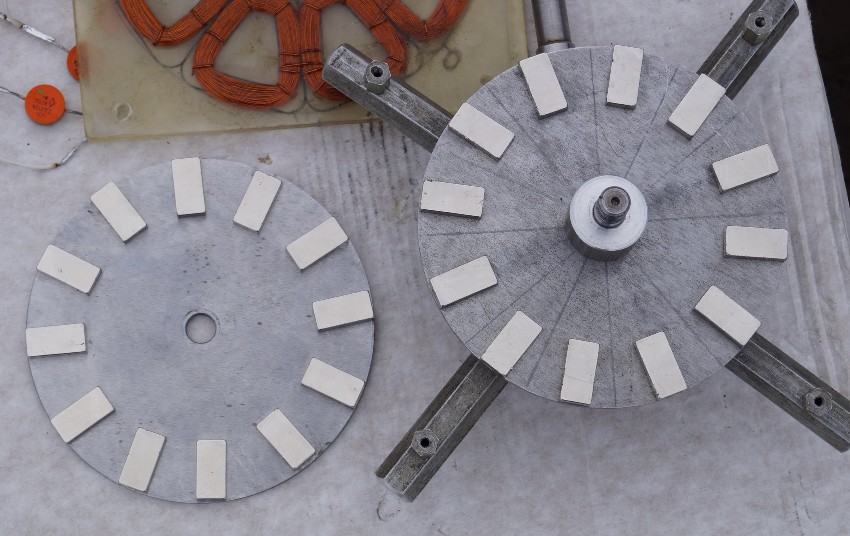

- neodymium magnets 5 and 12 mm each (32 pcs.);

- epoxy resina or cold welding.

The neodymium magnets will be mounted on the rotor. They can be purchased at many stationary or online stores. It is necessary to remove the cores from the rotor of the asynchronous motor. After that, these parts are partially cut off. The cutting depth should not exceed 2 mm. You can use a lathe for this. Further, grooves must be made in the cores, the depth of which is 5 mm.

At the next stage in the manufacture of a wind generator for a home, the installation of magnets is performed by hand. To begin with, a hard cover is mounted on the core. After that, magnets are placed in the appropriate places at an equal distance. It is very important to keep a distance, otherwise in the future the magnets will stick together, which will negatively affect the power of the wind farm. It is better to use super glue to fix these parts. When working, it is advisable to wear protective goggles, since the magnets can bounce off during the gluing process.

When the template with magnets is completely ready, it fits onto the rotor. The resulting gaps must be filled with epoxy resin or cold welding. At the end of the work, the rotor is carefully clamped in a vice, and its surface is processed with sandpaper. Before starting the windmill, check all bearings and bolted connections for strength. You should not use even partially worn parts for the assembly of the structure; it is better to buy new ones.

To create an impeller, it is better to choose a light material with a high margin of safety. For these purposes, fiberglass is suitable. As a result, the blades are lightweight and wear resistant. The mast is best made of steel pipes. The optimum diameter is 32 mm.

The assembly of a wind turbine can be handled by anyone with an understanding of how electrical circuits work. The main thing in this case is to be attentive to all the details and carefully check all your actions. To eliminate the likelihood of errors, you can use visual videos that describe in detail the entire process of manufacturing parts and their further assembly.